Physics:Rule of mixtures

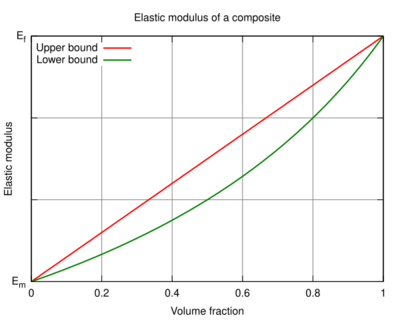

In materials science, a general rule of mixtures is a weighted mean used to predict various properties of a composite material .[2][3][4] It provides a theoretical upper- and lower-bound on properties such as the elastic modulus, ultimate tensile strength, thermal conductivity, and electrical conductivity.[4] In general there are two models, one for axial loading (Voigt model),[3][5] and one for transverse loading (Reuss model).[3][6]

In general, for some material property [math]\displaystyle{ E }[/math] (often the elastic modulus[2]), the rule of mixtures states that the overall property in the direction parallel to the fibers may be as high as

- [math]\displaystyle{ E_c = fE_f + \left(1-f\right)E_m }[/math]

where

- [math]\displaystyle{ f = \frac{V_f}{V_f + V_m} }[/math] is the volume fraction of the fibers

- [math]\displaystyle{ E_f }[/math] is the material property of the fibers

- [math]\displaystyle{ E_m }[/math] is the material property of the matrix

It is a common mistake to believe that this is the upper-bound modulus for Young's modulus. The real upper-bound Young's modulus is larger than [math]\displaystyle{ E_c }[/math] given by this formula. Even if both constituents are isotropic, the real upper bound is [math]\displaystyle{ E_c }[/math] plus a term in the order of square of the difference of the Poisson's ratios of the two constituents.[1]

The inverse rule of mixtures states that in the direction perpendicular to the fibers, the elastic modulus of a composite can be as low as

- [math]\displaystyle{ E_c = \left(\frac{f}{E_f} + \frac{1-f}{E_m}\right)^{-1}. }[/math]

If the property under study is the elastic modulus, this quantity is called the lower-bound modulus, and corresponds to a transverse loading.[3]

Derivation for elastic modulus

Voigt Modulus

Consider a composite material under uniaxial tension [math]\displaystyle{ \sigma_\infty }[/math]. If the material is to stay intact, the strain of the fibers, [math]\displaystyle{ \epsilon_f }[/math] must equal the strain of the matrix, [math]\displaystyle{ \epsilon_m }[/math]. Hooke's law for uniaxial tension hence gives

-

[math]\displaystyle{ \frac{\sigma_f}{E_f} = \epsilon_f = \epsilon_m = \frac{\sigma_m}{E_m} }[/math]

()

where [math]\displaystyle{ \sigma_f }[/math], [math]\displaystyle{ E_f }[/math], [math]\displaystyle{ \sigma_m }[/math], [math]\displaystyle{ E_m }[/math] are the stress and elastic modulus of the fibers and the matrix, respectively. Noting stress to be a force per unit area, a force balance gives that

-

[math]\displaystyle{ \sigma_\infty = f\sigma_f + \left(1-f\right)\sigma_m }[/math]

()

where [math]\displaystyle{ f }[/math] is the volume fraction of the fibers in the composite (and [math]\displaystyle{ 1-f }[/math] is the volume fraction of the matrix).

If it is assumed that the composite material behaves as a linear-elastic material, i.e., abiding Hooke's law [math]\displaystyle{ \sigma_\infty = E_c\epsilon_c }[/math] for some elastic modulus of the composite [math]\displaystyle{ E_c }[/math] and some strain of the composite [math]\displaystyle{ \epsilon_c }[/math], then equations 1 and 2 can be combined to give

- [math]\displaystyle{ E_c\epsilon_c = fE_f\epsilon_f + \left(1-f\right)E_m\epsilon_m. }[/math]

Finally, since [math]\displaystyle{ \epsilon_c = \epsilon_f = \epsilon_m }[/math], the overall elastic modulus of the composite can be expressed as[7]

- [math]\displaystyle{ E_c = fE_f + \left(1-f\right)E_m. }[/math]

