Engineering:Materials oscilloscope

A materials oscilloscope is a time-resolved synchrotron high-energy X-ray technique to study rapid phase composition and microstructural related changes in a polycrystalline sample.[1][better source needed] Such device has been developed for in-situ studies of specimens undergoing physical thermo-mechanical simulation.[2][3]

Principle

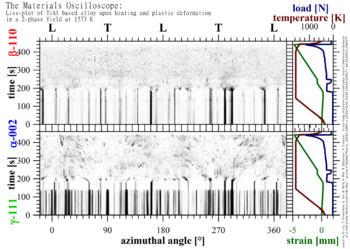

Two-dimensional diffraction images of a fine synchrotron beam interacting with the specimen are recorded in time frames, such that reflections stemming from individual crystallites of the polycrystalline material can be distinguished. Data treatment is undertaken in a way that diffraction rings are straightened and presented line by line streaked in time.[3] The traces, so-called timelines in azimuthal-angle/time plots resemble to traces of an oscilloscope, giving insight on the processes happening in the material, while undergoing plastic deformation, or heating, or both,[4][5][6][7][8][9][10] These timelines allow to distinguish grain growth or refinement, subgrain formation, slip deformation systems, crystallographic twinning, dynamic recovery, dynamic recrystallization, simultaneously in multiple phases.

History

The development has been undertaken from a project on modern diffraction methods for the investigation of thermo-mechanical processeses,[11][better source needed] and started with cold deformation of a copper specimen at the ESRF in 2007, followed by hot deformation of zirconium alloy at APS in 2008. Soon afterwards, a series of other materials has been tested and experience with the timeline traces gained. While ESRF and APS played the major role in experimental facilities, the Japanese high-energy synchrotron in the round, SPring-8 followed in 2013 by performing feasibility studies of this kind. Meanwhile, the new PETRA-III synchrotron at DESY built a dedicated beamline for this purpose, opening the Materials Oscilloscope investigations to a larger public. The name materials oscilloscope was introduced in 2013 and used onward upon conferences such as MRS and TMS.[12][13][better source needed]

Implementation

Besides setups in multi-purpose facilities, the first dedicated end-station has been built at the PETRA-III storage ring, where this technique is routinely applied.

References

- ↑ Klaus-Dieter Liss: "Towards the Materials Oscilloscope: In-Situ, Real-time Diffraction on Metals Under Thermo-Mechanical Deformation", TMS-2015, http://www.programmaster.org/PM/PM.nsf/ViewSessionSheets?OpenAgent&ParentUNID=4AE20368ED00DE3585257D3B0011C714

- ↑ Liss, K.-D. (2010). "Thermo-mechanical processing in a synchrotron beam - from simple metals to multiphase alloys and intermetallics". World Journal of Engineering 7 (Suppl 2): 438.

- ↑ 3.0 3.1 Liss, Klaus-Dieter; Yan, Kun (2010). "Thermo-mechanical processing in a synchrotron beam". Materials Science and Engineering: A 528: 11–27. doi:10.1016/j.msea.2010.06.017.

- ↑ 4.0 4.1 K.-D. Liss; T. Schmoelzer; K. Yan; M. Reid; M. Peel; R. Dippenaar; H. Clemens (December 2009). "In-situ study of dynamic recrystallization and hot deformation behavior of a multi-phase titanium aluminide alloy". Journal of Applied Physics 106 (11): 113526–(1–6). doi:10.1063/1.3266177. Bibcode: 2009JAP...106k3526L. https://ro.uow.edu.au/cgi/viewcontent.cgi?article=1997&context=engpapers.

- ↑ Yan, Kun; Liss, Klaus-Dieter; Garbe, Ulf; Daniels, John; Kirstein, Oliver; Li, Huijun; Dippenaar, Rian (2009). "From Single Grains to Texture". Advanced Engineering Materials 11 (10): 771–773. doi:10.1002/adem.200900163. http://apo.ansto.gov.au/dspace/handle/10238/2431.

- ↑ Yan, Kun; Liss, Klaus-Dieter; Garbe, Ulf; Daniels, John; Kirstein, Oliver; Li, Huijun; Dippenaar, Rian (2009). "Adv. Eng. Mater. 10/2009". Advanced Engineering Materials 11 (10): NA. doi:10.1002/adem.200990026.

- ↑ Liss, Klaus-Dieter; Garbe, Ulf; Li, Huijun; Schambron, Thomas; Almer, Jonathan D.; Yan, Kun (2009). "In Situ Observation of Dynamic Recrystallization in the Bulk of Zirconium Alloy". Advanced Engineering Materials 11 (8): 637–640. doi:10.1002/adem.200900094.

- ↑ Liss, Klaus-Dieter; Garbe, Ulf; Li, Huijun; Schambron, Thomas; Almer, Jonathan D.; Yan, Kun (2009). "In Situ Observation of Dynamic Recrystallization in the Bulk of Zirconium Alloy (Adv. Eng. Mater. 8/2009)". Advanced Engineering Materials 11 (8): NA. doi:10.1002/adem.200990021.

- ↑ Yan, Kun; Carr, David G.; Callaghan, Mark D.; Liss, Klaus-Dieter; Li, Huijun (2010). "Deformation mechanisms of twinning-induced plasticity steels: In situ synchrotron characterization and modeling". Scripta Materialia 62 (5): 246–249. doi:10.1016/j.scriptamat.2009.11.008.

- ↑ Liss, Klaus-Dieter; Yan, Kun; Reid, Mark (2014). "Physical thermo-mechanical simulation of magnesium: An in-situ diffraction study". Materials Science and Engineering: A 601: 78–85. doi:10.1016/j.msea.2014.02.014.

- ↑ ThermoMech.Pro http://www.ansto.gov.au/ResearchHub/Bragg/CurrentResearch/ScientificProjects/Thermo-MecPro/index.htm

- ↑ 17. September 2013, Neutron Industrial Promotion Workshop on Residual Stress and Strain Analysis, Tokyo, Japan, invited talk: Klaus-Dieter Liss: "Modern Diffraction Methods for the Investigation of Thermo-Mechanical Processes"

- ↑ Neutron and synchrotron radiation with applications for in-situ studies in materials science http://www.campnano.org/web/en/communication/invited_visitors/2014/1016/728.html

|