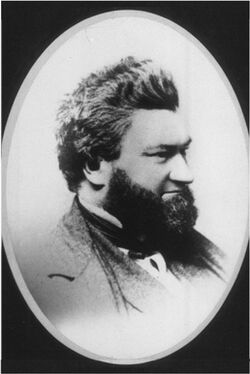

Biography:Daniel Davis Jr.

Daniel Davis Jr. | |

|---|---|

Davis, circa 1870 | |

| Born | February 8, 1813 Princeton, Massachusetts, U.S. |

| Died | March 22, 1887 (aged 74) |

| Known for | Electrical and mechanical innovations |

Daniel Davis Jr. (February 8, 1813 – March 22, 1887) was an American science instrument maker, electrical engineer, mechanic, photographer, daguerreotypist and ambrotypist. Through the course of his work he became known for his practical knowledge and understanding of electromagnetic principles. He worked with college professors, notable electricians and popular scientists of the nineteenth century. He was consulted for practical knowledge on mechanics and electricity by inventors, including Samuel Morse for his telegraph and Elias Howe for his sewing machine. He was the first man in the United States to work with gold and silver electroplating, patented a method for coloring daguerrotypes through electroplating in 1842, and sold franchises to others for photographic studios. Davis published an exhaustive work on electromagnetism that became a textbook for academies, high schools, and colleges.

Early life

Daniel Davis Jr. was born on February 8, 1813, in Princeton, Massachusetts. His father and brothers had a mechanical background. While growing up, Davis worked as a helper on his father's homestead until the age of twenty, and then moved to Boston in 1833.[1][2] He was first employed as a laborer by a Mr. Darling, who had a soda factory called Darling & Ireland on Franklin Avenue that produced carbonated water.[2][3]

Davis was much interested in electrical experimentation and soon became acquainted with one William King, who operated a small factory on Cornhill Street that made static electricity machinery and lightning rods. Davis was soon employed by King to install the lightning rods manufactured by King's factory.[4] His first job was helping to put up the lightning rod on the Boston courthouse. The lightning rod was made of a solid copper rod laid out in a long flat ribbon shape.[2] He also helped make and install the lightning rods on the wooden structures in the Charlestown Navy Yard.[3]

Mid-life

Davis began doing business for himself in 1835 at No. 11 Cornhill Street (later 428 Washington Street) in Boston. He engaged John Temple as his business partner, and they called the firm Davis & Temple. Davis secured Temple's share of the firm in 1837 and began making electromagnetic mechanisms. As a philosophical instrument maker,[5] he was the earliest manufacturer of electromagnetic apparatus in the United States.[6][7] Among his customers were Robert Hare, Benjamin Silliman, Joseph Henry, Charles G. Page, John White Webster, Moses G. Farmer, William Francis Channing, Francis Thomas Bacon, and Edward Hitchcock.[2] [4] At that time there was no use for electricity in everyday applications for the general public, so Davis made a business out of making devices to illustrate the general principles of electricity. With Page, he devised and invented many electric tools and circuit components that were put into general use.[8] Together they did electrical test trials and experiments to gather knowledge of outcomes for certain procedures. In the fall of 1839, Page took a position in the Patent Office in Washington, D.C., as an examiner of patents related to electrical apparatus. Davis's business increased rapidly, as he was the only person in the United States who manufactured electromagnetic devices. He did not consider patents for his inventions; had he obtained such rights on his innovations and developments, he would have become wealthy instead of merely making an average business income.[2][9]

Davis made a daguerreotype apparatus set in 1840 soon after Professor Gareaux of Paris came to Boston with the invention.[9] He took one of the first daguerrotype pictures taken in the United States, of the old German Catholic Church on Shawmut Avenue in Boston.[10] The picture was taken when witnesses saw a gentleman standing at the side of the church holding his wooden cane in his clutched right hand. When Davis developed and finished the picture out, to the surprise of these witnesses, the crooked cane was in the man's left hand. This puzzled them for some time, until they learned that the picture rendered on a darkened surface, was a reversed image.[9]

