Chemistry:Inverse vulcanization

Inverse vulcanization is a process that produces polysulfide polymers, which also contain some organic linkers.[1] In contrast, sulfur vulcanization produces material that is predominantly organic but has a small percentage of polysulfide crosslinks.

Synthesis

Like Thiokols and sulfur-vulcanization, inverse vulcanization uses the tendency of sulfur catenate. The polymers produced by inverse vulcanization consist of long sulfur linear chains interspersed with organic linkers. Traditional sulfur vulcanization produces a cross-linked material with short sulfur bridges, down to one or two sulfur atoms.

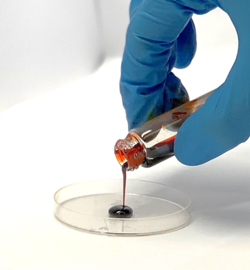

The polymerization process begins with the heating of elemental sulfur above its melting point (115.21 °C), to favor the ring-opening polymerization process (ROP) of the S8 monomer, occurring at 159 °C. As a result, the liquid sulfur is constituted by linear polysulfide chains with diradical ends, which can be easily bridged together with small dienes, such as 1,3-Diisopropylbenzene(DIB),[1] 1,4-diphenylbutadiyne,[2] limonene,[3] divinylbenzene (DVB),[4] dicyclopentadiene,[5] styrene,[6] 4-vinylpyridine,[7] cycloalkene[8] and ethylidene norbornene,[9] or longer organic molecules as polybenzoxazines,[10] squalene[11] and triglyceride.[12] Chemically, the diene carbon-carbon double bond (C=C) of the substitutional group disappears, forming the carbon-sulfur single bond (C-S) which binds together the sulfur linear chains. The advantage of such a polymerization is the absence of a solvent; Sulphur acts as comonomer and solvent. This makes the process highly scalable at the industrial level, and kilogram-scale synthesis of the poly(S-r-DIB) has already been accomplished.[13]

Products, characterization and properties

Vibrational spectroscopy was performed to investigate the chemical structure of the copolymers, and the presence of the C-S bonds was detected through Infrared or Raman spectroscopies.[14] The high amount of S-S bonds makes the copolymer highly IR-inactive in the near and mid-infrared spectrum. As a consequence, sulfur-rich materials made via inverse vulcanization are characterized by a high refractive index (n~1.8), whose value depends again upon the composition and crosslinking species.[15] As shown by thermogravimetric analysis (TGA), the copolymer thermal stability increases with the amount of added crosslinker; however, all the tested compositions degrade above 222 °C.[2][4]

Copolymer behavior included that, the glass-transition temperature depends upon the composition and crosslinking species. For given comonomers, the behavior of the copolymers as a function of the temperature depends on the chemical composition; for example, the poly (sulfur-random-divinylbenzene) behaves as a plastomer for a diene content between 15-25%wt, and as a viscous resin with the 30–35%wt of DVB. On the other hand, the poly (sulfur-random-1,3-diisopropenylbenzene) acts as thermoplastic at 15–25%wt of DIB, while it becomes a thermoplastic-thermosetting polymer for a diene concentration of 30-35%wt.[16] The potential to break and reform the chemical bonds along the polysulfide chains (S-S) allows the repair of the copolymer by simply heating above 100 °C. This increases the ability to reform and recycle the high molecular weight copolymer.[17]

Potential applications

The sulfur-rich copolymers made via inverse vulcanization could in principle find diverse applications due to their simple synthesis process and thermoplasticity.

