Engineering:Vibrating structure gyroscope

A vibrating structure gyroscope (VSG), defined by the IEEE as a Coriolis vibratory gyroscope (CVG),[1] is a gyroscope that uses a vibrating (as opposed to rotating) structure as its orientation reference. A vibrating structure gyroscope functions much like the halteres of flies (insects in the order Diptera).

The underlying physical principle is that a vibrating object tends to continue vibrating in the same plane even if its support rotates. The Coriolis effect causes the object to exert a force on its support, and by measuring this force the rate of rotation can be determined.

Vibrating structure gyroscopes are simpler and cheaper than conventional rotating gyroscopes of similar accuracy. Inexpensive vibrating structure gyroscopes manufactured with micro-electromechanical systems (MEMS) technology are widely used in smartphones, gaming devices, cameras and many other applications.

Theory of operation

Consider two proof masses vibrating in plane (as in the MEMS gyro) at frequency . The Coriolis effect induces an acceleration on the proof masses equal to , where is a velocity and is an angular rate of rotation. The in-plane velocity of the proof masses is given by , if the in-plane position is given by . The out-of-plane motion , induced by rotation, is given by:

where

- is a mass of the proof mass,

- is a spring constant in the out of plane direction,

- is a magnitude of a rotation vector in the plane of and perpendicular to the driven proof mass motion.

By measuring , we can thus determine the rate of rotation .

Implementations

Cylindrical resonator gyroscope (CRG)

This type of gyroscope was developed by GEC Marconi and Ferranti in the 1980s using metal alloys with attached piezoelectric elements and a single-piece piezoceramic design. Subsequently, in the 90s, CRGs with magneto-electric excitation and readout were produced by American-based Inertial Engineering, Inc. in California, and piezoceramic variants by Watson Industries. A recently patented variant by Innalabs uses a cylindrical design resonator made from Elinvar-type alloy with piezoceramic elements for excitation and pickoff at its bottom.

This technology gave a substantially increased product life (MTBF > 500,000 hours); with its shock resistance (>300g), it should qualify for "tactical" (mid-accuracy) applications.

The resonator is operated in its second-order resonant mode. The Q-factor is usually about 20,000; that predetermines its noise and angular random walks. Standing waves are elliptically-shaped oscillations with four antinodes and four nodes located circumferentially along the rim.

The angle between two adjacent antinode – nodes is 45 degrees. One of the elliptical resonant modes is excited to a prescribed amplitude. When the device rotates about its sensitive axis (along its inner stem), the resulting Coriolis forces acting on the resonator's vibrating mass elements excite the second resonant mode. The angle between major axes of the two modes is also 45 degrees.

A closed loop drives the second resonant mode to zero, and the force required to null this mode is proportional to the input rotation rate. This control loop is designated the force-rebalanced mode.

Piezoelectric elements on the resonator produce forces and sense induced motions. This electromechanical system provides the low output noise and large dynamic range that demanding applications require, but suffers from intense acoustic noises and high overloads.

Piezoelectric gyroscopes

A piezoelectric material can be induced to vibrate, and lateral motion due to Coriolis force can be measured to produce a signal related to the rate of rotation.[2]

Tuning fork gyroscope

This type of gyroscope uses a pair of test masses driven to resonance. Their displacement from the plane of oscillation is measured to produce a signal related to the system's rate of rotation.

Frederick William Meredith registered a patent for such a device in 1942 while working at the Royal Aircraft Establishment. Further development was carried out at the RAE in 1958 by G. H. Hunt and A. E. W. Hobbs, who demonstrated drift of less than 1°/h or (2.78×10−4)°/s.[3]

Modern variants of tactical gyros use doubled tuning forks such as those produced by American manufacturer Systron Donner in California and French manufacturer Safran Electronics & Defense / Safran Group.[4]

Wine-glass resonator

Also called a hemispherical resonator gyroscope or HRG, a wine-glass resonator uses a thin solid-state hemisphere anchored by a thick stem. The hemisphere with its stem is driven to flexural resonance and the nodal points are measured to detect rotation. There are two basic variants of such a system: one based on a rate regime of operation ("force-to-rebalance mode") and another variant based on an integrating regime of operation ("whole-angle mode"). Usually, the latter one is used in combination with a controlled parametric excitation. It is possible to use both regimes with the same hardware, which is a feature unique to these gyroscopes.

