Chemistry:MAX phases

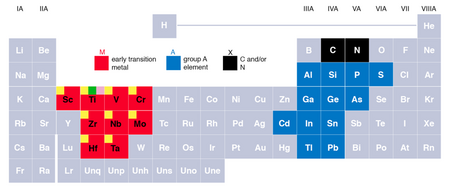

The MAX phases are layered, hexagonal carbides and nitrides which have the general formula: Mn+1AXn, (MAX) where n = 1 to 4,[1] and M is an early transition metal, A is an A-group (mostly IIIA and IVA, or groups 13 and 14) element and X is either carbon and/or nitrogen. The layered structure consists of edge-sharing, distorted XM6 octahedra interleaved by single planar layers of the A-group element.

| 211 | Ti2CdC, Sc2InC, Sc2SnC,Ti2AlC, Ti2GaC, Ti2InC, Ti2TlC, V2AlC, V2GaC, Cr2GaC, Ti2AlN, Ti2GaN, Ti2InN, V2GaN, Cr2GaN, Ti2GeC, Ti2SnC, Ti2PbC, V2GeC, Cr2AlC, Cr2GeC, V2PC, V2AsC, Ti2SC, Zr2InC, Zr2TlC, Nb2AlC, Nb2GaC, Nb2InC, Mo2GaC, Zr2InN, Zr2TlN, Zr2SnC, Zr2PbC, Nb2SnC, Nb2PC, Nb2AsC, Zr2SC, Nb2SC, Hf2InC, Hf2TlC, Ta2AlC, Ta2GaC, Hf2SnC, Hf2PbC, Hf2SnN, Hf2SC, Zr2AlC, Ti2ZnC, Ti2ZnN, V2ZnC, Nb2CuC, Mn2GaC, Mo2AuC, Ti2AuN |

|---|---|

| 312 |

Ti3AlC2, Ti3GaC2, Ti3InC2, V3AlC2, Ti3SiC2, Ti3GeC2, Ti3SnC2, Ta3AlC2, Ti3ZnC2, Zr3AlC2 |

| 413 |

Ti4AlN3, V4AlC3, Ti4GaC3, Ti4SiC3, Ti4GeC3, Nb4AlC3, Ta4AlC3, (Mo,V)4AlC3 |

| 514 |

Mo4VAlC4 |

History

In the 1960s, H. Nowotny and co-workers discovered a large family of ternary, layered carbides and nitrides, which they called the 'H' phases,[3][4][5][6] now known as the '211' MAX phases (i.e. n = 1), and several '312' MAX phases.[7][8] Subsequent work extended to '312' phases such as Ti3SiC2 and showed it to have unusual mechanical properties.[9] In 1996, Barsoum and El-Raghy synthesized for the first time fully dense and phase pure Ti3SiC2 and revealed, by characterization, that it possesses a distinct combination of some of the best properties of metals and engineering ceramics.[10] In 1999 they also synthesized Ti4AlN3 (i.e. a '413' MAX phase) and realized that they were dealing with a much larger family of solids that all behaved similarly. In 2020, Mo4VAlC4 (i.e. a '514' MAX phase) was published, the first major expansion of the definition of the family in over twenty years.[1] Since 1996, when the first "modern" paper was published on the subject, tremendous progress has been made in understanding the properties of these phases. Since 2006 research has focused on the fabrication, characterization and implementation of composites including MAX phase materials. Such systems, including aluminium-MAX phase composites,[11] have the ability to further improve ductility and toughness over pure MAX phase material.[12][11]

Synthesis

The synthesis of ternary MAX phase compounds and composites has been realized by different methods, including combustion synthesis, chemical vapor deposition, physical vapor deposition at different temperatures and flux rates,[13] arc melting, hot isostatic pressing, self-propagating high-temperature synthesis (SHS), reactive sintering, spark plasma sintering, mechanical alloying and reaction in molten salt.[14][15][16][17][18][19] An element replacement method in molten salts is developed to obtain series of Mn+1ZnXn and Mn+1CuXn MAX phases.[20][21][22][23]

Properties

These carbides and nitrides possess an unusual combination of chemical, physical, electrical, and mechanical properties, exhibiting both metallic and ceramic characteristics under various conditions.[24][25] These include high electrical and thermal conductivity, thermal shock resistance, damage tolerance,[11] machinability, high elastic stiffness, and low thermal expansion coefficients. Some MAX phases are also highly resistant to chemical attack (e.g. Ti3SiC2) and high-temperature oxidation in air (Ti2AlC, Cr2AlC, and Ti3AlC2). They are useful in technologies involving high efficiency engines, damage tolerant thermal systems, increasing fatigue resistance, and retention of rigidity at high temperatures.[26] These properties can be related to the electronic structure and chemical bonding in the MAX phases.[27] It can be described as periodic alteration of high and low electron density regions.[28] This allows for design of other nanolaminates based on the electronic structure similarities, such as Mo2BC[29] and PdFe3N.[30]

