How CFD simulation is applied in various industries?

December 5, 2023 - Reading time: 3 minutes

Computational fluid dynamics (CFD) simulation technology is very versatile owing to its applicability across many industries. In this article, we will give real-world applications of how CFD simulation is applied in two very different industries, namely, the built environment and the chemical & petrochemical industries.

Built Environment

Thermal comfort CFD simulation

CFD simulations are applied in the built environment to analyze and optimize various aspects of buildings and their surroundings. CFD is employed to simulate airflow patterns within buildings to optimize natural ventilation and assess the effectiveness of mechanical ventilation systems. It helps architects to predict indoor air quality by analyzing the dispersion of pollutants and contaminants.

CFD simulations aid mechanical engineers to design and optimize heating, ventilation and air conditioning (HVAC) systems for energy efficiency and thermal comfort. It is employed to analyze the performance of different air distribution systems and help in the design of effective thermal zones. It is also employed to assess the thermal performance of building components, such as windows, walls and roofs, to optimize insulation and reduce energy consumption.ÂÂ

CFD simulations are used to predict wind loads on buildings and other structures, thus assisting structural engineers to design building structures that can withstand different wind conditions.

CFD simulations are used to model the propagation of fire and smoke within buildings, thus assisting fire engineers and architects to design effective fire safety systems and evacuation strategies.

CFD is employed to simulate how sunlight interacts with buildings, helping architects to design shading devices, solar panels and optimizing daylighting strategies.

Finally, CFD simulations can assess the drainage and flooding risks in urban areas, helping in the design of effective stormwater management systems.

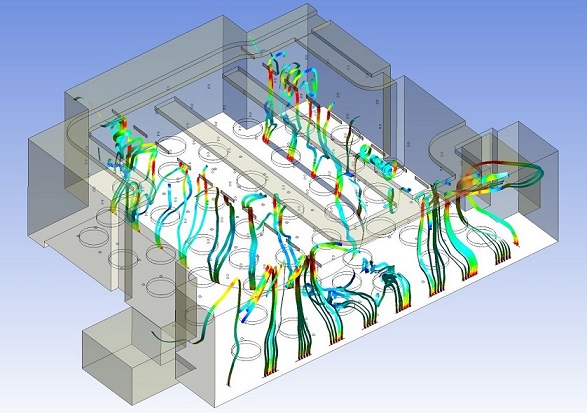

Chemical & Petrochemical

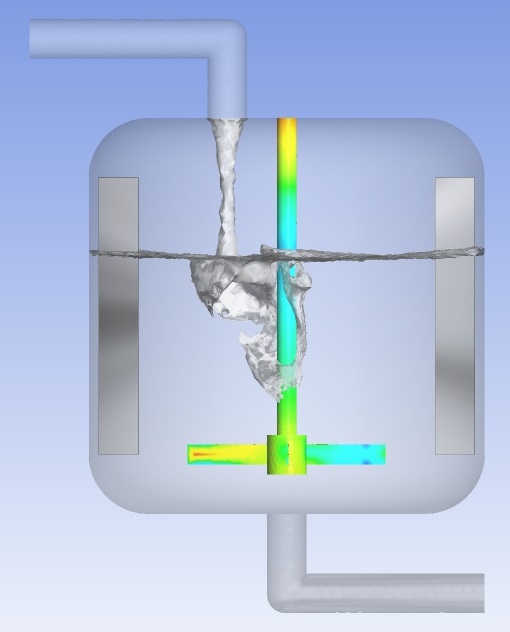

CFD simulation of a CSTR

CFD simulation of a CSTR

CFD simulations are applied in the chemical and petrochemical industry to model and analyze fluid flow, heat transfer and chemical reactions within various processes. CFD helps in optimizing the design and operation of chemical and petrochemical processes, improving efficiency and minimizing energy consumption. It aids in the evaluation of different reactor configurations, flow patterns and heat transfer mechanisms to enhance overall process performance.

CFD simulations are used to study the fluid dynamics and heat transfer in chemical reactors. This includes modeling reactions, species transport and temperature profiles. Thus, chemical engineers can use CFD results to optimize reactor design, assess mixing efficiency and understand the impact of various parameters on reaction kinetics. This simulation technology is also applied to analyze mixing processes in tanks and reactors, ensuring homogeneous distribution of chemicals and promoting efficient reactions. It helps in designing and optimizing impeller configurations, baffle systems and other mixing equipment.

CFD simulations aid in the design and analysis of heat exchangers, ensuring optimal heat transfer and temperature distribution within the system. Thus, mechanical engineers can assess different heat exchanger geometries, fin designs and fluid flow patterns to enhance thermal performance.

CFD is employed to model fluidized bed reactors and granular flows, providing insights into particle behavior, heat transfer and reaction kinetics. It assists chemical design engineers to optimize fluidization conditions for various processes, including catalytic cracking and gas-solid reactions.

CFD simulations help in analyzing fluid flow through pipes, valves, instrument and other equipment, ensuring proper distribution and minimizing pressure drops. Thus, plant design engineers can optimize the design of piping network systems to reduce energy consumption and improve overall system performance.

CFD is used to model the dispersion of pollutants and hazardous substances, helping in the design of safety systems, emergency response plans and plant hazard mitigation. It aids plant safey engineers to better understand the impact of accidental releases and optimizing ventilation systems to mitigate risks.

CFD simulations are applied to model the behavior of multiphase gas-liquid mixtures in separation devices such as cyclones, scrubbers and separators. Engineers can optimize the design of separation equipment to achieve efficient phase separation and minimize entrainment.

Finally, CFD is also utilized to study fluid flow and mass transfer in packed beds and columns, thus providing insights into separation processes such as distillation and absorption. It helps chemical engineers to optimize column design, packing materials and operating conditions.