Engineering:APCBC

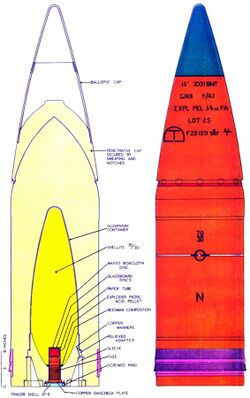

The armour-piercing capped ballistic cap (APCBC) is a type of armor-piercing shell introduced in the 1930s. The ballistic cap was a thin shell, typically metal, that fitted over the rounded nose of an otherwise unchanged armour-piercing round to improve its aerodynamics. This allowed the APCBC shells to retain higher velocities, delivering more energy to the target, especially at long range. On impact the shell crumpled, allowing the armour-piercing component to impact as normal.

Development

The APCBC munition type was an evolutionary development of the early war armour-piercing capped (APC) shell, itself an evolution of the more basic AP (armor-piercing or solid shot) and APHE (armor-piercing high-explosive) shell types. With respect to armored land warfare, the primary intended function of both AP and APHE shell types was to penetrate an enemy armored vehicle and incapacitate the vehicle and crew by internal explosion (in the case of APHE) or fragmentation/ricochet (in the case of AP rounds).

As the war lengthened, target armor became progressively thicker (and sloped) as new tank designs emerged, and early war AP and APHE became progressively less effective. The initial response to this thickening in armor had been to increase the muzzle velocity in newly developed anti-tank guns. However, it was found that steel shot tended to shatter on impact at velocities upward of about 823 m/s (2700 feet/second).[1]

Based on this deficiency, a new form of shell was developed which was designated APC (armor-piercing capped). In this form of munition, a cap of softer metal was attached to the tip of an AP (solid) round. The purpose of this cap was many-fold. The cap transferred energy from the tip of the shell to the sides of the projectile, thereby helping to reduce shattering. In addition, the cap appeared to improve penetration of sloped armor by deforming, spreading and “sticking” to the armor on impact and thereby reducing the tendency of the shell to deflect at an angle. However, the cap structure of the APC shell reduced the aerodynamic efficiency of the round with a resultant reduction in accuracy and range'[1]

Early World War II-era uncapped AP projectiles fired from high-velocity guns were able to penetrate about twice their caliber at close range (100 m). At longer ranges (500–1,000 m), this dropped to 1.5–1.1 calibers due to the poor ballistic shape and higher drag of the smaller-diameter early projectiles. Later in the conflict, APCBC fired at close range (100 m) from large-caliber, high-velocity guns (75–128 mm) were able to penetrate a much greater thickness of armor in relation to their caliber (2.5 times) and also a greater thickness (2–1.75 times) at longer ranges (1,500–2,000 m). Comparative testing of British Ordnance QF 17 pounder APCBC rounds fired into captured German Panther tanks indicated the APCBC munitions were more accurate than late war armour-piercing discarding sabot (APDS) shot.[2]

APCBC shot was produced for a wide range of anti-tank artillery ranging from 2 pounders to the German 88 mm. This type of munition was also designated as APBC (Armor Piercing Ballistic Capped), in reference to the Soviet version of APCBC. APCBC shot was also used in naval armaments in World War II. After World War II, the trend in armor-piercing munitions development centered on sub-caliber projectiles. No tank guns designed since the late 1950s have used full-caliber AP, APC, or APCBC ammunition.[3]

Countermeasures

One way to defeat APC rounds was to increase the thickness of armour. However, it became increasingly impractical to up-armour vehicles. One alternative was the use of spaced armour, which consists of a thin outer layer of armour sufficient to deform the armour piercing cap and a main armour layer sufficient to resist the now "decapped" round.

Notes

- ↑ 1.0 1.1 "Juno Beach Centre – Anti-Tank Projectiles". Junobeach.org. http://www.junobeach.org/e/4/can-tac-art-atp-e.htm. Retrieved 2010-06-12.

- ↑ U.S. Army Firing Test No. 3, U.S. Army Firing Tests conducted August 1944 by 12th U.S. Army Group at Isigny, France. Report of tests conducted during 20–21 August 1944.

- ↑ Orgokiewicz, p. 77.

References

- Orgokiewicz, Richard M. Technology of Tanks, Volume I. Coulsdon: Jane's Information Group, 1991.

- https://web.archive.org/web/20090812141445/http://www.wargaming.info/ww2/ustest3.htm

- British Anti-tank Artillery 1939-45. C. Henry, B. Delf. Edition: illustrated. Osprey Publishing, 2004