Physics:Vibrating-sample magnetometer

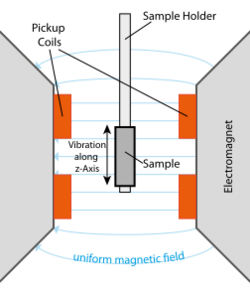

A vibrating-sample magnetometer (VSM) (also referred to as a Foner magnetometer) is a scientific instrument that measures magnetic properties based on Faraday’s Law of Induction. Simon Foner at MIT Lincoln Laboratory invented VSM in 1955 and reported it in 1959.[1] Also it was mentioned by G.W. Van Oosterhout[2] and by P.J Flanders in 1956.[3] A sample is first placed in a constant magnetic field and if the sample is magnetic it will align its magnetization with the external field. The magnetic dipole moment of the sample creates a magnetic field that changes as a function of time as the sample is moved up and down. This is typically done through the use of a piezoelectric material. The alternating magnetic field induces an electric field in the pickup coils of the VSM.[4] The current is proportional to the magnetization of the sample - the greater the induced current, the greater the magnetization. As a result, typically a hysteresis curve will be recorded[5] and from there the magnetic properties of the sample can be deduced.

The idea of vibrating sample came from D. O. Smith's[6] vibrating-coil magnetometer.

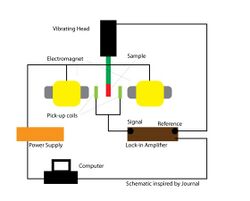

Typical VSM overview

Parts of a typical VSM setup

- Actively cooled electromagnet/power supply

- Amplifier

- Control Chassis

- Meter

- Computer interface

- Sensor coils

- Vibration exciter with sample holder

- Hall probe (optional)

Sample Operating Procedure:[4]

- Mounting the sample in the sample holder

- Turning on the VSM system

- Run the computer software to initialize the system

- Calibrate the system

- Optimize the system for M[4]

- Calibrate the Lock-In Amplifier

- Take measurements and record data

Conditions for VSM to be effective

- Magnetic field must be strong enough to fully saturate the samples (or else inaccurate measurements will be taken)

- Magnetic field must be uniform across the sample space (otherwise the addition of field gradients[5][7] will induce force that alter the vibration once again leading to inaccurate results

Importance of pick-up coils

These allow the VSM to maximize the induced signal, reduce the noise, give a wide saddle point, minimize the volume in between the sample and electromagnet to achieve a more uniform magnetic field at the sample space.[5] The configuration of the coils can vary depending on the type of material being studied.[5]

Relation to Physics

The VSM relies on Faraday's law of induction, with the detection of the emf given by [math]\displaystyle{ \varepsilon = N{d \over dt}(BAcos\vartheta) }[/math],[7] where N is the number of wire turns, A is the area, and [math]\displaystyle{ \vartheta }[/math] the angle between the normal of the coil and the B field. However, N and A are often unnecessary if the VSM is properly calibrated.[7] By varying the strength of the electromagnet through computer software, the external field is sweeped from high to low and back to high.[7] Typically this is automated through a computer process and a cycle of data is printed out. The electromagnet is typically attached to a rotating base[7] so as to allow the measurements be taken as a function of angle. The external field is applied parallel to the sample length[7] and the aforementioned cycle prints out a hysteresis loop. Then using known magnetization of the calibration material and wire volume the high field voltage signal can be converted into emu units - useful for analysis.[7]

Advantages and Disadvantages

The precision and accuracy of VSM's are quite high even among other magnetometers and can be on the order of ~ [math]\displaystyle{ \displaystyle 10^ {-6} }[/math] emu.[5] VSM's further allow for a sample to be tested at varying angles with respect to its magnetization letting researchers minimize the effects of external influences.[8] However, VSM's are not well suited for determining the magnetization loop due to the demagnetizing effects incurred by the sample.[8] VSM's further suffer from temperature dependence and cannot be used on fragile samples that cannot undergo acceleration (from the vibration).[5][7][8]

References

- ↑ Foner, Simon (1959). "Versatile and Sensitive Vibrating-Sample Magnetometer". Rev. Sci. Instrum. 30 (7): 548–557. doi:10.1063/1.1716679. Bibcode: 1959RScI...30..548F.

- ↑ Van Oosterhout, G.W. (1956). Appl. Sci. Res. B6: 101.

- ↑ Flanders, P.J. (1956). IEEE Special Publication, Conference on Magnetism and Magnetic Materials T-91: 315–317.

- ↑ 4.0 4.1 4.2 SWT Physics Department. "Vibrating Sample Magnetometer". https://gato-docs.its.txstate.edu/jcr:7543b8ec-f619-49c3-888f-01c3ad13c7da/vsm.pdf.

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 Lopez-Dominguez, V.; Quesada, A.; Guzmán-Mínguez, J. C.; Moreno, L.; Lere, M.; Spottorno, J.; Giacomone, F.; Fernández, J. F. et al. (2018-03-01). "A simple vibrating sample magnetometer for macroscopic samples". Review of Scientific Instruments 89 (3): 034707. doi:10.1063/1.5017708. ISSN 0034-6748. PMID 29604780. Bibcode: 2018RScI...89c4707L. https://aip.scitation.org/doi/10.1063/1.5017708.

- ↑ Smith, D. O. (1956). "Development of a Vibrating‐Coil Magnetometer". Rev. Sci. Instrum. 27 (261): 261–268. doi:10.1063/1.1715538. Bibcode: 1956RScI...27..261S.

- ↑ 7.0 7.1 7.2 7.3 7.4 7.5 7.6 7.7 Burgei, Wesley; Pechan, Michael J.; Jaeger, Herbert (2003-07-10). "A simple vibrating sample magnetometer for use in a materials physics course". American Journal of Physics 71 (8): 825–828. doi:10.1119/1.1572149. ISSN 0002-9505. Bibcode: 2003AmJPh..71..825B. https://aapt.scitation.org/doi/10.1119/1.1572149.

- ↑ 8.0 8.1 8.2 "Interpretation of Vibrating Sample Magnetometer (VSM) analysis" (in en-GB). 2021-03-16. http://www.analyzetest.com/index.php/2021/03/16/interpretation-of-vibrating-sample-magnetometer-vsm-analysis/.

See also

- Magnetometer

- Alternating (Field) Gradient Magnetometer (AFGM or AGM)

- SQUID Magnetometer

|