Chemistry:Hafnium compounds

Hafnium compounds are compounds containing the element hafnium (Hf). Due to the lanthanide contraction, the ionic radius of hafnium(IV) (0.78 ångström) is almost the same as that of zirconium(IV) (0.79 angstroms).[1] Consequently, compounds of hafnium(IV) and zirconium(IV) have very similar chemical and physical properties.[1] Hafnium and zirconium tend to occur together in nature and the similarity of their ionic radii makes their chemical separation rather difficult. Hafnium tends to form inorganic compounds in the oxidation state of +4. Halogens react with it to form hafnium tetrahalides.[1] At higher temperatures, hafnium reacts with oxygen, nitrogen, carbon, boron, sulfur, and silicon.[1] Some compounds of hafnium in lower oxidation states are known.[2]

Halides

Hafnium(IV) fluoride (HfF4) is a white crystalline powder.[3] It has a monoclinic crystal structure, with space group C2/c (No.15), and lattice constants a = 1.17 nm, b = 0.986 nm and c = 0.764 nm.[4] Hafnium(IV) chloride (HfCl4) is also a white crystalline powder, with a monoclinic structure. It can be prepared in many ways:

- By the reaction of carbon tetrachloride and hafnium oxide at above 450 °C;[5][6]

- HfO2 + 2 CCl4 → HfCl4 + 2 COCl2

- Chlorination of a mixture of HfO2 and carbon above 600 °C using chlorine gas or sulfur monochloride:[7][8]

- HfO2 + 2 Cl2 + C → HfCl4 + CO2

- Chlorination of hafnium carbide above 250 °C.[9]

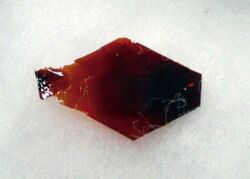

Hafnium(IV) bromide (HfBr4) is a colourless, diamagnetic moisture sensitive solid that sublimes in vacuum.[10] It adopts a structure very similar to that of zirconium tetrabromide, featuring tetrahedral Hf centers, in contrast to the polymeric nature of hafnium tetrachloride.[11] Hafnium(IV) iodide (HfI4) is a red-orange, moisture sensitive, sublimable solid that is produced by heating a mixture of hafnium with excess iodine.[12] It is an intermediate in the crystal bar process for producing hafnium metal. In this compound, the hafnium centers adopt octahedral coordination geometry. Like most binary metal halides, the compound is a polymeric. It is one-dimensional polymer consisting of chains of edge-shared bioctahedral Hf2I8 subunits, similar to the motif adopted by HfCl4. The nonbridging iodide ligands have shorter bonds to Hf than the bridging iodide ligands.[12]

Hafnium(IV) chloride and hafnium(IV) iodide have some applications in the production and purification of hafnium metal. They are volatile solids with polymeric structures.[13] These tetrachlorides are precursors to various organohafnium compounds such as hafnocene dichloride and tetrabenzylhafnium.

Hafnium does form lower halides such as hafnium(III) iodide. Hafnium trihalides are strongly reducing compounds and as such do not have any aqueous chemistry.[14]

Oxides

The white hafnium(IV) oxide (HfO2), also known as hafnium dioxide or hafnia, with a melting point of 2,812 °C and a boiling point of roughly 5,100 °C, is very similar to zirconia, but slightly more basic.[13] It is an electrical insulator with a band gap of 5.3~5.7 eV.[15]

Hafnium(IV) oxide typically adopts the same structure as zirconia (ZrO2). Unlike TiO2, which features six-coordinate Ti in all phases, zirconia and hafnia consist of seven-coordinate metal centres. A variety of other crystalline phases have been experimentally observed, including cubic fluorite (Fm3m), tetragonal (P42/nmc), monoclinic (P21/c) and orthorhombic (Pbca and Pnma).[16] It is also known that hafnia may adopt two other orthorhombic metastable phases (space group Pca21 and Pmn21) over a wide range of pressures and temperatures,[17] presumably being the sources of the ferroelectricity observed in thin films of hafnia.[18]

Thin films of hafnium oxides deposited by atomic layer deposition are usually crystalline. Because semiconductor devices benefit from having amorphous films present, researchers have alloyed hafnium oxide with aluminum or silicon (forming hafnium silicates), which have a higher crystallization temperature than hafnium oxide.[19]

Other compounds

Hafnium diboride belongs to the class of ultra-high temperature ceramics, a type of refractory ceramic composed of hafnium and boron. It has a melting temperature of about 3250 °C. It is an unusual ceramic, having relatively high thermal and electrical conductivities, properties it shares with isostructural titanium diboride and zirconium diboride. Nanocrystals of HfB2 with rose-like morphology were obtained combining HfO2 and NaBH4 at 700-900°C under argon flow:[20]

- HfO2 + 3NaBH4 → HfB2 + 2Na(g,l) + NaBO2 + 6H2(g)

