| Curated Articles |

The Day Your Lab Turns Into a Detective Story

February 20, 2026 - Reading time: 5 minutes

A lot of people imagine research as a straight line: question, experiment, result. In reality it often feels like a crime scene. Something “happened” in the data, and your job is to figure out whether it was nature talking or your setup whispering nonsense through a loose connector.

The first time I ran into this seriously, I didn’t need a new theory. I needed a better method for catching tiny lies in my measurement chain, plus a clearer view of what tools belong where. I’ve bookmarked more than one guide on Research Instrumentation for exactly that reason: when you’re debugging reality, it helps to think in terms of the whole pipeline, from sensing to logging to interpretation.

The Ultimate Guide to Embedded Processors and Controllers

April 23, 2025 - Reading time: 6 minutes

Imagine a future where every device-from your smartwatch to autonomous vehicles-is intelligent, responsive, and seamlessly connected. At the core of this transformation are embedded processors and controllers. These specialized microchips are the silent orchestrators of the digital age, bringing computational power to everyday objects and industrial machines alike.

Embedded processors and controllers are integral to modern electronics. They empower devices to perform real-time operations efficiently and reliably. As we explore this field, we'll trace the evolution of embedded systems, examine the major types of processors and controllers, delve into their design and integration, and highlight their revolutionary role across industries-from smart homes to aerospace. Whether you're an engineer or a curious technophile, understanding embedded computing is key to grasping the forces shaping our digital future.

The Pros of Minimalist Engagement Rings: Why Less Can Truly Be More

September 9, 2024 - Reading time: 7 minutes

When it comes to engagement rings, many people envision something extravagant-large stones, intricate designs, and dazzling brilliance. However, in recent years, there has been a significant shift towards minimalist engagement rings. These rings, characterized by simple designs and understated elegance, are gaining popularity among those who value timeless beauty and subtle sophistication. In this article, we will explore the various benefits of minimalist engagement rings and why they are becoming the go-to choice for modern couples.

Advanced PCB Designs for Improved Fault Detection in Electrical Installations

April 25, 2024 - Reading time: 6 minutes

In the realm of electrical installations, advanced PCB designs offer a pathway to not just detect faults but to predict and prevent them. Imagine seamlessly integrating cutting-edge technology into traditional setups, revolutionizing fault detection mechanisms.

As you explore the intricate web of PCB components and circuitry advancements, a new horizon emerges, where fault detection becomes more than a reactive measure.

Keep an eye out for how these innovations, alongside the expertise of a leading PCB assembly manufacturer, are shaping the future of electrical safety and reliability.

Top Reasons to Pursue a Degree in Engineering

April 19, 2024 - Reading time: 3 minutes

[source]

An engineering degree is not limited to solving intricate systems or complex mathematical equations. It offers a gateway of endless opportunities to shape the future, making it very exciting and compelling. Engineers are responsible for designing groundbreaking innovations and structures that fuel our planet, from cutting-edge smartphones and eco-friendly cities to revolutionary healthcare technologies.

Embracing a career in engineering entails facing unique hurdles and triumphs within distinct fields such as civil, mechanical, electrical, and software. Moreover, it requires keeping on par with the continuously changing technology landscape while making tangible changes to society's well-being.

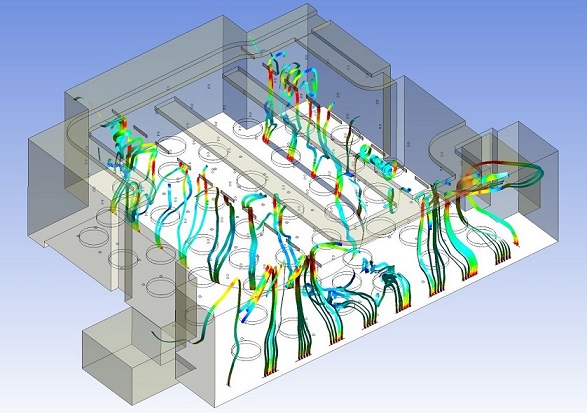

What is a simulation-based design of a semiconductor cleanroom?

February 4, 2024 - Reading time: 11 minutes

Design of Semiconductor Cleanroom

Designing a high-tech semiconductor cleanroom is no small feat - it requires extensive planning and an understanding of complex engineering principles. A well-designed semiconductor cleanroom ensures quality, safety and efficiency throughout the facility operations life.

Currently, the design of a semiconductor cleanroom is commonly based on a prescriptive approach which involves adopting a set design heuristic in the form of tables and charts. The prescriptive approach, which aims to cover as many building features, sizes, shapes and scenarios as possible, may lead to under- or over-estimation.

In contrast, simulation technology offers bespoke assessments specific to a building's features or scenarios and delivers much more accurate results than those relying on the prescriptive approach. This article aims to outline how simulation technology adds value to the design of a semiconductor cleanroom.

How CFD simulation is applied in various industries?

December 5, 2023 - Reading time: 3 minutes

Computational fluid dynamics (CFD) simulation technology is very versatile owing to its applicability across many industries. In this article, we will give real-world applications of how CFD simulation is applied in two very different industries, namely, the built environment and the chemical & petrochemical industries.

Built Environment

Thermal comfort CFD simulation

CFD simulations are applied in the built environment to analyze and optimize various aspects of buildings and their surroundings. CFD is employed to simulate airflow patterns within buildings to optimize natural ventilation and assess the effectiveness of mechanical ventilation systems. It helps architects to predict indoor air quality by analyzing the dispersion of pollutants and contaminants.