Engineering:Deep foundation

File:Deep foundation drilling.ogv

A deep foundation is a type of foundation that transfers building loads to the earth farther down from the surface than a shallow foundation does to a subsurface layer or a range of depths.

A pile or piling is a vertical structural element of a deep foundation, driven or drilled deep into the ground at the building site.

There are many reasons that a geotechnical engineer would recommend a deep foundation over a shallow foundation, such as for a skyscraper. Some of the common reasons are very large design loads, a poor soil at shallow depth, or site constraints like property lines. There are different terms used to describe different types of deep foundations including the pile (which is analogous to a pole), the pier (which is analogous to a column), drilled shafts, and caissons. Piles are generally driven into the ground in situ; other deep foundations are typically put in place using excavation and drilling. The naming conventions may vary between engineering disciplines and firms. Deep foundations can be made out of timber, steel, reinforced concrete or prestressed concrete.

Driven foundations

Prefabricated piles are driven into the ground using a pile driver. Driven piles are constructed of wood, reinforced concrete, or steel. Wooden piles are made from the trunks of tall trees. Concrete piles are available in square, octagonal, and round cross-sections (like Franki piles). They are reinforced with rebar and are often prestressed. Steel piles are either pipe piles or some sort of beam section (like an H-pile). Historically, wood piles used splices to join multiple segments end-to-end when the driven depth required was too long for a single pile; today, splicing is common with steel piles, though concrete piles can be spliced with mechanical and other means. Driving piles, as opposed to drilling shafts, is advantageous because the soil displaced by driving the piles compresses the surrounding soil, causing greater friction against the sides of the piles, thus increasing their load-bearing capacity. Driven piles are also considered to be "tested" for weight-bearing ability because of their method of installation; thus the motto of the Pile Driving Contractors' Association is "A Driven Pile...Is a Tested Pile!".[1]

Pile foundation systems

Foundations relying on driven piles often have groups of piles connected by a pile cap (a large concrete block into which the heads of the piles are embedded) to distribute loads which are larger than one pile can bear. Pile caps and isolated piles are typically connected with grade beams to tie the foundation elements together; lighter structural elements bear on the grade beams, while heavier elements bear directly on the pile cap.[2]

Monopile foundation

A monopile foundation utilizes a single, generally large-diameter, foundation structural element to support all the loads (weight, wind, etc.) of a large above-surface structure.

A large number of monopile foundations[3] have been utilized in recent years for economically constructing fixed-bottom offshore wind farms in shallow-water subsea locations.[4] For example, the Horns Rev wind farm from 2002 in the North Sea west of Denmark utilizes 80 large monopiles of 4 metres diameter sunk 25 meters deep into the seabed,[5] while the Lynn and Inner Dowsing Wind Farm off the coast of England went online in 2008 with over 100 turbines, each mounted on a 4.7-metre-diameter monopile foundation in ocean depths up to 18 metres of water.[6]

The typical construction process for a wind turbine subsea monopile foundation in sand includes driving a large hollow steel pile, of some 4 m in diameter with approximately 50mm thick walls, some 25 m deep into the seabed, through a 0.5 m layer of larger stone and gravel to minimize erosion around the pile. A "transition piece (complete with pre-installed features such as boat-landing arrangement, cathodic protection, cable ducts for sub-marine cables, turbine tower flange, etc.)" is attached to the now deeply driven pile, the sand and water are removed from the centre of the pile and replaced with concrete. An additional layer of even larger stone, up to 0.5 m diameter, is applied to the surface of the seabed for longer-term erosion protection.[4]

Drilled piles

Also called caissons, drilled shafts, drilled piers, Cast-in-drilled-hole piles (CIDH piles) or Cast-in-Situ piles, a borehole is drilled into the ground, then concrete (and often some sort of reinforcing) is placed into the borehole to form the pile. Rotary boring techniques allow larger diameter piles than any other piling method and permit pile construction through particularly dense or hard strata. Construction methods depend on the geology of the site; in particular, whether boring is to be undertaken in 'dry' ground conditions or through water-saturated strata. Casing is often used when the sides of the borehole are likely to slough off before concrete is poured.

