Advanced PCB Designs for Improved Fault Detection in Electrical Installations

April 25, 2024 - Reading time: 6 minutes

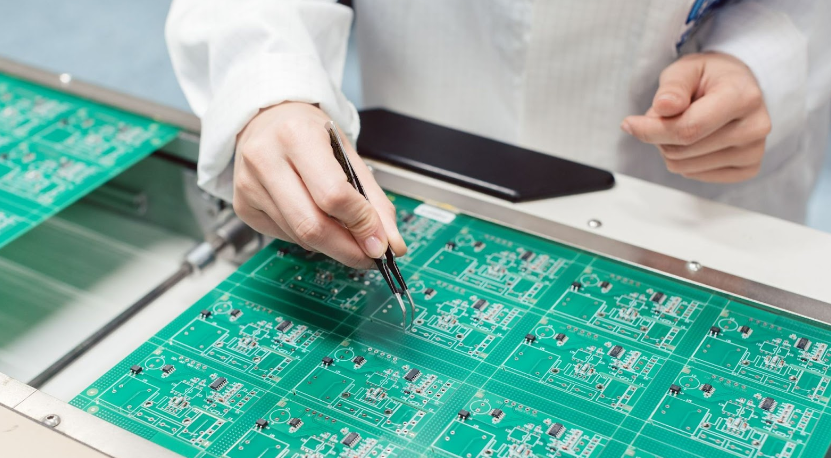

In the realm of electrical installations, advanced PCB designs offer a pathway to not just detect faults but to predict and prevent them. Imagine seamlessly integrating cutting-edge technology into traditional setups, revolutionizing fault detection mechanisms.

As you explore the intricate web of PCB components and circuitry advancements, a new horizon emerges, where fault detection becomes more than a reactive measure.

Keep an eye out for how these innovations, alongside the expertise of a leading PCB assembly manufacturer, are shaping the future of electrical safety and reliability.

Key Takeaways:

PCB evolution enables advanced fault detection capabilities.

Key components like GFCI and thermistors crucial for fault detection.

Advanced circuitry integration enhances fault detection accuracy.

Machine learning algorithms offer proactive fault detection solutions.

Evolution of PCB Designs

Explore how PCB designs have evolved over time to meet the growing demands of modern technologies. Initially, PCBs consisted of simple single-layer designs with through-hole components. However, as technology advanced, the need for more compact and efficient designs arose. This led to the development of double-sided and multi-layer PCBs, allowing for increased component density and better signal integrity.

With the rise of high-speed digital devices, designers began incorporating controlled impedance traces and differential pairs to minimize signal interference and ensure reliable performance. The introduction of surface mount technology further revolutionized PCB designs by enabling smaller components to be placed on both sides of the board, optimizing space utilization.

Moreover, the demand for increased functionality in smaller devices pushed the development of flexible and rigid-flex PCBs. These designs offer greater flexibility in terms of shape and size, making them ideal for applications where space is limited or where boards need to be bent or twisted. Overall, the evolution of PCB designs continues to play a crucial role in meeting the ever-changing needs of modern technologies.

Key Components for Fault Detection

As PCB designs have advanced to accommodate the demands of modern technologies, incorporating key components for fault detection has become essential in ensuring reliable performance.

One crucial component is the ground fault circuit interrupter (GFCI), which quickly shuts off power when a ground fault is detected, preventing potential electrical hazards.

Another vital element is the surge protection device (SPD), which safeguards electronic equipment from power surges and voltage spikes that could lead to failures or fires.

Additionally, using current transformers can help monitor electrical currents and detect abnormalities that may indicate faults in the system.

Thermistors are also valuable components for fault detection, as they can detect overheating in circuits and trigger protective measures.

Advanced Circuitry Integration

How can advanced circuitry integration enhance fault detection in modern PCB designs? By incorporating advanced circuitry integration techniques, you can significantly improve fault detection capabilities in your electrical installations. Here are four key ways this integration can benefit your PCB designs:

Increased Sensing Accuracy: Advanced circuitry integration allows for more precise sensing of electrical parameters, enabling quicker detection of faults such as short circuits or overloads.

