Physics:Water frame

The water frame is a spinning frame that is powered by a water-wheel.

History

Water frames in general have existed since Ancient Egyptian times.[citation needed] Richard Arkwright, who patented the technology in 1769,[1] designed a model for the production of cotton thread, which was first used in 1765.[2][3] The Arkwright water frame was able to spin 96 threads at a time, which was an easier and faster method than ever before.[4] The design was partly based on a spinning machine built for Thomas Highs by clockmaker John Kay, who was hired by Arkwright.[5] Being run on water power, it produced stronger and harder yarn than the "spinning jenny", and propelled the adoption of the modern factory system.[6]

Another water-powered frame for the production of textiles was developed in 1760 in the early industrialized town of Elberfeld, Prussia (now in Wuppertal, Germany ), by German bleach plant owner Johann Heinrich Bockmühl.[7][8]

The name water frame is derived from the use of a water wheel to drive a number of spinning frames. The water wheel provided more power to the spinning frame than human operators, reducing the amount of human labor needed and increasing the spindle count dramatically. However, unlike the spinning jenny, the water frame could spin only one thread at a time until 1779, when Samuel Compton combined the two inventions into his spinning mule, which was more effective.

The water frame was originally powered by horses at a factory built by Arkwright and partners in Nottingham. In 1770, Arkwright and his partners built a water-powered mill in Cromford, Derbyshire.

Cromford

In 1771, Arkwright installed the water frame in his cotton mill at Cromford, Derbyshire, on the River Derwent, creating one of the first factories that was specifically built to house machinery rather than just bring workers together. It was one of the first instances of the working day being determined by the clock instead of the daylight hours and of people being employed rather than just contracted. In its final form, combined with his carding machine, it was the first factory to use a continuous process from raw material to finished product in a series of operations.[9]

Arkwright played a significant role in the development of the factory system as he combined water power, the water frame, and continuous production with modern employment practices.

International success

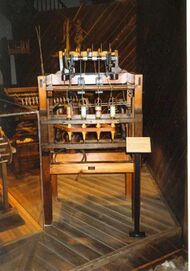

The water frame played a significant role in the development of the Industrial Revolution – first in England,[10] but soon also in continental Europe after German entrepreneur Johann Gottfried Brügelmann managed to find out details of the technology, which had been kept very secret; disclosure of details was punishable by the death penalty. Brügelmann managed to build working water frames and used them to open the first spinning factory on the continent, built in 1783 in Ratingen and also named "Cromford", from where the technology spread over the world. The factory building today hosts a museum, which is the world's only place to see a functioning water frame.[11]

Samuel Slater brought the water frame to America, circumventing the 1774 English ban on textile workers leaving and memorizing details of its construction; he left for New York City in 1789.[12] Moses Brown and Slater partnered to create the Slater Mill in Pawtucket in 1793, the first water-powered machine to make thread in America.[13]

References

- ↑ "Sir Richard Arkwright". https://www.britannica.com/biography/Richard-Arkwright.

- ↑ John Simkin. "British History – The Textile System – The Water Frame". Spartacus Educational Publishers Ltd., 1997. https://spartacus-educational.com/TEXframe.htm.

- ↑ "A History of the World – Arkwright's Water Frame spinning machine". BBC. http://www.dbt.co.uk/ahistoryoftheworld/objects/RyHIgvgsSeCYGZRl4Ep5RQ.[yes|permanent dead link|dead link}}]

- ↑ Limited, Alamy. "An old engraving of Arkwright's water or spinning frame. It is from a Victorian mechanical engineering book of the 1880s. The water frame is a spinning frame that is powered by a water-wheel. Richard Arkwright (1732–1792), who patented it in 1769, designed the machine for making cotton thread. It was first used in 1765 and was able to spin 96 threads at a time, far faster than ever before. In 1770 Arkwright and partners built a water-powered mill in Cromford, Derbyshire, England, UK. It soon employed over 300 people and is often regarded as the first factory of the Industrial Revolution Stock Photo – Alamy" (in en). https://www.alamy.com/an-old-engraving-of-arkwrights-water-or-spinning-frame-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-the-water-frame-is-a-spinning-frame-that-is-powered-by-a-water-wheel-richard-arkwright-17321792-who-patented-it-in-1769-designed-the-machine-for-making-cotton-thread-it-was-first-used-in-1765-and-was-able-to-spin-96-threads-at-a-time-far-faster-than-ever-before-in-1770-arkwright-and-partners-built-a-water-powered-mill-in-cromford-derbyshire-england-uk-it-soon-employed-over-300-people-and-is-often-regarded-as-the-first-factory-of-the-industrial-revolution-image388000233.html.

- ↑ McNeil, Ian (1990). An Encyclopedia of the History of Technology. London: Routledge. pp. 827–30. ISBN 0415147921. https://archive.org/details/isbn_9780415147927.

- ↑ Richard L. Hills, "Hargreaves, Arkwright and Crompton. Why Three Inventors?." Textile history 10.1 (1979): 114–126.

- ↑ "Industrial Heritage Expeditions – Textile in Wuppertal". Bergische Struktur- und Wirtschaftsförderungsgesellschaft mbH. https://www.die-bergischen-drei.de/en/tips-for-tours/industrial-heritage-expeditions/textil-im-wuppertal/stationen-in-elberfeld.html.

- ↑ Hinrich Heyken. "Von Bleichern, Färbern und Fabrikanten". City of Wuppertal. http://stadtgeschichte-wuppertal.de/hheyken_bilder/heyken_elberfelder_osten.pdf.

- ↑ The blast furnace, often considered the first continuous process, was a single process. The water frame, or more specifically the cotton mill of which it was a part, embodied a whole series of processes in one continuity, from raw cotton bale to the spun thread.

- ↑ Maxine Berg, The age of manufactures, 1700–1820: Industry, innovation and work in Britain (Routledge, 2005).

- ↑ "Textilfabrik Cromford" (in DE). https://industriemuseum.lvr.de/de/die_museen/ratingen/textilfabrik_cromford/textilfabrik_cromford.html.

- ↑ "Samuel Slater: American hero or British traitor?" (in en-GB). BBC News. 2011-09-22. https://www.bbc.com/news/uk-england-derbyshire-15002318.

- ↑ Pawtucket, Mailing Address: 67 Roosevelt Ave; Us, RI 02860 Phone: 401-725-8638 Contact. "SlaterMill – Blackstone River Valley National Historical Park (U.S. National Park Service)" (in en). https://www.nps.gov/blrv/learn/historyculture/slatermill.htm.

External links

|