Physics:Tribo-fatigue

Tribo-Fatigue is a subdiscipline of mechanics,[1][2] which studies wear-fatigue damage (WFD) in and the fracture of tribo-fatigue systems.[3][4] The field was founded at the junction of tribology, and mechanics of fatigue damage and fracture in materials and structural elements.[5][6][7][8][9][10] [11][12][13]

Etymology

The term Tribo-Fatigue is derived from τριβο (translit. tribo) in Greek, meaning friction, and fatigue in French and English, meaning fatigue. It was first proposed in a letter of L. А. Sosnovskiy to K.V. Frolov on September 30, 1984.[1]. This term was first published in 1986.[14] It is included in the Belarusian Encyclopedia[3] and the Great Encyclopedic Dictionary.[4]

History

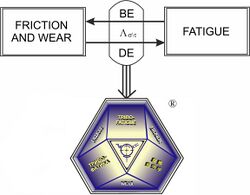

The sources of Tribo-Fatigue are such scientific disciplines as Friction, Tribology, Fatigue, etc (Figure 1).

The initial stage of development (1985–1993) ended with the holding of the first International Symposium on Tribo-Fatigue (ISTF) in 1993, the preparatory materials for which were published in the following references[2][15][16][17] and many other works. Likewise, they are summarized in the following reference sources[18][19] and many other works. Seven International Symposiums on Tribo-Fatigue (ISTF) were held in four countries: Belarus, Russia, China, and Ukraine. Their reports and proceedings are published in the mentioned countries (see, for example, the following references).[20][21][22][23][24][25] More than 2,500 scientists and experts took part in the symposiums, and 147 authors from many countries were awarded honorary diplomas "For the Contribution to Tribo-Fatigue Development." In 2010, 25 scientists and scientific coordinators from different countries were awarded with the Honorable Anniversary Sign "TRIBO-FATIGUE-25."

In 2015, a bibliographic index was published; it included 930 works on Tribo-Fatigue, including about 40 books and 12 state and interstate standards that had been developed based on the results of research in a new field. Currently, the number of works exceeds 1,100 titles.[26]

Objects

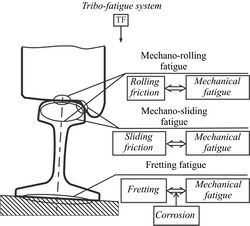

Tribo-Fatigue studies mechanical systems where the friction process is implemented in its manifestations during rolling, sliding, slipping, impact, erosion, and the like. At the same time, friction accommodates and transfers the volume-alternating load, which is in particular cyclic.[5][6][8][9] These are high-duty products. Thus, in the traditionally studied friction pair of the wheel and rail, the rail head is simultaneously subjected to alternating bending. Therefore, the performance of this system is determined by the complex wear-fatigue damage (WFD), which is the mechanical rolling fatigue.[5][6][27] Similarly in the pair of the crankshaft and connecting rod, the shaft journal is simultaneously subjected to bending and torsion; therefore, its performance is determined by the complex WFD, which is the mechanic sliding fatigue[5][6][28]. In a variety of shaft-and-hub joints, the shaft is additionally subjected to bending with rotation. The joints' performance is determined by the complex WFD, which is the fretting fatigue[5][6][29]. Meanwhile, the pipe-and-fluid system, often using oil, simultaneously realizes both hydrodynamic friction and internal pressure that loads in an alternating pattern. Therefore, its performance is determined by the complex WFD, which is the mechanic corrosion fatigue, also called the corrosion-erosion fatigue.[5][6][30][31]. Similarly, radiation-mechanical fatigue is characteristic of the primary circuit pipes of the nuclear power plant.[32]

A tribo-fatigue system is any friction pair where at least one of the elements is additionally and simultaneously loaded with the volume (non-contact) load. At least one tribo-fatigue system can be found in virtually every modern machine, such as a car; the system must be heavily loaded and largely determines the operational reliability of the product. When particular damaging phenomena such as fatigue, friction, and wear are implemented simultaneously and jointly as the complex WFD, which is studied by Tribo-Fatigue, the technical and economic significance to modern technology increases by several times. This relates to friction and wear problems, studied by tribology, and problems of fatigue damage and fracture, studied by the field concerning mechanical fatigue.[1]

Wear-fatigue damage

Figure 2 shows the classification of the main types of wear-fatigue damage (in four languages). Table 1 describes the three main classes of tribo-fatigue systems: 1) solid / solid; 2) solid / liquid; 3) solid / particles.

File:Tribo-fatigue-2 EN 2 ch-2.tif

| Typical tribo-fatigue system | Complex damage and fracture | Definition |

|---|---|---|

| Crankpin / connecting-rod end with sliding bearing | Mechano-sliding fatigue | Wear-fatigue damage due to the effect of kinetic interaction between the phenomena of mechanical fatigue and sliding friction |

| Wheel / rail | Mechano-rolling fatigue | Wear-fatigue damage due to the effect of kinetic interaction between the phenomena of mechanical fatigue and rolling friction (rolling friction with slippage) |

| Spline shaft / bushing | Fretting fatigue | Wear-fatigue damage due to the effect of kinetic interaction between the phenomena of mechanical fatigue and fretting |

| Propeller shaft / sea water | Mechano-corrosion fatigue | Fatigue of the material under the simultaneous effect of alternating stresses and corrosive environ¬ment |

| Turbine blades / fluid or gas flow carrying solid particles | Mechano-erosion fatigue | Wear-fatigue damage due to the effect of kinetic interaction between the phenomena of mechanical fatigue and erosion |

| Pipe / fluid flow under pressure | Corrosion-erosion fatigue | Wear-fatigue damage due to the effect of kinetic interaction between the phenomena of mechanical fatigue, corrosion and erosion |

Effects

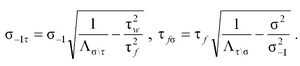

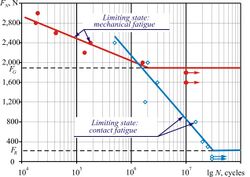

Table 2 summarizes the subject matter of Tribo-Fatigue as compared to tribology and mechanical fatigue, the two of which are the sources of Tribo-Fatigue. There are three main effects established and studied in Tribo-Fatigue.[5][6][7][8][9][10] The direct effect in Tribo-Fatigue is to study the influence of processes and conditions of friction and wear on the change in the characteristics of fatigue resistance of tribo-fatigue systems and their elements.[6][11][33] Experiments prove that friction and wear can reduce by 3 to 7 times or more or significantly increase by 30 to 40 percent[34][6][34] the fatigue limit σ−1 of structural elements (Figure 3). The back effect is the impact of alternating stresses on the change in the characteristics of friction and wear of the tribo-fatigue system and its elements.[6][11][33][35] Likewise, experiments prove that cyclic stresses under the volume load excited in the contact zone can, depending on the conditions, either reduce or increase the wear resistance of a friction pair by 10 to 60 percent or more.

| Discipline | Object of study | Basic methods of studies | Tasks | |

| experimental | theoretical | |||

| Tribo-Fatigue | Tribo-fatigue system | Wear-fatigue tests | Mechanics of wear-fatigue damage | Optimal management of complex wear-fatigue damage processes of tribo-fatigue systems in order to reduce labor, equipment and materials costs in their production and operation |

| Tribology | Friction pair | Tribotesting | Contact mechanics | Combating wear up to wear-free friction and preventing jamming of friction pairs |

| Fatigue | Structural element | Fatigue tests | Mechanics of deformation and fracture | Reducing the rate of accumulation of damage and preventing fatigue failure of structural elements |

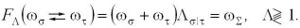

The effect of Λ-interactions of damage (ωσ, ωτ) is caused by normal stresses (index σ) due to non-contact volume loads, which produce fatigue, and frictional stresses (index τw), which produce friction and wear.[6] They can be illustrated by the following rule:

According to this rule, damage from contact and volume loads is non-additive: they are not summed but interact dialectically. The dialectical nature of the interaction of damage is determined by the principle of L. A. Sosnovskiy:

in which ωσ, ωτ, ωT is irreversible damage under normal (index (σ), shear (under friction) (index τ) and thermal (index T) stresses. Λ-functions should take three classes of values (Λ > 1, Λ < 1, Λ = 1) to describe unity, diversity, and physical hardening-softening processes in a system (Figure 3).[6] There are formulas for calculating the limiting stresses with direct (σ−1τ) and back (τfσ) effects, taking into account Λ-interactions of damage:[6][36]

Λ-functions defined at the macro-level are similar to non-additivity parameters in q-estimation.[37] They were used as the basis for development of the statistical theory of non-additive systems at the nano-level.[38] They are fundamental in modern concepts of non-additive systems. The tribo-fatigue systems can be viewed as a real class of non-additive systems at the macro-level.