Davis was the first person in the United States to work with gold and silver electroplating as a business.[2][9] He first advertised for this business in the Boston Post newspaper in 1842 at his Cornhill location.[11] His 1843 advertisement added medical applications and read:[12]

Magneto-Electric Gilding and Silvering done to order by Daniel Davis, Jr., 11 Cornhill, Boston, Mass. Watches, Spoons, Knives, Thimbles, Brass or Copper Ornaments, of all descriptions, Gilt or Silvered - Surgical and Dental Instruments, Knives and Forks, etc. Gilt in the best manner, at the lowest prices, and warranted superior to any other process. Apparatus for Gilding and Silvering at reasonable prices. Apparatus for illustrating the principles of Magnetism, Electro-Magnetism, Magneto Electricity, and Thermo Electricity. Improved Magneto Electric Apparatus, for medical use. Electricity Medically applied at No 11 Cornhill.

He taught others these electromagnetic techniques for their businesses.[9] In 1842, Davis patented a method for coloring daguerreotypes through electroplating,[13] and then sold franchise rights to other photographers like John Plumbe to set up photography galleries across the nation.[14][15]

Davis was awarded gold medals from various exhibitions for his electrical and mechanical innovations.[2] One gold medal was received in 1840 from the Massachusetts Charitable Association for a complete set of electromagnetic apparatus for the Vermont Medical College.[16] Davis's shop in Boston was the headquarters for college professors and experienced electricians for many years. It was frequented by many of the scientists and inventors of the time. Samuel Morse in 1844 asked Davis for help in developing out his telegraph.[2] [17] Davis made Elias Howe's first sewing machine, with the assistance of his brother Ari, at his workplace on Cornhill Street in Boston.[9] One of Davis's sizable projects was a couple of large scale electric generators that were powered by railroad steam locomotives from the Boston and Lowell Railroad.[18]

Davis's Manual of Magnetism

Davis had practical knowledge of mechanics and published an exhaustive work on electricity and magnetism titled A Manual of Magnetism, including Galvanism, Magnetism, Electro-Magnetism, Electro-Dynamics, Magneto-Electricity and Thermo-Electricity.[2] The manual cost 75 cents in 1842 (equivalent to $20 in 2019), and was an expanded catalog in the form of a book, containing more than a hundred original detailed hand drawings to illustrate and explain these principles. It was the first catalogue published on philosophical instruments.[19] Davis originally published this manual to advertise his wares and call attention to his business. He furnished a list of more than a hundred hand-made electrical items with prices for the items that averaged around $5 each (equivalent to $132 in 2019) with dozens of magnets and batteries for sale that had an average price of $1 (equivalent to $26 in 2019).[20] Davis's manual was not made as a textbook on electrotechnics, but its value as a reference book of electrical information was at once seen, and it was put into wide use. It was the first American textbook on electricity.[21][22]

Davis's electrical manual for the use of students and literary institutions was first printed in 1842, with an enlarged edition following in 1848. Both were written under the supervision of William Francis Channing, who brought an elegant, clear style of writing that made the book a success. It was adopted by several colleges and high schools in the nation. It became a favorite of the United States Military Academy at West Point for the practical demonstrations shown in the pages. There were at least twelve more editions of the manual until 1872. Many trained electricians from 1842 to 1872 had confessed that they had learned their skills from Davis's manual.[1][23]

Electromagnetic devices for medical purposes

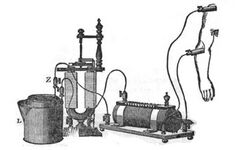

In 1838, Davis already had a reputation for electromagnetic devices for medical remedies that he made at his Cornhill shop.[24] He described in his 1842 Manual of Magnetism that electric sparks and electric shocks could be used for medical purposes.[25] These were produced by high voltages through electromagnetic devices that he made.[26] He constructed various styles and types of electromagnetic devices that would turn low voltage into high voltage that would produce electrical sparks and shocks to a person.[27]

