Chemistry:List of commercially available roofing material

Roofing material is the outermost layer on the roof of a building, sometimes self-supporting, but generally supported by an underlying structure. A building's roofing material provides shelter from the natural elements. The outer layer of a roof shows great variation dependent upon availability of material, and the nature of the supporting structure. Those types of roofing material which are commercially available range from natural products such as thatch and slate to commercially produced products such as tiles and polycarbonate sheeting. Roofing materials may be placed on top of a secondary water-resistant material called underlayment.

Materials

The weatherproofing material is the topmost or outermost layer exposed to the weather. Many materials have been used as weatherproofing material:

- Thatch is roofing made of plant stalks in overlapping layers

- Wheat straw, widely used in England, France, and other parts of Europe

- Seagrass, used in coastal areas where there are estuaries such as Scotland. Has a longer life than straw. Claimed to have a life in excess of 60 years.

- Rye straw, commonly used in a barn.

- Raffia palm leaves:A well organised raffia palm leaves is mainly used as roof houses in Nigeria, especially among the Igbos.

- Rice straw, commonly used in Eastern Asia.

- Water reed, commonly used in Ireland for Thatching.

- Shingle is the generic term for an individual roofing unit that is applied with other such units in an overlapping fashion.[1]

- Wood shingle, shingles sawn from bolts of wood such as red cedar which has a useful performance life expectancy of up to 30 years. However, young growth red cedar has a short life expectancy and high cost. In the United States and Canada, eastern white cedar is also used. Some hardwoods were very durable roofing found in Colonial Australian and American colonial architecture; their use is now usually limited to building restoration. All wood shingles benefit by being allowed to breathe (dry out from below).

- Shake (shingle), Are different than wood shingles in that they are split on one side and sawed on the back side. Commonly referred to as "resawn Shakes". A cedar shake is NOT the same as a cedar shingle.[2]

- Slate. High cost with a life expectancy of 80 to 400 years. See the article slate industry for an overview including names of quarries. Some of the famous quarries where the highest quality slate comes from that are available in Australia are Bethesda in Wales and areas of Spain.

- Asphalt shingle made of bitumen embedded in an organic or fiberglass mat, usually covered with colored, man-made ceramic grit. Cheaper than slate or tiles. The reduced cost of this particular style of roofing is especially apparent in its application and removal. Installation is very streamlined and a rapid process. Depending on the size of the roof and the experience of the crew, it is possible to remove old shingles and apply new ones on 2-3 houses in one day. Life span varies. Use only on slanted roofs.[3]

- Rubber shingle, alternative to asphalt shingle, slate, shake or tile. Made primarily of rubber, often recycled tire-derived rubber. Other typical ingredients include binders, UV (ultraviolet light) inhibitors and color. Warranted and designed to last at least 50 years in most cases.

- Asbestos shingles. Very long lifespan, fireproof, and low cost but now rarely used because of health concerns.[4]

- Stone slab. Heavy stone slabs (not to be confused with slate) 1–2 inches thick were formerly used as roofing tiles in some regions in England, the Alps, and Scandinavia. Stone slabs require a very heavyweight roof structure, but their weight makes them stormproof. An obsolete roofing material, now used commercially only for building restoration.

- Collyweston stone slate

- Solar shingle

- Metal shakes or shingles. Long life. High cost, suitable for roofs of 3:12 pitch or greater. Because of the flexibility of metal, they can be manufactured to lock together, giving durability and reducing assembly time. For a discussion of copper system shingles, see Copper in architecture.

- Ceramic tile. High cost, life of more than 100 years.

- Imbrex and tegula, style dating back to ancient Greece and Rome.

- Monk and Nun, a style similar to Imbrex and tegula, but basically using two Imbrex tiles.

- Dutch roof tiles, Netherlands

- Mangalore tiles, India

- Membrane roofing. Membrane roofing is in large sheets, generally fused in some way at the joints to form a continuous surface.

- Thermoset membrane (e.g. EPDM rubber). Synthetic rubber sheets adhered together with contact adhesive or tape. Primary application is big box stores with large open areas.

- Thermoplastics (e.g. PVC, TPO, CSPE) – Plastic sheets welded together with hot air, creating one continuous sheet membrane. They can be re-welded with the exception of CSPE. Lends itself well to both big box and small roof application because of its hot air weldability. This membrane is installed by two methods: 1.) Rolls of membrane are attached to the ridged insulation using a bonding adhesive; 2.) The edge of each roll is fastened through ridged insulation into structural deck, and the proceeding roll is lapped over the fasteners. The overlap is then heat-welded with hot air to create a mechanically fastened thermoplastic roof. PVC is also known as IB.Vinyl roof membrane.

- Liquid roofing

- Asphalt roll roofing including single and double coverage types.

- Bituminous waterproofing is a general term for:

- Modified bitumen – heat-welded, asphalt-adhered, or installed with adhesive. Asphalt is mixed with polymers such as APP or SBS, then applied to fiberglass and/or polyester mat, seams sealed by locally melting the asphalt with heat, hot mopping of asphalt, or adhesive. Lends itself well to most applications.