For end-bearing piles, drilling continues until the borehole has extended a sufficient depth (socketing) into a sufficiently strong layer. Depending on site geology, this can be a rock layer, or hardpan, or other dense, strong layers. Both the diameter of the pile and the depth of the pile are highly specific to the ground conditions, loading conditions, and nature of the project. Pile depths may vary substantially across a project if the bearing layer is not level.

Drilled piles can be tested using a variety of methods to verify the pile integrity during installation.

Under-reamed piles

Under-reamed piles have mechanically formed enlarged bases that are as much as 6 m in diameter.[citation needed] The form is that of an inverted cone and can only be formed in stable soils. The larger base diameter allows greater bearing capacity than a straight-shaft pile.

These pile are suited for expansive soils which are often subjected to seasonal moisture variations, as also filled up ground and loose or soft strata. They are used in normal ground condition also where economics are favorable. [7][full citation needed]

Augercast pile

An augercast pile, often known as a continuous flight augering (CFA) pile, is formed by drilling into the ground with a hollow stemmed continuous flight auger to the required depth or degree of resistance. No casing is required. A cement grout mix is then pumped down the stem of the auger. While the cement grout is pumped, the auger is slowly withdrawn, conveying the soil upward along the flights. A shaft of fluid cement grout is formed to ground level. Reinforcement can be installed. Recent innovations in addition to stringent quality control allows reinforcing cages to be placed up to the full length of a pile when required. A typical reinforcing cage will consist of 4 to 8 bars from #5 to #8 bars typically 1/3 the length of the pile with longitudinal circular ties spaced along the length of the cage. Where tension loads are present it is typical to see a single full length bar placed at the center of each pile.

Augercast piles cause minimal disturbance, and are often used for noise and environmentally sensitive sites. Augercast piles are not generally suited for use in contaminated soils, due to expensive waste disposal costs. In cases such as these however a displacement pile may provide the cost efficiency of an augercast pile and minimal environmental impact. In ground containing obstructions or cobbles and boulders, augercast piles are less suitable as refusal above the design pile tip elevation may be encountered. In certain cases drill motors that produce more torque and horsepower may be able to mitigate these events.[citation needed]

Pier and grade beam foundation

In drilled pier foundations, the piers can be connected with grade beams on which the structure sits, sometimes with heavy column loads bearing directly on the piers. In some residential construction, the piers are extended above the ground level and wood beams bearing on the piers are used to support the structure. This type of foundation results in a crawl space underneath the building in which wiring and duct work can be laid during construction or re-modelling.[8]

Specialty piles

Micropiles

Micropiles, also called mini piles, are often used for underpinning. They are also used to create foundations for a variety of project types, including highway, bridge and transmission tower projects. They are especially useful at sites with difficult or restricted access, or with environmental sensitivity.[9][10] Micropiles are made of steel with diameters of 60 to 200 mm. Installation of micropiles through top soil, sand and cobblestones overburden and into soil rock can be achieved using Air Rotary or Mud Rotary drilling, impact driving, jacking, vibrating or screwing machinery.[11] Micropiles can also be used to construct a grout column around the shaft of a standard Helical Pile system, allowing for use in higher load applications.[12]

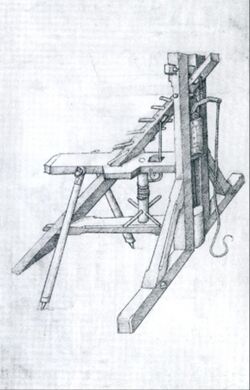

Tripod piles

The use of a tripod rig to install piles is one of the more traditional ways of forming piles. Although unit costs are generally higher than with most other forms of piling,[citation needed] it has several advantages which have ensured its continued use through to the present day. The tripod system is easy and inexpensive to bring to site, making it ideal for jobs with a small number of piles.

