What is Process Engineering Design?

December 12, 2022 - Reading time: 4 minutes

The chemical manufacturing processes have involved from modest to complex production of chemicals converting raw materials such as fossil fuels, water, minerals, metals, and others to become thousands of products central to our everyday modern living. Chemical and process engineering deals with the development, design, operation, and management of converting these raw materials safely and cost- effectively. It is founded on the principles of chemistry, physics, and mathematics. The laws of physical chemistry and physics govern the practicability and efficiency of chemical engineering operations, whilst mathematics aids the essential tool in optimization and modelling.

Chemical Process Engineering in Design

The design of a process plant starts with an idea to produce a new product or improve an existing one. It is usually a result of one or more chemical reactions and mainly the physical processes such as the separation of the components or a group of components from a natural mixture, are the subject of the design. An excellent example of such a process is crude oil primary separation. The engineering design of a chemical manufacturing process can be categorized into two broad phases.

- The conceptual or process design is the first phase that includes the selection of the chemical process, technology, process conditions, collection of required data, issuing of process flow-sheets, selection, specification, and chemical engineering calculations of equipment, and preliminary cost estimation. Typically, in a project organization, the process engineering design team is heavily involved in this phase also known as the front-end engineering design (FEED).

- The second phase, basic plant design, includes the detailed mechanical design of equipment, detailed design of electrical systems, civil structures, piping and ancillary services. The support design group is responsible for these engineering activities as they have the expertise in other engineering disciplines required to complete the plant design.

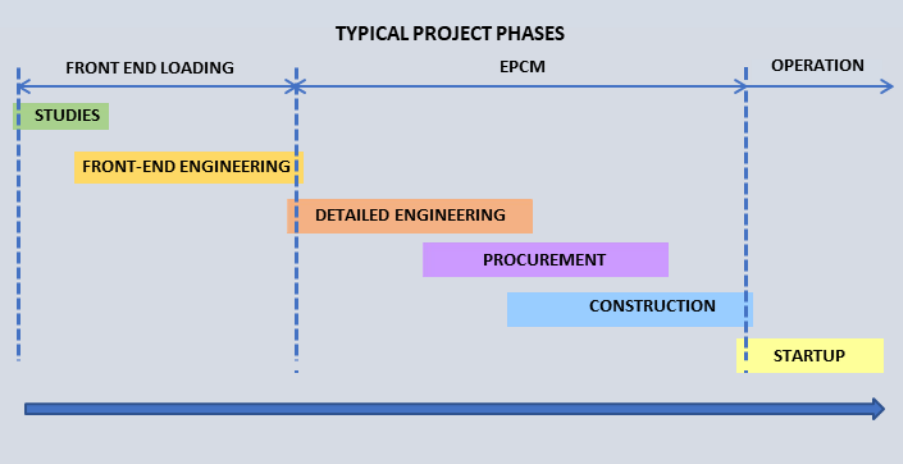

A typical chemical process plant design can be illustrated in these phases, as shown in figure 1.

Figure 1. Typical Project Phases.

The different phases of the project in Figure 1 illustrates that the goal of plant design is to complete them within the framework of projects. The process engineers are heavily involved in FEED within this project phase and constantly interact and communicate with other engineering disciplines.

