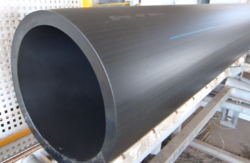

Engineering:HDPE pipe

HDPE pipes are a type of flexible plastic pipe used to transfer fluids and gases. It is often employed for replacing aging concrete or steel mains pipelines. constructed from the thermoplastic HDPE (high-density polyethylene), it has low permeability and robust molecular bonding, making it suitable for high pressure pipelines. HDPE pipe is often used for; water mains, gas mains,[1] sewer mains, slurry transfer lines, rural irrigation, fire system supply lines, electrical and communication conduits, stormwater pipes, and drainage pipes.[2]

Benefits

HDPE is strong and resistant to chemicals, corrosion, and light. It has growing use in situations where cheap but durable fluid piping systems are required. According to a press release from the Plastics Pipe Institute, "PE [polyethylene] piping has been used for water and other fluids in Europe and America since the 1950s due to its durability, leak free joints, resistance to corrosion, and long-term cost-effectiveness".

HDPE pipe can be joined by butt welding, electrofusion welding, socket welding, or extrusion welding. These joints heat the pipe during the joining process, creating a completely homogeneous joint so the weld becomes as strong, or stronger, than the existing pipe on either side of the weld. There is no need to use rubber seals or jointing chemicals, as is used for joining PVC pipe, which cause environmental health issues and increase the chance of failure over time. HDPE is less likely to have problems with root intrusion, and provides integrity for the pipeline, even when installed in unstable soils.

Due to the fusion welding system, the need for anchors or thrust restraint blocks is eliminated, as the joints become fully end load resistant, reducing costs for material and installation time. This also allows for safer excavation close to the pipeline in the future, which is particularly important for high pressure gas pipelines. Coils of HDPE Pipe make trench-less installation safer and less intrusive on the surrounding environment.

HDPE pipe systems are available for many applications, providing for standard trenching of water mains, fire ring mains, sewer mains, and gas mains pipelines, as well as horizontal drilling for electrical and telecommunications conduits.[3] According to a company that manufactures HDPE, HDPE systems are cost-effective to install and have long-term maintenance cost savings, and also allow for cheaper installation methods, such as HDD (horizontal directional drilling), sliplining, pipe bursting, floating and submerged pipe.[4]

HDPE pipe is highly durable and flexible, and it can be bent on-site to a radius of twenty-five times the nominal pipe diameter for SDR11 and SDR17 pipe at or below an ambient temperature of 20°C. This characteristic provides significant cost savings compared to other pipe systems that require glued fittings, restraints, or thrust blocks for even minor changes in direction. Due to its high impact resistance and flexibility, HDPE pipe is well-suited for installation in dynamic soils, including those in earthquake-prone areas. HDPE pipe also boasts very high flow capacity, thanks to its smooth bore and end-to-end jointing methods. Unlike ferrous piping systems, which will rust and build up internal resistance to fluid flow over time, HDPE pipe does not corrode in the environment and will maintain its flow capabilities.[5]

Because food-grade polyethylene virgin material is used to fabricate HDPE pipes, they are safe for the transfer of drinking water, provided that any initial debris has been flushed out. HDPE pipe is resistant to many chemicals, facilitating its use in process plants or around corrosive or acidic environments, without needing to use protective coatings or galvanising, as is required on steel pipes. As HDPE has a very low thermal conductivity, it can maintain more uniform temperatures compared to metal pipes when carrying fluids, which will greatly reduce any need for insulation to control condensation around the pipeline.[6]

Manufacturing

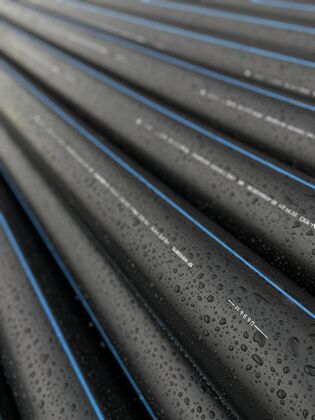

To make pipe lengths, HDPE resin is heated and extruded through a die, which determines the diameter of the pipeline. The wall thickness of the pipe is determined by a combination of the size of the die, the speed of the screw, and the speed of the haul-off tractor. Polyethylene pipe is usually black due to the addition of 3-5% of carbon black being added to the clear polyethylene material. The addition of carbon black creates a product that is UV light resistant. Other colours are available but are less common. Coloured or striped HDPE pipe is usually 90-95% black material, with just a coloured skin or stripe on the outside 5%.