Sheet piles

Sheet piling is a form of driven piling using thin interlocking sheets of steel to obtain a continuous barrier in the ground. The main application of sheet piles is in retaining walls and cofferdams erected to enable permanent works to proceed. Normally, vibrating hammer, t-crane and crawle drilling are used to establish sheet piles.[citation needed]

Soldier piles

Soldier piles, also known as king piles or Berlin walls, are constructed of wide flange steel H sections spaced about 2 to 3 m apart and are driven prior to excavation. As the excavation proceeds, horizontal timber sheeting (lagging) is inserted behind the H pile flanges.

The horizontal earth pressures are concentrated on the soldier piles because of their relative rigidity compared to the lagging. Soil movement and subsidence is minimized by maintaining the lagging in firm contact with the soil.[citation needed]

Soldier piles are most suitable in conditions where well constructed walls will not result in subsidence such as over-consolidated clays, soils above the water table if they have some cohesion, and free draining soils which can be effectively dewatered, like sands.[citation needed]

Unsuitable soils include soft clays and weak running soils that allow large movements such as loose sands. It is also not possible to extend the wall beyond the bottom of the excavation and dewatering is often required.[citation needed]

Screw piles

Screw piles, also called helical piers and screw foundations, have been used as foundations since the mid 19th century in screw-pile lighthouses.[13] Screw piles are galvanized iron pipe with helical fins that are turned into the ground by machines to the required depth. The screw distributes the load to the soil and is sized accordingly.

Suction Piles

Suction piles are used underwater to secure floating platforms. Tubular piles are driven into the seabed (or more commonly dropped a few metres into a soft seabed) and then a pump sucks water out at the top of the tubular, pulling the pile further down.

The proportions of the pile (diameter to height) are dependent upon the soil type. Sand is difficult to penetrate but provides good holding capacity, so the height may be as short as half the diameter. Clays and muds are easy to penetrate but provide poor holding capacity, so the height may be as much as eight times the diameter. The open nature of gravel means that water would flow through the ground during installation, causing 'piping' flow (where water boils up through weaker paths through the soil). Therefore, suction piles cannot be used in gravel seabeds.[citation needed]

Adfreeze Piles

In high latitudes where the ground is continuously frozen, adfreeze piles are used as the primary structural foundation method.

Adfreeze piles derive their strength from the bond of the frozen ground around them to the surface of the pile.[citation needed]

Adfreeze pile foundations are particularly sensitive in conditions which cause the permafrost to melt. If a building is constructed improperly, it will heat the ground below resulting in a failure of the foundation system.[citation needed]

Vibrated stone columns

Vibrated stone columns are a ground improvement technique where columns of coarse aggregate ("stone") are placed in soils with poor drainage or bearing capacity to improve the soils.[14]

Hospital Piles or Gallow Piles

Specific to marine structures, hospital piles are built to provide temporary support to marine structure components during refurbishment works. For example, when removing a river pontoon, the brow will be attached to hospital pile to support it. They are normal piles, usually with a chain or hook attachment. Also known as Gallow piles.

Piled walls

These methods of retaining wall construction employ bored piling techniques, normally CFA or rotary. They provide special advantages where available working space dictates that basement excavation faces be vertical. Both methods offer technically effective and offer a cost efficient temporary or permanent means of retaining the sides of bulk excavations even in water bearing strata. When used in permanent works, these walls can be designed to accommodate vertical loads in addition to moments and horizontal forces. Construction of both methods is the same as for foundation bearing piles. Contiguous walls are constructed with small gaps between adjacent piles. The size of this space is determined by the strength of the soils.

Secant piled walls

Secant pile walls are constructed such that space is left between alternate 'female' piles for the subsequent construction of 'male' piles. Construction of 'male' piles involves boring through the concrete in the 'female' piles hole in order to key 'male' piles between. The male pile is the one where steel reinforcement cages are installed, though in some cases the female piles are also reinforced.