Process Engineering Key Role

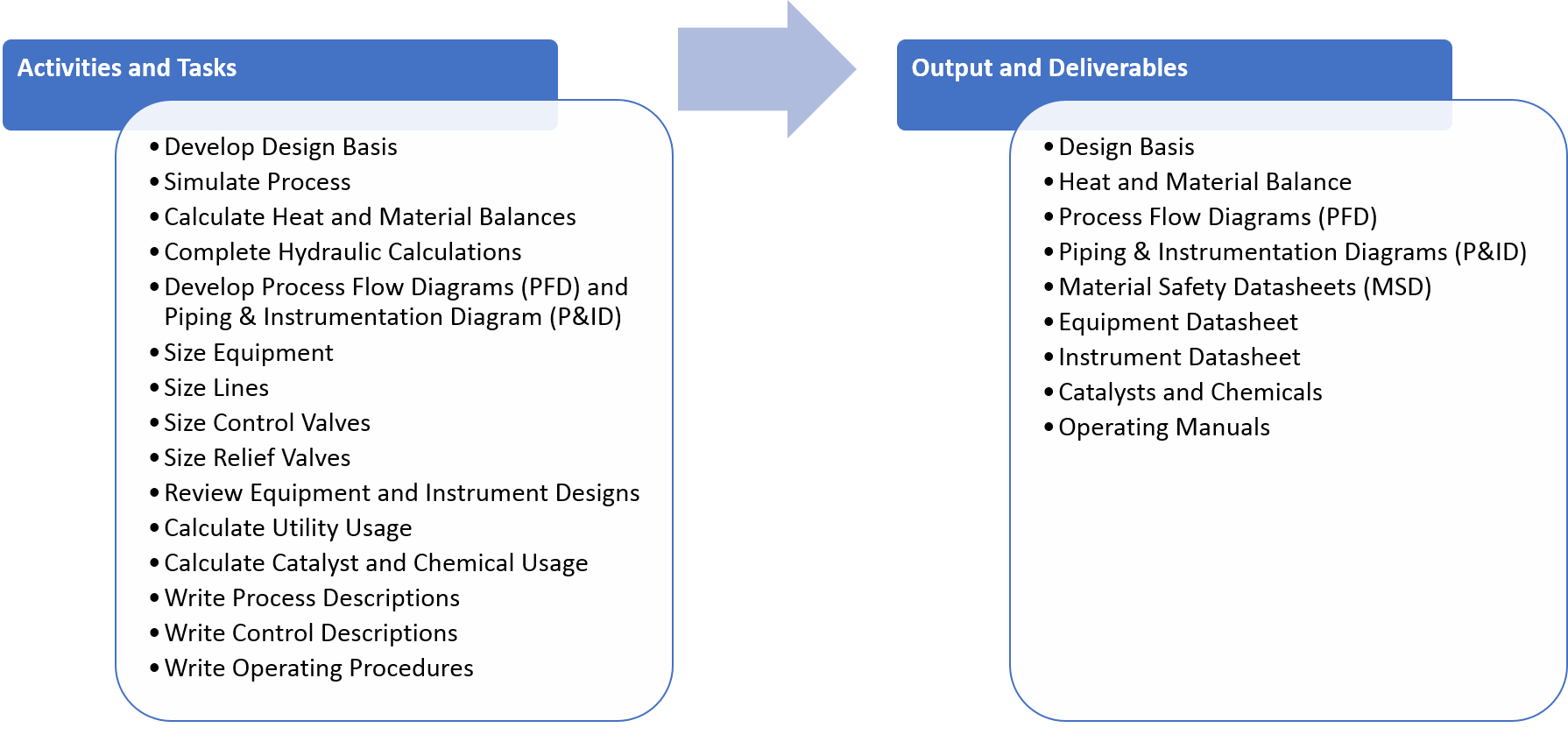

Establishing the steps in a chemical plant design is essential and recognizes the involvement of the multi-discipline engineering. Since process engineering design is conducted at the front-end of plant engineering design, therefore, outputs or deliverables from this stage have a significant impact on the subsequent design stages. The non-exhaustive list of process engineering workflow is illustrated in figure 2.