By taking into account the above three effects, it is possible to formulate and address the tasks of optimal management in view of economic responsibility of the WFD processes of tribo-fatigue systems as well as to calculate strength and wear resistance of high-duty mechanical systems (see Table 2 and [6][7][8][9][10]).

Interdisciplinary results

Tribo-Fatigue has contributed to discoveries impacting other fields, including fundamental ones.

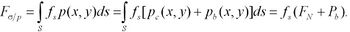

- The generalized law of friction has been theoretically formulated[7][39] and experimentally confirmed [6][7][40][41]: in the general case, the friction force is proportional both to contact load (FN) and volume load (Pb) if the latter excites cyclic stresses (±σ) in the area of contact:

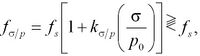

The coefficient of friction in the tribo-fatigue system is:

where p0 is the maximum value of pressure p distribution in the contact area, kσ/p is the function that depends on the correlation of stresses acting in the area of contact and caused by non-contact and contact loads, and f is the coefficient of friction according to the classic Amonton-Coulomb law. If friction is implemented in a tension zone with volume loading, fσ/p < fs, while in the compression zone, becomes fσ/p > fs. The difference between the values of fσ/p and fs reaches 10% to 50% or more, depending on the loading conditions.[40] Practical use of the classic law for analysis of friction in tribo-fatigue systems is unjustified since it results in a significant calculation error.

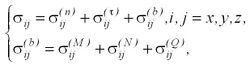

- The mechanical-mathematical model of the combined stress-strain state of the tribo-fatigue system in three-dimensional setting (i, j) is as such:[6][7][10][42]

where ij(n), σij(τ),σij(b) are the stresses caused respectively by the normal contact load (superscript (n)), tangential τ contact load, and non-contact (b) loads. Superscripts M, N and Q correspond to the internal moment, and longitudinal and transverse forces during volumetric deformation such as by bending, tension, compression, and torsion. This model is the basis of formulating and solving a new class of contact problems, supplemented by the action of various non-contact forces.[7][43] It also results in a new subdiscipline in the theory of elasticity, supplemented to consider the local effects in the load application area.[7][44] Calculations of direct and back effects for this model are adequate to the experimental results.

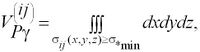

- Based on the statistical model of a deformable solid,[45] a new and effective measure for the volume damage of friction pairs and tribo-fatigue systems at any (i, j) stress condition has been proposed:[7][46]

where σ*min is the lower limit of the scattering of the limiting stress for a given object and P is the probability of damage determined with a confidence probability γ. This measure helps to solve tasks of analyzing the scale effect, calculation, and experimental assessment of the wear, since the latter is implemented within a dangerous volume VPγ.[47] Dangerous volumes in friction pairs and tribo-fatigue systems, depending on the damage assessment criteria, have been systematized and classified. Dangerous volumes are classified according to various criteria (stress state, deformed state, potential strain energy) in dynamic and static setting.[7]

- The generalized energy theory[6][36][48][49] of limiting states of tribo-fatigue systems can predict the occurrence of failures according to various performance criteria such as fatigue failure, unacceptable wear, and critical density of pittings. There are solutions for several particular cases. Thus the equation concerning criteria for a special case of mechanic sliding fatigue takes the following form: aσσ2+aττw2)Λσ\τ=1, where a<<1 are coefficients, which single out from the total energy, which is the energy delivered to the system. The amount of total energy is used to form the irreparable damage. Methods for calculating such coefficients have been developed.[6][7][8][9][10] Numerous verifications of the equation showed its adequacy to experiments.

- Experimental and theoretical studies formulated nine tribo-fatigue surprises.[50][51][52] According to a 2005 work, "the scientists could not see, understand, imagine or analytically describe" occurrences relating to "the emergence of tribo-fatigue".[50] For example, surprise S3, a tribo-fatigue bomb,[50] is the abnormally low resistance to fracture at fretting fatigue due to the strong interaction of a complex of weak damages. It turned out that such a surprise is found in a rotor of a unique turbine with a unit capacity of 1200 megawatts (MW) in a fusion reactor with a strong magnetic field, which was in a rocket engine with hydrogen fuel, in turn in an installation for drilling ultra-deep wells.[1] Surprise S5, also known as the Troppy effect,[50] is the formation of irregular residual surface undulating damage as a result of non-stationary process of elastoplastic deformation in an area of contact interaction during rolling friction. This phenomenon occurs in a wheel-and-rail system as wavy damage that occurs on the tread surface under severe operating conditions.[53]

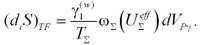

- Entropy in thermodynamics is a characteristic of energy dissipation. Tribo-Fatigue proposes a similar characteristic of its absorption:[54]

Tribo-fatigue entropy, which is surprise S7,[50] generates irreversible damage ωΣ in dangerous volumes VPγ on moving and deformable solids interacting with either each other or the medium. Here TΣ ≥ T is the temperature caused by all sources, being the medium temperature. γ1(w) is the pressure or stress that results in the damage of a dangerous volume of a unit value UΣ,eff is the effective absorbed energy caused by loads of a different nature. Tribo-fatigue entropy was used to formulate and analytically record the general law of entropy increase for the first time in history.[55][56] This law, like the concept of entropy itself, is useful for cosmological studies.[57][58][59] According to surprise S8, concerning tribo-fatigue life,[50] life is a special way of existence of protein bodies evolving through inevitable states of irreparable damage. This concept is based on the analysis of the phenomena of fatigue, wear, biochemical, and other damage characteristic of a living organism; besides, it has helped describe the way of life of Homo sapiens,[60] as well as in philosophy and social studies.[61][62]

System design

Principles and methods[6][10][63] developed for the design of tribo-fatigue systems for strength, durability, reliability, and durability taking into account the risk of an operation can solve many tasks.[64] Tribo-Fatigue moves away from the traditional design of individual parts and turns to the estimation and design of mechanical systems.[1] With regard to the mechanic sliding fatigue of the bending shaft and sliding-surface bearing system, the following tasks can be set and practically solved:

- determining the required diameter of the shaft taking into account the direct effect,

- determining the required area of contact of the system elements taking into account the back effect,

- selecting materials for both elements of the system,

- setting the requirements of the value of the friction coefficient,

- calculating the durability of the system and its elements,

- assessing the reliability of the system under given operating conditions,

- and calculating the risk factors and indicators of safe system operation.

