Biology:Chlorella vulgaris

| Chlorella vulgaris | |

|---|---|

| |

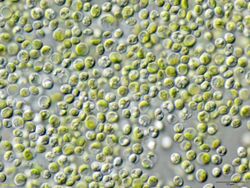

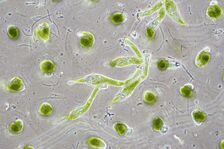

| Chlorella vulgaris on microscope view | |

| Scientific classification | |

| (unranked): | Viridiplantae |

| Division: | Chlorophyta |

| Class: | Trebouxiophyceae |

| Order: | Chlorellales |

| Family: | Chlorellaceae |

| Genus: | Chlorella |

| Species: | C. vulgaris

|

| Binomial name | |

| Chlorella vulgaris Beijerinck 1890

| |

| Varieties | |

| |

| Synonyms[1] | |

| |

Chlorella vulgaris is a species of green microalga in the division Chlorophyta. It is mainly used as a dietary supplement or protein-rich food additive in Japan .

Description

C. vulgaris is a green eukaryotic microalga in the genus Chlorella, which has been present on earth since the Precambrian period.[3] This unicellular alga was discovered in 1890 by Martinus Willem Beijerinck as the first microalga with a well-defined nucleus.[4] At the beginning of the 1990s, German scientists noticed the high protein content of C. vulgaris and began to consider it as a new food source. Japan is currently the largest consumer of Chlorella,[3][5] both for nutritional and therapeutic purposes.[6]

Symbiosis

Chlorella vulgaris occurs as a symbiont in tissues of the freshwater flatworms Dalyellia viridis and Typhloplana viridata.[7]

Production

The world annual production of the various species of Chlorella was 2000 tonnes (dry weight) in 2009, with the main producers being Germany, Japan and Taiwan.[3] C. vulgaris is a candidate for commercial production due to its high resistance against adverse conditions and invading organisms. In addition, the production of the various organic macromolecules of interest (proteins, lipids, starch) differ depending on the technique used to create biomass and can be therefore targeted.[3] Under more hostile conditions, the biomass decreases, but lipids and starch contents increase.[8] Under nutrient and light-replete conditions, protein content increases along with the biomass.[9] Different growth techniques have been developed. Different modes of growth (autotrophic, heterotrophic, and mixotrophic) has been investigated for Chlorella vulgaris; autotrophic growth is favoured as it does not require provision of costly organic carbon and relies on inorganic carbon sources (CO

2, carbonates) and light for photosynthesis.[10]

Chlorella sp. cultivated in digested and membrane-pretreated swine manure is capable of improving the growth medium performance of microalgae cultivations in terms of final biomass productivity, showing that algal growth depends on the turbidity of liquid digestate streams rather than on their nutrient availability.[11]

Uses

Bioremediation

Chlorella vulgaris has been the microalgae of choice for several bioremediation processes. Owing to its ability to remove a variety of pollutants such as inorganic nutrients (nitrate, nitrite, phosphate and ammonium), fertilizers, detergents, heavy metals, pesticides, pharmaceuticals and other emerging pollutants from wastewater and effluents, carbon dioxide and other gaseous pollutants from flue gases, besides having high growth rates and simple cultivation requirements, Chlorella vulgaris has emerged as a potential microorganism in bioremediation studies for mitigation of environmental pollution.[12]

Bioenergy

C. vulgaris is seen as a promising source of bioenergy. It may be a good alternative to biofuel crops, like soybean, corn or rapeseed, as it is more productive and does not compete with food production.[13] It can produce large amount of lipids, up to 20 times more than crops[14] that have a suitable profile for biodiesel production.[15] This microalgae also contains high amounts of starch, good for the production of bioethanol.[3] However, microalgal biofuels are far from competitive with fossil fuels, given their high production costs and controversial sustainability.[3][16]

