Fanning friction factor

The Fanning friction factor, named after John Thomas Fanning, is a dimensionless number used as a local parameter in continuum mechanics calculations. It is defined as the ratio between the local shear stress and the local flow kinetic energy density:

where:

- is the local Fanning friction factor (dimensionless)

- is the local shear stress (unit in or or Pa)

- is the bulk flow velocity (unit in or )

- is the density of the fluid (unit in or )

In particular the shear stress at the wall can, in turn, be related to the pressure loss by multiplying the wall shear stress by the wall area ( for a pipe with circular cross section) and dividing by the cross-sectional flow area ( for a pipe with circular cross section). Thus

Fanning friction factor formula

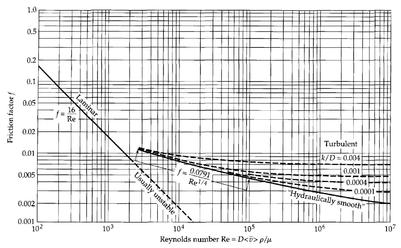

This friction factor is one-fourth of the Darcy friction factor, so attention must be paid to note which one of these is meant in the "friction factor" chart or equation consulted. Of the two, the Fanning friction factor is the more commonly used by chemical engineers and those following the British convention.

The formulas below may be used to obtain the Fanning friction factor for common applications.

The Darcy friction factor can also be expressed as[3]

where:

- is the shear stress at the wall

- is the density of the fluid

- is the flow velocity averaged on the flow cross section

For laminar flow in a round tube

From the chart, it is evident that the friction factor is never zero, even for smooth pipes because of some roughness at the microscopic level.

The friction factor for laminar flow of Newtonian fluids in round tubes is often taken to be:[4]

where Re is the Reynolds number of the flow.

For a square channel the value used is:

For turbulent flow in a round tube

Hydraulically smooth piping

Blasius developed an expression of friction factor in 1913 for the flow in the regime .

Koo introduced another explicit formula in 1933 for a turbulent flow in region of

Pipes/tubes of general roughness

When the pipes have certain roughness , this factor must be taken in account when the Fanning friction factor is calculated. The relationship between pipe roughness and Fanning friction factor was developed by Haaland (1983) under flow conditions of

where

- is the roughness of the inner surface of the pipe (dimension of length)

- D is inner pipe diameter;

The Swamee–Jain equation is used to solve directly for the Darcy–Weisbach friction factor f for a full-flowing circular pipe. It is an approximation of the implicit Colebrook–White equation.[10]

Fully rough conduits

As the roughness extends into turbulent core, the Fanning friction factor becomes independent of fluid viscosity at large Reynolds numbers, as illustrated by Nikuradse and Reichert (1943) for the flow in region of . The equation below has been modified from the original format which was developed for Darcy friction factor by a factor of

General expression

For the turbulent flow regime, the relationship between the Fanning friction factor and the Reynolds number is more complex and is governed by the Colebrook equation[6] which is implicit in :

Various explicit approximations of the related Darcy friction factor have been developed for turbulent flow.

Stuart W. Churchill[5] developed a formula that covers the friction factor for both laminar and turbulent flow. This was originally produced to describe the Moody chart, which plots the Darcy-Weisbach Friction factor against Reynolds number. The Darcy Weisbach Formula , also called Moody friction factor, is 4 times the Fanning friction factor and so a factor of has been applied to produce the formula given below.

- Re, Reynolds number (unitless);

- ε, roughness of the inner surface of the pipe (dimension of length);

- D, inner pipe diameter;

Flows in non-circular conduits

Due to geometry of non-circular conduits, the Fanning friction factor can be estimated from algebraic expressions above by using hydraulic radius when calculating for Reynolds number

Application

The friction head can be related to the pressure loss due to friction by dividing the pressure loss by the product of the acceleration due to gravity and the density of the fluid. Accordingly, the relationship between the friction head and the Fanning friction factor is:

where:

- is the friction loss (in head) of the pipe.

- is the Fanning friction factor of the pipe.

- is the flow velocity in the pipe.

- is the length of pipe.

- is the local acceleration of gravity.

- is the pipe diameter.

References

- ↑ Khan, Kaleem (2015). Fluid Mechanics and Machinery.. Oxford University Press India. ISBN 9780199456772. OCLC 961849291.

- ↑ 2.0 2.1 2.2 2.3 Lightfoot, Edwin N.; Stewart, Warren E. (2007). Transport phenomena. Wiley. ISBN 9780470115398. OCLC 288965242.

- ↑ Cengel, Yunus; Ghajar, Afshin (2014). Heat and Mass Transfer: Fundamentals and Applications. McGraw-Hill. ISBN 978-0-07-339818-1. https://books.google.com/books?id=B89MnwEACAAJ.

- ↑ McCabe, Warren; Smith, Julian; Harriott, Peter (2004). Unit Operations of Chemical Engineering (7th ed.). New York, NY: McGraw-Hill. pp. 98–119. ISBN 978-0072848236.

- ↑ 5.0 5.1 Churchill, S.W. (1977). "Friction factor equation spans all fluid-flow regimes". Chemical Engineering 84 (24): 91–92.

- ↑ 6.0 6.1 Colebrook, C. F.; White, C. M. (3 August 1937). "Experiments with Fluid Friction in Roughened Pipes". Proceedings of the Royal Society of London. Series A, Mathematical and Physical Sciences 161 (906): 367–381. doi:10.1098/rspa.1937.0150. Bibcode: 1937RSPSA.161..367C.

- ↑ Klinzing, E. G. (2010). Pneumatic conveying of solids : a theoretical and practical approach.. Springer. ISBN 9789048136094. OCLC 667991206.

- ↑ 8.0 8.1 Bragg, R (1995). Fluid Flow for Chemical and Process Engineers.. Butterworth-Heinemann [Imprint]. ISBN 9780340610589. OCLC 697596706.

- ↑ Heldman, Dennis R. (2009). Introduction to food engineering. Academic. ISBN 9780123709004. OCLC 796034676.

- ↑ Swamee, P.K.; Jain, A.K. (1976). "Explicit equations for pipe-flow problems". Journal of the Hydraulics Division 102 (5): 657–664. doi:10.1061/JYCEAJ.0004542.

- ↑ Rehm, Bill (2012). Underbalanced drilling limits and extremes. Gulf Publishing Company. ISBN 9781933762050. OCLC 842343889.

- ↑ Pavlou, Dimitrios G. (2013). Composite materials in piping applications : design, analysis and optimization of subsea and onshore pipelines from FRP materials. DEStech Publications. ISBN 9781605950297. OCLC 942612658.

Further reading

- Fanning, J.T. (1896). A practical treatise on hydraulic and water-supply engineering. D. Van Nostrand. ISBN 978-5-87581-042-8. https://books.google.com/books?id=qbMNAwAAQBAJ&pg=PP1.

|