Figure 4 shows a comparative analysis of the methods of calculation of tribo-fatigue systems based on the criteria of Tribo-Fatigue (the parameters with the index TF), the criteria of mechanical fatigue (the parameters with the index F) and also the tribological parameter or the coefficient of friction. In all the graphs the horizontal dotted line means that in calculations based on individual criteria of either mechanical fatigue or tribology, the required parameters are assumed as singles. The curvilinear dotted lines describe the direct or the back effects providing the function of interaction of damages is Λσ/τ=1. The remaining (solid) lines characterize the above effects with the account of various conditions of interaction of damages: the softening processes prevail at Λσ/τ>1, the hardening processes prevail at Λσ/τ<1.

For example, let us comment on determination of the required cross section of the shaft. Its diameter dF taken according to the known method of calculation for mechanical fatigue is assumed equal to a unity dF=1.

If the shaft is an element of the tribo-fatigue system, then the allowance for the effect of the processes of friction and wear, that are generally characterized by the relative value of friction stresses τW2/τf2, leads to the fact that in order to provide its strength reliability the value of dTF can be either significantly less (for example, 0.9dF) or significantly more (for example, 1.3dF) than the value of dF; it depends on the ratio between the occurring processes of hardening-softening (Λσ/τ>1 or Λσ/τ<1).

The analysis of other graphs in Figure 4 leads to similar conclusions in deciding on the selection of the required area of contact, properties of a material, friction coefficient, etc.

Testing machines

A new class of testing equipment, called SI-series machines, for wear-fatigue testing of materials, models of friction pairs, and tribo-fatigue systems is based on inventions within the Tribo-Fatigue framework (Figure 5).[6][41][65][66][67] The main feature of such machines is the use of standardized sizes of test objects (Figure 6). This ensures correct comparison of the results of tests carried out under different conditions.

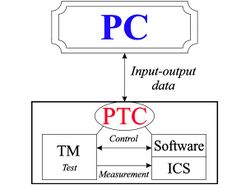

SI series machines are equipped with information-control system built on the basis of a personal computer. The software allows you to fully automate testing, registration of measured parameters (Figure 7) and processing of statistical arrays of experimental data.

The SI-series machines are installed in the research laboratories of JSC "Gomselmash", JSC "Gomeltransneft Druzhba", Belarusian-Russian University in Mogilev, Belarusian State University in Minsk, and other academic institutions. Technical characteristics of the SI-series machines are regulated by the requirements of the interstate standard GOST 30755-2001 "Tribo-Fatigue. Machines for wear-fatigue tests. General technical requirements". The main test methods are standardized.[68]

In 2018, a prototype model of a personal desktop test center (PTC) on the base of the SI-series machines as a result of their miniaturization was manufactured under the government of Belarus.[69] Such a center is planned to be used as a peripheral device for PCs (Figure 8) in the universities. Test complexes are intended for the setting of a modern laboratory workshop for students and undergraduates as a part of the disciplines of the mechanical science, which include tribo-fatigue.

As academic discipline

Tribo-Fatigue has been introduced as a course in the curricula of several universities in Belarus since 1996 and China (Dalian University of Technology) since 2018. Complete academic and methodological support is available.[10][70][71][72] Online courses on Tribo-Fatigue are officially registered in Belarus.[73] During the last twenty years, the course has been attended by more than 3,500 students and undergraduates, who contributed to improving the quality of training of mechanical engineers and mechanical mathematicians.[74][75][76]

Tribo-Fatigue for industry

Hi-Tech: cast knives for cutting and grinding apparatus of high-performance forage harvesters

The tribo-fatigue system “knife–clamp–bolts–base” in this apparatus works in difficult conditions: high shock-cyclic loads, contact loads and the influence of an aggressive environment (green mass). The operability of the most critical element of this system – cutting knives, in essence, largely determines the reliability and performance of combines. [77][78]

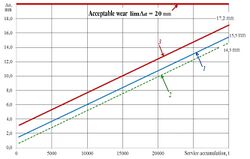

Figure 9 shows a drawing of knives, a diagram and a photo of their installation. The operational reliability of knives is determined by two parameters: a decrease in Δa of the width of the cutting edge (wear) and an increase in the radius of curvature r of the cutting edge. JSC "Gomselmash" and S&P Group TRIBOFATIGUE Ltd replaced steel knives with cast iron knives. The knives are made of ductile iron with spherical graphite and high fatigue resistance DITG (MONICA). [79][80][81][82] The results of field tests of knives are presented in Figure 10.[83] It is seen that cast iron knives fully provide the condition for wear resistance: Δa = 17.2 mm < limΔa = 20 mm.

Figure 11 shows the results of field tests for blunting the cutting edge of a knife. Steel and cast cast iron knives were comparatively tested.[84] It is seen that cast knives by this criterion are more efficient than steel knives: Δr = 0.19 – 0.10 = 0.09 mm, i.e. almost 2 times.

JSC "Gomselmash" and S&P Group TRIBOFATIGUE Ltd have also developed an original technique for accelerated laboratory testing of knives under conditions close to operational.[85]

Operational reliability of the linear part of the pipeline

The pipe / fluid (oil) flow system under pressure is tribo-fatigue (Figure 12): the pressure during operation is repeatedly variable, and the friction of oil during movement causes corrosion-erosion wear on the inner surface of the pipe.[86][87][30][88] A statistical study was conducted of changes in internal pressure in 4 sections of the “Druzhba” pipeline with a total length of 882 km. for 5 years.[88][89][90][91] The sample was about 400,000 pressure values over 5 years. It was shown (see the example in Figure 12b) that the pressure swing is in the range from 0.4 to 3.7 MPa. The maximum deviation of the daily average pressure from the annual average exceeds 2 MPa, which is more than half of the largest. It turned out that the parameters of the loading process are different in different seasons of the year. Figure 12c-d shows the wall friction for a two-dimensional problem statement caused by the motion of a viscous fluid: c – distribution of the transverse component vy of the flow velocity (in the circumferential direction) along the pipe length (v0 = 10 m/s); d – tangential stresses on the pipe wall. [86][87]

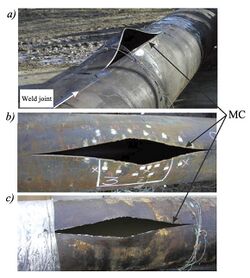

Specialists came to the conclusion that the alternating nature of the load is the main reason for the accumulation of damage to the inner surface of the pipe. This initiates the formation of crack-like defects, the development of which during operation leads to a pipeline accident. From figure 13 it can be seen that during the period of operation before the development of the depreciation period (1964…1996), accidents were almost annually.

In connection with the approaching depreciation period, JSC "Gomeltransneft Druzhba" and S&P Group TRIBOFATIGUE Ltd developed a set of measures to restore the operability of such sections of the pipeline. The main ones were: stabilizing the pressure during operation and increasing the strength of the pipe material by loading with increased internal pressure (25% higher than the working one). The operation of the pipeline after the depreciation period (after 1996 in Figure 13) showed that there were no accidents for 12 years. The three accidents shown during this period relate to damage to the pipeline during repair and construction works. The working pressure was increased: before depreciation – 42 MPa, after depreciation – 45 MPa.