Hafnium carbide is the most refractory binary compound known, with a melting point over 3,890 °C, and hafnium nitride is the most refractory of all known metal nitrides, with a melting point of 3,310 °C.[1] This has led to proposals that hafnium or its carbides might be useful as construction materials that are subjected to very high temperatures. The mixed carbide tantalum hafnium carbide (Ta4HfC5) possesses the highest melting point of any currently known compound, 4,263 K (3,990 °C; 7,214 °F).[21] Recent supercomputer simulations suggest a hafnium alloy with a melting point of 4,400 K.[22] Hafnium silicate (HfSiO4) is a silicate of hafnium, and it is a tetragonal crystal.[23] Thin films of hafnium silicate and zirconium silicate grown by atomic layer deposition, chemical vapor deposition or MOCVD, can be used as a high-k dielectric as a replacement for silicon dioxide in modern semiconductor devices.[24] Hafnium(IV) nitrate (Hf(NO3)4[25][26][27]) is the nitrate of hafnium(IV). It can be prepared by the reaction of hafnium tetrachloride and dinitrogen pentoxide.[28]

Hafnium disulfide is a layered dichalcogenide with the chemical formula of HfS2. A few atomic layers of this material can be exfoliated using the standard Scotch Tape technique (see graphene) and used for the fabrication of a field-effect transistor.[29] High-yield synthesis of HfS2 has also been demonstrated using liquid phase exfoliation, resulting in the production of stable few-layer HfS2 flakes.[30] Hafnium disulfide powder can be produced by reacting hydrogen sulfide and hafnium oxides at 500–1300 °C.[31]

See also

- Titanium compounds

- Zirconium compounds

- Lutetium compounds

- Tantalum compounds

- Lanthanide contraction

References

- ↑ 1.0 1.1 1.2 1.3 1.4 "Los Alamos National Laboratory – Hafnium". http://periodic.lanl.gov/72.shtml.

- ↑ Greenwood, Norman N.; Earnshaw, Alan (1997). Chemistry of the Elements (2nd ed.). Butterworth-Heinemann. pp. 971–975. ISBN 978-0-08-037941-8.

- ↑ Haynes, William M., ed (2011). CRC Handbook of Chemistry and Physics (92nd ed.). Boca Raton, FL: CRC Press. p. 4.66. ISBN 1439855110.

- ↑ Zachariasen, W. H. (1949). "Crystal chemical studies of the 5f-series of elements. XII. New compounds representing known structure types". Acta Crystallographica 2 (6): 388–390. doi:10.1107/S0365110X49001016.

- ↑ Kirk-Othmer Encyclopedia of Chemical Technology. 11 (4th ed.). 1991.

- ↑ Hummers, W. S.; Tyree, Jr., S. Y.; Yolles, S. (1953). "Zirconium and Hafnium Tetrachlorides". Inorganic Syntheses. 4. pp. 121–126. doi:10.1002/9780470132357.ch41. ISBN 9780470132357.

- ↑ Hopkins, B. S. (1939). "13 Hafnium". Chapters in the chemistry of less familiar elements. Stipes Publishing. p. 7.

- ↑ Hála, Jiri (1989). Halides, oxyhalides and salts of halogen complexes of titanium, zirconium, hafnium, vanadium, niobium and tantalum. 40 (1st ed.). Oxford: Pergamon. pp. 176–177. ISBN 978-0080362397.

- ↑ Elinson, S. V. and Petrov, K. I. (1969) Analytical Chemistry of the Elements: Zirconium and Hafnium. 11.

- ↑ W. Thomas, H. Elias "Darstellung von HfCl4 und HfBr4 durch Umsetzung von Hafnium mit Geschmolzenen Metallhalogeniden" Journal of Inorganic and Nuclear Chemistry 1976, Volume 38, Pages 2227–2229. doi:10.1016/0022-1902(76)80199-6

- ↑ Berdonosov, S. S.; Berdonosova, D. G.; Lapitskii, A. V.; Vlasov, L. G. "X-ray study of hafnium tetrabromide" Zhurnal Neorganicheskoi Khimii, 1963, vol. 8, 531-2.

- ↑ 12.0 12.1 Krebs, B.; Sinram, D. (1980). "Hafniumtetrajodid HfI4: Struktur und eigenschaften. Ein neuer AB4-strukturtyp". Journal of the Less Common Metals 76 (1–2): 7–16. doi:10.1016/0022-5088(80)90005-3.

- ↑ 13.0 13.1 Holleman, Arnold F.; Wiberg, Egon; Wiberg, Nils (1985) (in de). Lehrbuch der Anorganischen Chemie (91–100 ed.). Walter de Gruyter. pp. 1056–1057. doi:10.1515/9783110206845. ISBN 978-3-11-007511-3.