Lithium-sulfur batteries

This new way of sulfur processing has been exploited for the cathode preparation of long-cycling lithium-sulfur batteries. Such electrochemical systems are characterized by a greater energy density than commercial Li-ion batteries, but they are not stable for long service life. Simmonds et al. first demonstrated improved capacity retention for over 500 cycles with an inverse vulcanization copolymer, suppressing the typical capacity fading of sulfur-polymer composites.[18] The poly (sulfur-random-1,3-diisopropenylbenzene), briefly defined as poly (S-r-DIB), showed a higher composition homogeneity compared with other cathodic materials, together with greater sulfur retention and an enhanced adjustment of the polysulfides' volume variations. These advantages made it possible to assemble a stable and durable Li-S cell. Subsequently, other copolymers were synthesized via inverse vulcanization and tested inside these electrochemical devices, again providing high stability over their cycles.

| Cathode | Date | Source | Specific Capacity after cycling |

|---|---|---|---|

| Poly (sulfur-random-1,3-diisopropylbenzene) | 2014 | University of Arizona[18] | 800 mA⋅h/g after 300 cycles (at 0.1 C) |

| Poly (sulfur-random-1,4-Diphenyl-1,3-butadiene) | 2015 | University of Arizona[2] | 800 mA⋅h/g after 300 cycles (at 0.2 C) |

| Poly (sulfur-random-divinylbenzene) | 2016 | University of the Basque Country[19] | 700 mA⋅h/g after 500 cycles (at 0.25 C) |

| Poly (sulfur-random-diallyl disulfide) | 2016 | University of the Basque Country[20] | 616 mA⋅h/g after 200cycles (at 0.2 C) |

| Poly (sulfur-random-bismaleimide-divinylbenzene) | 2016 | Istanbul Technical University[21] | 400 mA⋅h/g after 50 cycles (at 0.1 C) |

| Poly (sulfur-random-styrene) | 2017 | University of Arizona[6] | 485 mA⋅h/g after 1000 cycles (at 0.2 C) |

In order to overcome the disadvantages related to the materials' low electrical conductivity (1015–1016 Ω·cm),[16] researchers have started to add special carbon-based particles to increase electron transport inside the copolymer. Furthermore, such carbonaceous additives improve the polysulfides' retention at the cathode through the polysulfides-capturing effect, increasing the battery performances. Examples of employed nanostructures are long carbon nanotubes,[22] graphene,[11] and carbon onions.[23]

Capturing Mercury

The new materials could be used to remove toxic metals from soil or water. Pure sulfur cannot be employed to manufacture a functional filter because of its low mechanical properties; therefore, inverse vulcanization was investigated to produce porous materials, in particular for the mercury capturing process. The liquid metal binds together with the sulfur-rich copolymer, remaining mostly inside the filter.[3][24][25]

Infrared transmission

Sulfur-rich copolymers, made via inverse vulcanization, have advantages over traditional IR optical materials due to the simple manufacturing process, low cost reagents, and high refractive index. As mentioned before, the latter depends upon the S-S bonds concentration, leading to the ability to tune the optical properties of the material by modifying the chemical formulation. The ability to change the material's refractive index to fulfill the specific application requirements makes these copolymers applicable in military, civil or medical fields.[15][26][27][28]

Others

The inverse vulcanization process can also be employed for the synthesis of activated carbon with narrow pore-size distributions. The sulfur-rich copolymer acts as a template where the carbons are produced. The final material is doped with sulfur and exhibits a micro-porous network and high gas selectivity. Therefore, inverse vulcanization could also be used for gas separation applications.[29]

See also

- Sulfur

- Free-radical polymerization

- Lithium-sulfur batteries

References

- ↑ 1.0 1.1 Chung, Woo Jin; Griebel, Jared J.; Kim, Eui Tae; Yoon, Hyunsik; Simmonds, Adam G.; Ji, Hyun Jun; Dirlam, Philip T.; Glass, Richard S. et al. (14 April 2013). "The use of elemental sulfur as an alternative feedstock for polymeric materials". Nature Chemistry 5 (6): 518–524. doi:10.1038/NCHEM.1624. PMID 23695634. Bibcode: 2013NatCh...5..518C.

