Engineering:Cycloconverter

A cycloconverter (CCV) or a cycloinverter converts a constant amplitude, constant frequency AC waveform to another AC waveform of a lower frequency by synthesizing the output waveform from segments of the AC supply without an intermediate DC link (Dorf 1993, pp. 2241–2243 and Lander 1993, p. 181). There are two main types of CCVs, circulating current type or blocking mode type, most commercial high power products being of the blocking mode type.[2]

Characteristics

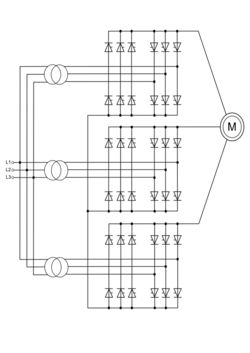

Whereas phase-controlled semiconductor controlled rectifier devices (SCR) can be used throughout the range of CCVs, low cost, low-power TRIAC-based CCVs are inherently reserved for resistive load applications. The amplitude and frequency of converters' output voltage are both variable. The output to input frequency ratio of a three-phase CCV must be less than about one-third for circulating current mode CCVs or one-half for blocking mode CCVs.(Lander 1993)[3] Output waveform quality improves as the pulse number of switching-device bridges in phase-shifted configuration increases in CCV's input. In general, CCVs can be with 1-phase/1-phase, 3-phase/1-phase and 3-phase/3-phase input/output configurations, most applications however being 3-phase/3-phase.[1]

Applications

The competitive power rating span of standardized CCVs ranges from few megawatts up to many tens of megawatts. CCVs are used for driving mine hoists, rolling mill main motors,[4] ball mills for ore processing, cement kilns, ship propulsion systems,[5] slip power recovery wound-rotor induction motors (i.e., Scherbius drives) and aircraft 400 Hz power generation.[6] The variable-frequency output of a cycloconverter can be reduced essentially to zero. This means that very large motors can be started on full load at very slow revolutions, and brought gradually up to full speed. This is invaluable with, for example, ball mills, allowing starting with a full load rather than the alternative of having to start the mill with an empty barrel then progressively load it to full capacity. A fully loaded "hard start" for such equipment would essentially be applying full power to a stalled motor. Variable speed and reversing are essential to processes such as hot-rolling steel mills. Previously, SCR-controlled DC motors were used, needing regular brush/commutator servicing and delivering lower efficiency. Cycloconverter-driven synchronous motors need less maintenance and give greater reliability and efficiency. Single-phase bridge CCVs have also been used extensively in electric traction applications to for example produce 25 Hz power in the U.S. and 16 2/3 Hz power in Europe.[7][8]

Whereas phase-controlled converters including CCVs are gradually being replaced by faster PWM self-controlled converters based on IGBT, GTO, IGCT and other switching devices, these older classical converters are still used at the higher end of the power rating range of these applications.[3]

Harmonics

CCV operation creates current and voltage harmonics on the CCV's input and output. AC line harmonics are created on CCV's input accordance to the equation,

- fh = f1 (kq±1) ± 6nfo,[9]

where

- fh = harmonic frequency imposed on the AC line

- k and n = integers

- q = pulse number (6, 12 . . .)

- fo = output frequency of the CCV

- Equation's 1st term represents the pulse number converter harmonic components starting with six-pulse configuration

- Equation's 2nd term denotes the converter's sideband characteristic frequencies including associated interharmonics and subharmonics.

References

- In-line references

- ↑ 1.0 1.1 Bose, Bimal K. (2006). Power Electronics and Motor Drives : Advances and Trends. Amsterdam: Academic. p. 126. ISBN 978-0-12-088405-6.

- ↑ Klug, Dieter-Rolf; Klaassen, Norbert (2005). "High Power Medium Voltage Drives - Innovations, Portfolio, Trends". p. 5. doi:10.1109/EPE.2005.219669.

- ↑ 3.0 3.1 Bose (2006), p. 153

- ↑ Watzmann, Marcus Watzmann; Raskowetz, Steffen (Sep–Oct 1996). Chinese rolling mill for extra high grade aluminium strip. http://www05.abb.com/global/scot/scot271.nsf/veritydisplay/c2be0f4cc18285dac1256ddd00346eed/$file/28-33m214.pdf. Retrieved Aug 5, 2011.

- ↑ Pakaste, Risto (Feb 1999). Experience with Azipod propulsion systems on board marine vessels. http://www05.abb.com/global/scot/scot271.nsf/veritydisplay/2314773146eb2d77c1256ec300341511/$file/12-18%20ENG%209902.pdf. Retrieved 28 April 2012.

- ↑ Bose (2006), p. 119

- ↑ Heydt, G.T.; Chu, R.F. (Apr 2005). "The power quality impact of cycloconverter control strategies". IEEE Transactions on Power Delivery 20 (2): 1711–1718. doi:10.1109/tpwrd.2004.834350.

- ↑ ACS 6000c. "Cycloconverter application for high performance speed and torque control of 1 to 27 MW synchronous motors". http://www05.abb.com/global/scot/scot216.nsf/veritydisplay/2abc426982e203e6c1256e4d004deb49/$file/acs%206000c%20cycloconverter.pdf.

- ↑ IEEE Std 519 (1992). IEEE Recommended Practices and Requirements for Harmonic Control in Electrical Power Systems. IEEE. p. 25. doi:10.1109/IEEESTD.1993.114370. ISBN 978-0-7381-0915-2.

- General references

- Dorf, Richard C., ed. (1993), The Electrical Engineering Handbook, Boca Raton: CRC Press, ISBN 0-8493-0185-8

- Lander, Cyril W (1993), Power Electronics (3rd ed.), London: McGraw-Hill, ISBN 0-07-707714-8

|