In 1846, Davis published a 24-page supplemental manual called Medical Application of Electricity, specifically on the application of electricity in medical procedures using electromagnetic apparatus devices he made. He says in this booklet that electricity through his devices was being used to treat disease of the muscular system. He pointed out that electricity itself was not the direct agent for the cure, but acted as a vital stimulant to help the body do the curing. With this idea in mind, electricity was used for the treatment of paralysis and all sorts of nervous disorders. This was carried still further to treat almost every disease of every nature and class in which the nervous system played a role. He pointed out that the new field of curing a body of a disease using electricity was experimental and should be used carefully under the supervision of a medical practitioner.[28]

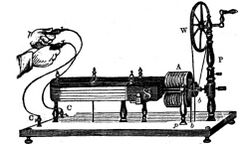

A class of instruments to which Davis referred was the magneto-electric machines that did not use batteries, but were powered by hand to make electricity. He described a strong permanent steel magnet as being the source of electrical power. In the Hand shocker figure, the letter S is the south pole of a permanent U magnet. The letter A represents a U armature of soft iron mounted on an axis that can revolve around rapidly by means of the hand operated wheel pulley mechanism. The iron ends rotated around the magnet poles of North and South of the permanent steel magnet. On the legs of this armature are wound coils of wire connected together. Whenever the legs of the armature approach or recede from the poles of the strong permanent magnet they acquire or lose magnetism and accordingly electrical currents are generated in the coils of wire. This electricity passes by another coil and is mechanically intermittently broken by the revolution of the hand wheel mechanism. This collapsing and building of magnetic fields between the coils produces a high voltage shock to the medical patient.[29]

Electrotype copying process

In his Manual of Magnetism, Davis explains that the term electrotype is the copying of coins, award medals, plaster casts and engraved copper plates using electricity. He explains the process of low temperature melting metallic solutions being used to form a mold of the original object. The metallic solution then is electrified with a current and deposited on a battery plate of opposite charge, giving an exact copy of the original object that was molded. The copies are electrotypes, since they are a type of the original produced by electricity. The elaborate process is referred to as The Electrotype technique.[30]

The frontispiece to the Manual depicts an engraving printed from an electrotype plate as a specimen of the technique. Very little difference can be detected between the impressions from the original copper plate and the electrotype copy made by Davis.[31] This was an important application of 19th-century electrotype where a large number of impressions were to be made.[32] It was only necessary to engrave one plate, and it was not marred in the slightest degree by taking many copies from it using the electrotype technique.[33] John W. Wilcox, the foreman for Davis, was the first commercial electrotyper.[34]

Later life and death

Davis was successful in the electrical field for 15 years, and in 1848 sold his firm and retired to his farm in Princeton, where he passed the remainder of his days in agricultural pursuits.[1] He died at the age of 74 on March 22, 1887.[2]

See also

- Thomas Hall, associate inventor

References

- ↑ 1.0 1.1 1.2 Sherman 1988, p. 35.

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 Scientific American 1887, p. 256.

- ↑ 3.0 3.1 Blake 1915, p. 295.

- ↑ 4.0 4.1 Henry 1972, p. 444.

- ↑ Page 1839, p. 264.

- ↑ Channing 1865, p. 9.

- ↑ Hall 1859, p. 16.

- ↑ Blake 1915, p. 297.

- ↑ 9.0 9.1 9.2 9.3 9.4 9.5 Blake 1915, p. 298.

- ↑ Acton 2004, p. 24.

- ↑ "Gilding and Silvering". Boston Post (Boston, Massachusetts): p. 4. November 23, 1842. https://www.newspapers.com/clip/99678650/.