Further operation of the pipeline (after 2010) showed that failures of underwater sections of the pipeline may not be according to the criterion of crack resistance (Figure 14, upper image), but according to the criterion of wear (Figure 14, lower images).[92][93] In this regard, an original method of wear-resistant tests of pipe steel samples in an oil medium was developed (Figure 15).[94] The tests were carried out on a SI-series machine (see Figure 5). To eliminate accidents due to wear, the underwater sections of the pipeline were reconstructed.[95]

According to the results of the work, normative documents were developed.[96][97] Thus, the effectiveness of the “tribo-fatigue approach” to ensure the reliability of the linear sections of the “Druzhba” oil pipeline was confirmed.[86][87][30]

Hi-Tech: cast iron rails

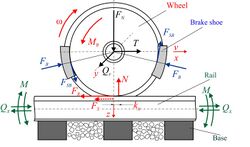

The wheel / rail system is tribo-fatigue: it is loaded with a spatial system of cyclic forces (Figure 16) and simultaneously works under friction conditions (during rolling, sliding and fretting) (Figure 17).[98][99][100][101] Modern production of its main element – steel rails is carried out by rolling.[102]

JSC “Gomselmash” and S&P Group TRIBOFATIGUE Ltd developed a technology for casting rails made of high-strength cast iron with spherical graphite and high fatigue resistance DITG (MONICA).[80][103][81]

On August 24, 2008 JSC “Gomselmash” and S&P Group TRIBOFATIGUE Ltd cast the first rail R65 from DITG cast iron (Figure 18).

By permission of the Gomel Department of the Belarusian Railway in 2012–2014 (all seasons of the year) the planned operation of the experimental batch of R65 rails from the DITG was carried out on the tracks of the organized train traffic (Figure 19). After operational tests, the rails were dismantled for study. It was established: there was no vertical and lateral wear of the rail heads, there were no additional difficulties during operation in winter and summer, the general appearance and condition of the rails was normal, the rails can be re-stacked and operated in the existing section of the track.

According to calculations,[104][105] the wear resistance of cast iron rails is approximately 1.5 times higher than steel, under the same operating conditions. This is due to the special properties of cast iron (self-lubrication, ability to dampen vibrations, etc.).

For accelerated laboratory tests, original physical models of the wheel / rail system were developed (Figure 20), which are tested on SI-series machines (see Figure 5) under conditions close to operational. For example, test specimens are cut from the rail head in such a way that they contain a surface area damaged during operation (see Figure 20). A laboratory test procedure has been developed, during which rail corrugation is reproduced (Figure 21).[106][107]

Thus, it is shown that cast iron rails are promising. Given the uniqueness of the railway track, experts believe[104] that it is more rational to cast railway wheels from cast iron, especially for locomotives.

Large-sized gears

Toothed gears are a tribo-fatigue system: in the contact zone, rolling friction with slippage occurs, and in the transition zone from the tooth to the crown there is a cyclic bending (fatigue). Laboratory models are shown in Figure 22. Accelerated laboratory tests of such models are carried out on SI-series machines (see Figure 5). An example of tests is shown in Figure 23. The test method allows you to establish the conditions for the transition of failures either by the criterion of wear resistance, or by the criterion of fatigue.[108][109][110]

As a result of the studies, it was shown that steel large-sized (~500 mm diameter) gears of gearboxes of forage and grain harvesters manufactured by JSC “Gomselmash” can be made by casting of ductile iron with spheroidal graphite with high fatigue resistance DITG (MONICA).[80][81] Fifteen gearboxes were manufactured with pilot cast iron gears and serial steel gears. For each harvester, these gearboxes were installed as follows: on the one hand, a gearbox with a cast iron gears, and on the other hand, a gearbox with a steel gears. This ensured comparability of the results of field tests under the same conditions. The results of field (full-scale) tests are shown in Figure 24. It can be seen: the operability of cast iron large-sized gears is higher than that of steel gears.

JSC “MAZ”, OIM NASB and S&P Group TRIBOFATIGUE Ltd have also devel-oped an integrated approach to assessing the reliability of the drive axle of a MAZ-5440 truck tractor produced by the Minsk Automobile Plant.[111][112]

“From science to education and production”

Articles [113][69] provide a general analysis of the work on Tribo-Fatigue over the past 20–25 years: “from science to education and production”[113], i.e. in three main areas of activity. Figure 25 illustrates the principles of such activities. When scientific results are introduced into production, this is a recognition of their practical effectiveness. When they form a new academic discipline of the university, it becomes the common property of the scientific and educational sphere of society. The same figure shows the relationship between Tribo-Fatigue and Mechanothermodynamics, a branch of physics, one of the sources of which is Tribo-Fatigue.[114]

References

- ↑ 1.0 1.1 1.2 1.3 1.4 Word on Tribo-Fatigue / V. I. Strazhev, K. V. Frolov, M. S. Vysotsky, V. T. Troshchenko, L. A. Sosnovskiy, N. A. Makhutov, A. V. Kukharev, P. S. Gruntov, E. I. Starovoitov, V. A. Marchenko, V. N. Koreshkov, V. A. Shurinov, L. R. Botvina, Yu. N. Drozdov, M. I. Gorbatsevich, V. G. Pavlov, D. G. Efros. – Gomel, Minsk, Moscow, Kiev : Remika, 1996. – 132 p. (in Russian).

- ↑ 2.0 2.1 Tribo-Fatigue: New ideas in a promising direction / K. V. Frolov, L. A. Sosnovskiy, N.A. Makhutov, Yu.N. Drozdov. – Gomel : BIRE, 1990. – 7 р. (in Russian).

- ↑ 3.0 3.1 Tribo-Fatigue // Belarusian encyclopedia. – Minsk : Belarusian encyclopedia, 2002. – V. 15. – P. 542. (in Belarusian).

- ↑ 4.0 4.1 Tribo-Fatigue // Big Belarusian Encyclopedic Dictionary / Ed. by : T. V. Belova (chairman) [et al.]. – Minsk : Belarusian encyclopedia named after P. Brouka, 2011. – P. 354. (in Belarusian).

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 5.6 GOST 30638–99. Tribo-Fatigue. Terms and definitions (interstate standard). – Intr. 1999–06–17. – Minsk : Interstate Council on Standardization, Metrology, and Certification, 1999. – 17 р. (in Russian).

- ↑ 6.00 6.01 6.02 6.03 6.04 6.05 6.06 6.07 6.08 6.09 6.10 6.11 6.12 6.13 6.14 6.15 6.16 6.17 6.18 6.19 Sosnovskiy, L. A. Wear-fatigue mechanics / L. A. Sosnovskiy. – Gomel : BelSUT, 2007. – 434 p. (in Russian).

- ↑ 7.00 7.01 7.02 7.03 7.04 7.05 7.06 7.07 7.08 7.09 7.10 Sherbakov, S. S. Mechanics of Tribo-Fatigue systems / S. S. Sherbakov, L. A. Sosnovskiy. – Minsk : BSU, 2010. – 407 р. (in Russian).

- ↑ 8.0 8.1 8.2 8.3 8.4 Sosnovskiy, L. A. Tribo-Fatigue. Wear-fatigue damage and its prediction / L. A. Sosnovskiy // Series : Foundations of Engineering Mechanics, Springer, 2005. – 424 p.

- ↑ 9.0 9.1 9.2 9.3 9.4 摩擦疲劳学 磨损 – 疲劳损伤及其预测. L. A. 索斯洛-夫斯基著, 高万振译 – 中国矿业大学出版社, 2013. – 324 p.

- ↑ 10.0 10.1 10.2 10.3 10.4 10.5 10.6 Sosnovskiy, L. А. Fundamental and applied tasks of Tribo-Fatigue: lectures / L. А. Sosnovskiy, М. А. Zhuravkov, S. S. Sherbakov. – Minsk : BSU, 2010. – 488 p. (in Russian).

- ↑ 11.0 11.1 11.2 Vysotsky, М. S. New Word in Mechanics / M. S. Vysotsky // Science and Innovations. – 2010. – № 9 (91). – P. 17–19. (in Russian).