Food ingredient and dietary supplement

The protein content of C. vulgaris varies from 42 to 58% of its biomass dry weight.[17][18][19][20] These proteins are considered as having a good nutritional quality compared to the standard profile for human nutrition of the World Health Organization and Food and Agriculture Organization, as the algae synthesizes amino acids.[3] The algae also contains lipids (5–40% of the dry mass),[6][17] carbohydrates (12–55% dry weight),[21][22][23] and pigments including chlorophyll, reaching 1–2 % of the dry weight.[24][25]

Containing dietary minerals and vitamins,[3] C. vulgaris is marketed as a dietary supplement, food additive, or food colorant.[26][27] Extracted proteins have been investigated for manufacturing of emulsion and foams.[28] It is not widely incorporated in food products due to its dark green color and smell similar to that of fish.[29] As a dietary supplement, it may be sold as capsules, extracts, tablets or powder.[30][31] Vitamin B12, specifically in the form of methylcobalamin, has been identified in Chlorella vulgaris.[32]

In popular culture

In Alan Dean Foster's short story, "Village of the Chosen", published in The Best of Omni in 1983, a pair of scientists engineer a strain of Chlorella to be in symbiosis with humans, so humans can become photosynthetic.

References

- ↑ "Chlorella vulgaris" (in en). Bethesda, MD: National Center for Biotechnology Information. https://www.ncbi.nlm.nih.gov/Taxonomy/Browser/wwwtax.cgi?mode=Info&id=3077&lvl=3&lin=f&keep=1&srchmode=1&unlock. "Other names: synonym: Chlorella vulgaris var. viridis Chodat includes: Chlorella vulgaris Beijerink IAM C-27 formerly Chlorella ellipsoidea Gerneck IAM C-27"

- ↑ Duval B., Margulis L. (1995). "The microbial community of Ophrydium versatile colonies: endosymbionts, residents, and tenants". Symbiosis 18: 181–210. PMID 11539474.

- ↑ 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7 Safi, C., Zebib, B., Merah, O., Pontalier, P. Y., & Vaca-Garcia, C. (2014). "Morphology, composition, production, processing and applications of Chlorella vulgaris: A review". Renewable and Sustainable Energy Reviews 35: 265–278. doi:10.1016/j.rser.2014.04.007. https://hal.archives-ouvertes.fr/hal-02064882/file/Safi_23269.pdf.

- ↑ Beijerinck, M. W. (1890). "Culturversuche mit Zoochlorellen, Lichenengonidien und anderen niederen Algen". Bot. Zeitung 48: 781–785.

- ↑ Kitada, K., Machmudah, S., Sasaki, M., Goto, M., Nakashima, Y., Kumamoto, S., & Hasegawa, T. (2009). "Supercritical CO2 extraction of pigment components with pharmaceutical importance from Chlorella vulgaris". Journal of Chemical Technology and Biotechnology 84 (5): 657–661. doi:10.1002/jctb.2096.

- ↑ 6.0 6.1 Freitas, Hércules Rezende (2017-08-25). "Chlorella vulgaris as a Source of Essential Fatty Acids and Micronutrients: A Brief Commentary". The Open Plant Science Journal 10 (1). doi:10.2174/1874294701710010092. https://benthamopen.com/ABSTRACT/TOPSJ-10-92.

- ↑ Young, J. O. (2001). Keys to the freshwater microturbellarians of Britain and Ireland. Ambleside: Freshwater Biological Association. pp. 92.

- ↑ Přibyl, P., Cepak, V., & Zachleder, V. (2012). "Production of lipids in 10 strains of Chlorella and Parachlorella, and enhanced lipid productivity in Chlorella vulgaris". Applied Microbiology and Biotechnology 94 (2): 549–61. doi:10.1007/s00253-012-3915-5. PMID 22361856.

