Engineering:Ship launching airbag

Template:MergeTo Ship launching airbags are specialized air bags that are used for launching marine vessels. This method of launching ships is called airbag launching. These air bags are made of synthetic-tire-cord reinforcement layers and rubber layers,[1] and are also known as marine airbags. They were invented in 1980.[citation needed] The first known use of marine airbags occurred on January 20, 1981 with the launch of a tank barge from the Xiao Qinghe shipyard. From then on, more and more shipyards, especially in China and Southeast Asia, began to use air bags to launch small and medium-sized vessels.

In recent years, higher strength materials have been used in air bag production, allowing them to have much more bearing capacity. Hence, they have begun to be used at the launchings of larger vessels. In October 2011, the successful launch of one vessel with a deadweight tonnage (DWT) of 75000 tonnes set a world record for ship launches utilizing air bags.[citation needed] The following year, on June 6, 2012, the ship "He Ming" (IMO number 9657105), with a DWT of 73541 tonnes, total length of 224.8m, breadth of 34m, and depth of 18.5m, also launched successfully using air bags[2].

Air bag structure

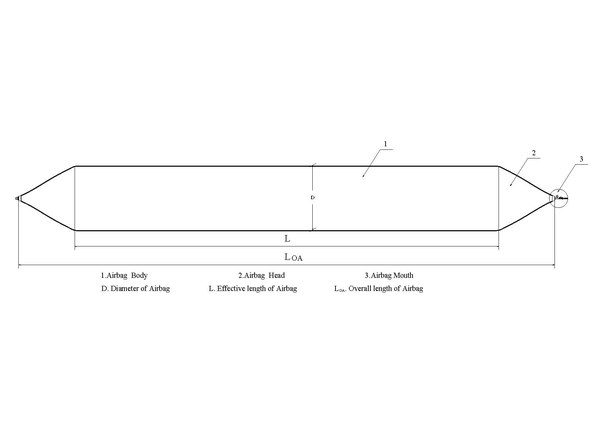

Marine air bags consist of three parts:

- Air bag body: the main, cylindrical part of the air bag after being fully inflated with compressed air,

- Air bag heads: conical parts connecting the body and the mouths of the air bag, and

- Air bag mouths: either metal valves mounted on both ends of the air bag for inflating with air or a valve on one end and a metal lug on the other end used to haul the air bag.

Air bag size and model

Size

The diameter of an air bag varies; sizes include 0.8 m, 1.0 m, 1.2 m, 1.5 m, 1.8 m, etc.

The length of an air bag is specified by the customer when it is manufactured.

Model

Air bags are commonly divided into three to six tire-cord reinforcement layers. There can be more layers, though there are normally less than ten.

Air bag bearing capacity

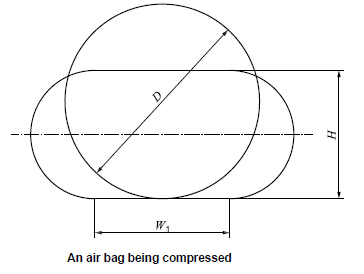

The maximum load carrying capacity of an air bag, which is the maximum load under which it will suffer no permanent deformation or damage, can be found as follows:

Let:

[math]\displaystyle{ D }[/math] be the original diameter of the air bag

[math]\displaystyle{ H }[/math] be the height of the compressed air bag

[math]\displaystyle{ W_{1} }[/math] be the width of the air bag contacting the ship bottom

[math]\displaystyle{ P_{1} }[/math] be the internal pressure of the air bag

[math]\displaystyle{ L }[/math] be the effective length of the air bag

Given these variables, [math]\displaystyle{ \text{bearing capacity} = P_{1} \times W_{1} \times L }[/math]

Air bag materials

Ship launching air bags are constructed of synthetic-tire-cord layers; inner and outer rubber layers are sometimes added. All materials used are vulcanized.

Air bag test

Air tightness test: Without carrying any load, fill the air bag till the internal pressure of the air bag reaches rated working pressure. After 1 hour. The pressure loss should be less than 5 % of initial pressure.

Bursting test: Fill the air bag with water until the air bag bursts. The water pressure at the time of bursting shall be no less than three times of rated working pressure[1].

See also

- Airbag launching

- US Navy

References

- ↑ 1.0 1.1 ISO14409-Ships and marine technology of Ship launching air bags

- ↑ "He Ming". https://www.marinetraffic.com/en/ais/details/ships/shipid:649866/mmsi:414124000/imo:9657105/vessel:HE_MING. Retrieved 2018-06-19.

External links