Physics:Yarn engineering

Yarn engineering is the process of constructing yarn using procedures designed to change its properties. The purpose of yarn engineering is to optimize the performance and minimize the cost of textile products through the process of selecting the most effective raw materials, fiber type, manufacturing method, and yarn structure[1].

Yarn is a versatile fiber used in fabric-making. The methods in which it is constructed as well as its individual properties determine the properties of the final product. The process of manufacturing yarn is complex, and each step in this process can change the porosity, thinness, and flexibility of the final fabric[2]. The steps of yarn-making are carding, combing, drawing out, twisting, and spinning.

Yarn classifications

Yarns are made from either natural or synthetic fibers. There are differences between the two, and one type may be chosen over another depending on the goals of the manufacturer. The two most common classifications in yarn making are staple-spun and continuous-filament yarn. Staple spun yarn consists of fibers that have restricted lengths, while continuous filament fibers are made up of long strands[3]. The fibers listed below are the most common fibers used today and are provided as exemplary fibers. However, there are other less common fibers that can fall into the natural and synthetic categories. For additional research, other raw materials include flax, mohair, acrylic fiber, and more.

Synthetic

Synthetic fibers are easier to handle than natural fibers, and the process for making them requires much less energy and time. Most synthetic fibers are continuous filaments and made in chemical factories.

- Polyesters are durable fibers resistant to stretching and shrinking, often used in clothing.

- Rayons are thin fibers made from cellulose used to make comfortable clothes.

- Nylons are complex synthetic fibers with many uses. Properties vary depending on manufacturing methods.

Natural

Natural fibers normally fall into the staple spun category and require much more experience and time to manufacture. Large technological advancements continue to make manufacturing natural fibers simpler and have contributed to them still being viable resources.

- Cotton is the most commonly used staple spun yarn. It is used in clothing, coffee filters, book binding, etc.

- Wool is another common textile that must go through a purification process involving the removal of animal fat and plant based matter before being made into yarn at a spinning mill.

- Silk is the only natural continuous filament fiber. It has a reputation of being soft and comfortable. It is produced by silkworms and cultivated on farms.

Manufacturing process

As stated above, each step in the process of making fiber into yarn is unique and can contribute different properties to the yarn. These steps are carding, combing, drawing out, twisting, and spinning[4].

Carding

A card is the first machine for spinning preparation. Carding is a process that cleans, disentangles, and blends slivers, which prepares the fibers to be spun into yarn. Carding causes parallelizing of the fibers, mixes, drafts, and forms slivers. (Gries)

Combing

Combing occurs after the carding process. It is an extra processing stage that removes short fibers and contaminants and causes fiber parallelization. Combing cotton, for example, allows for yarns of finer titer to be spun, higher production speeds, and the reduction of yarn twist and breakage. (Gries)

Drawing Out

During the drawing process, the fibers are drafted which further reduce the weight per yard of the fiber. The fibers are further straightened by drawing, which causes the randomized directions of the macromolecules to be oriented in the fiber direction and a decrease in fiber diameter. (Gries, Richards)

Twisting

Twisting is the process which binds fibers or yarn together for added tenacity, especially in staple fiber yarn. More twist is added during each process to hold the fibers together to create yarn. The direction and the amount of twist will have an influence on the properties of the yarn.

Spinning

Spinning has been a part of human culture since thousands of years before the Middle Ages. In early years, it was very slow and required a lot of work. In 1828, an American named Thorp, advanced spinning techniques by creating ring spinning. In 1967, commercial rotor-spinning was created, another improvement on ring-spinning. And then in the 1970s, air-jet and friction-spinning became popular.

- Ring-spun

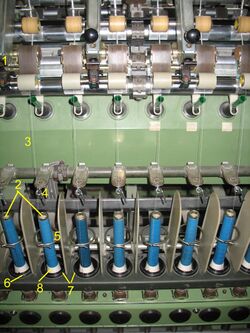

Ring-spinning is one of the oldest methods of making yarn. Yarn is fed through the front dating rolls by the pigtail guide to the ring. The ring twirls around the bobbin, wrapping the yarn around the bobbin. The spindle rail moves up and down so that the yarn wraps around the bobbin evenly.[citation needed]

- Rotor-spun

Rotor-spinning is mostly used for cotton and is up to ten times faster than ring-spinning. Material is fed through the feed and the open roller individualizes the strands. It is then fed to the yarn arm through the fibre transportation tube. The rotor then spins the yarn around the rolling yarn arm, creating yarn.[citation needed]

- Air jet-spun

Air-jet spinning was the next advancement in spinning technology. Material is fed through the spinners to individualize the strands up to the spinning head. Air jets spin the yarn by creating air pressure through a spinning vortex. This weaved yarn is then fed through the spinning head to the winding stage. The winding stage is similar to rotor spinning, where the yarn is wound around a yarn arm[5].

Textile engineering

Yarn engineering is an important sector of the textile industry, where yarn engineers work with textile engineers and machinery to create the most efficient mill possible. Advancing technology has made looms faster. With this increase in speed, engineers must consider the type of yarn they can use. It must be able to withstand higher velocity and acceleration, higher frequency of shed opening, and more energetic weaving motions[6].

Modern looms are automatic, so the yarn should minimize the potential machine stoppage that would stop the loom. One way to prevent stoppages is weaving in a more ideal condition with low humidity and temperature[7].

References

- Elmogahzy, Fundamentals of Yarn Engineering, Indian Journal of Fiber and Textile Research Vol. 31 (2006)

- Cele, Dlodlo, Hunter, Botha, An Expert Yarn Engineering System (2008)

- Wang, Fundamentals of Yarn Technology (2009)

- Textile School, Physical Classification of Fibers (2018)

- Gries, Thomas, et al. Textile Technology, An Introduction. vol. 2nd edition, Carl Hanser Verlag GmbH & Co. KG (2014)

- C. J.F. Rödlich, Investment Decisions in Weaving–An Investment Support Model (ISM), The Journal of The Textile Institute, (2009)

- How Products are Made, Yarn Manufacturing (2008)