For a single-piece design (i.e., the hemispherical cup and stem(s) form a monolithic part) made from high-purity quartz glass, it is possible to reach a Q-factor greater than 30-50 million in vacuum, so the corresponding random walks are extremely low. The Q is limited by the coating, an extremely thin film of gold or platinum, and by fixture losses.[5] Such resonators have to be fine-tuned by ion-beam micro-erosion of the glass or by laser ablation. Engineers and researchers in several countries have been working on further improvements of these sophisticated state-of-art technologies.[6]

Safran and Northrop Grumman are the major manufacturers of HRG.[7][8]

Vibrating wheel gyroscope

A wheel is driven to rotate a fraction of a full turn about its axis. The tilt of the wheel is measured to produce a signal related to the rate of rotation.[9]

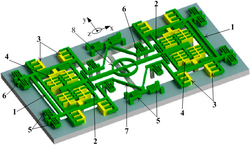

MEMS gyroscopes

Inexpensive vibrating structure microelectromechanical systems (MEMS) gyroscopes have become widely available. These are packaged similarly to other integrated circuits and may provide either analogue or digital outputs. In many cases, a single part includes gyroscopic sensors for multiple axes. Some parts incorporate multiple gyroscopes and accelerometers (or multiple-axis gyroscopes and accelerometers), to achieve output that has six full degrees of freedom. These units are called inertial measurement units, or IMUs. Panasonic, Robert Bosch GmbH, InvenSense, Seiko Epson, Sensonor, Hanking Electronics, STMicroelectronics, Freescale Semiconductor, and Analog Devices are major manufacturers.

Internally, MEMS gyroscopes use micro-lithographically constructed versions of one or more of the mechanisms outlined above (tuning forks, vibrating wheels, or resonant solids of various designs, i.e., similar to TFG, CRG, or HRG mentioned above).[10]

MEMS gyroscopes are used in automotive roll-over prevention and airbag systems, image stabilization, and have many other potential applications.[11]

Applications of gyroscopes

Automotive

Automotive yaw sensors can be built around vibrating structure gyroscopes. These are used to detect error states in yaw compared to a predicted response when connected as an input to electronic stability control systems in conjunction with a steering wheel sensor.[12] Advanced systems could conceivably offer rollover detection based on a second VSG but it is cheaper to add longitudinal and vertical accelerometers to the existing lateral one to this end.

Entertainment

The Nintendo Game Boy Advance game Software:WarioWare: Twisted! uses a piezoelectric gyroscope to detect rotational movement. The Sony SIXAXIS PS3 controller uses a single MEMS gyroscope to measure the sixth axis (yaw). The Nintendo Wii MotionPlus accessory uses multi-axis MEMS gyroscopes provided by InvenSense to augment the motion sensing capabilities of the Wii Remote.[13] Most modern smartphones and gaming devices also feature MEMS gyroscopes.

Hobbies

Vibrating structure gyroscopes are commonly used in radio-controlled helicopters to help control the helicopter's tail rotor and in radio-controlled airplanes to help keep the attitude steady during flight. They are also used in multirotor flight controllers, since multirotors are inherently aerodynamically unstable and cannot stay airborne without electronic stabilization.

Industrial robotics

Epson Robots uses a quartz MEMS gyroscope, called QMEMS, to detect and control vibrations on their robots. This helps the robots position the robot end effector with high precision in high speed and fast-deceleration motion.[14]

Photography

Many image stabilization systems on video and still cameras employ vibrating structure gyroscopes.

Spacecraft orientation

The oscillation can also be induced and controlled in the vibrating structure gyroscope for the positioning of spacecraft such as Cassini–Huygens.[15] These small hemispherical resonator gyroscopes made of quartz glass operate in vacuum. There are also prototypes of elastically decoupled cylindrical resonator gyroscopes (CRG)[16][17] made from high-purity single-crystalline sapphire. The high-purity leuko-sapphire have Q-factor an order of value higher than quartz glass used for HRG, but this material is hard and has anisotropy. They provide accurate 3 axis positioning of the spacecraft and are highly reliable over the years as they have no moving parts.

Other

The Segway Human Transporter uses a vibrating structure gyroscope made by Silicon Sensing Systems to stabilize the operator platform.[18]

References

- ↑ IEEE Std 1431–2004 Coriolis Vibratory Gyroscopes.

- ↑ "NEC TOKIN's ceramic piezo gyros". http://www.nec-tokin.com/english/product/piezodevice2/ceramicgyro.html.

- ↑ Collinson, R.P.G. Introduction to Avionics, Second edition, Kluwer Academic Publishers: Netherlands, 2003, p.235

- ↑ "Sagem Défense Sécurité : MARCHÉS / PRODUITS - Systèmes Avioniques & Navigation - Navigation". archive.org. October 16, 2007. http://www.sagem-ds.com/fra/site.php?spage=02010306.

