Chemistry:Hy-Rib

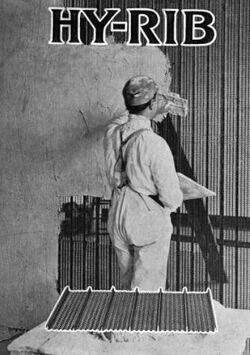

Cover page of Hy-Rib Handbook, 1909 | |

| Manufacturer | Trussed Concrete Steel Company |

|---|---|

| Available | Not available |

Hy-Rib was a brand name for a product manufactured by the Trussed Concrete Steel Company. It is an engineering reinforcement system for floors, walls, and ceilings of buildings and houses. This product is a derivative of the Kahn Trussed Bar for beams and columns that was invented by Julius Kahn. Kahn engineered the Hy-Rib products and they were first manufactured in 1908.[1]

Hy-Rib is a steel encasement stiffened by rigid ribs used in reinforced walls, ceilings, and floors.[2] They are helical hooping units of steel sheathing forms used in concrete, stucco and plaster.[3] Hy-Rib products are a derivative of the "wings" used in the patented Kahn System of reinforced concrete, invented by Julius Kahn in 1903.[4] The products are made from a single plate of steel.[2] Hy-Rib products were used in concrete doors, ceilings, and roofs.[2] It was also used in sidings, partitions and ceilings to eliminate channels.[2] Hy-Rib products were designed to take on plaster and cement to eliminate layout forms in the construction of buildings.[2] The steel sheet form would be embedded with plaster or cement directly and would flow into the lath surface to attach itself to the steel and harden to secure the material into the steel.[5]

Description and application

Hy-Rib products came in steel sheathing forms that could be bent, cut and connected together to make various size floors, walls, and ceilings. They were designed with the idea to reduce weight as compared to wood structures of the same building size. The steel forms of sheathing were stiffened by rigid high ribs and a complete unit was made with a single sheet of steel. This technique increased floor space because it cut down on center posts that were normally used in wood structured buildings. The Hy-Rib reinforced concrete floors, ceilings and walls were fireproof, being a major safety factor over wooden structures. The Packard automobile factory plant building number 10 is a demonstration of Hy-Rib product application of this reinforced concrete technique.[5][6] This was the first time reinforced concrete products were used for automobile factory construction.[7][8]

Hy-Rib products are used in the construction of tunnels, conduits, flumes, culverts, silos, cisterns, chimneys, and water tanks. For these applications the lath sheet products come in curved steel sheets. They are locked together to form a complete tube or tunnel on site. The curved sheets are stood on edge in the case of silos, water tanks, cisterns, and chimneys. The connected form then is plastered with cement. In some cases a few steel rods are added for extra strength and connecting purposes.[9]

Hy-Rib products are used in flooring due to its ability to interlock prefabricated pieces. It has plaster applied to the underside creating the ceiling. The top would have wet cement poured on it to form the floor above. If the floor were required to carry heavy loads the Hy-Rib sheathing material could be bent into an arch to provide additional strength and then wet cement could poured as usual on top to make a floor.[5]

Product

See also

| Wikimedia Commons has media related to Hy-Rib. |

- Julius Kahn

- Kahn System

- Truscon Laboratories

- Albert Kahn Associates

- Trussed Concrete Steel Company

References

- ↑ "Hy-Rib Sheathing". Cement Era 6 (8): 200. August 1908.

- ↑ 2.0 2.1 2.2 2.3 2.4 Truscon 1917, p. 5.

- ↑ Skinner 1997, p. 13.

- ↑ Hughes, Allen & Hecht 2001, p. 142.

- ↑ 5.0 5.1 5.2 Sedlar, Frank (June 24, 2013). "Engineering Industrial Architecture: Albert Kahn and the Trussed Concrete Steel Company". 2012–2013 MLibrary Undergraduate Research Award Maize Award for Single-Term Projects (University of Michigan). http://deepblue.lib.umich.edu/bitstream/handle/2027.42/98436/Sedlar_Engineering_Industrial_Architecture.pdf.

- ↑ Hildebrand 1974, pp. 28–30.

- ↑ Hildebrand 1974, p. 31. "Thus Plant Number Ten represented a clear advance in factory construction for Packard and for the automobile industry in general, as it was the first automobile plant to be built of reinforced concrete."

- ↑ Sedlar 2013, p. 31. "The Packard #10 building was the first to utilize reinforced concrete with Julius Kahn's Kahn Bar but also as previously discussed, the full range of steel building products from the Trussed Concrete Steel Company."

- ↑ Truscon 1917, pp. 119–130.

Bibliography

- Hildebrand, Grant (1974). Designing for industry: the architecture of Albert Kahn. MIT Press. ISBN 978-0-262-08054-5. https://books.google.com/books?id=ILRbAAAAMAAJ.

- Hughes, Agatha C.; Allen, Michael Thad; Hecht, Gabrielle (2001). Technologies of Power: Essays in Honor of Thomas Parke Hughes and Agatha Chipley Hughes. MIT Press. ISBN 978-0-262-51124-7. https://books.google.com/books?id=I6fC_M92lrEC&pg=PA141.

- Skinner, Joan S. (1997). Form and Fancy: Factories and Factory Buildings by Wallis, Gilbert & Partners, 1916–1939. Liverpool University Press. ISBN 978-0-85323-612-2. https://books.google.com/books?id=yzZpi-FbEooC&pg=PA290.

- Truscon (1917). Hy-Rib Handbook; roofs—floors—walls—sidings—partitions—ceilings—furring—silos—tanks—conduits, concrete without forms. Youngstown, Ohio: Trussed Concrete Steel Company. OCLC 33111897. https://books.google.com/books?id=ITEyAQAAMAAJ&pg=PA5.

External links

- Video on "Engineering Industrial Architecture: Albert Kahn and the Trussed Concrete Steel Company"

- Michigan Historical Collections, Bentley Historical Library, University of Michigan, Albert Kahn Papers, 1896–2011