- ↑ 2.0 2.1 2.2 Dirlam, Philip T.; Simmonds, Adam G.; Kleine, Tristan S.; Nguyen, Ngoc A.; Anderson, Laura E.; Klever, Adam O.; Florian, Alexander; Costanzo, Philip J. et al. (2015). "Inverse vulcanization of elemental sulfur with 1,4-diphenylbutadiyne for cathode materials in Li–S batteries". RSC Advances 5 (31): 24718–24722. doi:10.1039/c5ra01188d. Bibcode: 2015RSCAd...524718D.

- ↑ 3.0 3.1 Crockett, Michael P.; Evans, Austin M.; Worthington, Max J. H.; Albuquerque, Inês S.; Slattery, Ashley D.; Gibson, Christopher T.; Campbell, Jonathan A.; Lewis, David A. et al. (26 January 2016). "Sulfur-Limonene Polysulfide: A Material Synthesized Entirely from Industrial By-Products and Its Use in Removing Toxic Metals from Water and Soil". Angewandte Chemie International Edition 55 (5): 1714–1718. doi:10.1002/anie.201508708. PMID 26481099.

- ↑ 4.0 4.1 Salman, Mohamed Khalifa; Karabay, Baris; Karabay, Lutfiye Canan; Cihaner, Atilla (20 July 2016). "Elemental sulfur-based polymeric materials: Synthesis and characterization". Journal of Applied Polymer Science 133 (28). doi:10.1002/app.43655.

- ↑ Parker, D. J.; Jones, H. A.; Petcher, S.; Cervini, L.; Griffin, J. M.; Akhtar, R.; Hasell, T. (2017). "Low cost and renewable sulfur-polymers by inverse vulcanisation, and their potential for mercury capture". Journal of Materials Chemistry A 5 (23): 11682–11692. doi:10.1039/C6TA09862B. https://eprints.lancs.ac.uk/id/eprint/87095/1/Sulfur_polymers_JmatchemA_resubmission_CHANGES_ACCEPTED.pdf.

- ↑ 6.0 6.1 Zhang, Yueyan; Griebel, Jared J.; Dirlam, Philip T.; Nguyen, Ngoc A.; Glass, Richard S.; Mackay, Michael E.; Char, Kookheon; Pyun, Jeffrey (1 January 2017). "Inverse vulcanization of elemental sulfur and styrene for polymeric cathodes in Li-S batteries". Journal of Polymer Science Part A: Polymer Chemistry 55 (1): 107–116. doi:10.1002/pola.28266. Bibcode: 2017JPoSA..55..107Z.

- ↑ Berk, Hasan; Balci, Burcu; Ertan, Salih; Kaya, Murat; Cihaner, Atilla (June 2019). "Functionalized polysulfide copolymers with 4-vinylpyridine via inverse vulcanization". Materials Today Communications 19: 336–341. doi:10.1016/j.mtcomm.2019.02.014.

- ↑ Omeir, Meera Y.; Wadi, Vijay S.; Alhassan, Saeed M. (January 2020). "Inverse vulcanized sulfur–cycloalkene copolymers: Effect of ring size and unsaturation on thermal properties". Materials Letters 259: 126887. doi:10.1016/j.matlet.2019.126887.

- ↑ Smith, Jessica A.; Wu, Xiaofeng; Berry, Neil G.; Hasell, Tom (15 August 2018). "High sulfur content polymers: The effect of crosslinker structure on inverse vulcanization". Journal of Polymer Science Part A: Polymer Chemistry 56 (16): 1777–1781. doi:10.1002/pola.29067. PMID 30333680. Bibcode: 2018JPoSA..56.1777S.

- ↑ Arslan, Mustafa; Kiskan, Baris; Yagci, Yusuf (22 January 2016). "Combining Elemental Sulfur with Polybenzoxazines via Inverse Vulcanization". Macromolecules 49 (3): 767–773. doi:10.1021/acs.macromol.5b02791. Bibcode: 2016MaMol..49..767A.