- ↑ Vityaz, P. А. Mechanical scientist Leonid Adamovich Sosnovskiy (to a scientific biography) / P. А. Vityaz, M. S. Vysotsky, V. A. Zhmailik // Tribo-Fatigue : Proc. of VI Intern. Symposium on Tribo-Fatigue ISTF 2010, Minsk, Oct. 25 – Nov. 1, 2010 : in 2 pt. / Belarusian State University ; ed. board. : M. A. Zhuravkov (prev.) [et al.]. – Minsk : BSU Press, 2010. — V. 1. — P. 55-64. (in Russian).

- ↑ Zhuravkov, M. A. Personality. Scientist. Poet / M. A. Zhuravkov // Personality. Scientist. Poet / ed. by V. I. Senko. — Gomel : BelSUT, 2015. — P. 8-19. (in Russian).

- ↑ Sosnovskiy, L. A. On a comprehensive assessment of the reliability of active systems / L. A. Sosnovskiy // Republican Scientific and Technical Conference : Abstracts, Minsk, November 20–21, 1986. – Minsk, 1986. – P. 29.(in Russian).

- ↑ Sosnovskiy, L. A. Tribo-Fatigue : problems and potentials / L. A. Sosnovskiy // Report at Thematic Exhibition of USSR Ac. of Sci. Mathematics and Mechanics – the National Economy. – Gomel : BIRE, 1989. – 65 p. (in Russian).

- ↑ Sosnovskiy, L. A. Methodological problems of complex assessment of damage and limiting state of tribo-fatigue systems / L. A. Sosnovskiy, N. A. Makhutov // Industrial Laboratory. Diagnostics of Materials. – 1991. – № 5. – Р. 27–40. (in Russian).

- ↑ Sosnovskiy, L. A. Tribo-Fatigue. Basic terms and definitions / L. A. Sosnovskiy // Journal of Friction and Wear. –1992. – № 4. – Р. 728–734. (in Russian).

- ↑ Tribo-Fatigue – new ways of improving reliability of machines / M. S. Vysotsky, V. N. Koreshkov, V. A. Marchenko, L. A. Sosnovskiy, V. I. Strazhev // Transactions of Belarusian Academy of Sciences. – 1994. – № 4. – Р. 32–41. (in Russian).

- ↑ Starovoitov, E. I. International Symposium on Tribo-Fatigue / E. I. Starovoitov // Strength Problems. – 1994. – № 11. – P. 92–94. (in Russian).

- ↑ Abstracts of 1st International Symposium on Tribo-Fatigue / ed. by L. A. Sosnovskiy. – Gomel, 1993. – 121 p. (in Russian).

- ↑ Abstracts of 2nd Intern. Symposium on Tribo-Fatigue / ed. by V. A. Andriyashin [et al.]. – Moscow–Gomel : SPAS – TRIBOFATIGUE S&P Group, 1996. – 104 p. (in Russian).

- ↑ Proceedings of the III International Symposium on Tribo-Fatigue (ISTF 2000), Beijing, China, Oct. 22–26, 2000 / ed. by Gao Wanzhen and Jian Li. – Beijing : Hunan University Press, 2000. – 653 p.

- ↑ ISTF 2002 : Proc. of 4th Intern. Symposium on Tribo-Fatigue, Sept. 23–27, 2002 Ternopol, Ukraine : in 2 pt. / Ternopil Ivan Puluj National Technical University : Rep. Ed. V. T. Troshchenko. – Ternopol : TNTU, 2002. – V. 1. – 530 p. – V. 2. – 324 p. (in Russian).

- ↑ Proceedings of V International Symposium on Tribo-Fatigue (ISTF 2005), October 3–7 2005, Irkutsk (Russia) / ed. by A. P. Khomenko. – Irkutsk: Irkutsk State Transport University, 2005. – V. 1. – 497 p.; V. 2. – 383 p.; V. 3. – 388 p. (in Russian).

- ↑ Tribo-Fatigue : Proc. of VI Intern. Symposium on Tribo-Fatigue ISTF 2010, Minsk, Oct. 25 – Nov. 1, 2010. : in 2 pt. / Belarusian State University ; ed. board. : M. A. Zhuravkov (prev.) [et al.]. – Minsk : BSU Press, 2010. – V. 1. – 840 p.; V. 2. – 724 p. (in Russian).

- ↑ Tribo-Fatigue: bibliographic index (1985-2015) / compiled by S. A. Tyurin; Belarusian State University of Transport. – Gomel : BelSUT, 2015. – 61 p. (in Russian).

- ↑ Sosnovskiy, L. A. Mechano-rolling fatigue: the main laws (summary article) / L. A. Sosnovskiy, N. A. Makhutov, V. A. Shurinov // Industrial laboratory. Diagnostics of materials. – 1992. – № 11. – P. 44–61. (in Russian).

- ↑ Sosnovskiy, L. A. Mechano-sliding fatigue: the main laws (summary article) / L. A. Sosnovskiy, N. A. Makhutov, V. A. Shurinov // Industrial laboratory. Diagnostics of materials. – 1992. – № 9. – P. 46–63. (in Russian).

- ↑ Sosnovskiy, L. A. Fretting-fatigue: the main laws (summary article) / L. A. Sosnovskiy, N. A. Makhutov, V. A. Shurinov // Industrial laboratory. Diagnostics of materials. – 1992. – № 8. – P. 45–62. (in Russian).

- ↑ 30.0 30.1 30.2 Sosnovsky, L. A. On a multidisciplinary approach to the analysis and prediction of operational damageability and resource life of linear sections of the pipeline from the standpoint of tribo-fatigue / L. A. Sosnovskiy, Yu. V. Lisin, A. N. Kozik // Mechanics of machines, mechanisms and materials. – 2017. – № 3 (40). – P. 75–84. (in Russian).

- ↑ Sosnovskiy, L. A. Mechano-corrosion fatigue: the main laws (summary article) / L. A. Sosnovskiy, N. A. Makhutov, V. A. Shurinov // Industrial laboratory. Diagnostics of materials. – 1993. – № 7. – P. 33–44. (in Russian).

- ↑ Troshchenko, V. Т. Fatigue resistance of metals and alloys: handbook : in 2 volumes / V. Т. Troshchenko, L. А. Sosnovskiy. – Kiev : Naukova dumka, 1987. – V. 2. – P. 320–325. (in Russian).

- ↑ 33.0 33.1 Sosnovskiy, L. A. Sliding-mechanical fatigue. Direct and back effects / L. A. Sosnovskiy, A. V. Marchenko // Proceedings of the World Tribology Congress (London, Sept. 8–12, 1997). – London, 1997. – P. 569.

- ↑ 34.0 34.1 Serensen, S. V. The problem of fatigue and wear resistance of machine parts (brief overview) / S. V. Serensen // In book : Increased wear resistance and machine life. – Кiev : Ukrainian Academy of Science Publishing, 1960. – V. 1. – P. 10–14. (in Russian).

- ↑ Sharay, V. Т. Comprehensive study of wear and fatigue in steels / V. T. Sharay. – Kiev : Ukrainian Publishing of technical literature, 1959. – 32 p. (in Russian).

- ↑ 36.0 36.1 Bogdanovich, A. V. Prediction of limiting states of tribo-fatigue systems / A. V. Bogdanovich. – Grodno : Grodno State University, 2008. – 372 p. (in Russian).

- ↑ A. B. Abiba, A. A. Moreirab, J. S. Andrade Jr., M. P. Almeida, Phys. A, 322 (2003), 276–284.

- ↑ Olemskiy A. I., Yushchenko O. V., Badalyan A. Yu. Statisticheskaya teoriya polya neadditivnoy sistemy // TMF. – 2013. – V. 174. – № 3. – pp. 444–466. (in Russian).