- ↑ Sarapuloff S.A., Rhee H.-N., and Park S.-J. Avoidance of Internal Resonances in Hemispherical Resonator Assembly from Fused Quartz Connected by Indium Solder //Proceedings of the 23rd KSNVE (Korean Society for Noise & Vibration Engineering) Annual Spring Conference. Yeosu-city, April 24–26, 2013. – P.835-841.

- ↑ Sarapuloff S.A. 15 Years of Solid-State Gyrodynamics Development in the USSR and Ukraine: Results and Perspectives of Applied Theory //Proc. of the National Technical Meeting of Institute of Navigation (Santa Monica, Calif., USA. January 14–16, 1997). – P.151-164.

- ↑ "Chanakya Aerospace Defence & Maritime Review". http://www.chanakyaaerospacedefence.com/newsdetails.aspx?Nid=6415.

- ↑ "Archived copy". http://www.northropgrumman.com/Capabilities/HRG/Documents/hrg.pdf.

- ↑ "Inertial Sensors – Angular Rate Sensors". http://www.hsg-imit.de/index.php?id=41&L=1.

- ↑ Bernstein, Jonathan. "An Overview of MEMS Inertial Sensing Technology" , Sensors Weekly, February 1, 2003.

- ↑ Cenk Acar, Andrei Shkel. "MEMS Vibratory Gyroscopes: Structural Approaches to Improve Robustness". 2008. p. 8 section "1.5 Applications of MEMS Gyroscopes".

- ↑ "The Falling Box (Video)". http://dl3.interlake.net/shared/wm/M225693_20071211_153047/ESPerience/uk/the_falling_box.wmv.

- ↑ "InvenSense IDG-600 Motion Sensing Solution Showcased In Nintendo's New Wii MotionPlus Accessory" (Press release). InvenSense. July 15, 2008. Archived from the original on April 17, 2009. Retrieved May 28, 2009.

- ↑ "Epson Quartz Crystal Device – About QMEMS". http://www5.epsondevice.com/en/quartz/aboutus/qmems/index.html.

- ↑ Jet Propulsion Laboratory, "Cassini Spacecraft and Huygens Probe," pg. 2, [1]

- ↑ Sarapuloff S.A. High-Q Sapphire Resonator of Solid-State Gyroscope CRG-1 – In book: 100 Selected Technologies of Academy of Technological Sciences of Ukraine (ATS of Ukraine). Catalogue. – Published by STCU (Science & Technological Council for Ukraine). Kyiv. http://www.stcu.int/documents/reports/distribution/tpf/MATERIALS/Sapphire_Gyro_Sarapuloff_ATSU.pdf

- ↑ Sarapuloff S. A., Lytvynov L.A., et al. Particularities of Designs and Fabrication Technology of High-Q Sapphire Resonators of CRG-1 Type Solid-State Gyroscopes //XIVth International Conference on Integrated Navigation Systems (May 28–30, 2007. St.-Petersburg, RF.). – St.-Petersburg. The State Research Center of Russia – Central Scientific & Research Institute "ElektroPribor". RF. 2007. – P.47-48.

- ↑ Steven Nasiri. "A Critical Review of MEMS Gyroscopes Technology and Commercialization Status". http://www.invensense.com/mems/gyro/documents/whitepapers/MEMSGyroComp.pdf.

External links

- Proceedings of Anniversary Workshop on Solid-State Gyroscopy (May 19–21, 2008. Yalta, Ukraine). - Kyiv-Kharkiv. ATS of Ukraine. 2009. - ISBN 978-976-0-25248-5. See also the next meetings at: International Workshops on Solid-State Gyroscopy [2].

- Silicon Sensing – Case Study: Segway HT

- Apostolyuk V. Theory and Design of Micromechanical Vibratory Gyroscopes

- Prandi L., Antonello R., Oboe R., and Biganzoli F. Automatic Mode-Matching in MEMS Vibrating Gyroscopes Using Extremum Seeking Control //IEEE Transactions on Industrial Electronics. 2009. Vol.56. - P.3880-3891.. [3]

- Prandi L., Antonello R., Oboe R., Caminada C., and Biganzoli F. Open-Loop Compensation of the Quadrature Error in MEMS Vibrating Gyroscopes //Proceedings of 35th Annual Conference of the IEEE Industrial Electronics Society – IECON-2009. 2009. [4]

|