- ↑ Yuvraj; Ambarish Sharan Vidyarthi; Jeeoot Singh (2016). "Enhancement of Chlorella vulgaris cell density: Shake flask and bench-top photobioreactor studies to identify and control limiting factors". Korean Journal of Chemical Engineering 33 (8): 2396–2405. doi:10.1007/s11814-016-0087-5. https://doi.org/10.1007/s11814-016-0087-5.

- ↑ Yuvraj; Padmini Padmanabhan (2017). "Technical insight on the requirements for CO

2-saturated growth of microalgae in photobioreactors". 3 Biotech 07 (2): 119. doi:10.1007/s13205-017-0778-6. PMID 28567633. PMC 5451369. https://doi.org/10.1007/s13205-017-0778-6. - ↑ Ledda, Claudio; Ida, Antonio; Allemand, Donatella; Mariani, Paola (November 1, 2015). "Production of wild Chlorella sp. cultivated in digested and membrane-pretreated swine manure derived from a full-scale operation plant" (PDF). Algal Research 12: Abstract, 70. doi:10.1016/j.algal.2015.08.010. ISSN 2211-9264. OCLC 5878756379. https://www.researchgate.net/publication/281314164.

- ↑ "Microalgal Bioremediation: A Clean and Sustainable Approach for Controlling Environmental Pollution" (in en). Innovations in Environmental Biotechnology. 1. Singapore: Springer Singapore. 2022. pp. 305–318. doi:10.1007/978-981-16-4445-0_13. ISBN 978-981-16-4445-0.

- ↑ Singh, A., Nigam, P. S., & Murphy, J. D. (2011). "Renewable fuels from algae: An answer to debatable land based fuels". Bioresource Technology 102 (1): 10–16. doi:10.1016/j.biortech.2010.06.032. PMID 20615690.

- ↑ Demirbas, M. F. (2011). "Biofuels from algae for sustainable development". Applied Energy 88 (10): 3473–3480. doi:10.1016/j.apenergy.2011.01.059.

- ↑ Wang, K. G., Brown, R. C., Homsy, S., Martinez, L., & Sidhu, S. S. (2013). "Fast pyrolysis of microalgae remnants in a fluidized bed reactor for bio-oil and biochar production". Bioresource Technology 127: 494–499. doi:10.1016/j.biortech.2012.08.016. PMID 23069615.

- ↑ Lavars, Nick (2019-09-19). "Algae-fueled bioreactor soaks up CO

2 400x more effectively than trees" (in en). https://newatlas.com/environment/algae-fueled-bioreactor-carbon-sequestration/. - ↑ 17.0 17.1 Becker, E. W. (1994). Microalgae: biotechnology and microbiology. Vol. 10. Cambridge University Press.

- ↑ Morris, H. J., Almarales, A., Carrillo, O., & Bermúdez, R. C. (2008). "Utilisation of Chlorella vulgaris cell biomass for the production of enzymatic protein hydrolysates". Bioresource Technology 99 (16): 7723–7729. doi:10.1016/j.biortech.2008.01.080. PMID 18359627.

- ↑ Servaites, J. C., Faeth, J. L., & Sidhu, S. S. (2012). "A dye binding method for measurement of total protein in microalgae". Analytical Biochemistry 421 (1): 75–80. doi:10.1016/j.ab.2011.10.047. PMID 22138185.

- ↑ Seyfabadi, J., Ramezanpour, Z., & Khoeyi, Z. A. (2011). "Protein, fatty acid, and pigment content of Chlorella vulgaris under different light regimes". Journal of Applied Phycology 23 (4): 721–726. doi:10.1007/s10811-010-9569-8.

- ↑ Brányiková, I., Maršálková, B., Doucha, J., Brányik, T., Bišová, K., Zachleder, V., & Vítová, M. (2011). "Microalgae—novel highly efficient starch producers". Biotechnology and Bioengineering 108 (4): 766–776. doi:10.1002/bit.23016. PMID 21404251.