The following describes the process for HDPE pipe extrusion:

Polyethylene raw material is pulled from a silo, into the hopper dryer, which removes any moisture from the pellets. Then it is pulled by a vacuum pump into the blender, where it is heated by a barrel heater. The PE material becomes molten at around 180 °C (356 °F), allowing it to be fed through a mould/die, which shapes the molten material into a circular shape. After coming through the die, the newly formed pipe quickly enters the cooling tanks, which submerge or spray water at the pipe exterior, each one reducing the temperature of the pipe by 10-20 degrees. Because polyethylene has a high specific heat capacity, the pipe must be cooled in stages, to avoid deforming the shape, and by the time it reaches the "haul-off tractor", it is hard enough to be gently pulled by the 2-3 belts. A laser or powder printer prints the size, type, date, and manufacturer's name on the side of the pipe. It is then cut by a saw cutter, either into lengths of 3 or 6 or 12 or 24 meters (9.8 or 19.7 or 39.4 or 78.7 ft), or it is coiled to 50 or 100 or 200 m (164 or 328 or 656 ft) lengths on a coiler.

A different die is used for a striped HDPE pipe, which has small channels that the coloured material runs through, just before it is pushed through the die. This means the stripes are formed as an integral part of the pipe and are not likely to separate from the main pipe body. Co-extruded, or co-ex HDPE pipe, has a second extrusion screw that adds an extra skin of colour around the black HDPE pipe, this allows the pipe to be coloured on the outside, for the identification or thermal cooling requirements.

Uses

A 600 m (1,969 ft) long HDPE boom is used for the Ocean Cleanup project. The HDPE pipeline is being released into the ocean to help clean up the Great Pacific Garbage Patch.

HDPE pipe has been used in rural and mining environments in Australia for over 50 years, where it proved to be a very durable and effective means of fluid and gas transfer.[7][self-published source?]

Life expectancy

HDPE pipes are often estimated to last 50 years. However, technical white papers written by the PIPA (Plastics Industry Pipe Association) asserted that HDPE pipe systems can be reasonable expected to last up to 100 years, if not more.[5] In Australia, PE pipes and PE fittings were introduced during the mid-1900s, mainly for irrigation or water supply, but also for gas, fuel, and other industrial applications. They were used for a 50-year time interval, which led to misunderstanding that it represents a 50-year pipe life. For pipe systems that have been correctly manufactured and installed, the actual life cannot be predicted but can be expected to be over 100 years until major rehabilitation is needed.[5]

References

- ↑ Stahmer (2008). "PIPA Technical Paper on Polyethylene used for Gas Pipe Material" (in en). http://www.pipa.com.au/wp-content/uploads/2018/09/tn004.pdf.

- ↑ "HDPE" (in en). https://www.plasticpipe.org/PowerCommunications/BuildingConstruction/HDPE.aspx.

- ↑ Ireland, Beck (1 September 2009). "Fast, Cheap, and Out of Control?". Endeavor Business Media. https://www.ecmweb.com/design/fast-cheap-and-out-control.

- ↑ "Why use HPDE" (in en). 2024. https://www.acu-tech.com.au/about-us/why-use-hdpe/.

- ↑ Jump up to: 5.0 5.1 5.2 "Life Expectancy for Plastics Pipes" (in en). Plastics Industry Pipe Association of Australia Ltd. 2018. http://www.pipa.com.au/wp-content/uploads/2018/09/tn013.pdf.

- ↑ "Chapter 8: Above-Ground Applications for PE Pipe". Handbook of Polyethylene Pipe (2nd ed.). CLVR Company. 2012. ISBN 9781952632006.

- ↑ "Technical Commentary: Polyethylene pipes for pressure applications" (in en). Plastics Industry Pipe Association of Australia Ltd.. 2003. http://www.pipa.com.au/wp-content/uploads/2018/09/tc4130.pdf.

|