Chemistry:BARS apparatus

BARS (or "split sphere", transliteration from Russian: БАРС abbreviation of Russian: Беспрессовая Аппаратура Высокого Давления «РАЗРЕЗНАЯ СФЕРА», (bespressovaya apparatura vysokogo davleniya «razreznaya sfera»), "press-free high-pressure setup «split sphere»") a high-pressure high-temperature apparatus usually used for growing or processing minerals, especially diamond and boron nitride.[1] Typical pressures and temperatures achievable with BARS are 10 GPa (99,000 atm) and 2,500 °C (4,530 °F; 2,770 K).[2][1]

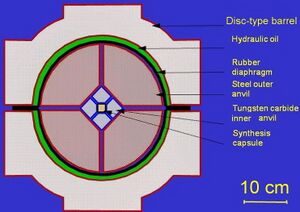

The BARS technology was invented around 1989–1991 by the scientists from the Institute of Geology and Geophysics of the Siberian Branch of the Academy of Sciences of the USSR.[2] In the center of the device, there is a ceramic cylindrical reaction cell of about 2 cm3 in size. The cell is placed into a cubic-shaped pressure-transmitting material, which is pressed by elements made from cemented carbide (VK10 hard alloy).[3] The outer octahedral cavity is pressed by 8 steel sectors. After mounting, the whole assembly is locked in a disc-type barrel with a diameter ~1 meter. The barrel is filled with oil, which pressurizes upon heating; the oil pressure is transferred to the central cell. The central cell is heated up by a coaxial graphite heater. Temperature is measured with a thermocouple. The exterior size is 2.2 х 1.0 х 1.2 meters. Weight of the sphere is 2.8 tonnes (6,200 lb). Claimed energy consumption is in between 1.5 - 2 kWh.[4]

The growth rate for 5 carats (1.0 g) type Ib (yellow, nitrogen-rich) crystals using Fe–Ni catalyst reaches as high as ~20 mg/h towards the end of 100 h growth cycle, i.e. crystals of 5 carats (1.0 g) to 6 carats (1.2 g) can be grown in less than 100 h.[5]

See also

- Synthetic diamond

- Material properties of diamond

- Crystallographic defects in diamond

- Diamond color

- Diamond enhancement

- Diamond

References

- ↑ 1.0 1.1 "Беспрессовая аппаратура высокого давления "РАЗРЕЗНАЯ СФЕРА" (БАРС)" (in ru-ru). http://www.igm.nsc.ru/index.php?option=com_k2&view=item&id=1232:%D0%B1%D0%B5%D1%81%D0%BF%D1%80%D0%B5%D1%81%D1%81%D0%BE%D0%B2%D0%B0%D1%8F-%D0%B0%D0%BF%D0%BF%D0%B0%D1%80%D0%B0%D1%82%D1%83%D1%80%D0%B0-%D0%B2%D1%8B%D1%81%D0%BE%D0%BA%D0%BE%D0%B3%D0%BE-%D0%B4%D0%B0%D0%B2%D0%BB%D0%B5%D0%BD%D0%B8%D1%8F-%D1%80%D0%B0%D0%B7%D1%80%D0%B5%D0%B7%D0%BD%D0%B0%D1%8F-%D1%81%D1%84%D0%B5%D1%80%D0%B0-%D0%B1%D0%B0%D1%80%D1%81&Itemid=554&lang=ru.

- ↑ 2.0 2.1 N. Pal'yanov (2002). "Fluid-bearing alkaline carbonate melts as the medium for the formation of diamonds in the Earth's mantle: an experimental study". Lithos 60 (3–4): 145. doi:10.1016/S0024-4937(01)00079-2. Bibcode: 2002Litho..60..145P.

- ↑ M. G. Loshak and L. I. Alexandrova (2001). "Rise in the efficiency of the use of cemented carbides as a matrix of diamond-containing studs of rock destruction tool". Int. J. Refractory Metals and Hard Materials 19: 5. doi:10.1016/S0263-4368(00)00039-1.

- ↑ "Беспрессовая аппаратура высокого давления "РАЗРЕЗНАЯ СФЕРА" (БАРС)" (in ru-ru). http://www.igm.nsc.ru/index.php?option=com_k2&view=item&id=1232:%D0%B1%D0%B5%D1%81%D0%BF%D1%80%D0%B5%D1%81%D1%81%D0%BE%D0%B2%D0%B0%D1%8F-%D0%B0%D0%BF%D0%BF%D0%B0%D1%80%D0%B0%D1%82%D1%83%D1%80%D0%B0-%D0%B2%D1%8B%D1%81%D0%BE%D0%BA%D0%BE%D0%B3%D0%BE-%D0%B4%D0%B0%D0%B2%D0%BB%D0%B5%D0%BD%D0%B8%D1%8F-%D1%80%D0%B0%D0%B7%D1%80%D0%B5%D0%B7%D0%BD%D0%B0%D1%8F-%D1%81%D1%84%D0%B5%D1%80%D0%B0-%D0%B1%D0%B0%D1%80%D1%81&Itemid=554&lang=ru. "оптимальные габариты (2,2 х 1,0 х 1,2 м) и масса установки (2,8 т); высокая экологичность и безопасность; низкая энергоемкость (1,5 - 2 квт/час); заменяемость многопуансонного блока в зависимости от задач"

- ↑ R. Abbaschian (2005). "High pressure–high temperature growth of diamond crystals using split sphere apparatus". Diam. Relat. Mater. 14 (11–12): 1916. doi:10.1016/j.diamond.2005.09.007. Bibcode: 2005DRM....14.1916A.

External links

- hpht – high pressure high temperature

- Pressless High-Pressure Equipment “SPLIT SPHERE"

- Synthetic threat to gem quality diamonds

|