- ↑ Sherbakov, S. S. The change in the force and coefficient of friction under the action of non-contact load (theoretical analysis) / S. S. Sherbakov // Bulletin of BelSUT. – 2016. – № 1 (32). – P. 110–115. (in Russian).

- ↑ 40.0 40.1 Sosnovskiy, L. A. The law of (external) friction and its generalization: theory and experiment / L. A. Sosnovskiy, S. S. Sherbakov, V. V. Komissarov // Bulletin of BelSUT. – 2016. – № 1 (32). – P. 91–101. (in Russian).

- ↑ 41.0 41.1 Sosnovskiy, L. A. Methods and main results of tribo-fatigue tests / L. A. Sosnovskiy, A. V. Bogdanovich, O. M. Yelovoy, S. A. Tyurin, V. V. Komissarov, S. S. Sherbakov // International Journal of Fatigue. – 2014. – V. 66. – P. 207–219.

- ↑ Vityaz, P. А. New approaches in the mechanics of deformable systems / P. А. Vityaz, L. А. Sosnovskiy, S. S. Sherbakov // Proc. of Belarusian National Academy of Sciences. – 2009. – V. 53. – № 4. – P. 102–110. (in Russian).

- ↑ Sosnovskiy, L. A. Special class of contact problems and the calculation of the state of stress of wheel / rail system elements (CM105) / L. A. Sosnovskiy, S. S. Sherbakov // Proc. of the 7th International Conference on Contact Mechanics and Wear of Rail / Wheel Systems (Brisbane, Australia, Sept. 24–27, 2006). – Brisbane, 2006. – V. 1. – P. 93–104.

- ↑ Sherbakov, S. S. Contact interaction, volume damageability and multicriterial limiting states of multielement Tribo-Fatigue systems / S. S. Sherbakov, M. A. Zhuravkov, L. A. Sosnovskiy // Selected Problems on Experimental Mathematics / R. Witula [et al.]. – Gliwice : Wydawnictwo Politechniki Slaskiej, 2017. – P. 17–38.

- ↑ Sosnovskiy, L. A. Statistical mechanics of fatigue fracture / L. A. Sosnovskiy. – Minsk : Nauka i Tekhnika, 1987. – 288 p. (in Russian).

- ↑ Sosnovskiy, L. A. The method of strength calculation in volume fracture and surface damage / L. A. Sosnovskiy // Proceedings of the World Tribology Congress III (Washington, 12–16 September 2005). –Washington, 2005. – 2 p.

- ↑ Sherbakov, S. S. New wear model / S. S. Sherbakov, L. A. Sosnovskiy // Bulletin of BelSUT. – 2016. – № 1 (32). – P. 74–82. (in Russian).

- ↑ Sosnovskiy, L. A. Generalized theory of limiting states of tribo-fatigue systems / L. A. Sosnovskiy, S. S. Sherbakov // News of the National Academy of Sciences of Belarus, Physical and Technical Series. – Minsk, 2008. – №. 4. – P. 17–23. (in Russian).

- ↑ Sosnovskiy, L. A. Theory of the limiting states of active systems / L. A. Sosnovskiy, A. V. Bogdanovich // Proceedings of the World Tribology Congress III (Washington, 12–16 September 2005). –Washington, 2005. – 2 p.

- ↑ 50.0 50.1 50.2 50.3 50.4 50.5 Sosnovskiy, L. A. Surprises of Tribo-Fatigue / L. A. Sosnovskiy, S. S. Sherbakov. – Gomel : BelSUT, 2005. – 192 p. (in Russian).

- ↑ Nine Tribo-Fatigue surprises (selection of articles) // Science and Innovations. – 2010. – № 9 (91). – P. 5–28. (in Russian).

- ↑ Sosnovskiy, L. A. Surprises of Tribo-Fatigue / L. A. Sosnovskiy, S. S. Sherbakov. – Minsk : Magic Book, 2009. – 200 p.

- ↑ Grassie, S. L.; Kalousek, J. (1993). "Rail Corrugation: Characteristics, Causes and Treatments". Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit 207: 57–68. doi:10.1243/PIME_PROC_1993_207_227_02.

- ↑ Sosnovskiy, L. A. On one type of entropy as a measure of the absorption of energy spent on the production of damage in a mechanothermodynamic system / L. A. Sosnovskiy // Reports of the National Academy of Sciences of Belarus. – 2007. – V. 51. – № 6. – P. 100–104. (in Russian).

- ↑ Sosnovskiy, L. A. Mechanothermodynamics (about combining great competitors: 1850-2015) / L. A. Sosnovskiy // Mechanics of machines, mechanisms and materials. – 2016. – № 4 (37). – P. 19–41. (in Russian).

- ↑ Sosnovskiy, L. А. Fundamentals of the theory of the evolution of inorganic and organic systems, the number of living and reasonable / L. А. Sosnovskiy, S. S. Sherbakov, А. А. Lazarevich // National philosophy in a global world : proc. of the First Belarusian Congress of Philosophy, Minsk, oct. 18–20, 2017. – Minsk : Belarusian science, 2018. – P. 155–178. (in Russian).

- ↑ Bekenstein, J. D. Black holes and entropy // Physical Review, 1973, D 7, p. 2333–2346.

- ↑ Peter V. Coveney. The second law of thermodynamics: entropy, irreversibility and dynamics // Nature. Vol. 333 1988. – P. 409–415.

- ↑ Bardeen, J. M., Carter, B., Hawking, S. W. The four laws of black hole mechanics // Communications in Mathematical Physics, 1973, 31, – P. 161–170.

- ↑ Sosnovskiy, L. A. Tribo-Fatigue : the dialectics of life / L. A. Sosnovskiy. – Ed. 2nd. – Gomel : BelSUT, 1999. – 116 p. (in Russian).

- ↑ Sosnovskiy, L. А. Philosophy and Tribo-Fatigue / L. А. Sosnovskiy, А. А. Lazarevich // Tribo-Fatigue : proc. of VI Intern. Symposium on Tribo-Fatigue ISTF 2010, Minsk, oct. 25 – Nov. 1, 2010. : in 2 p. / Belarusian State University ; ed. board. : M. A. Zhuravkov (prev.) [et al.]. – Minsk : BSU Press, 2010. – V. 2. – P. 591–620. (in Russian).

- ↑ Lazarevich, A. A. On the possibility of quantitative analysis of good and evil in socio-humanitarian studies / A. A. Lazarevich, L. A. Sosnovskiy // Tribo-Fatigue : proc. of VI Intern. Symposium on Tribo-Fatigue ISTF 2010, Minsk, oct. 25 – Nov. 1, 2010. : in 2 p. / Belarusian State University ; ed. board. : M. A. Zhuravkov (prev.) [et al.]. – Minsk : BSU Press, 2010. – V. 2. – P. 497–500. (in Russian).

- ↑ Elovoy, О. М. To development of regulatory methods for calculating and designing of tribo-fatigue systems. Parts 1 and 2 / О. М. Elovoy, А. V. Bogdanovich // Mechanics of machines, mechanisms and materials. – 2017. – № 4 (41). – P. 82–88; – 2018. – № 1 (42). – P. 58–66. (in Russian).

- ↑ Sosnovskiy, L. A. L-Risk (Mechanothermodynamics of irreversible damages) / L. A. Sosnovskiy. – Gomel : BelSUT, 2004. – 317 p. (in Russian).

- ↑ Sosnovskiy, L. А. Wear-fatigue tests / L. А. Sosnovskiy, N. А. Makhutov // Mechanical Engineering : Encyclopedia / Ed. by : К. V. Frolov (chairman) [et al.]. – V. II-1. Physical and mechanical properties. Tests of metallic materials / L. V. Agamirov [et al.]; general edition Е. I. Mamaeva. – М. : Mechanical Engineering, 2010. – P. 354–385. (in Russian).

