Chemistry:Brookhart's acid

| |

| Identifiers | |

|---|---|

3D model (JSmol)

|

|

| ChemSpider | |

PubChem CID

|

|

| |

| |

| Properties | |

| C40H33BF24O2 | |

| Molar mass | 1012.46 |

| Appearance | White crystalline solid |

| Hazards | |

| Main hazards | Strong acid |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

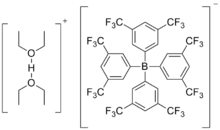

Brookhart's acid is the salt of the diethyl ether oxonium ion and tetrakis[3,5-bis(trifluoromethyl)phenyl]borate (BAr′4). It is a colorless solid, used as a strong acid. The compound was first reported by Volpe, Grant, and Brookhart in 1992.[1]

Preparation

This compound is prepared by treatment of NaBAr′4 in diethyl ether (Et2O) with hydrogen chloride:

- NaBAr′4 + HCl + 2 Et2O → [H(OEt2)2]+BAr′−4 + NaCl

NaBAr′4 is soluble in diethyl ether, whereas sodium chloride is not. Precipitation of sodium chloride thus drives the formation of the oxonium acid compound, which is isolable as a solid.[1]

Structure and properties

The acid crystallizes as a white, hygroscopic crystalline solid. NMR and elemental analysis showed that the crystal contains two equivalents of diethyl ether. In solution, the compound slowly degrades to m-C6H3(CF3)2 and BAr′3.[1]

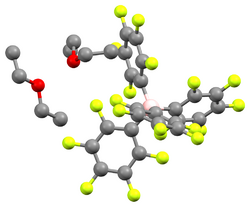

[H(OEt2)2][B(C6F5)4] is a related compound with a slightly different weakly coordinating anion; it was first reported in 2000. An X-ray crystal structure of that compound was obtained, showing the acidic proton coordinated by both ethereal oxygen centers, although the crystal was not good enough to determine whether the proton is located symmetrically or unsymmetrically between the two.[2]

Uses

Traditional weakly coordinating anions, such as perchlorate, tetrafluoroborate, and hexafluorophosphate, will nonetheless coordinate to very electrophilic cations, making these counterions unsuitable for some complexes.[3] The highly reactive species [Cp2Zr(CH3)]+, for example, has been reported to abstract F− from PF6.[4] Starting in the 1980s, new types of weakly coordinating anions began to be developed. BAr′4 anions are used as counterions for highly electrophilic, cationic transition metal species, as they are very weakly coordinating and unreactive towards electrophilic attack.[1] One common method of generating these cationic species is via protonolysis of a dialkyl complexes or an olefin complex. For example, an electrophilic palladium catalyst, [(2,2′-bipyridine)Pd(CH3)(CH3CN)][BAr′4], is prepared by protonating the dimethyl complex with Brookhart's acid. This electrophilic, cationic palladium species is used for the polymerization of olefins with carbon monoxide to polyketones in aprotic solvents.[5]

Potential application

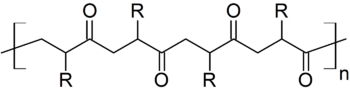

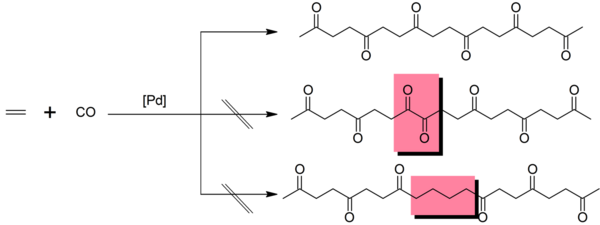

Polyketones, thermoplastic polymers,[6][7] are formed by the copolymerisation of carbon monoxide and one or more alkenes (typically ethylene with propylene). The process utilises a palladium(II) catalyst with a bidentate ligand like 2,2′-bipyridine or 1,10-phenanthroline (phen) with a non-coordinating BARF counterion, such as [(phen)Pd(CH3)(CO)]BArF4.[8] The preparation of the catalyst involves the reaction of a dimethyl palladium complex with Brookhart's acid in acetonitrile with loss of methane and the catalytic species is formed by uptake of carbon monoxide to displace acetonitrile.[8]

- [(Et2O)2H]BArF4 + [(phen)Pd(CH3)2] + MeCN → [(phen)Pd(CH3)(MeCN)]BArF4 + 2 Et2O + CH4