- ↑ Greenwood, Norman N.; Earnshaw, Alan (1997). Chemistry of the Elements (2nd ed.). Butterworth-Heinemann. p. 965. ISBN 978-0-08-037941-8.

- ↑ Bersch, Eric (2008). "Band offsets of ultrathin high-k oxide films with Si". Phys. Rev. B 78 (8): 085114. doi:10.1103/PhysRevB.78.085114. Bibcode: 2008PhRvB..78h5114B.

- ↑ Table III, V. Miikkulainen (2013). "Crystallinity of inorganic films grown by atomic layer deposition: Overview and general trends". Journal of Applied Physics 113 (2): 021301–021301–101. doi:10.1063/1.4757907. Bibcode: 2013JAP...113b1301M.

- ↑ T. D. Huan; V. Sharma; G. A. Rossetti, Jr.; R. Ramprasad (2014). "Pathways towards ferroelectricity in hafnia". Physical Review B 90 (6): 064111. doi:10.1103/PhysRevB.90.064111. Bibcode: 2014PhRvB..90f4111H.

- ↑ T. S. Boscke (2011). "Ferroelectricity in hafnium oxide thin films". Applied Physics Letters 99 (10): 102903. doi:10.1063/1.3634052. Bibcode: 2011ApPhL..99j2903B.

- ↑ J.H. Choi (2011). "Development of hafnium based high-k materials—A review". Materials Science and Engineering: R 72 (6): 97–136. doi:10.1016/j.mser.2010.12.001.

- ↑ Zoli, Luca; Galizia, Pietro; Silvestroni, Laura; Sciti, Diletta (23 January 2018). "Synthesis of group IV and V metal diboride nanocrystals via borothermal reduction with sodium borohydride". Journal of the American Ceramic Society 101 (6): 2627–2637. doi:10.1111/jace.15401. https://zenodo.org/record/1292491.

- ↑ Agte, C.; Alterthum, H. (1930). "Researches on Systems with Carbides at High Melting Point and Contributions to the Problem of Carbon Fusion". Z. Tech. Phys. 11: 182–191.

- ↑ Hong, Qi-Jun; van de Walle, Axel (2015). "Prediction of the material with highest known melting point from ab initio molecular dynamics calculations". Phys. Rev. B 92 (2): 020104. doi:10.1103/PhysRevB.92.020104. Bibcode: 2015PhRvB..92b0104H.

- ↑ Haynes, William M., ed (2011). CRC Handbook of Chemistry and Physics (92nd ed.). Boca Raton, FL: CRC Press. p. 4-66. ISBN 1439855110.

- ↑ Mitrovic, I.Z.; Buiu, O.; Hall, S.; Bungey, C.; Wagner, T.; Davey, W.; Lu, Y. (April 2007). "Electrical and structural properties of hafnium silicate thin films". Microelectronics Reliability 47 (4–5): 645–648. doi:10.1016/j.microrel.2007.01.065.

- ↑ "Hafnium(IV) nitrate". Sigma Aldrich. https://www.sigmaaldrich.com/RU/en/product/aldrich/530778.

- ↑ "Hafnium Nitrate". American Elements. https://www.americanelements.com/hafnium-nitrate-15509-05-4.

- ↑ (in en) The Metallurgy of Hafnium. Naval Reactors, Division of Reactor Development, U.S. Atomic Energy Commission. 1960. p. 31. https://books.google.com/books?id=dqKgCIbq7hEC&dq=hafnium+nitrate&pg=PA31. Retrieved 29 October 2021.

- ↑ Zhuang, Weiwei; Conley, John F.; Ono, Yoshi; Evans, David R.; Solanki, R. (January 2002). "Hafnium Nitrate Precursor Synthesis and HfO2 Thin Film Deposition". Integrated Ferroelectrics 48 (1): 3–12. doi:10.1080/10584580215449. Bibcode: 2002InFer..48....3Z.

- ↑ Kanazawa, Toru; Amemiya, Tomohiro; Ishikawa, Atsushi; Upadhyaya, Vikrant; Tsuruta, Kenji; Tanaka, Takuo; Miyamoto, Yasuyuki (2016). "Few-layer HfS2 transistors". Scientific Reports 6: 22277. doi:10.1038/srep22277. PMID 26926098. Bibcode: 2016NatSR...622277K.

- ↑ Kaur, Harneet (2017). "High Yield Synthesis and Chemical Exfoliation of Two-Dimensional Layered Hafnium Disulphide". Nano Research. doi:10.1007/s12274-017-1636-x.

- ↑ Kaminskii, B. T.; Prokof'eva, G. N.; Plygunov, A. S.; Galitskii, P. A. (1973-07-01). "Manufacture of zirconium and hafnium sulfide powders". Soviet Powder Metallurgy and Metal Ceramics 12 (7): 521–524. doi:10.1007/BF00796747.

|