Electrical

The MAX phases are electrically and thermally conductive due to the metallic-like nature of their bonding. Most of the MAX phases are better electric and thermal conductors than Ti. This is also related to the electronic structure.[31]

Physical

While MAX phases are stiff, they can be machined as easily as some metals. They can all be machined manually using a hacksaw, despite the fact that some of them are three times as stiff as titanium metal, with the same density as titanium. They can also be polished to a metallic luster because of their excellent electrical conductivity. They are not susceptible to thermal shock and are exceptionally damage tolerant. Some, such as Ti2AlC and Cr2AlC, are oxidation and corrosion resistant.[32] Polycrystalline Ti3SiC2 has zero thermopower, a feature which is correlated to their anisotropic electronic structure.[33]

Mechanical

The MAX phases as a class are generally stiff, lightweight, and plastic at high temperatures. Due to the layered atomic structure of these compounds,[11] some, like Ti3SiC2 and Ti2AlC, are also creep and fatigue resistant,[34] and maintain their strengths to high temperatures. They exhibit unique deformation characterized by basal slip (evidences of out-of-basal plane a-dislocations and dislocation cross-slips were recently reported in MAX phase deformed at high temperature[35] and Frank partial c-dislocations induced by Cu-matrix diffusion were also reported[36]), a combination of kink and shear band deformation, and delaminations of individual grains.[37][38][39] During mechanical testing, it has been found that polycrystalline Ti3SiC2 cylinders can be repeatedly compressed at room temperature, up to stresses of 1 GPa, and fully recover upon the removal of the load while dissipating 25% of the energy. It was by characterizing these unique mechanical properties of the MAX phases that kinking non-linear solids were discovered. The micromechanism supposed to be responsible for these properties is the incipient kink band (IKB). However no direct evidence of these IKBs has been yet obtained, thus leaving the door open to other mechanisms that are less assumption-hungry. Indeed, a recent study demonstrates that the reversible hysteretic loops when cycling MAX polycrystals can be as well explained by the complex response of the very anisotropic lamellar microstructure.[40]

Potential applications

- Tough, machinable, thermal shock-resistant refractories[41]

- High-temperature heating elements[32]

- Coatings for electrical contacts

- Neutron irradiation resistant parts for nuclear applications [42]

- Precursor for the synthesis of carbide-derived carbon[43]

- Precursor for the synthesis of MXenes, a family of two-dimensional transition metal carbides, nitrides, and carbonitrides [44]

References

- ↑ 1.0 1.1 Deysher, Grayson; Shuck, Christopher Eugene; Hantanasirisakul, Kanit; Frey, Nathan C.; Foucher, Alexandre C.; Maleski, Kathleen; Sarycheva, Asia; Shenoy, Vivek B. et al. (5 December 2019). "Synthesis of Mo4VAlC4 MAX Phase and Two-Dimensional Mo4VC4 MXene with Five Atomic Layers of Transition Metals". ACS Nano 14 (1): 204–217. doi:10.1021/acsnano.9b07708. PMID 31804797.

- ↑ Eklund, P.; Beckers, M.; Jansson U.; Högberg, H.; Hultman, L. (2010). "The Mn+1AXn phases: Materials science and thin-film processing". Thin Solid Films 518 (8): 1851–1878. doi:10.1016/j.tsf.2009.07.184. Bibcode: 2010TSF...518.1851E. http://urn.kb.se/resolve?urn=urn:nbn:se:liu:diva-54387.

- ↑ Jeitschko, W.; Nowotny, H.; Benesovsky, F. (1964-08-01). "Carbides of formula T2MC". Journal of the Less Common Metals 7 (2): 133–138. doi:10.1016/0022-5088(64)90055-4.

- ↑ Schuster, J. C.; Nowotny, H.; Vaccaro, C. (1980-04-01). "The ternary systems: CrAlC, VAlC, and TiAlC and the behavior of H-phases (M2AlC)". Journal of Solid State Chemistry 32 (2): 213–219. doi:10.1016/0022-4596(80)90569-1. Bibcode: 1980JSSCh..32..213S.

