Software:PERMAS

Gearing Calculation | |

| Original author(s) | INTES GmbH |

|---|---|

| Stable release | 17.00.360

/ February 2020 |

| Written in | Fortran, C |

| Operating system | Linux, Windows |

| Platform | Linux x86-64 Windows x86-64 |

| Available in | https://de.wikipedia.org/wiki/PERMAS |

| Type | Finite element analysis |

| License | Commercial (EULA) |

| Website | INTES.de |

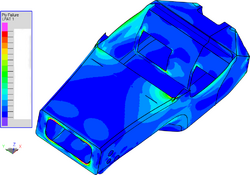

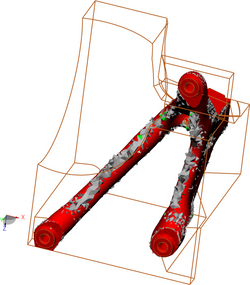

PERMAS is a general-purpose finite element analysis (FEA) software with roots back to the 1960s. It is further developed by the company INTES GmbH, Stuttgart, Germany and is particularly suitable for linear and non-linear structural mechanics calculations, fluid structure interaction in acoustics, for the analysis of electromagnetic fields and heat conduction including radiation exchange. In addition, there is a fully integrated optimization functionality for topology/sizing/shape (also in combination) and for a robust optimum (stochastic parameters). Since 2008 PERMAS consists of two major products:

- PERMAS the finite element solver and

- VisPER (Visual PERMAS) a graphic model editor and postprocessor.

Description

The native input takes place via own data formats for the model description and the control of the calculation process. PERMAS has numerous interfaces to pre- and post-processors like e.g. ANSA, HyperMesh, MEDINA, Simcenter(NX)[1], as well as direct (input) interfaces to solvers like Abaqus or Nastran. Direct interfaces to multi-body simulation (MBS, morebms,[2]), as well as to fatigue assessment are also included. Moreover, boundary conditions of flow simulations e.g. with OpenFOAM may be taken into account. With the help of the IDEAS universal file format, a model updating with measurement models can be carried out. Especially for demanding and complex simulations a task graph based, general parallelization [3] is available. The Open Telecom Cloud provides a cloud computing service. PERMAS and VisPER use the open-source scripting language Python (programming language) for scripting and customization.

History

The roots of PERMAS date back to the early 1960s, when the ASKA (de) program system [4] was developed at the Institute of Statics and Dynamics of Aerospace Structures [5] at the University of Stuttgart under the lead of John Argyris as a pioneering software of this technology. In 1984, some of the authors decided to found a spin-off company in order to enable continuous development.[6] At the end of the 1980s, a new program generation was realized, which was subsequently marketed for the first time as PERMAS Version 5 in 1993[7]. This new development took into account the fast evolution on the hardware market (e.g. with vectorization and RISC architecture) and formed the basis for a general parallelization concept: PTM (Parallel Task (graph) Manager)[8]. Since then, an extensive functional expansion has taken place, also within the scope of research projects, e. g.: Optiamix[9], EC project LISA [10], EU projects PERMPAR, PARMAT, and ASRA-HPC [11]

In addition to its headquarters in Germany (Stuttgart), INTES has its own subsidiaries in France and Japan.

Release history

| PERMAS version | Release date |

|---|---|

| 5.0 | 1993 |

| 5.1 | 1994 |

| 5.2 | 1995 |

| 6 | 1996 |

| 6.1 | 1997 |

| 7 | 1999 |

| 8 | 2000 |

| 9 | 2002 |

| 10 | 2004 |

| 11 | 2006 |

| 12 | 2008 |

| 13 | 2010 |

| 14 | 2012 |

| 15 | 2014 |

| 16 | 2016 |

| 17 | 2018 |

| 18 | 2020 |

A new version of PERMAS is released every two years.

Application Fields

- Major applications: Stiffness, strength, contact, thermomechanical analysis [12], vibrations [13] (including random vibration and integrated active control [14]), acoustics[15], rotor dynamics [16], stability (e. g. brake squeal[17]), temperature and electromagnetic fields

- Industries: Automotive, aerospace, tooling machines, shipbuilding and construction, wind turbine

Architecture

- PERMAS is a modular software system based on a centralized software architecture.

- A hypermatrix storage scheme is used as basis for vectorization and parallelization allowing to adapt matrices to caches und thus for an efficient handling of large simulation models.

- Task Graph based parallelization scheme for hypermatrix operations with asynchronous I/O and in combination with (Nvidia) GPU.

- Specific algorithms e.g. for contact analysis, coupled fluid-structure interaction[18] and model testing.

- Integrated optimization methods [19] , e.g. topology, shape, dimensioning and their combination, reliability analysis (robust design[20] and sampling(DOE).[21])

Distribution

- Germany: automotive, commercial vehicle- and supplier, mechanical engineering, wind energy

- France: aerospace[22] and shipbuilding [23]

- Italy/Suisse: automotive

- Japan: car- and supplier

- Korea: car

- South Africa: construction

- USA/Brasilia: car- and supplier

- India: car- and supplier

- Czech Republic: engineering services/ supplier

- China: trains, nuclear power

See also

External links

References

- ↑ Permas-Integration bei Dr. Binde Design & Engineering

- ↑ morembs

- ↑ Ast, M. et. al. (2000). "Sparse Matrix Structure for Dynamic Parallelisation Efficiency", In: Bode A., Ludwig T., Karl W., Wismüller R. (eds) Euro-Par 2000 Parallel Processing. Euro-Par 2000. Lecture Notes in Computer Science, vol 1900. Springer, Berlin, Heidelberg