- ↑ "Gilding and Silvering". Boston Post (Boston, Massachusetts): p. 4. May 20, 1843. https://www.newspapers.com/clip/99782835/boston-post/.

- ↑ Cartwright 2011, p. 26.

- ↑ Kelbaugh 1989, p. 108.

- ↑ Cupples 1840, p. 98.

- ↑ Blake 1915, p. 299.

- ↑ "Electricity in Steam". The Pilot and Transcript (Baltimore. Maryland): p. 1. January 7, 1841. https://www.newspapers.com/clip/99783760/.

- ↑ Post 1976, pp. 29, 37.

- ↑ Channing 1852, p. contents.

- ↑ Newhall 1976, p. 120.

- ↑ Sherman 1988, pp. 35–39.

- ↑ Sherman 1988, pp. 40–43.

- ↑ Boston Medical 1838, p. 227.

- ↑ Bacon 1842, pp. 192–193.

- ↑ Bacon 1842, pp. 194–196.

- ↑ Bacon 1842, pp. 135–165.

- ↑ Davis 1846, p. 4.

- ↑ Davis 1846, p. 14.

- ↑ Bacon 1842, p. 199.

- ↑ Partridge 1898, p. 713.

- ↑ Quimby 1974, p. 39.

- ↑ Bacon 1842, p. 204.

- ↑ Hatch 1918, p. 2.

External links

- Harvard University – Collection of Historical Scientific Instruments made by Daniel Davis Jr

- Written material of Daniel Davis held by Princeton University

Sources

- Acton, Francis Everett (2004). Photography at the Worcester Art Museum. Worcester Art Museum. ISBN 9789053495087.

- Bacon, John (1842). Davis's Manual of Magnetism. Daniel Davis, Jr.. OCLC 270724728. https://www.google.com/books/edition/Davis_s_Manual_of_Magnetism_Including_al/yxtkAAAAcAAJ?hl=en&gbpv=0.

- Blake, Francis Everett (1915). History of the town of Princeton. Town of Princeton, Massachusetts. OCLC 57275389. https://babel.hathitrust.org/cgi/pt?id=hvd.32044009811993&view=1up&seq=347&skin=2021&q1=%22Charlestown%20Navy%20Yard%22.

- Boston Medical (1838). "A New Magnetic Electrical Machine". Boston Medical and Surgical Journal (Massachusetts Medical Society) 17–18: 227.

- Cartwright, Angela (2011). Mixed Emulsions. United States: Quarry Books. ISBN 9781616735159. https://www.google.com/books/edition/Mixed_Emulsions/GdUE4IGLFCwC?hl=en&gbpv=1&dq=%22Daniel+Davis+Jr%22+electroplating&pg=PA26&printsec=frontcover.

- Channing, William Francis (1852). Manual of Magnetism. Daniel Davis, Jr.. pp. 199. OCLC 832911749. https://www.google.com/books/edition/A_MANUAL_OF_MAGNETISM/K9oKnB1iElEC?hl=en&gbpv=1&dq=%22Daniel+Davis+Jr%22+++%22Davis%27s+manual+of+magnetism%22&pg=PT1&printsec=frontcover.

- Channing, William Francis (1865) (in en). Medical application of electricity. T. Hall. pp. 242. OCLC 956536441. https://archive.org/details/medicalapplicati00chan/page/n7/mode/2up?q=earliest.

- Cupples, Upham (1840). "Medical Miscellany". Boston Medical and Surgical Journal (D. Clapp Jr.) 22. https://www.google.com/books/edition/The_Boston_Medical_and_Surgical_Journal/t8s9AQAAMAAJ?hl=en&gbpv=1&dq=%22Daniel+Davis+Jr+who+received+the+gold%22&pg=PA98&printsec=frontcover.

- Davis, Daniel (1846). Medical Application of Electricity. Daniel Davis, Junr.. OCLC 556550603. https://www.google.com/books/edition/The_Medical_Application_of_Electricity_w/Znw89iBJU5wC?hl=en&gbpv=0.