- ↑ 11.0 11.1 Sahu, Tuhin Subhra; Choi, Sinho; Jaumaux, Pauline; Zhang, Jinqiang; Wang, Chengyin; Zhou, Dong; Wang, Guoxiu (April 2019). "Squalene-derived sulfur-rich copolymer@ 3D graphene-carbon nanotube network cathode for high-performance lithium-sulfur batteries". Polyhedron 162: 147–154. doi:10.1016/j.poly.2019.01.068.

- ↑ Tikoalu, Alfrets D.; Lundquist, Nicholas A.; Chalker, Justin M. (13 February 2020). "Mercury Sorbents Made By Inverse Vulcanization of Sustainable Triglycerides: The Plant Oil Structure Influences the Rate of Mercury Removal from Water". Advanced Sustainable Systems 4 (3): 1900111. doi:10.1002/adsu.201900111.

- ↑ Griebel, Jared J.; Li, Guoxing; Glass, Richard S.; Char, Kookheon; Pyun, Jeffrey (15 January 2015). "Kilogram scale inverse vulcanization of elemental sulfur to prepare high capacity polymer electrodes for Li-S batteries". Journal of Polymer Science Part A: Polymer Chemistry 53 (2): 173–177. doi:10.1002/pola.27314. Bibcode: 2015JPoSA..53..173G.

- ↑ Bastian, Ernest J.; Martin, R. Bruce (April 1973). "Disulfide vibrational spectra in the sulfur-sulfur and carbon-sulfur stretching region". The Journal of Physical Chemistry 77 (9): 1129–1133. doi:10.1021/j100628a010.

- ↑ 15.0 15.1 Griebel, Jared J.; Namnabat, Soha; Kim, Eui Tae; Himmelhuber, Roland; Moronta, Dominic H.; Chung, Woo Jin; Simmonds, Adam G.; Kim, Kyung-Jo et al. (May 2014). "New Infrared Transmitting Material via Inverse Vulcanization of Elemental Sulfur to Prepare High Refractive Index Polymers". Advanced Materials 26 (19): 3014–3018. doi:10.1002/adma.201305607. PMID 24659231.

- ↑ 16.0 16.1 Diez, Sergej; Hoefling, Alexander; Theato, Patrick; Pauer, Werner (15 February 2017). "Mechanical and Electrical Properties of Sulfur-Containing Polymeric Materials Prepared via Inverse Vulcanization". Polymers 9 (12): 59. doi:10.3390/polym9020059. PMID 30970741.

- ↑ Chalker, Justin M.; Worthington, Max J. H.; Lundquist, Nicholas A.; Esdaile, Louisa J. (20 May 2019). "Synthesis and Applications of Polymers Made by Inverse Vulcanization". Topics in Current Chemistry 377 (3): 16. doi:10.1007/s41061-019-0242-7. PMID 31111247.

- ↑ 18.0 18.1 Simmonds, Adam G.; Griebel, Jared J.; Park, Jungjin; Kim, Kwi Ryong; Chung, Woo Jin; Oleshko, Vladimir P.; Kim, Jenny; Kim, Eui Tae et al. (20 February 2014). "Inverse Vulcanization of Elemental Sulfur to Prepare Polymeric Electrode Materials for Li–S Batteries". ACS Macro Letters 3 (3): 229–232. doi:10.1021/mz400649w. PMID 35590512.

- ↑ Gomez, Iñaki; Mecerreyes, David; Blazquez, J. Alberto; Leonet, Olatz; Ben Youcef, Hicham; Li, Chunmei; Gómez-Cámer, Juan Luis; Bondarchuk, Oleksandr et al. (October 2016). "Inverse vulcanization of sulfur with divinylbenzene: Stable and easy processable cathode material for lithium-sulfur batteries". Journal of Power Sources 329: 72–78. doi:10.1016/j.jpowsour.2016.08.046. Bibcode: 2016JPS...329...72G.

- ↑ Gomez, Iñaki; Leonet, Olatz; Blazquez, J. Alberto; Mecerreyes, David (20 December 2016). "Inverse Vulcanization of Sulfur using Natural Dienes as Sustainable Materials for Lithium-Sulfur Batteries". ChemSusChem 9 (24): 3419–3425. doi:10.1002/cssc.201601474. PMID 27910220.