- ↑ Jeitschko, W.; Nowotny, H.; Benesovsky, F. (1963-11-01). "Ti2AlN, eine stickstoffhaltige H-Phase" (in de). Monatshefte für Chemie und Verwandte Teile Anderer Wissenschaften 94 (6): 1198–1200. doi:10.1007/bf00905710. ISSN 0343-7329.

- ↑ Jeitschko, W.; Nowotny, H.; Benesovsky, F. (1964-03-01). "Die H-Phasen Ti2TlC, Ti2PbC, Nb2InC, Nb2SnC und Ta2GaC" (in de). Monatshefte für Chemie und Verwandte Teile Anderer Wissenschaften 95 (2): 431–435. doi:10.1007/bf00901306. ISSN 0343-7329.

- ↑ Jeitschko, W.; Nowotny, H. (1967-03-01). "Die Kristallstruktur von Ti3SiC2—ein neuer Komplexcarbid-Typ" (in de). Monatshefte für Chemie - Chemical Monthly 98 (2): 329–337. doi:10.1007/bf00899949. ISSN 0026-9247.

- ↑ Wolfsgruber, H.; Nowotny, H.; Benesovsky, F. (1967-11-01). "Die Kristallstruktur von Ti3GeC2" (in de). Monatshefte für Chemie und Verwandte Teile Anderer Wissenschaften 98 (6): 2403–2405. doi:10.1007/bf00902438. ISSN 0343-7329.

- ↑ Goto, T.; Hirai, T. (1987-09-01). "Chemically vapor deposited Ti3SiC2". Materials Research Bulletin 22 (9): 1195–1201. doi:10.1016/0025-5408(87)90128-0.

- ↑ Barsoum, Michel W.; El-Raghy, Tamer (1996-07-01). "Synthesis and Characterization of a Remarkable Ceramic: Ti3SiC2". J. Am. Ceram. Soc. 79 (7): 1953–1956. doi:10.1111/j.1151-2916.1996.tb08018.x. ISSN 1551-2916.

- ↑ 11.0 11.1 11.2 11.3 Hanaor, D.A.H.; Hu, L.; Kan, W.H.; Proust, G.; Foley, M.; Karaman, I.; Radovic, M. (2016). "Compressive performance and crack propagation in Al alloy/Ti2AlC composites". Materials Science and Engineering A 672: 247–256. doi:10.1016/j.msea.2016.06.073.

- ↑ Bingchu, M.; Ming, Y.; Jiaoqun, Z.; Weibing, Z. (2006). "Preparation of TiAl/Ti2AlC composites with Ti/Al/C powders by in-situ hot pressing.". Journal of Wuhan University of Technology-Mater. Sci 21 (2): 14–16. doi:10.1007/bf02840829.

- ↑ Magnuson, M.; Tengdelius, L.; Greczynski, G.; Eriksson, F.; Jensen, J.; Lu, J.; Samuelsson, M.; Eklund, P. et al. (2019). "Compositional dependence of epitaxial Tin+1SiCn MAX-phase thin films grown from a Ti3SiC2 compound target". Journal of Vacuum Science & Technology A 37 (2): 021506. doi:10.1116/1.5065468. ISSN 0734-2101. Bibcode: 2019JVSTA..37b1506M. http://urn.kb.se/resolve?urn=urn:nbn:se:liu:diva-154004.

- ↑ Yin, Xi; Chen, Kexin; Zhou, Heping; Ning, Xiaoshan (August 2010). "Combustion Synthesis of Ti3SiC2/TiC Composites from Elemental Powders under High-Gravity Conditions". Journal of the American Ceramic Society 93 (8): 2182–2187. doi:10.1111/j.1551-2916.2010.03714.x.

- ↑ Max phase composites Materials Science and Engineering A

- ↑ Arunajatesan, Sowmya; Carim, Altaf H. (March 1995). "Synthesis of Titanium Silicon Carbide". Journal of the American Ceramic Society 78 (3): 667–672. doi:10.1111/j.1151-2916.1995.tb08230.x.

- ↑ Gao, N. F.; Miyamoto, Y.; Zhang, D. (1999). "Dense Ti3SiC2 prepared by reactive HIP". Journal of Materials Science 34 (18): 4385–4392. doi:10.1023/A:1004664500254. Bibcode: 1999JMatS..34.4385G.

- ↑ Li, Shi-Bo; Zhai, Hong-Xiang (8 June 2005). "Synthesis and Reaction Mechanism of Ti3SiC2 by Mechanical Alloying of Elemental Ti, Si, and C Powders". Journal of the American Ceramic Society 88 (8): 2092–2098. doi:10.1111/j.1551-2916.2005.00417.x.

