Chemistry:Shrinkage (fabric)

Shrinkage (in fabric) is a parameter of testing textile fabrics to measure changes in length and width after washing. Shrinkage failing materials are dimensionally unstable and they can cause deforming of the garments or products made out of those materials. Shrinkage is tested at various stages, but most importantly before cutting the fabric into further sewn products and after cutting and sewing prior to supplying the products to buyers and end users. It is a required parameter of quality control to ensure the sizes of the products to avoid any complaints regarding deformation or change in dimensions after domestic laundry.[1] The tests[2] are conducted with provided specifications of buyers imitating the same conditions like washing cycle time, temperature and water ratio and fabric load and sometimes top loading and front loading washing machines are chosen to authenticate the test and assurance of the results. This procedure[3] provides standard and alternate home laundering conditions using an automatic washing machine. While the procedure includes several options, it is not possible to include every existing combination of laundering parameters. The test is applicable to all fabrics and end products suitable for home laundering.

Types of shrinkage

Shrinkage is a change in dimensions across the length and width of the fabric after washing, usage and when exposed to relaxing of fabrics. Mainly shrinkage is of two types one is minus shrinkage and other is plus shrinkage. Skew (twisting of the vertical grains) is also observed along with shrinkage. Abnormal twisting is also considered as a non-conformity.

- Contraction: Any noticeable decrease in dimensions is known as Contraction(minus) shrinkage.

- Expansion: Any noticeable increase or expansion in dimension is known as Expansion (plus) shrinkage.

Causes

- Composition and properties of the fibres[4]

Composition and content determine the type and percentage of fibres. Natural fibres shrink more than synthetic fibres. Synthetic fibres are more stable due to their crystalline and thermoplastic nature. They do not shrink, whereas natural fibres are more prone to shrink because of more amorphous region in their fibre structure which allows more absorption of water, swelling of fibres and increased lubricity increases the shrinking tendency. Blended fabrics normally synthetic and natural are also considered more stable.

- Structure of the fabric/ knit or weave, loose and tight structure

This factor also plays a vital role in the shrinking of the products. The products which are loosely woven or knitted are prone to shrink more and tightly knitted and woven products are more stable. The main reason is that knitted fabrics shrinkage is because they are made by interlooping the yarn which is comparatively a loose and flexible structure whereas woven are considered more stable and less sensitive to shrinkage.

- Finishing applications and procedures

Fibres to fabric conversion implies many mechanical tensions and forces during manufacturing, which includes following steps for fibre to yarn conversion with spinning then fabric with weaving, knitting. When the products are immersed in water, the water acts as a relaxing medium and all stresses and strains get relaxed and try to come back to its original relaxed state. Even after finishing with sophisticated finishing machines some residual shrinkage remains, which is carried forward to the garment stage. This residual shrinkage may cause deformity or de-shaping of the products after domestic laundry. There are certain acceptance limits of shrinkage levels for every product. Abnormal shrinkage levels are considered a non-conformity to quality standards.

Test methods

The different test methods are used as per the final destination of the product (Europe, U.S.A., etc) and the expected washing or laundry methods in practice. Mainly I.S.O. and AATCC standards are used for shrinkage testing. There are few brands which are customizing the test method as per their quality norms. Test Method(s)[5]:

- AATCC Test Method 135

- AATCC Test Method 150

- ISO 6330

- CAN/CGSB 58

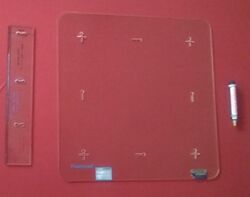

AATCC Test Method 135, Dimensional Change of Fabrics After Home Laundering Scope: Determines the dimensional changes of garments when subjected to home laundering procedures used by consumers. The method is for fabric not yet made into a garment. A sample is marked with benchmarks before home laundering. Then it is laundered 3 times total, then the benchmarks are measured again. Before and after laundering benchmarks are compared.

AATCC Test Method 150, Dimensional Change of Fabrics After Home Laundering Scope: Determines the dimensional changes of garments when subjected to home laundering procedures used by consumers.

Importance

Shrinkage has great importance because any expansion or shrinkage can deform the product which could be a serious concern for end-user and brand can lose its reputation.

Shrinkage controlling methods

There are various procedures to minimise the residual shrinkage of the fabrics, it begins with right selection of yarn count or denier to achieve particular g.s.m(Grams per square meters),Right selection of tightness factor of loops (which is called loop length then chemical procedures like mercerising of cotton,Resin[6] of cotton in case of woven materials, Pre-heat-setting and post-heat setting of synthetic and blended fabrics( Heat setting[7] is a thermal process taking place mostly in either a steam atmosphere or a dry heat environment. The effect of the process gives fibers, yarns or fabric dimensional stability). Finishing on machines like sanphorizing[8] Mechanical shrinking (sometimes referred to as sanforizing), whereby the fabric is forced to shrink width and/or lengthwise, creates a fabric in which any residual tendency to shrink after subsequent laundering is minimal compacting[9] machines. For wool garments, shrinkage is due to scales on the fibers which heat, water and agitation cause to stick together. Other fabrics are stretched by mechanical forces during production, and can shrink slightly when heated (though to a lesser degree than wool). Some clothes are shrunk in the factory to avoid this problem.[10]

See also

- List of laundry topics

- https://sciencetrends.com/science-behind-clothes-shrink-polyester-viscose-cotton

References

- ↑ "Laundry". 24 December 2018. https://en.wikipedia.org/w/index.php?title=Laundry&oldid=875226966. Retrieved 21 January 2019.

- ↑ "AATCC Test Methods, Technical Manual & Standards". https://www.aatcc.org/test/methods/. Retrieved 21 January 2019.

- ↑ "LP1 Home Laundering: Machine Washing". https://members.aatcc.org/store/lp001/2212/. Retrieved 21 January 2019.

- ↑ "Fiber". 24 December 2018. https://en.wikipedia.org/w/index.php?title=Fiber&oldid=875172967. Retrieved 21 January 2019.

- ↑ "AATCC, ISO and CAN/CGSB 58 Dimensional Change/ Stability (Shrinkage) Test". http://www.manufacturingsolutionscenter.org/dimensional-change-stability-shrinkage.html. Retrieved 21 January 2019.

- ↑ https://thebusinesstactics.com/519691/global-urea-formaldehyde-resin-market-2025-company-and-financial-overview-product-portfolio-business-strategies-and-recent-developments/

- ↑ "Heatsetting". 17 December 2018. https://en.wikipedia.org/w/index.php?title=Heatsetting&oldid=874228308. Retrieved 21 January 2019.

- ↑ "Sanforization". 28 December 2018. https://en.wikipedia.org/w/index.php?title=Sanforization&oldid=875737998. Retrieved 21 January 2019.

- ↑ "Calendering (textiles)". 16 January 2019. https://en.wikipedia.org/w/index.php?title=Calendering_(textiles)&oldid=878662193. Retrieved 21 January 2019.

- ↑ "Why Clothes Shrink". https://www.npr.org/templates/transcript/transcript.php?storyId=98759520.