- Built-up roof – Multiple plies of salt-saturated organic felt or coated fiberglass felts. Plies of felt are adhered with hot asphalt, coal tar pitch, or adhesive. Although the roof membrane can be left bare, it is typically covered with a thick coat of the waterproofing material and covered with gravel. The gravel provides protection from ultra-violet degradation, stabilizes the temperature changes, protects surface of the roof, and increases the weight of the roof system to resist wind blow-off.

- Fabric

- polyester.

- PTFE, (synthetic fluoropolymer) embedded in fibreglass.

- Metal roofing.

- Corrugated galvanised iron is Galvanised steel manufactured with wavy corrugations to resist lateral flexing and fitted with exposed fasteners. Widely used for low cost and durability. Sheds are normally roofed with this material. Gal iron or Corro was the most extensively used roofing material of 20th century Australia, now replaced in popularity by steel with longer-lasting, coloured, alloy coatings.

- Copper roofs can last for hundreds of years. Copper roofing offers durability, ease of fabrication, lighter weight than some other roofing materials, can be curved, low maintenance, corrosion resistance, low thermal movement, lightning protection, radio frequency shielding, and are 100% recyclable. Copper roofs have a high initial cost but very long lifetime: tests on European copper roofs from the 18th Century showed that, in theory, copper roofs can last one thousand years.[5] Another advantage of copper roofing systems is that they are relatively easy to repair.

- Standing-seam metal with concealed fasteners.

- Mechanically seamed metal with concealed fasteners contains sealant in seams for use on very low sloped roofs, suitable for roofs of low pitch such as 0.5/12 to 3/12 pitch.

- Flat-seam metal with or without soldered seams.

- Steel coated with a coloured alloy of zinc and aluminium.

- Stone-coated metal roofing.

- Concrete or fibre cement, usually reinforced with fibres of some sort.

- may also be in the form of concrete tiles.

- Structural concrete can also be used for flat roof constructions. There are three main categories, precast/prestressed, cast-in-place and shell. There are many types of precast/prestressed concrete roofing. The following are the most common types.[6]

- Double tees are the most common products for short spans up to 60 feet (18 m)

- Hollow-core slabs are used when there is a need for flushed ceiling.

- T-beams are similar to double tees but can be used for span ranging from 30 feet (9.1 m) to 100 feet (30 m).

- Joists and planks are combination of using prestressed joists with prestressed planks. Keystone-shape joists can be used for up to 36-foot (11 m) spans and tee-shape joists can be used for up to 60-foot (18 m) span.

Other components

Underlayments

- Tar paper and felt paper

- Synthetic underlayment

- Ice and water shield

- Insolation(Dens deck)

- Fire Sheet

Drip edge

- Drip edge is a metal installed to the edges of a roof deck, after the roofing material is installed. The metal may be galvanized, steel, aluminum, charcoal, white (painted or not), copper and possibly others.

Gallery

-

Reed thatch on the island of Sylt

-

Slate, England

-

A church roof under repair with terracotta tiles

-

Bitumen, United States

-

Corrugated iron, Australia

-

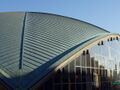

Sheet metal roof

-

PVC roof

-

Air-supported polyester roof, Michigan, USA

-

Copper clad roof, MIT, United States

See also

- Roof

- Domestic roof construction

- List of roof shapes

- Board roof

- Building construction

- Building insulation

- Building envelope

- Grouted roof

- Sod roof

- Birch-bark roof

- Stone roofs such as on a clochán or trullo

- Mud roofs such as on beehive house

- Sedum a plant used in green roofs

References

- ↑ Harris, Cyril M. (editor). Dictionary of Architecture and Construction, Third Edition, New York, McGraw Hill, 2000, p. 828

- ↑ "Grading and Manufacturing | Products | Cedar Shake and Shingle Bureau". http://www.cedarbureau.org/frequently-asked-questions/product/grading-and-manufacturing.asp. Retrieved 2015-10-28.

- ↑ "Roofing Requirements One- and Two- Family Dwellings". Regulatory Services Department. http://roofingroger.com/roofing-requirements-one-and-two-family-dwellings/. Retrieved 29 August 2015. "Asphalt-based organic and fiberglass shingles may only be used on roofs with slopes of 2:12 and greater."

- ↑ "Asbestos and your health". Better Health Channel. State Government of Victoria. September 2011. http://www.betterhealth.vic.gov.au/BHCV2/bhcarticles.nsf/pages/Asbestos_and_your_health?open. Retrieved 26 October 2014.

- ↑ The glory of copper; Metal Roofing Magazine, December 2002/January 2003

- ↑ Concrete Roof Systems Part 1: Precast/Prestressed Constructions. Archived from the original on 26 May 2015. https://web.archive.org/web/20150526171509/http://www.concreteconstruction.net/Images/Concrete%20Roof%20Systems%20Part%20I_%20Precast_Prestressed%20Construction_tcm45-348518.pdf. Retrieved 26 May 2015.