Chemistry:Haskelite

Haskelite is the brand name of a plywood, once made by the Michigan based Haskelite Manufacturing Corporation. It was made from waterproof glue developed by Henry L. Haskell. The moldable plywood was originally called Ser-O-Ply. It was used in the construction of various vehicles including military tanks, boats, airplanes, buses, trucks, and automobiles.

Background

Haskell invented a process for making glue from blood-albumin. The process used slaughterhouse blood from the Chicago stock yards.[1] The inexpensive waterproof adhesive was called "black albumin glue."[2] It was used to bond wood pieces.[3] One product Haskell made from this was a lightweight waterproof plywood, first known as Ser-O-Ply.[4] He applied this glue to wood veneers and manufactured plywood for various applications. Some of these applications were boats, airplanes, tanks, trucks, automobiles and rail cars.[4] They were from 1/8th inch thick to just over an inch thick, and had various layers of ply veneers. Typical moldable plywood panels were about five feet wide by twenty feet long and 3/16th of an inch thick.[5] The plywood sheets made this way were eventually given the brand trade name of "haskelite."[6] It is named after Henry L. Haskell, inventor of the glue bonding the plywood.[7]

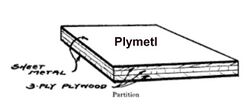

Haskell formed a company for making plywood that ultimately became the Haskell Manufacturing Company in Ludington, Michigan and the Haskelite Manufacturing Corporation in Grand Rapids, Michigan. The glue was applied cold and spread onto wood veneers with rollers. A stack of three sheets of veneer was then put through a press, where each panel was subjected to a pressure of 150 psi between metal plates at 210 degrees F.[6] This pressure and heat made the bond between the veneers permanent and the glue became insoluble.[3] The plywood was given brand names depending its characteristics.[8] Plymetl had metal faces; Plymold was a plastic-based plywood that could be molded, and Phemaloid was a fire-resistant paneling.[9]

Boats

Thinner moldable plywood was used to make watercraft.[10] One model was the Haskell canoe. It was made from a type of plywood Haskell produced, consisting of veneers of birch on the outside and a redwood core. The unseamed canoe was made from a single piece of plywood; thousands were sold in the US. There was no ribs used in the building of the canoe.[3]

Airplanes

Haskel plywood was used for aircraft parts, especially fuselages and wings.[3] The Haskelite company was considered Ludington's most important industry during WWI, since over 3000 military aircraft were constructed for the US and allies using its plywood.[11][12]

The first plane made with moldable plywood was constructed with Haskelite, and was the Curtiss two-place fighter Whistling Bill.[13] Haskell plywood was used for construction of experimental and commercial aircraft.[14] A Johnson Twin 60 experimental airplane was built in 1927 that had 85% Haskelite plywood in its wings, seats, instrument board, and fuselage parts.[15] The first successful commercial airplane it was used on was the 1937 Fairchild Aircraft model F-46.[16]

See also

- Carrom Company

- Haskell Manufacturing Company

- Haskelite Manufacturing Corporation

References

- ↑ Smith 1930, p. 18.

- ↑ "Manufacturers:Haskell Boat Company". Wooden Canoe Heritage Association. 2016. https://www.wcha.org/content/haskell-boat-company.

- ↑ 3.0 3.1 3.2 3.3 Dunbar 1955, p. 439.

- ↑ 4.0 4.1 Smith 1930, p. 19.

- ↑ Williams, Leonard P. (December 22, 1952). "Carrom Industries / Into Plywood Business (page 7)". Daily News (Ludington, Michigan). https://www.newspapers.com/clip/5153556//.

- ↑ 6.0 6.1 Motor_Body 1919, p. 54.

- ↑ Motor_Boat 1920, p. 38.

- ↑ Hardwood_Record 1920, p. 30.

- ↑ Marine_Engineering 1933, p. 208-213.

- ↑ "New Material Used in Boats". The News-Palladium (Benton Harbor, Michigan). June 24, 1939. https://www.newspapers.com/clip/5240989//.

- ↑ "Local Company Contributed to war effort". Daily News (Ludington, Michigan). June 26, 1993. https://news.google.com/newspapers?nid=110&dat=19930626&id=ljVQAAAAIBAJ&sjid=3lUDAAAAIBAJ&pg=2161,7253929&hl=en.

- ↑ "Carrom Company Is Diversified". Daily News (Ludington, Michigan). September 3, 1965. https://www.newspapers.com/clip/5229992//.

- ↑ Kane, p. 70.

- ↑ "Haskelite, Hughs to Build Planes". Daily News (Ludington, Michigan). August 1, 1939. https://www.newspapers.com/clip/5240634//.

- ↑ "New Johnson Twin 60 adopts HASKELITE". Aero-Digest 10: 2. 1927. https://archive.org/stream/aerodigest1019unse/aerodigest1019unse_djvu.txt. Retrieved May 12, 2016.

- ↑ "Ludington is Birthplace of Plywood Airplanes". Daily News (Ludington, Michigan). July 15, 1943. https://www.newspapers.com/clip/5239496//.

Sources

- Dunbar, Willis Frederick (1955). Michigan Through the Centuries. Lewis Historical Publishing Company. https://books.google.com/books?id=zn3hAAAAMAAJ.

- Hardwood_Record (1920). Hardwood Record. Hardwood Company. https://books.google.com/books?id=kgI3AQAAMAAJ&pg=PA29.

- Kane, Joseph Nathan. FAMOUS FIRST FACTS AND RECORDS. https://books.google.com/books?id=NttiC-UaOTMC. "The first airplane of molded plywood was the "Whistling Bill," a two-place fighter, built in 1918 by the Curtiss Aeroplane and Motor Company, Garden City, Long Island, N.Y. The fuselage was made of four 3/32nd-inch longitudinal sheets of Haskelite, three-ply birch plywood, steamed and formed to contour in a concrete die."

- Marine_Engineering (1933). Marine Engineering. Simmons-Boardman Publishing Corporation.

- Motor_Boat (1920). Motor Boat. Motor Boat Publishing Company. https://books.google.com/books?id=M-k_AQAAMAAJ&pg=RA7-PA38.

- Motor_Body (1919). Motor Body, Paint and Trim. https://books.google.com/books?id=--w_AQAAMAAJ&pg=RA3-PA54.

- Smith, S.H. (1930). Veneers and Plywood. S.H. Smith.. https://books.google.com/books?id=8r_kAAAAMAAJ.

External links

| Wikimedia Commons has media related to Haskelite. |