- ↑ SI-series machines for wear-fatigue tests. – Minsk, 2009. – 62 p.

- ↑ Sosnovskiy, L. A. Methods and machines for wear-fatigue tests of materials and their standardization / L. A. Sosnovskiy, V. N. Koreshkov, O. M. Yelovoy // Proceedings of the World Tribology Congress (London, Sept. 8–12, 1997). – London, 1997. – P. 723.

- ↑ Koreshkov, V. N. Standardization in the field of Tribo-Fatigue / V. N. Koreshkov, V. A. Andriyashin, S. A. Tyurin // Proc. of V Intern. Symposium on Tribo-Fatigue ISTF 2005, Irkutsk, oct. 3–7, 2005 / Ed. by A. P. Khomenko. – Irkutsk : Irkutsk State University of Communications, 2005. – V. 1. – P. 204–233. (in Russian).

- ↑ 69.0 69.1 Sosnovskiy, L. A. Modern science and multidisciplinary education–science–production system: some achievements / L. A. Sosnovskiy, S. S. Sherbakov, A. V. Bogdanovich // Theoretical and Applied Mechanics. – 2018. – V. 33. – P. 3–11. (in Russian).

- ↑ Sosnovskiy, L. A. Fundamentals of Tribo-Fatigue : in 2 pt. / L. A. Sosnovskiy. – Gomel : BelSUT, 2003. – V. 1. – 246 p.; V. 2. – 234 p. (in Russian).

- ↑ Bogdanovich, A. V. Laboratory workshop on experimental mechanics: a teaching aid / A. V. Bogdanovich, S. S. Sherbakov, D. E. Marmysh. – Minsk : BSU, 2017. – 107 p. (in Russian).

- ↑ Komissarov, V. V. Characterization of resistance to wear-fatigue damage: a teaching aid for the implementation of work in the discipline «Basics of Tribo-Fatigue» / V. V. Komissarov. – Gomel : BelSUT, 2013. – 47 p. (in Russian).

- ↑ Electronic educational and methodical complex on academic discipline «Tribo-Fatigue». Registration certificate № 7731816154 on the inclusion in the State Register information resource. (in Russian).

- ↑ Senko, V. I. Experience of twenty years of teaching of «Foundations of Tribo-Fatigue» / V. I. Senko, L. A. Sosnovskiy, A. V. Putyato, V. V. Komissarov, E. S. Taranova, S. S. Sherbakov, A. V. Bogdanovich, V. B. Popov // Bulletin of BelSUT. – 2016. –№ 1 (32). – P. 11–31. (in Russian).

- ↑ Sosnovskiy, L. A. Tribo-Fatigue in engineering education / L. A. Sosnovskiy, A. S. Shaginyan // Proceedings of the World Tribology Congress (London, Sept. 8–12, 1997). – London, 1997. – P. 639.

- ↑ Senko, V. I. Fundamentals ideas of Tribo-Fatigue and their study in Belarus / V. I. Senko, L. A. Sosnovskiy // Proceedings of the International Mechanical Engineering Congress and Exposition (Orlando, 5–11 November 2005). –Orlando, 2005. – 7 p.

- ↑ Bogdanovich, P. N. Investigation of the physico-mechanical properties of materials of knives of a cutting drum of a forage harvester on their wear resistance / P. N. Bogdanovich, M. I. Mikhailov, K. M. Mikhailov // Bulletin of the Gomel State Technical University named after P.O. Sukhoi. – 2015. – No. 3. – P. 3–9. (in Russian).

- ↑ Belov, M. I. Grinding apparatus of modern forage harvesters / M. I. Belov, A. Yu. Gubernsky, P. I. Gadzhiev, V. I. Slavkin, V. Yu. Pronin // Tractors and agricultural machines. – 2012. – No. 3. – P. 43–50. (in Russian).

- ↑ Cast iron with spherical graphite and high fatigue resistance: Patent 15617 Rep. of Belarus, IPC С 22С37 / 04 / L. A. Sosnovskiy, V. A. Zhmailik, N. V. Psyrkov, V. O. Zamyatnin, V. V. Komissarov; applicants RUE "Gomselmash", S&P Group TRIBOFATIGUE Ltd. – No. a20101428; declared 04.10.2010; publ. 30.04.2012. – 2012. – 4 p.

- ↑ 80.0 80.1 80.2 High-strength nodular cast iron with high fatigue resistance. Brands and mechanical properties (Standard of Belarus): STB 2544–2019. – Enter 10.01.2019. – Minsk: GOSSTANDART, 2019. – 7 p. (in Russian).

- ↑ 81.0 81.1 81.2 Sosnovskiy, L. A. Cast iron and steel in tribo-fatigue systems of modern machinery and equipment / L. A. Sosnovskiy, P. A. Vityaz, V. A. Gapanovich, N. V. Psyrkov, N. A. Makhutov // Mechanics of machines, mechanisms and materials. – 2014. – № 4 (29). – P. 5–20. (in Russian).

- ↑ Novikov, A. A. Mechanical and operational properties of cast iron of the VCHTG brand / A. A. Novikov, P. S. Drobyshevsky, S. A. Tyurin, D. S. Chumak // Bulletin of the Gomel State Technical University named after P.O. Sukhoi. – 2018. – No. 1 (72). – P. 61–69. (in Russian).

- ↑ Novikov, A. A. Knives for cutting and grinding apparatus of forage har-vesters (calculation, material, manufacturing technology, test results and certification in MIS) / A. A. Novikov, P. S. Drobyshevsky, V. S. Golubev, V. V. Komissarov // Actual issues of machine science: collection of scientific papers. – Vol. 6. Minsk: OIM NASB, 2017. – P. 231–236. (in Russian).

- ↑ Novikov, A. A. Estimation of the resistance of knives of feeding and grinding apparatus of agricultural combines: theory, bench and field tests / A. A. Novikov, V. V. Komissarov, V. O. Zamyatnin, P. S. Drobyshevsky, S. S. Sherbakov, L. A. Sosnovskiy // Bulletin of BelSUT: Science and Transport. – 2016. –№ 1 (32). – P. 201–208. (in Russian).

- ↑ A method for the comparative evaluation of the wear resistance of the tested knives for the feeding and grinding apparatus of an agricultural combine: Patent 21970 Rep. of Belarus, IPC G 01N3 / 58 / L. A. Sosnovskiy, N. V. Psyrkov, S. G. Volchenko, V. O. Zamyatnin, V. V. Komissarov, D. S. Chumak; applicants JSC "Gomselmash", S&P Group TRIBOFATIGUE Ltd. –№ a20140422; declared 14.08.2014; publ. 27.02.2018. – 2018. – 5 p.

- ↑ 86.0 86.1 86.2 Sherbakov, S. S. The Cross-disciplinary Approach to Analysis and Forecast of Operational Damage Tolerance of the Oil Pipeline System – Part 1 / S. S. Sherbakov // Pipeline Science and Technology. – 2019. – Vol. 3. – № 2. – P. 134–148.

- ↑ 87.0 87.1 87.2 Sherbakov, S. S. The Cross-disciplinary Approach to Analysis and Forecast of Operational Damage Tolerance of the Oil Pipeline System – Part 2 / S. S. Sherbakov // Pipeline Science and Technology. – 2020. – Vol. 4. – № 1 (3). – P. 62–73.

