Engineering:Pipe Erosion

Pipe erosion, also known as pipe corrosion or pipe wear, refers to the gradual degradation and loss of material from the internal surfaces of pipes. Several factors can contribute to pipe erosion, and they can vary depending on the specific type of pipe and the substances flowing through it. Some of the common causes of pipe erosion include:

Rapid fluid flow can cause erosion in certain types of pipes. The turbulent flow of high-velocity fluids can create pressure differentials that lead to localized erosion at specific points in the pipe. In certain cases, such as elbows and fittings, the fluid velocity may change direction abruptly, leading to localized erosion and wear. When fluids containing abrasive particles flow through pipes, these particles can cause physical wear on the inner surface of the pipe, leading to erosion over time. The extent of erosion will depend on the size, hardness and concentration of the abrasive particles in the fluid.

Cavitation occurs when the pressure of a fluid drops below its vapor pressure, leading to the formation of vapor bubbles that subsequently collapse with high intensity. This collapsing of bubbles near the pipe wall can cause erosion. Water hammer is a phenomenon that occurs when there is a sudden change in fluid flow velocity, leading to pressure surges. These pressure surges can cause physical damage to the inner surface of the pipes. Extreme temperatures, especially in industrial processes, can cause thermal expansion and contraction of pipes. This repeated thermal stress can lead to fatigue and eventual erosion.

When dissimilar metals are in contact in a pipe system, and an electrolyte (such as water) is present, an electrochemical reaction can occur, leading to corrosion and erosion of one of the metals. In some cases, microorganisms can thrive in the pipe's interior and produce acidic by-products that corrode the pipe surface.

Certain fluids, especially those with high acidity or alkalinity, can react with the pipe material, causing chemical corrosion and weakening the pipe's surface. This is often seen in metal pipes, where the reaction with corrosive substances leads to the formation of pits or grooves. In addition, if the fluid flowing through the pipes contains impurities or contaminants, they may react with the pipe material or promote corrosion, accelerating erosion.

Employing CFD Simulation to Mitigate Pipe Erosion

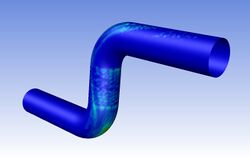

Computational Fluid Dynamics (CFD) simulation can be a valuable tool in understanding and mitigating pipe erosion[1]. CFD is a numerical analysis technique used to simulate the behavior of fluid flow and heat transfer in complex systems. In the context of pipe erosion, CFD simulations can provide valuable insights and aid in various ways:

CFD simulations allow engineers to visualize the fluid flow patterns inside the pipe. By understanding the flow characteristics, they can identify regions of high turbulence and potential erosion-prone areas. CFD simulations can provide information about the velocity profiles and pressure distributions within the pipe. This data helps in identifying regions with high flow velocities that could contribute to erosion. By analyzing the fluid properties, pipe material, and flow conditions, CFD can predict erosion rates in different sections of the pipe. This information is crucial for estimating the expected service life of the pipe and planning maintenance intervals.

CFD simulations allow engineers to evaluate different pipe geometries and configurations. By optimizing the pipe design, they can reduce areas of high flow velocity and turbulence, minimizing the likelihood of erosion.

CFD simulations can identify regions where cavitation might occur, leading to erosion due to bubble collapse. Engineers can then take measures to reduce or eliminate cavitation, such as using flow control devices. If there are changes in flow rate, temperature, or fluid composition, CFD simulations can evaluate the impact on erosion rates. This helps in making informed decisions about operational adjustments to minimize erosion risks.

In cases where pipe erosion has already occurred, CFD simulations can be used to investigate the causes and locations of erosion. This information is useful in designing targeted repairs or replacements. Understanding erosion patterns and potential risks through CFD simulations can help prevent pipe failure, leaks, and spills, reducing environmental hazards and ensuring safety. CFD simulations can be used to validate experimental data obtained from physical tests, offering a more comprehensive understanding of the erosion process.

To mitigate pipe erosion, it is important to select appropriate pipe material based on the properties of the fluid being transported and variables such as flow velocity, temperature and the presence of abrasive materials must be factored into the design. During operations, regular maintenance and monitoring can help identify early signs of erosion and prevent more significant issues in the future. CFD simulations can be employed as a valuable tool to provide a cost-effective and efficient way to study pipe erosion and aid in designing and maintaining robust pipe systems that can withstand erosive forces, thereby enhancing their longevity and reliability.

References

- ↑ "CFD Simulation of Pipe Erosion". https://www.jimmylea.com/cfd-consultants.html. Retrieved 21 July 2023.