- Hall, Thomas (1859). Illustrated Catalogue Electro-Medical Instruments. Palmer & Hall. OCLC 230989755. https://iiif.wellcomecollection.org/pdf/b21056511#page=10&zoom=auto,-107,586.

- Hannavy, John (2013). Encyclopedia of Nineteenth-Century Photography. Taylor & Francis. ISBN 9781135873264. https://www.google.com/books/edition/Encyclopedia_of_Nineteenth_Century_Photo/yVFdAgAAQBAJ?hl=en&gbpv=1&dq=%22Daniel+Davis%22+patented+in+1842+a+method+for+coloring+daguerreotypes+through+electroplating&pg=PA1138&printsec=frontcover.

- Hatch, Harris B (1918). Electrotyping and Stereotyping. Typographic technical series for apprentices, pt. I,no 15. United typothetae of America. OCLC 894139962. https://babel.hathitrust.org/cgi/pt?id=hvd.hw2gmm&view=1up&seq=14&skin=2021&q1=Wilcox.

- Henry, Joseph (1972). The Papers of Joseph Henry / the Albany years. Smithsonian Institution Press. OCLC 37842760.

- Kelbaugh, Ross J. (1989). "Charles Page, Daniel Davis, and Their Electromagnetic Apparatus". Maryland Historical Magazine 84: 101–197. https://msa.maryland.gov/megafile/msa/speccol/sc5800/sc5881/000001/000000/000335/pdf/msa_sc_5881_1_335.pdf.

- Newhall, Beaumont (1976). The daguerreotype in America. United States: Dover Publications. ISBN 9780486233222.

- Page, Charles (1839). "Electro-magnetic Apparatus and Experiments". The American Journal of Science and Arts (B. L. Hamlen) 35 (1): 264. https://www.google.com/books/edition/American_Journal_of_Science/BihGAAAAcAAJ?hl=en&gbpv=1&dq=%22Several+of+these+engines+have+been+made+by+Mr+Daniel+Davis+Jr+philosophical+instrument+maker+of+Boston%22&pg=PA264&printsec=frontcover.

- Partridge, C. S. (1898). "Notes and queries on electrotyping and stereotyping". The Inland Printer (Inland Printer Company) 21: 713. https://www.google.com/books/edition/The_Inland_Printer/_UI_AQAAMAAJ?hl=en&gbpv=1&dq=two+pages+one+of+which+was+printed+from+an+original+on+copper+and+the+other+from+an+electrotype+duplicate+made+by+depositing+on+the+original+for+a+matrix+and+by+depositing+on+the+matrix+to+make+the+plate+printed+from&pg=PA713&printsec=frontcover.

- Post, Robert C. (1976). Physics, Patents, and Politics - Biography of Charles G. Page. Science History Publications. ISBN 9780882020464. https://www.google.com/books/edition/Physics_Patents_and_Politics/PeW3AAAAIAAJ?hl=en&gbpv=0. "(page 29) He did returnn to Boston briefly in October to consult with Davis, whose first catalogue of philosophical instruments was about to go to press."

- Quimby, Angela (1974). Technological Innovation and the Decorative Arts. Chicago. ISBN 9780813905693.

- Scientific American (1887). "Daniel Davis". Scientific American (Nature America) 56 (17): 256. https://www.google.com/books/edition/Scientific_American/E6IzAQAAMAAJ?hl=en&gbpv=1&dq=%22On+March+22+at+the+age+of+74+years%22+%22Daniel+Davis%22&pg=PA256&printsec=frontcover.

- Sherman, Roger (1988). "Charles Page, Daniel Davis, and Their Electromagnetic Apparatus". Journal of the American Scientific Instrument Enterprise (Rittenhouse) 2 (2): 31–47. https://www.uvm.edu/~dahammon/museum/Page_Davis.pdf.