- ↑ 88.0 88.1 Sosnovskiy, S. V. Methods and results of experimental studies of a linear section of an oil pipeline as a tribo-fatigue system / S. V. Sosnovskiy, A. M. Bordovsky, A. N. Kozik, V. V. Vorobyov // Tribo-Fatigue : Proc. of VI Intern. Symposium on Tribo-Fatigue ISTF 2010, Minsk, Oct. 25 – Nov. 1, 2010 : in 2 pt. / Belarusian State University ; ed. board. : M. A. Zhuravkov (prev.) [et al.]. – Minsk : BSU Press, 2010. – V. 1. – P. 351–360. (in Russian).

- ↑ Bordovsky, A. M. Analysis of the random process of loading the oil pipeline / A. M. Bordovsky, V. V. Vorobyov // Mechanics-99: materials of the II Belarusian Congress on Theoretical and Applied Mechanics, Minsk, June 28–30, 1999. – Gomel: IMMS NASB, 1999. – P. 271–273. (in Russian).

- ↑ Bordovsky, A. M. Method of Accelerated Statistical Fatigue Tests of Plates / A. M. Bordovsky, V. V. Vorobyev // Proc. of the III International Symposium on Tribo-Fatigue (ISTF 2000), Beijing, China, Oct. 22–26, 2000. – Beijing : Hunan University Press, 2000. – P. 204–207.

- ↑ Bordovsky, A. M. Assessment of Reliability of Oil Pipeline Linear / A. M. Bordovsky, V. V. Vorobyev // Proc. of the III International Symposium on Tribo-Fatigue (ISTF 2000), Beijing, China, Oct. 22–26, 2000. – Beijing : Hunan University Press, 2000. – P. 380–381.

- ↑ Kozik, A.N. The effect of corrosion damage on the bearing capacity of oil pipes / A.N. Kozik, V.V. Vorobyov // Mechanics of machines, mechanisms and materials. – 2011. – № 2 (15). – P. 90-94. (in Russian).

- ↑ Kozik, A.N. Tests of oil pipes by internal pressure / A.N. Kozik // Bulletin of Polotsk State University. – 2011. – № 8. – P.110–114. (in Russian).

- ↑ Device for testing material for corrosion-erosion fatigue: Patent 9573 Rep. of Belarus, IPC G 01N3 / 56, G 01N17 / 00 / A. A. Kostyuchenko, A. M. Bordovsky, V. V. Vorobyov, V. O. Zamyatnin, L. A. Sosnovskiy; applicants RUE “Gomeltransneft Druzhba”, S&P Group TRIBOFATIGUE Ltd. – № a20050020; declared 10.01.2005; publ. 30.08.2007. – 2007. – 6 p.

- ↑ Kostyuchenko, A. A. Corrosion-mechanical strength of underwater sections of oil pipelines / A. A. Kostyuchenko / scientific ed. L. A. Sosnovsky. – Gomel: BelSUT, 2008. – 47 p. (in Russian).

- ↑ Oil pipeline pipes. Testing method by internal pressure to fracture (Standard of Belarus): STB 2162–2011. – Enter 01.07.2011. – Minsk: GOSSTANDART, 2011. – 34 p. (in Russian).

- ↑ Oil supply pipes. Methods for testing pipeline steel crack growth resistance (Standard of Belarus): STB 2502–2017. – Enter 01.10.2017. – Minsk: GOSSTANDART, 2017. – 29 p. (in Russian).

- ↑ Tuzik, Bob (8 January 2014). “Taking the Long View: 20 years of Wheel/Rail Interaction (Part 1 of 2)”. Interface: The Journal of Wheel/Rail Interaction.

- ↑ Proceedings of the 7th International Conference on Contact Mechanics and Wear of Rail / Wheel Systems (Brisbane, Australia, Sept. 24–27, 2006). – Brisbane, 2006.

- ↑ Proceedings of World Tribology Congress V: Turin, Italy, September 8–13, 2013. – Turin, 2013.

- ↑ The device and the maintenance of the track and rolling stock with heavy and high-speed movement of trains "wheel / rail": proceedings of scientific-practical conference, Moscow, VNIIZHT, October 28–29, 2008. – M.: VNIIZHT, 2008. (in Russian).

- ↑ http://rus.evraz.com/press/infographics/rails/

- ↑ Psyrkov, N. V. Special high-strength cast iron with spherical graphite as a new structural material / N. V. Psyrkov // Mechanics of machines, mechanisms and materials. – 2012. – № 3 (20). – 4 (21). – P. 213–218. (in Russian).

- ↑ 104.0 104.1 Sosnovskiy, L. A. Tribo-fatigue wheel / rail system for heavy movement: increasing loads and... reducing costs? / L. A. Sosnovskiy, V. A. Gapanovich, V. I. Senko, V. I. Matvetsov, S. S. Sherbakov, V. V. Komissarov // Bulletin of BelSUT: Science and Transport. – 2016. – № 1 (32). – P. 219–226. (in Russian).

- ↑ Sherbakov, S. S. Stress-strain state and volumetric damage in the vicinity of contact interaction in the wheel / rail tribo-fatigue system taking into account non-contact deformation of the rail / S. S. Sherbakov, O. A. Nasan // Bulletin of BelSUT: Science and Transport. – 2016. – № 1 (32). – P. 234–247. (in Russian).

- ↑ Hampton, R. D. “Rail corrugation – experience of US transit properties” // R. D. Hampton // Transp. Res. Rec. – 1986. – № 1071. – P. 16–18.

- ↑ Tyurin, S. A. Experimental investigation of residual wave-like damages at the initiated initial distortion of the specimen shape / S. A. Tyurin, S. S. Sherbakov // Bulletin of BelSUT: Science and Transport. – 2005. – № 2. – P. 88–93. (in Russian).

- ↑ The method of testing the gear material for contact and bending fatigue: Patent 9247 Rep. of Belarus, IPC G 01M13 / 02 / V. A. Zhmaylik, V. A. Andriyashin, L. A. Sosnovsky, A. M. Zakharik, Al. M. Zakharik, V. V. Komissarov, S. S. Sherbakov; applicants RUE “Gomselmash”, OIM NASB. – No. a20040781; declared 19.08.2004; publ. 30.04.2007. – 2007. – 6 p.

- ↑ Sosnovskiy, L. A. Contact and Bending Fatigue of Toothed Gearings / L. A. Sosnovskiy, V. A. Zhmailik, S. S. Shcharbakou, V. V. Komissarov // Proc. of World Tribology Congress III: Washington, D.C. USA, September 12–16, 2005. – Washington, 2005.

- ↑ Zhmailik, V. A. An experimental study of fatigue resistance, quality and risk of using materials for gears / V. A. Zhmailik // Bulletin of the Brest State Technical University. – 2001. – No. 4. – P. 15-17. (in Russian).

- ↑ Zakharik, A. M. A comprehensive approach to assessing the strength reliability of gears / A. M. Zakharik, A. M. Goman, V. V. Komissarov // Science and Innovation. – 2010. – No. 9 (91). – P. 20–23. (in Russian).

- ↑ Zhmailik, V. A. Calculation and experimental method for assessing the strength reliability of the gears of the main pair of the MAZ-5440 drive axle / V. A. Zhmailik, A. M. Zakharik, Al. M. Zakharik, A. M. Goman, Yu. L. Soliterman, V. V. Komissarov, L. A. Sosnovskiy // Bulletin of BelSUT: Science and Transport. – 2008. – No. 1 (16). – P. 72–80. (in Russian).

- ↑ 113.0 113.1 Vityaz, P. A. From science to education and production / P. A. Vityaz // Science and Innovation. – 2010. – No. 9 (91). – P. 12–16. (in Russian).

- ↑ Sosnovskiy, L. A. On the Development of Mechanothermodynamics as a New Branch of Physics / L.A. Sosnovskiy, S.S. Sherbakov // Entropy. – 2019. – №21. – С.1–49.