Physics:Laser-heated pedestal growth

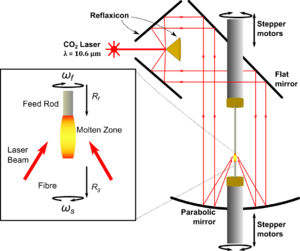

Laser-heated pedestal growth (LHPG) or laser floating zone (LFZ) is a crystal growth technique. A narrow region of a crystal is melted with a powerful CO2 or YAG laser. The laser and hence the floating zone, is moved along the crystal. The molten region melts impure solid at its forward edge and leaves a wake of purer material solidified behind it. This technique for growing crystals from the melt (liquid/solid phase transition) is used in materials research.[1][2]

Advantages

The main advantages of this technique are the high pulling rates (60 times greater than the conventional Czochralski technique) and the possibility of growing materials with very high melting points.[3][4][5] In addition, LHPG is a crucible-free technique, which allows single crystals to be grown with high purity and low stress.

The geometric shape of the crystals (the technique can produce small diameters), and the low production cost, make the single-crystal fibers (SCF) produced by LHPG suitable substitutes for bulk crystals in many devices, especially those that use high-melting-point materials.[6][7] However, single-crystal fibers must have equal or superior optical and structural qualities compared to bulk crystals to substitute for them in technological devices. This can be achieved by carefully controlling the growth conditions.[8][9][10]

Optical elements

Until 1980, laser-heated crystal growth used only two laser beams focused over the source material.[11] This condition generated a high radial thermal gradient in the molten zone, making the process unstable. Increasing the number of beams to four did not solve the problem, although it improved the growth process.[12]

An improvement to the laser-heated crystal growth technique was made by Fejer et al.,[13] who incorporated a special optical component known as a reflaxicon, consisting of an inner cone surrounded by a larger coaxial cone section, both with reflecting surfaces. This optical element converts the cylindrical laser beam into a larger diameter hollow cylinder surface.[14] This optical component allows radial distribution of the laser energy over the molten zone, reducing radial thermal gradients. The axial temperature gradient in this technique can go as high as 10000 °C/cm, which is very high when compared to traditional crystal growth techniques (10–100 °C/cm).

Convection speed

A feature of the LHPG technique is its high convection speed in the liquid phase due to Marangoni convection.[15][16] It is possible to see that it spins very fast. Even when it appears to be standing still, it is in fact spinning fast on its axis.

See also

- Crystal structure

- Crystallite

- Crystallization and engineering aspects

- Fractional crystallization

- Micro-pulling-down

- Nucleation

- Protocrystalline

- Recrystallization (metallurgy)

- Seed crystal

References

- ↑ Feigelson, R.S. (1985). "Growth of fiber crystals". in Kaldis, E. Crystal Growth of Electronic Materials. p. 127. ISBN 978-0-444-86919-7.

- ↑ Andreeta, M.R.B.; Hernandes, A.C. (2010). "Laser-Heated Pedestal Growth of Oxide Fibers". in Dhanaraj, G.. Springer Handbook of Crystal Growth. p. 393. ISBN 978-3-540-74182-4.

- ↑ Ardila, D.R. et al. (1997). "Laser heated pedestal growth of Sr2RuO4 single-crystal fibers from SrRuO3". Journal of Crystal Growth 177 (1–2): 52–56. doi:10.1016/S0022-0248(96)00904-9. Bibcode: 1997JCrGr.177...52A.

- ↑ De Camargo, A.S.S et al. (2002). "Near-infrared and upconversion properties of neodymium-doped RE0.8La0.2VO4 (RE = Y, Gd) single-crystal fibres grown by the laser-heated pedestal growth technique". Journal of Physics 14 (50): 13889–13897. doi:10.1088/0953-8984/14/50/314. Bibcode: 2002JPCM...1413889D.

- ↑ De Vicente, F.S. et al. (1999). "Photoluminescence spectrum of rare earth doped zirconia fibre and power excitation dependence". Radiation Effects and Defects in Solids 149 (1–4): 153–157. doi:10.1080/10420159908230149. Bibcode: 1999REDS..149..153D.

- ↑ De Camargo, A.S.S. et al. (2006). "1.8 µm emission and excited state absorption in LHPG grown Gd0.8La0.2VO4:Tm3+ single crystal fibers for miniature lasers". Optical Materials 28 (5): 551–555. doi:10.1016/j.optmat.2005.07.002. Bibcode: 2006OptMa..28..551D.

- ↑ Romero, J.J. et al. (2004). "Multiwavelength laser action of Nd3+:YAlO3 single crystals grown by the laser heated pedestal growth method". Optical Materials 24 (4): 643–650. doi:10.1016/S0925-3467(03)00179-4. Bibcode: 2004OptMa..24..643R.

- ↑ Prokofiev, V.V. et al. (1995). "Microstructure of single-crystal sillenite fibers". Radiation Effects and Defects in Solids 134 (1–4): 209–211. doi:10.1080/10420159508227216. Bibcode: 1995REDS..134..209P.

- ↑ Prokofiev, V.V. et al. (1995). "The influence of temperature gradients on structural perfection of single-crystal sillenite fibers grown by the LHPG method". Optical Materials 4 (4): 521–527. doi:10.1016/0925-3467(94)00123-5. Bibcode: 1995OptMa...4..521P.

- ↑ Andreeta, M.R.B. et al. (2002). "Thermal gradient control at the solid–liquid interface in the laser-heated pedestal growth technique". Journal of Crystal Growth 234 (4): 759–761. doi:10.1016/S0022-0248(01)01736-5. Bibcode: 2002JCrGr.234..759A.

- ↑ Burrus, C.A.; Stone, J. (1975). "Single−crystal fiber optical devices: A Nd:YAG fiber laser". Applied Physics Letters 26 (6): 318. doi:10.1063/1.88172. Bibcode: 1975ApPhL..26..318B.

- ↑ Haggerty, J.S. (1972). Production of fibers by a floating zone fiber drawing technique, Final Report. NASA-CR-120948.

- ↑ Fejer, M.M.; Byer, R.L.; Feigelson R.; Kway W. (1982). "Growth and characterization of single crystal refractory oxide fibers". 320. Bellingham, WA: SPIE. p. 50. ISBN 978-0-89252-355-9.

- ↑ Edmonds, W.R. (1973). "The reflaxicon: a new reflective optical element, and some applications". Applied Optics 12 (8): 1940–5. doi:10.1364/AO.12.001940. PMID 20125635. Bibcode: 1973ApOpt..12.1940E. http://www.opticsinfobase.org/ao/abstract.cfm?URI=ao-12-8-1940.

- ↑ Liu, M.; Chen, J.C.; Chiang, C.H.; Hu, L.J.; Lin, S.P. (2006). "Mg-doped sapphire crystal fibers grown by laser-heated pedestal growth method". Japanese Journal of Applied Physics 45 (1A): 194–199. doi:10.1143/JJAP.45.194. Bibcode: 2006JaJAP..45..194L.

- ↑ The video presented in the following reference shows the liquid phase convection during lithium niobate (LiNbO3) fiber pulling using a very small piece of platinum wire inside the liquid that is allowed to spin. "Convection in Laser Heated Pedestal Growth technique". https://www.youtube.com/watch?v=b-oynmLOYrg.

|