- ↑ Arslan, Mustafa; Kiskan, Baris; Cengiz, Elif Ceylan; Demir-Cakan, Rezan; Yagci, Yusuf (July 2016). "Inverse vulcanization of bismaleimide and divinylbenzene by elemental sulfur for lithium sulfur batteries". European Polymer Journal 80: 70–77. doi:10.1016/j.eurpolymj.2016.05.007.

- ↑ Tiwari, Vimal K.; Song, Hyeonjun; Oh, Yeonjae; Jeong, Youngjin (March 2020). "Synthesis of sulfur-co-polymer/porous long carbon nanotubes composite cathode by chemical and physical binding for high performance lithium-sulfur batteries". Energy 195: 117034. doi:10.1016/j.energy.2020.117034.

- ↑ Choudhury, Soumyadip; Srimuk, Pattarachai; Raju, Kumar; Tolosa, Aura; Fleischmann, Simon; Zeiger, Marco; Ozoemena, Kenneth I.; Borchardt, Lars et al. (2018). "Carbon onion/sulfur hybrid cathodes inverse vulcanization for lithium–sulfur batteries". Sustainable Energy & Fuels 2 (1): 133–146. doi:10.1039/c7se00452d.

- ↑ Hasell, T.; Parker, D. J.; Jones, H. A.; McAllister, T.; Howdle, S. M. (2016). "Porous inverse vulcanised polymers for mercury capture". Chemical Communications 52 (31): 5383–5386. doi:10.1039/c6cc00938g. PMID 26931278.

- ↑ Parker, D. J.; Jones, H. A.; Petcher, S.; Cervini, L.; Griffin, J. M.; Akhtar, R.; Hasell, T. (2017). "Low cost and renewable sulfur-polymers by inverse vulcanisation, and their potential for mercury capture". Journal of Materials Chemistry A 5 (23): 11682–11692. doi:10.1039/c6ta09862b. https://eprints.lancs.ac.uk/id/eprint/87095/1/Sulfur_polymers_JmatchemA_resubmission_CHANGES_ACCEPTED.pdf.

- ↑ Baumgartner, Thomas; Jäkle, Frieder (19 December 2017). Main group strategies towards functional hybrid materials. Wiley. ISBN 9781119235972.

- ↑ Griebel, Jared J.; Nguyen, Ngoc A.; Namnabat, Soha; Anderson, Laura E.; Glass, Richard S.; Norwood, Robert A.; Mackay, Michael E.; Char, Kookheon et al. (16 August 2015). "Dynamic Covalent Polymers via Inverse Vulcanization of Elemental Sulfur for Healable Infrared Optical Materials". ACS Macro Letters 4 (9): 862–866. doi:10.1021/acsmacrolett.5b00502. PMID 35596448.

- ↑ Kleine, Tristan S.; Nguyen, Ngoc A.; Anderson, Laura E.; Namnabat, Soha; LaVilla, Edward A.; Showghi, Sasaan A.; Dirlam, Philip T.; Arrington, Clay B. et al. (23 September 2016). "High Refractive Index Copolymers with Improved Thermomechanical Properties via the Inverse Vulcanization of Sulfur and 1,3,5-Triisopropenylbenzene". ACS Macro Letters 5 (10): 1152–1156. doi:10.1021/acsmacrolett.6b00602. PMID 35658175.

- ↑ Bear, Joseph C.; McGettrick, James D.; Parkin, Ivan P.; Dunnill, Charles W.; Hasell, Tom (September 2016). "Porous carbons from inverse vulcanised polymers". Microporous and Mesoporous Materials 232: 189–195. doi:10.1016/j.micromeso.2016.06.021. https://cronfa.swan.ac.uk/Record/cronfa29226.

External links

- "New “inverse vulcanization” process produces polymeric sulfur that can function as high performance electrodes for Li-S batteries". 15 April 2013.

|