- ↑ Choix, F. J., de-Bashan, L. E., & Bashan, Y. (2012). "Enhanced accumulation of starch and total carbohydrates in alginate-immobilized Chlorella spp. induced by Azospirillum brasilense: II. Heterotrophic conditions". Enzyme and Microbial Technology 51 (5): 300–309. doi:10.1016/j.enzmictec.2012.07.013. PMID 22975128.

- ↑ Fernandes, B., Dragone, G., Abreu, A. P., Geada, P., Teixeira, J., & Vicente, A. (2012). "Starch determination in Chlorella vulgaris—a comparison between acid and enzymatic methods". Journal of Applied Phycology 24 (5): 1203–1208. doi:10.1007/s10811-011-9761-5.

- ↑ de-Bashan, L. E., Bashan, Y., Moreno, M., Lebsky, V. K., & Bustillos, J. J. (2002). "Increased pigment and lipid content, lipid variety, and cell and population size of the microalgae Chlorella spp. when co-immobilized in alginate beads with the microalgae-growth-promoting bacterium Azospirillum brasilense". Canadian Journal of Microbiology 48 (6): 514–521. doi:10.1139/w02-051. PMID 12166678.

- ↑ Gonzalez, L. E., & Bashan, Y. (2000). "Increased growth of the microalga Chlorella vulgaris when coimmobilized and cocultured in alginate beads with the plant-growth-promoting bacterium Azospirillum brasilense". Applied and Environmental Microbiology 66 (4): 1527–1531. doi:10.1128/aem.66.4.1527-1531.2000. PMID 10742237. Bibcode: 2000ApEnM..66.1527G.

- ↑ Fradique, M., Batista, A. P., Nunes, M. C., Gouveia, L., Bandarra, N. M., & Raymundo, A. (2010). "Incorporation of Chlorella vulgaris and Spirulina maxima biomass in pasta products. Part 1: Preparation and evaluation". Journal of the Science of Food and Agriculture 90 (10): 1656–1664. doi:10.1002/jsfa.3999. PMID 20564448. Bibcode: 2010JSFA...90.1656F.

- ↑ Li, H.-B., Jiang, Y., & Chen, F. (2002). "Isolation and purification of lutein from the microalga Chlorella vulgaris by extraction after saponification". Journal of Agricultural and Food Chemistry 50 (5): 1070–1072. doi:10.1021/jf010220b. PMID 11853482.

- ↑ Bertsch, Pascal; Böcker, Lukas; Mathys, Alexander; Fischer, Peter (February 2021). "Proteins from microalgae for the stabilization of fluid interfaces, emulsions, and foams". Trends in Food Science & Technology 108: 326–342. doi:10.1016/j.tifs.2020.12.014.

- ↑ Becker, E. (2007). "Micro-algae as a source of protein". Biotechnology Advances 25 (2): 207–210. doi:10.1016/j.biotechadv.2006.11.002. PMID 17196357.

- ↑ Liang, S., Liu, X., Chen, F., & Chen, Z. (2004). Ang, Put O. ed. Current microalgal health food R & D activities in China. Asian Pacific Phycology in the 21st Century: Prospects and Challenges. pp. 45–48. doi:10.1007/978-94-007-0944-7. ISBN 978-94-007-0944-7.

- ↑ Yamaguchi, K. (1996). "Recent advances in microalgal bioscience in Japan, with special reference to utilization of biomass and metabolites: a review". Journal of Applied Phycology 8 (6): 487–502. doi:10.1007/BF02186327.

- ↑ Kumudha A, Selvakumar S, Dilshad P, Vaidyanathan G, Thakur MS, Sarada R. (2015). "Methylcobalamin--a form of vitamin B12 identified and characterised in Chlorella vulgaris". Journal of Food Chemistry 170: 316–320. doi:10.1016/j.foodchem.2014.08.035. PMID 25306351.

Wikidata ☰ Q309972 entry

|