Figure 2. Summary – Process Engineering Tasks and Deliverables

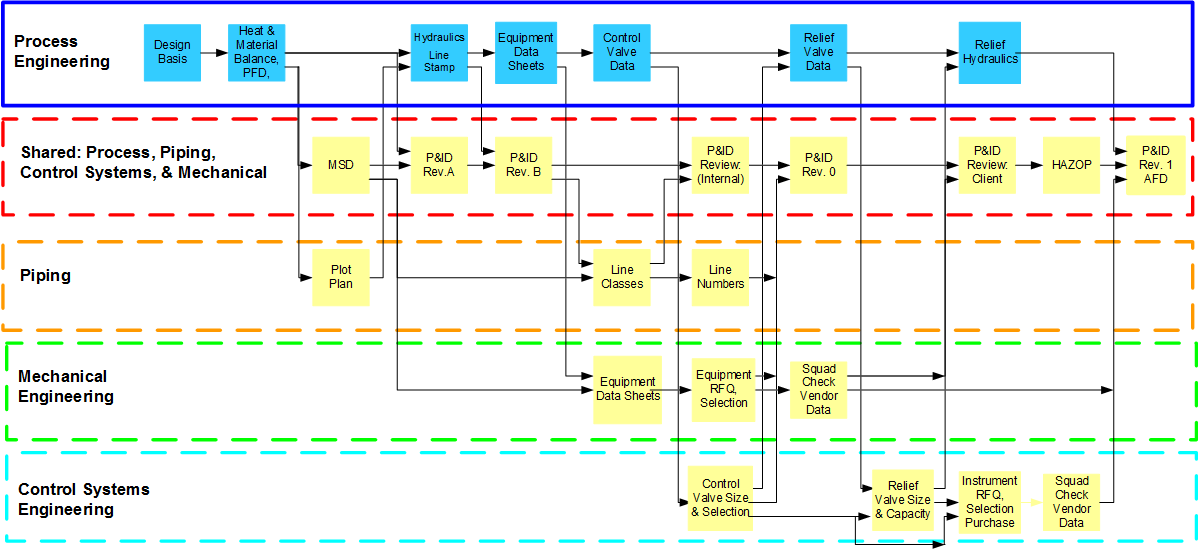

Seamless collaboration among different engineering disciplines is key to a successful chemical plant design execution. With this tight collaboration with other engineering disciplines, process engineers set work priorities, choose equipment, select instrument from alternatives, identify key hydraulic and elevation constraints. Aligning process engineering activities as well as deliverables sets the groundwork for the whole design execution and strategy. Figure 3 illustrates the interaction and the process engineering deliverable workflow to other engineering disciplines.

Figure 3. Process Engineering Simplified Workflow

The process information flow is communicated through the activities and deliverables that the process engineering owns or shares with another engineering discipline. One deliverable example is the piping and instrumentation diagram (P&ID). The P&ID is a schematic representation used to facilitate the design process, convey intent, or construct and communicate information to the client and all involved disciplines. The development of P&ID, as shown in figure 3, illustrates the involvement of process engineering and its interaction with other engineering disciplines.

Process Plant Consultants

Large-scale organizations may utilize their own design teams and conduct the entire project design and even construction within their organization. However, most commercial-scale process plants are very complex, made of various unit operations linked together by piping and automatically controlled via basic process control system (BPCS). Many process engineers working in a process plant are operations engineers specifically trained to troubleshoot an under-performing - or optimize a chemical plant but may lack the skills and experience to design a chemical plant. To minimize risks, organizations of many sizes usually outsource and commission a process plant consultant also known as engineering, procurement and construction management (EPCM) to design the process plant. The process engineers can be part of either the EPCM’s organization or the owner's engineering design team. Process engineers in the EPCM’s organization are part of the project team executing the design and performing the deliverables in the project. The process engineers that are part of the owner's design and engineering team are the engineering consultants responsible for reviewing and approving the deliverables from the contracted EPCM organization to ensure that the deliverables comply with the design specifications and requirements.

Whichever organization you work for, as a process engineer, it is important to understand your role and know that being the main driver in the design executions requires a good engineering foundation to perform the plant design. A good understanding of your activities and deliverables and your collaboration with other engineering disciplines contribute to the successful execution of the project.

Melannie Nellas, PE

Senior Chemical Engineer

Jimmy Lea P/L