Enhanced Signal Processing: By integrating sophisticated signal processing algorithms into the circuitry, you can better analyze data in real-time, identifying potential faults more efficiently.

Fault Localization: Advanced integration enables the implementation of techniques like impedance monitoring, which can help pinpoint the exact location of a fault within the circuitry.

Remote Monitoring Capabilities: With advanced circuitry integration, you can enable remote monitoring of your electrical installations, allowing for proactive fault detection and maintenance to prevent costly downtime.

Role of Machine Learning Algorithms

Utilizing machine learning algorithms enhances fault detection capabilities in modern PCB designs by enabling predictive analysis of system behavior based on historical data patterns. By implementing machine learning techniques, you can train algorithms to recognize patterns indicative of potential faults within electrical installations. These algorithms can sift through vast amounts of data to identify anomalies or trends that may lead to system failures. Through continuous learning and adaptation, machine learning algorithms can improve their accuracy in predicting faults over time.

One key advantage of employing machine learning in fault detection is its ability to provide real-time monitoring and alerts. By analyzing incoming data in real-time, these algorithms can swiftly detect deviations from normal operation and issue alerts to prevent potential failures. Additionally, machine learning algorithms can help in prioritizing maintenance tasks by assessing the criticality of detected faults and recommending appropriate actions. Overall, integrating machine learning algorithms into PCB designs offers a proactive approach to fault detection, ultimately enhancing the reliability and safety of electrical installations.

Real-world Applications and Case Studies

To explore the practical implementation and impact of machine learning algorithms in fault detection within PCB designs, real-world applications and case studies provide valuable insights into their effectiveness. Here are four key points to consider:

Industrial Automation: In the manufacturing sector, machine learning algorithms integrated into PCB designs have shown significant improvements in detecting faults in real time, reducing downtime, and increasing overall operational efficiency.

Smart Grid Systems: Incorporating machine learning into PCBs for smart grid systems has enhanced the ability to pinpoint faults quickly, leading to improved grid stability and more reliable energy distribution.

Automotive Electronics: In the automotive industry, the utilization of machine learning algorithms in PCBs has enabled proactive fault detection, ensuring the safety and reliability of critical electronic components in vehicles.

Telecommunication Networks: By implementing machine learning algorithms in PCB designs for telecommunications, companies have achieved faster fault identification and resolution, resulting in enhanced network performance and customer satisfaction.

Can PCB Designs for Improved Fault Detection Be Used in Both Residential and Industrial Electrical Installations?

Yes, PCB designs for improved fault detection can be utilized in both residential and industrial electrical installations. They enhance safety by quickly identifying issues, reducing downtime, and facilitating prompt repairs in various settings.

How Does the Use of Machine Learning Algorithms in Fault Detection on PCBs Impact Overall System Reliability?

When you incorporate machine learning algorithms in fault detection on PCBS, it enhances overall system reliability by swiftly identifying issues and reducing downtime. This technology boosts efficiency and ensures optimal performance in various settings.

Are There Any Specific Industry Standards or Regulations That Govern the Implementation of Advanced PCB Designs for Fault Detection?

In the industry, specific standards and regulations govern the implementation of advanced PCB designs for fault detection. You must adhere to these guidelines to ensure compliance and optimal performance in your electrical installations.

What Are Some Common Challenges Faced When Integrating Advanced Circuitry for Fault Detection on Pcbs?

When integrating advanced circuitry for fault detection on PCBs, you may encounter challenges such as signal interference, component compatibility issues, and complex debugging processes. Ensuring proper testing and validation can help address these obstacles effectively.

How Do Real-World Applications and Case Studies of Advanced PCB Designs for Fault Detection Differ From Theoretical Models or Simulations?

In real-world applications and case studies, advanced PCB designs for fault detection often reveal unexpected challenges and nuances not accounted for in theoretical models or simulations. Practical testing is essential to refine and optimize performance.

By Nia