Physics:Indentation size effect

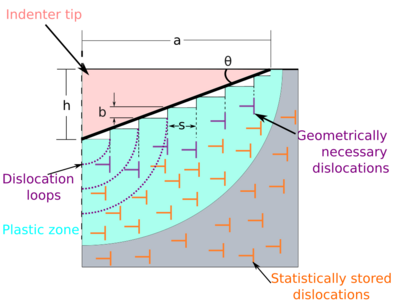

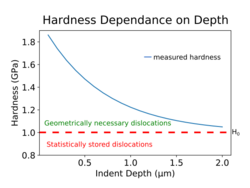

The indentation size effect (ISE) is the observation that hardness tends to increase as the indent size decreases at small scales.[1][2] When an indent (any small mark, but usually made with a special tool) is created during material testing, the hardness of the material is not constant. At the small scale, materials will actually be harder than at the macro-scale. For the conventional indentation size effect, the smaller the indentation, the larger the difference in hardness. The effect has been seen through nanoindentation and microindentation measurements at varying depths. Dislocations increase material hardness by increasing flow stress through dislocation blocking mechanisms.[3][clarification needed] Materials contain statistically stored dislocations (SSD) which are created by homogeneous strain and are dependent upon the material and processing conditions.[4] Geometrically necessary dislocations (GND) on the other hand are formed, in addition to the dislocations statistically present, to maintain continuity within the material.

These additional geometrically necessary dislocations (GND) further increase the flow stress in the material and therefore the measured hardness. Theory suggests that plastic flow is impacted by both strain and the size of the strain gradient experienced in the material.[5][6] Smaller indents have higher strain gradients relative to the size of the plastic zone and therefore have a higher measured hardness in some materials.

For practical purposes this effect means that hardness in the low micro and nano regimes cannot be directly compared if measured using different loads. However, the benefit of this effect is that it can be used to measure the effects of strain gradients on plasticity. Several new plasticity models have been developed using data from indentation size effect studies,[4] which can be applied to high strain gradient situations such as thin films.[7]

References

- ↑ Pharr, George M.; Herbert, Erik G.; Gao, Yanfei (June 2010). "The Indentation Size Effect: A Critical Examination of Experimental Observations and Mechanistic Interpretations". Annual Review of Materials Research 40 (1): 271–292. doi:10.1146/annurev-matsci-070909-104456. ISSN 1531-7331. Bibcode: 2010AnRMS..40..271P.

- ↑ Sargent, PM (1985), "Use of the Indentation Size Effect on Microhardness for Materials Characterization", Microindentation Techniques in Materials Science and Engineering, ASTM International, pp. 160–160–15, doi:10.1520/stp32956s, ISBN 978-0-8031-0441-9

- ↑ Askeland, Donald R. (2016). The science and engineering of materials. Wright, Wendelin J. (Seventh ed.). Boston, MA: Cengage Learning. pp. 111–118. ISBN 9781305076761. OCLC 903959750.

- ↑ 4.0 4.1 Nix, William D.; Gao, Huajian (October 1997). "Indentation size effects in crystalline materials: A law for strain gradient plasticity". Journal of the Mechanics and Physics of Solids 46 (3): 411–425. doi:10.1016/s0022-5096(97)00086-0. ISSN 0022-5096.

- ↑ Fischer-Cripps, Anthony C. (2000). Introduction to contact mechanics. New York: Springer. ISBN 0387989145. OCLC 41991465.

- ↑ Wu, Theodore; Hutchinson, John; Fleck, N (1997). "Strain Gradient Plasticity". Advances in Applied Mechanics. 33. Elsevier Science. pp. 296. ISBN 9780080564111.

- ↑ Voyiadjis, George; Yaghoobi, Mohammadreza (2017-10-23). "Review of Nanoindentation Size Effect: Experiments and Atomistic Simulation". Crystals 7 (10): 321. doi:10.3390/cryst7100321. ISSN 2073-4352.

|