- ↑ Dash, Apurv; Vaßen, Robert; Guillon, Olivier; Gonzalez-Julian, Jesus (May 2019). "Molten salt shielded synthesis of oxidation prone materials in air". Nature Materials 18 (5): 465–470. doi:10.1038/s41563-019-0328-1. ISSN 1476-4660. PMID 30936480. Bibcode: 2019NatMa..18..465D.

- ↑ Mian, LI; You-Bing, LI; Kan, LUO; Jun, LU; Per, EKLUND; Per, PERSSON; Johanna, ROSEN; Lars, HULTMAN et al. (2019). "Synthesis of Novel MAX Phase Ti3ZnC2 via A-site-element-substitution Approach". Journal of Inorganic Materials 34 (1): 60. doi:10.15541/jim20180377. ISSN 1000-324X.

- ↑ Li, Mian (2019). "Element Replacement Approach by Reaction with Lewis Acidic Molten Salts to Synthesize Nanolaminated MAX Phases and MXenes". Journal of the American Chemical Society 141 (11): 4730–4737. doi:10.1021/jacs.9b00574. PMID 30821963. https://pubs.acs.org/action/cookieAbsent. Retrieved 2019-05-09.

- ↑ Li, Youbing; Li, Mian; Lu, Jun; Ma, Baokai; Wang, Zhipan; Cheong, Ling-Zhi; Luo, Kan; Zha, Xianhu et al. (2019-07-24). "Single-Atom-Thick Active Layers Realized in Nanolaminated Ti 3 (Al x Cu 1– x )C 2 and Its Artificial Enzyme Behavior" (in en). ACS Nano 13 (8): 9198–9205. doi:10.1021/acsnano.9b03530. ISSN 1936-0851. PMID 31330102. http://urn.kb.se/resolve?urn=urn:nbn:se:liu:diva-160432.

- ↑ Huang, Qing; Huang, Ping; Wang, Hongjie; Chai, Zhifang; Huang, Zhengren; Du, Shiyu; Eklund, Per; Hultman, Lars; Persson, Per O. A. (2019-07-19). "Synthesis of MAX Phases Nb2CuC and Ti2(Al0.1Cu0.9)N by A-site Replacement Reaction in Molten Salts". arXiv:1907.08405 [cond-mat.mtrl-sci].

- ↑ Barsoum, M.W. (2000). "The Mn+1AXn Phases: a New Class of Solids; Thermodynamically Stable Nanolaminates". Prog. Solid State Chem. 28: 201–281. doi:10.1016/S0079-6786(00)00006-6. http://max.materials.drexel.edu/wp-content/uploads/2011/01/PSSChem.pdf.

- ↑ Barsoum, M.W. (2006) "Physical Properties of the MAX Phases" in Encyclopedia of Materials Science and Technology, K. H. J. Buschow (eds.). Elsevier, Amsterdam.

- ↑ Basu, Bikramjit; Kantesh Balani (2011). Advanced Structural Ceramics. Wiley. ISBN 978-0470497111.

- ↑ Magnuson, M.; Mattesini, M. (2017). "Chemical bonding and electronic-structure in MAX phases as viewed by X-ray spectroscopy and density functional theory". Thin Solid Films 621: 108–130. doi:10.1016/j.tsf.2016.11.005. Bibcode: 2017TSF...621..108M.

- ↑ Music, D.; Schneider, J.M. (2007). "The Correlation between the Electronic Structure and Elastic Properties of Nanolaminates". JOM 59 (7): 60. doi:10.1007/s11837-007-0091-7. Bibcode: 2007JOM....59g..60M.

- ↑ Emmerlich, J.; Music, D.; Braun, M.; Fayek, P.; Munnik, F.; Schneider, J.M. (2009). "A proposal for an unusually stiff and moderately ductile hard coating material: Mo2BC". Journal of Physics D: Applied Physics 42 (18): 185406. doi:10.1088/0022-3727/42/18/185406. Bibcode: 2009JPhD...42r5406E.

- ↑ Takahashi, T.; Music, D.; Schneider, J.M. (2012). "Influence of magnetic ordering on the elastic properties of PdFe3N". Journal of Vacuum Science and Technology A 30 (3): 030602. doi:10.1116/1.4703897. Bibcode: 2012JVSTA..30c0602T.

- ↑ Magnuson, M. (2006). "Electronic structure and chemical bonding in Ti2AlC investigated by soft x-ray emission spectroscopy". Phys. Rev. B 74 (19): 195108. doi:10.1103/PhysRevB.74.195108. Bibcode: 2006PhRvB..74s5108M.