- ↑ Argyris, J. 1969). "ASKA — Automatic System for Kinematic Analysis: A universal system for structural analysis based on the matrix displacement (finite element) method", Nuclear Engineering and Design, 10(4):441-455 https://doi.org/10.1016/0029-5493(69)90080-6

- ↑ https://www.isd.uni-stuttgart.de/

- ↑ Helfrich, R. (1990): "Die Portierung des FEM-Softwaresystems Permas auf verschiedenartige Rechenanlagen.", In: Reuter A. (eds) GI - 20. Jahrestagung I. Informatik-Fachberichte, vol 257. Springer, Berlin, Heidelberg https://doi.org/10.1007/978-3-642-76118-8_46

- ↑ Schulz, U.: PERMAS Version 5 - A New Generation of Finite Element Software, Proc. of the 7th World Congress of Finite Element Methods, Monte-Carlo, Nov. 1993.

- ↑ Ast, M.; Jerez, T.; Labarta, J.; Manz, H.; Perez, A.; Schulz, U.; Sole, J. (1997). "Runtime Parallelization of the Finite Element Code Permas", The International Journal of Supercomputer Applications and High Performance Computing, 11(4):328-335 https://doi.org/10.1177%2F109434209701100406

- ↑ Optiamix.de.

- ↑ Staat, M., Heitzer, M. (1997): "Limit and Shakedown Analysis Using a General Purpose Finite Element Code", Proceedings of NAFEMS World Congress '97 on Design, Simulation & Optimisation : reliability & applicability of computational methods ; Stuttgart, Germany, 9 - 11 April 1997, https://doi.org/10.21269/1557

- ↑ Badia, R.M., Labarta, J., Sirvent, R. et al. "Programming Grid Applications with GRID Superscalar". Journal of Grid Computing 1, 151–170 (2003). https://doi.org/10.1023/B:GRID.0000024072.93701.f3

- ↑ Hosseini, E.; Holdsworth, S.R.; Flueeler, U. (2017): "A temperature-dependent asymmetric constitutive model for cast irons under cyclic loading conditions", 53(2):106-114 https://doi.org/10.1177%2F0309324717749026

- ↑ Helfrich, R.; Marchesini, J. (2014): "Dynamic substructuring with mixed boundary conditions to cope with complex structural assemblies", Proceedings of the 13th European Conference on Spacecraft Structures, Materials & Environmental Testing, held 1-4 April, 2014 in Braunschweig, Germany. ESA-SP Vol. 727, ISBN: 978-92-9221-291-9. Edited by L. Ouwehand, 2014, id. 56

- ↑ Berkemer, J. (Ed.): "Effektive Nutzung des Leistungspotentials von Direktantrieben [Projekt EffeNDi] - Impulsentkopplung, Beschleunigungsregelung, achsübergreifende Regelung und gekoppelte Simulation" Fortschr.-Ber. VDI Reihe 1 Nr. 391. Düsseldorf: VDI Verlag 2006. ISBN:3-18-339101-5, ISSN 0178-949X

- ↑ Beckert, A.; Wendland, H. (2001): "Multivariate interpolation for fluid-structure-interaction problems using radial basis functions", 5(2):125-134 https://doi.org/10.1016/S1270-9638(00)01087-7

- ↑ Kirchgäßner, B. (2016). "Finite elements in rotordynamics", Procedia Engineering, 144:736-750 https://doi.org/10.1016/j.proeng.2016.05.079

- ↑ Gräbner, N. (2016): "Analyse und Verbesserung der Simulationsmethode des Bremsenquietschens". Dissertation TU Berlin https://doi.org/10.14279/depositonce-5577

- ↑ Besnier, F.; Fischer, R.; Kirchgäßner, B, (1999). "Coupled Fluid-Structure Analyses on Parallel Systems", Spacecraft structures, materials and mechanical testing, Proceedings of a European Conference held at Braunschweig, Germany, 4-6 November 1998. Paris: European Space Agency (ESA), ESA-SP, 428

- ↑ Thémiot, C.; Le Gallo, V.; Carrat, J.-M. (2017): "Design optimization and test campaign of a 1/50 th Ariane 5 representative dynamic model subjected to blast waves.", 0.13009/EUCASS2017-80,7th European Conference for Aeronautics and Space Sciences, 3-6 July, Milano, Italy

- ↑ S. Gollwitzer, B. Kirchgäßner, R. Fischer, R. Rackwitz: PERMAS-RA/STRUREL system of programs for probabilistic reliability analysis April 2006 Structural Safety 28(1-2):108-129, https://doi.org/10.1016/j.strusafe.2005.03.008

- ↑ Carvajal, S., Wallner, D., Helfrich, R., and Klein, M., "Excellent Brake NVH Comfort by Simulation - Use of Optimization Methods to Reduce Squeal Noise," SAE Technical Paper 2016-01-1779, 2016, https://doi.org/10.4271/2016-01-1779.

- ↑ Cédric Thémiot*, Vincent Le Gallo** and Jean-Marc Carrat: "Design optimization and test campaign of a 1/50 th ARIANE 5representative dynamic model subjected to blast waves" 0.13009/EUCASS2017-80,7TH EUROPEAN CONFERENCE FOR AERONAUTICS AND SPACE SCIENCES (EUCASS) (2017).

- ↑ T.T. Chau, F. Besnier: Numerical simulation of welding in Shipbuilding,Transactions on the Built Environment vol 68, © 2003 WIT Press, www.witpress.com, ISSN 1743-3509