Engineering:6L6

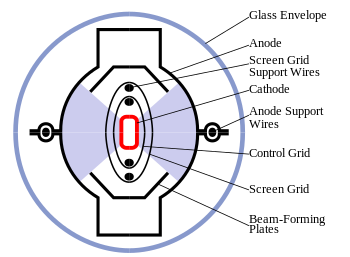

6L6 is the designator for a beam power tube introduced by Radio Corporation of America in April 1936 and marketed for application as a power amplifier for audio frequencies.[1][2] The 6L6 is a beam tetrode that utilizes formation of a low potential space charge region between the anode and screen grid to return anode secondary emission electrons to the anode and offers significant performance improvements over power pentodes.[1] The 6L6 was the first successful beam power tube marketed. In the 21st century, variants of the 6L6 are manufactured and used in some high fidelity audio amplifiers and musical instrument amplifiers.

History

In the UK, three engineers at EMI (Isaac Shoenberg, Cabot Bull and Sidney Rodda) had developed and filed patents in 1933 and 1934 on an output tetrode that utilized novel electrode structures to form electron beams to create a dense space charge region between the anode and screen grid to return anode secondary electrons to the anode.[3][4] The new tube offered improved performance compared to a similar power pentode and was introduced at the Physical and Optical Societies' Exhibition in January 1935 as the Marconi N40.[5] Around one thousand of the N40 output tetrodes were produced, but MOV (Marconi-Osram Valve) company, under the joint ownership of EMI and GEC, considered the design too difficult to manufacture due to the need for good alignment of the grid wires.[6] As MOV had a design-share agreement with RCA of America, the design was passed to that company.[6][7]

The metal tube technology utilized for the 6L6 had been developed by General Electric and introduced in April 1935, with RCA manufacturing the metal envelope tubes for GE at that time.[8] Some of the advantages of metal tube construction over glass envelope tubes were smaller size, ruggedness, electromagnetic shielding and smaller interelectrode capacitance.[9] The 6L6 incorporated an octal base, which had been introduced with the GE metal tubes. The 6L6 was rated for 3.5 watts screen power dissipation and 24 watts combined plate and screen dissipation.[10] The 6L6 and variants of it became popular for use in public address amplifiers, musical instrument amplifiers, radio frequency applications and audio stages of radio transmitters.[11] The 6L6 family has had one of the longest active lifetimes of any electronic component, more than 80 years. As of 2021, variants of the 6L6 are manufactured in Russia, China, and Slovakia.

Variations

The voltage and power ratings of the 6L6 series were gradually pushed upwards by such features as thicker plates, grids of larger diameter wire, grid cooling fins, ultra-black plate coatings and low loss materials for the base. Variants of the 6L6 included the 6L6G, 6L6GX, 6L6GA, 6L6GAY, 6L6GB, 5932/6L6WGA and the 6L6GC. All variants after the original 6L6 utilized glass envelopes. A "W" in the descriptor identified the tube as designed to withstand greater vibration and impact. A "Y" in the descriptor indicated that the insulating material of the base was Micanol.

Application

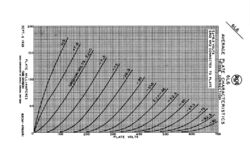

The high transconductance and high plate resistance of the 6L6 requires circuit design that incorporates topologies and components that smooth out the frequency response, suppress voltage transients and prevent spurious oscillation.[12][13]

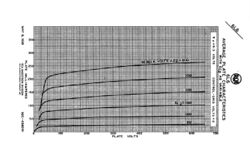

Characteristics

Improved substitute

- 5881

Similar tubes

- 6P3S (6П3С)

- 6P3S-E (6П3С-E)

- 7027a

- 6BG6

See also

References

- ↑ 1.0 1.1 J. F. Dreyer Jr., "The Beam Power Output Tube", New York: McGraw-Hill, Electronics, April 1936, pp. 18 - 21, 35

- ↑ RCA Manufacturing Co. Inc., "Here is the New RCA 6L6 Beam Power Amplifier", New York: McGraw-Hill, Electronics, May 1936, back cover

- ↑ Schoenberg, Rodda, Bull, Improvements in and relating to thermionic valves, GB patent 423,932, published Feb. 1935

- ↑ Schoenberg, Rodda, Bull, Electron discharge device and circuits therefor, US patent 2,113,801 published Apr. 1938

- ↑ Editors, "New Output Tetrode", New York: McGraw-Hill, Electronics, Feb. 1935, p. 65

- ↑ 6.0 6.1 K. R. Thrower, British Radio Valves The Classic Years: 1926-1946, Reading, UK: Speedwell, 2009, pp. 125 - 126

- ↑ O.H. Schade, "Beam Power Tubes" Proc. I.R.E., Vol. 26, No. 2, Feb. 1938, p. 153

- ↑ Editors, "Metal Tubes for Receivers", Radio Engineering, April 1935, pp. 18 - 19

- ↑ Metcalf, Beggs, "All-metal receiving tubes, the manufacturing technique", New York: McGraw-Hill, Electronics, May 1935, pp. 149 - 151

- ↑ RCA, RCA 6L6 Beam Power Amplifier, RCA Manufacturing Co., Inc.

- ↑ Wholesale Radio Service Co., Lafayette catalog no. 76, New York: Lafayette Radio Corp., 1939, pp. 38, 90, 96

- ↑ L. C. Hollands, "Circuit Design Related to Tube Performance", New York: McGraw-Hill, Electronics, Mar. 1939, pp. 18 - 20

- ↑ Editors, "The Electron Art" "Ultra-High Frequency Oscillation with the Beam Tube", New York: McGraw-Hill, Electronics, Jan. 1940, p. 69

External links

- TDSL Tube data [6L6]

- Electron Tube Data sheets: Several 6L6 datasheets from various manufacturers

- Kurt Prange. "6L6GC Comparison of Current Made Tubes". http://www.amplifiedparts.com/sites/all/modules/custom/tech_corner/files/6l6gc_comparison_of_current_made_tubes.pdf.

- Reviews of 6L6 tubes

- Barbour, Eric. "6L6 Forever (1936-1996): 60 Years of Amplifier Service." Vacuum Tube Valley 4:1 (Spring/Summer 1996), 3-10.

|