- ↑ 32.0 32.1 Tallman, Darin J. (2013). "A Critical Review of the Oxidation of Ti2AlC, Ti3AlC2 and Cr2AlC in Air". Materials Research Letters 1 (3): 115–125. doi:10.1080/21663831.2013.806364.

- ↑ Magnuson, M. (2012). "The electronic-structure origin of the anisotropic thermopower of nanolaminated Ti3SiC2 determined by polarized x-ray spectroscopy and Seebeck measurements". Phys. Rev. B 85 (19): 195134. doi:10.1103/PhysRevB.85.195134. Bibcode: 2012PhRvB..85s5134M.

- ↑ Gilbert, C.J. (2000). "Fatigue-crack Growth and Fracture Properties of Coarse and Finegrained Ti3SiC2". Scripta Materialia 238 (2): 761–767. doi:10.1016/S1359-6462(99)00427-3. http://www2.lbl.gov/ritchie/Library/PDF/Ti3SiC2.pdf.

- ↑ Guitton, A.; Joulain, A.; Thilly, L.; Tromas, C. (2014). "Evidence of dislocation cross-slip in MAX phase deformed at high temperature". Sci. Rep. 4: 6358. doi:10.1038/srep06358. PMID 25220949. Bibcode: 2014NatSR...4E6358G.

- ↑ Yu, W.; Guénolé, J.; Ghanbaja, J.; Vallet, M.; Guitton, A. (2021). "Frank partial dislocation in Ti2AlC-MAX phase induced by matrix-Cu diffusion". Scr. Mater. 19: 34–39. doi:10.1016/j.scriptamat.2020.09.007. https://hal.archives-ouvertes.fr/hal-02940841/file/Manuscript_MAX-Cu_Sc-Mat_preprint-HAL.pdf.

- ↑ Barsoum, M.W.; El-Raghy, T. (1999). "Room Temperature Ductile Carbides". Metallurgical and Materials Transactions A 30 (2): 363–369. doi:10.1007/s11661-999-0325-0. Bibcode: 1999MMTA...30..363B.

- ↑ Barsoum, M.W.; Farber, L.; El-Raghy, T.; Levin, I. (1999). "Dislocations, Kink Bands and Room Temperature Plasticity of Ti3SiC2". Met. Mater. Trans. 30A (7): 1727–1738. doi:10.1007/s11661-999-0172-z. Bibcode: 1999MMTA...30.1727B.

- ↑ Guitton, A.; Joulain, A.; Thilly, L.; Tromas, C. (2012). "Dislocation analysis of Ti2AlN deformed at room temperature under confining pressure". Philosophical Magazine 92 (36): 4536–4546. doi:10.1080/14786435.2012.715250. Bibcode: 2012PMag...92.4536G. https://hal.univ-lorraine.fr/hal-03041046/file/HAL_guitton2012.pdf.

- ↑ Guitton, A.; Van Petegem, S.; Tromas, C.; Joulain, A.; Van Swygenhoven, H.; Thilly, L. (2014). "Effect of microstructure anisotropy on the deformation of MAX polycrystals studied by in-situ compression combined with neutron diffraction". Applied Physics Letters 104 (24): 241910. doi:10.1063/1.4884601. Bibcode: 2014ApPhL.104x1910G. https://www.dora.lib4ri.ch/psi/islandora/object/psi%3A9187.

- ↑ Farle, A (2016). "Demonstrating the self-healing behaviour of some selected ceramics under combustion chamber conditions". Smart Materials and Structures 25 (8): 084019. doi:10.1088/0964-1726/25/8/084019. Bibcode: 2016SMaS...25h4019F.

- ↑ Hoffman, Elizabeth (2012). "MAX phase carbides and nitrides: Properties for future nuclear power plant in-core applications and neutron transmutation analysis". Nuclear Engineering and Design 244: 17–24. doi:10.1016/j.nucengdes.2011.12.009. https://zenodo.org/record/1259283.

- ↑ Hoffman, Elizabeth (2008). "Micro and mesoporosity of carbon derived from ternary and binary metal carbides". Microporous and Mesoporous Materials 112 (1–3): 526–532. doi:10.1016/j.micromeso.2007.10.033.

- ↑ Naguib, Michael (2011). "Two-Dimensional Nanocrystals Produced by Exfoliation of Ti3AlC2". Advanced Materials 23 (37): 4248–53. doi:10.1002/adma.201102306. PMID 21861270.

|