Reuss modulus

Now let the composite material be loaded perpendicular to the fibers, assuming that [math]\displaystyle{ \sigma_\infty = \sigma_f = \sigma_m }[/math]. The overall strain in the composite is distributed between the materials such that

- [math]\displaystyle{ \epsilon_c = f\epsilon_f + \left(1-f\right)\epsilon_m. }[/math]

The overall modulus in the material is then given by

- [math]\displaystyle{ E_c = \frac{\sigma_\infty}{\epsilon_c} = \frac{\sigma_f}{f\epsilon_f + \left(1-f\right)\epsilon_m} = \left(\frac{f}{E_f} + \frac{1-f}{E_m}\right)^{-1} }[/math]

since [math]\displaystyle{ \sigma_f=E\epsilon_f }[/math], [math]\displaystyle{ \sigma_m=E\epsilon_m }[/math].[7]

Other properties

Similar derivations give the rules of mixtures for

- mass density:[math]\displaystyle{ \rho_c=\rho_f\centerdot f+\rho_M\centerdot (1-f) }[/math] where f is the atomic percent of fiber in the mixture.

- ultimate tensile strength:[math]\displaystyle{ \left(\frac{f}{\sigma_{UTS,f}} + \frac{1-f}{\sigma_{UTS,m}}\right)^{-1} \leq \sigma_{UTS,c} \leq f\sigma_{UTS,f} + \left(1-f\right)\sigma_{UTS,m} }[/math]

- thermal conductivity:[math]\displaystyle{ \left(\frac{f}{k_f} + \frac{1-f}{k_m}\right)^{-1} \leq k_c \leq fk_f + \left(1-f\right)k_m }[/math]

- electrical conductivity:[math]\displaystyle{ \left(\frac{f}{\sigma_f} + \frac{1-f}{\sigma_m}\right)^{-1} \leq \sigma_c \leq f\sigma_f + \left(1-f\right)\sigma_m }[/math]

See also

When considering the empirical correlation of some physical properties and the chemical composition of compounds, other relationships, rules, or laws, also closely resembles the rule of mixtures:

- Amagat's law – Law of partial volumes of gases

- Gladstone–Dale equation – Optical analysis of liquids, glasses and crystals

- Kopp's law – Uses mass fraction

- Kopp–Neumann law – Specific heat for alloys

- Vegard's law – Crystal lattice parameters

References

- ↑ 1.0 1.1 Yu, Wenbin (2016). An Introduction to Micromechanics. Switzerland: Trans Tech Publications. pp. 3–24. ISBN 9783038357469. https://www.scientific.net/book/composite-materials-and-structures-in-aerospace-engineering/978-3-0357-0237-8.

- ↑ 2.0 2.1 Alger, Mark. S. M. (1997). Polymer Science Dictionary (2nd ed.). Springer Publishing. ISBN 0412608707.

- ↑ 3.0 3.1 3.2 3.3 "Stiffness of long fibre composites". University of Cambridge. http://www.doitpoms.ac.uk/tlplib/fibre_composites/stiffness.php. Retrieved 1 January 2013.

- ↑ 4.0 4.1 Askeland, Donald R.; Fulay, Pradeep P.; Wright, Wendelin J. (2010-06-21). The Science and Engineering of Materials (6th ed.). Cengage Learning. ISBN 9780495296027.

- ↑ Voigt, W. (1889). "Ueber die Beziehung zwischen den beiden Elasticitätsconstanten isotroper Körper". Annalen der Physik 274 (12): 573–587. doi:10.1002/andp.18892741206. Bibcode: 1889AnP...274..573V. https://zenodo.org/record/1423864.

- ↑ Reuss, A. (1929). "Berechnung der Fließgrenze von Mischkristallen auf Grund der Plastizitätsbedingung für Einkristalle". Zeitschrift für Angewandte Mathematik und Mechanik 9 (1): 49–58. doi:10.1002/zamm.19290090104. Bibcode: 1929ZaMM....9...49R.

- ↑ 7.0 7.1 "Derivation of the rule of mixtures and inverse rule of mixtures". University of Cambridge. http://www.doitpoms.ac.uk/tlplib/bones/derivation_mixture_rules.php. Retrieved 1 January 2013.

External links

|