Chemistry:Tantalum–tungsten alloys

Tantalum–tungsten alloys are in the refractory metals group that maintain useful physical and chemical properties even at high temperatures. The tantalum–tungsten alloys are characterized by their high melting point and the tension resistance. The properties of the final alloy are a combination of properties from the two elements: tungsten, the element with the highest melting point in the periodic table, and tantalum which has high corrosion resistance.[1][2] The tantalum–tungsten alloys typically vary in their percentage of tungsten. Some common variants are:

- (Ta – 2.5% W) → also called 'tantaloy 63 metal.' The percentage of tungsten is about 2 to 3% and includes 0.5% of niobium. This alloy has a good resistance to corrosion and performs well at high temperatures. An example application is piping in chemical industries.[1]

- (Ta - 7.5% W) → also called 'tantaloy 61 metal,' has between 7 and 8% tungsten. The difference from this alloy to the others is that this alloy represents a high resilience modulus while maintaining its refractory properties.[1]

- (Ta - 10% W) → also called 'tantaloy 60 metal,' contains 9 to 11% tungsten. This alloy is less ductile than the other alloys and exhibits less plasticity. Applications include high-temperature, high-corrosion environments such as aerospace components, furnaces, and piping in nuclear plants.[1]

Mechanical properties

The alloys of tantalum–tungsten have high corrosion resistance, and refractory properties. The crystalline structure of the material is body-centered cubic with a substitutional solid solution with atoms of tungsten. The alloy also has a high melting point and can reach high elastic modulus and high tensile strength.[3]

| Alloys | Hardness (HV) | Density (g/cm3) | Melting point (oc) | Tensile strength (MPa) | Yield Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|---|

| Ta – 2.5% W | 130 | 16.7 | 3005 | 345 | 230 | 195 |

| Ta – 7.5% W | 245 | 16.8 | 3030 | 550 | 460 | 205 |

| Ta – 10% W | 325–400 | 16.8 | 3025 | 1035–1165 | 875–1005 | 200 |

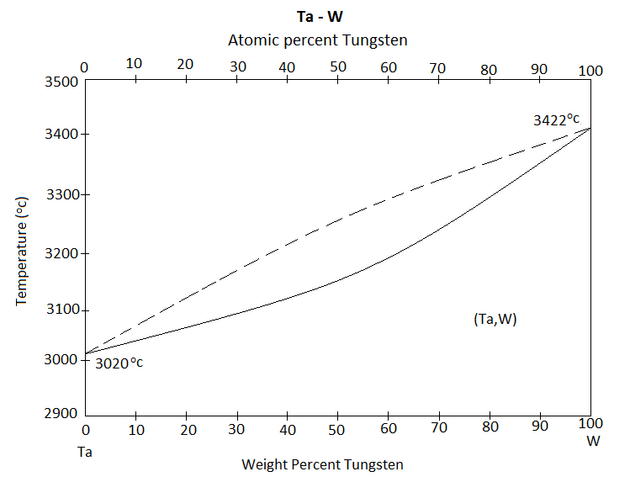

Phase diagram

The equilibrium phase diagram of the alloy formed between the two components tantalum and tungsten is a binary diagram, where the two components are totally soluble on each other. In this diagram the melting temperature of the two elements are shown. It can be seen that there are two lines, representing the solidus and liquidus.[3]

References

- ↑ Jump up to: 1.0 1.1 1.2 1.3 1.4 ASM Handbook. Properties and Selection Nonferrous Alloys and Special-Purpose Materials. V.2. USA: ASM International, 1990, p. 1746-1747

- ↑ Lassner, Erik; Schubert, Wolf-Dieter (1999-01-31). Tungsten: Properties, Chemistry, Technology of the Elements, Alloys, and Chemical Compounds. p. 258. ISBN 9780306450532. https://books.google.com/books?id=foLRISkt9gcC.

- ↑ Jump up to: 3.0 3.1 Handbook. Alloy Phase Diagrams. V.3. USA: ASM International, 1990, p. 1453.

|