Software:Nogrid

| Developer(s) | Nogrid GmbH |

|---|---|

| Initial release | 2006 |

| Stable release | 6.5.0

/ September 1, 2018 |

| Operating system | Microsoft Windows, Linux |

| Available in | English |

| Type | Computer-aided engineering |

| Website | www.nogrid.com |

| Developer(s) | Nogrid GmbH |

|---|---|

| Initial release | 2012 |

| Stable release | 2.8.8

/ August 1, 2018 |

| Operating system | Microsoft Windows, Linux |

| Available in | English |

| Type | Computer-aided engineering |

| Website | www.nogrid.com |

Nogrid GmbH is a German company headquartered in Bodenheim that offers meshless numerical flow simulation (meshless Computational fluid dynamics ((CFD)) software for prototyping new applications. The method is strong in case of computing moving parts or in case of computing complex free surfaces.

Products

Nogrid points

Nogrid points software is a software package to solve tasks in a wide area of flow and continuum mechanical problems. Nogrid points based on a grid-free method. In contrast to classical numerical methods, such as Finite Elements or Finite Volumes, Nogrid points does not require a grid or mesh. Nogrid points can be applied where grid-based methods reach their limits due to the necessary remeshing. Examples are fluid dynamical problems with free surfaces, multiphase flows, fluid-structure interactions with a strong change of the computing domain, or structure mechanical problems with substantial structure changes.

Nogrid pointsBlow

Nogrid pointsBlow is a simulation software especially developed and designed for container glass industry. The CFD software product computes the glass container forming process.

Features

Same as Nogrid points the NOGRID pointsBlow software is based on the meshless Finite Pointset Method (FPM) and is able to compute large deformations and moving parts/boundaries easily. [1]

The following container glass forming processes can be computed with Nogrid pointsBlow:

- BB (Blow and Blow)

- PB (Press and Blow or Wide Mouth PB)

- NNPB (Narrow Neck Press and Blow)

- PB (Press and Blow for the tableware industry)

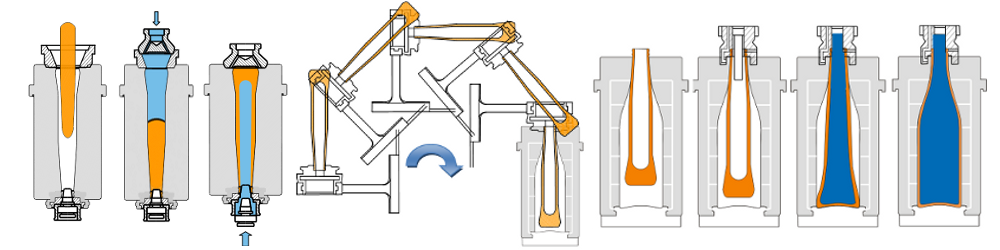

The first process step in the container production is the loading step. In this step the glass gob delivered from the feeder is moved into the blank mold. This is also the first step in the simulation. The next steps depends on the process type. The last step of the forming simulation is container take out. [2] [3] [4]

Figure 1: Steps during Blow&Blow container forming process

The geometry of initial gob can be designed without any restrictions. The temperature distribution within the gob is usually homogeneous, but can also be considered as inhomogeneous.[5] The loading position within the blank mold can be set by the user individually. NOGRID pointsBlow computes the forming process in 2-D or 3-D using all IS machine time data including pressure data, plunger movement and heat transfer data. The movement of the plunger can be driven by force or set by a time position curve.

References

- ↑ TIWARI, S.; KUHNERT, J. (2002). "A meshfree method for incompressible fluid flows with incorporated surface tension". Revue europeaenne des elements finis (11 7-8).

- ↑ MOELLER, A. (2014), "Practical Container Forming Simulation", Glass International (06)

- ↑ MOELLER, A. (2012), "Glass Container Forming Simulation", Glass Worldwide (43)

- ↑ BRUNO, M. (2016), "Integrated thermomechanical model for forming of glass containers", 2nd International Conference on Numerical Methods in Industrial Forming Processes (Troyes, France)

- ↑ MOELLER, A. (2013), "Effects of asymmetric gob temperature on container glass forming", Proceedings 13th International Congress on Glass (Prag)

External links