- [(phen)Pd(CH3)(MeCN)]BArF4 + CO → [(phen)Pd(CH3)(CO)]BArF4 + MeCN

The mechanism involves migratory insertion[9] whereby the polymer chain is bound to the catalytic centre and grows by the sequential insertion of carbon monoxide and the alkene between the palladium atom and the existing chain. Defects occur when insertions do not alternate – that is, a carbon monoxide insertion follows a carbon monoxide insertion or an alkene insertion follows an alkene insertion – these are highlighted in red in the figure below. This catalyst produces a very low rate of defects due to the difference in Gibbs energy of activation of each insertion – the energy barrier to inserting an alkene immediately following an alkene insertion is ~12 kJ mol−1 higher than barrier to carbon monoxide insertion.[10] Use of monodentate phosphine ligands also leads to undesirable side-products[11] but bidentate phosphine ligands like 1,3-bis(diphenylphosphino)propane have been used industrially.[9]

References

- ↑ 1.0 1.1 1.2 1.3 Brookhart, M.; Grant, B.; Volpe, A. F. (1992). "[(3,5-(CF3)2C6H3)4B]−[H(OEt2)2]+: A convenient reagent for generation and stabilization of cationic, highly electrophilic organometallic complexes". Organometallics 11 (11): 3920. doi:10.1021/om00059a071.

- ↑ 2.0 2.1 Jutzi, P.; Müller, C.; Stammler, A.; Stammler, H. G. (2000). "Synthesis, Crystal Structure, and Application of the Oxonium Acid [H(OEt2)2]+B(C6F5)4]−". Organometallics vol. 19, p. 1442. doi:10.1021/om990612w

- ↑ Krossing, I.; Raabe, I. (2004). "Noncoordinating Anions—Fact or Fiction? A Survey of Likely Candidates". Angewandte Chemie International Edition 43 (16): 2066–90. doi:10.1002/anie.200300620. PMID 15083452.

- ↑ Jordan, R. F.; Dasher, W. E.; Echols, S. F. (1986). "Reactive cationic dicyclopentadienyl zirconium(IV) complexes". Journal of the American Chemical Society 108 (7): 1718. doi:10.1021/ja00267a068.

- ↑ Brookhart, M.; Rix, F. C.; Desimone, J. M.; Barborak, J. C. (1992). "Palladium(II) catalysts for living alternating copolymerization of olefins and carbon monoxide". Journal of the American Chemical Society 114 (14): 5894. doi:10.1021/ja00040a082.

- ↑ Drent, E.; Mul, W. P.; Smaardijk, A. A. (2001). "Polyketones". Encyclopedia Of Polymer Science and Technology. doi:10.1002/0471440264.pst273. ISBN 9781118633892.

- ↑ Bianchini, C.; Meli, A. (2002). "Alternating copolymerization of carbon monoxide and olefins by single-site metal catalysis". Coord. Chem. Rev. 225 (1–2): 35–66. doi:10.1016/S0010-8545(01)00405-2.

- ↑ 8.0 8.1 Brookhart, M.; Rix, F. C.; DeSimone, J. M.; Barborak, J. C. (1992). "Palladium(II) catalysts for living alternating copolymerization of olefins and carbon monoxide". J. Am. Chem. Soc. 114 (14): 5894–5895. doi:10.1021/ja00040a082.

- ↑ 9.0 9.1 Shultz, C. S.; Ledford, J.; Desimone, J. M.; Brookhart, M. (2000). "Kinetic studies of migratory insertion reactions at the (1,3-bis(diphenylphosphino)propane)Pd(II) center and their relationship to the alternating copolymerization of ethylene and carbon monoxide". J. Am. Chem. Soc. 122 (27): 6351–6356. doi:10.1021/ja994251n.

- ↑ Rix, F. C.; Brookhart, M.; White, P. S. (1996). "Mechanistic studies of the palladium(II)-catalyzed copolymerization of ethylene with carbon monoxide". J. Am. Chem. Soc. 118 (20): 4746–4764. doi:10.1021/ja953276t.

- ↑ Drent, E.; Budzelaar, P. H. M. (1996). "Palladium-catalyzed alternating copolymerization of alkenes and carbon monoxide". Chem. Rev. 96 (2): 663–682. doi:10.1021/cr940282j. PMID 11848769.

|