Secant piled walls can either be true hard/hard, hard/intermediate (firm), or hard/soft, depending on design requirements. Hard refers to structural concrete and firm or soft is usually a weaker grout mix containing bentonite.

All types of wall can be constructed as free standing cantilevers, or may be propped if space and sub-structure design permit. Where party wall agreements allow, ground anchors can be used as tie backs.

Slurry walls

A slurry wall is a barrier built under ground using a mix of bentonite and water to prevent the flow of groundwater. A trench that would collapse due to the hydraulic pressure in the surrounding soil does not collapse as the slurry balances the hydraulic pressure.

Deep mixing/mass stabilization techniques

These are essentially variations of in situ reinforcements in the form of piles (as mentioned above), blocks or larger volumes.

Cement, lime/quick lime, flyash, sludge and/or other binders (sometimes called stabilizer) are mixed into the soil to increase bearing capacity. The result is not as solid as concrete, but should be seen as an improvement of the bearing capacity of the original soil.

The technique is most often applied on clays or organic soils like peat. The mixing can be carried out by pumping the binder into the soil whilst mixing it with a device normally mounted on an excavator or by excavating the masses, mixing them separately with the binders and refilling them in the desired area. The technique can also be used on lightly contaminated masses as a means of binding contaminants, as opposed to excavating them and transporting to landfill or processing.

Classification of pile with respect to type of material

Timber

As the name implies, timber piles are made of wood.

Historically, timber has been a plentiful, locally available resource in many areas. Today, timber piles are still more affordable than concrete or steel. Compared to other types of piles (steel or concrete), and depending on the source/type of timber, timber piles may not be suitable for heavier loads.

A main consideration regarding timber piles is that they should be protected from rotting above groundwater level. Timber will last for a long time below the groundwater level. For timber to rot, two elements are needed: water and oxygen. Below the groundwater level, dissolved oxygen is lacking even though there is ample water. Hence, timber tends to last for a long time below groundwater level. In 1648, the Royal Palace of Amsterdam was constructed on 13659 timber piles that still survive today since they were below groundwater level. Timber that is to be used above the water table can be protected from decay and insects by numerous forms of wood preservation using pressure treatment (alkaline copper quaternary (ACQ), chromated copper arsenate (CCA), creosote, etc.).

Splicing timber piles is still quite common and is the easiest of all the piling materials to splice. The normal method for splicing is by driving the leader pile first, driving a steel tube (normally 60–100 cm long, with an internal diameter no smaller than the minimum toe diameter) half its length onto the end of the leader pile. The follower pile is then simply slotted into the other end of the tube and driving continues. The steel tube is simply there to ensure that the two pieces follow each other during driving. If uplift capacity is required, the splice can incorporate bolts, coach screws, spikes or the like to give it the necessary capacity.

Iron

Iron may be used for piling. These may be ductile.[15]

Steel

Pipe piles are a type of steel driven pile foundation and are a good candidate for inclined (battered) piles.

Pipe piles can be driven either open end or closed end. When driven open end, soil is allowed to enter the bottom of the pipe or tube. If an empty pipe is required, a jet of water or an auger can be used to remove the soil inside following driving. Closed end pipe piles are constructed by covering the bottom of the pile with a steel plate or cast steel shoe.

In some cases, pipe piles are filled with concrete to provide additional moment capacity or corrosion resistance. In the United Kingdom, this is generally not done in order to reduce the cost. In these cases corrosion protection is provided by allowing for a sacrificial thickness of steel or by adopting a higher grade of steel. If a concrete filled pipe pile is corroded, most of the load carrying capacity of the pile will remain intact due to the concrete, while it will be lost in an empty pipe pile.

The structural capacity of pipe piles is primarily calculated based on steel strength and concrete strength (if filled). An allowance is made for corrosion depending on the site conditions and local building codes.

Steel pipe piles can either be new steel manufactured specifically for the piling industry or reclaimed steel tubular casing previously used for other purposes such as oil and gas exploration.

H-Piles are structural beams that are driven in the ground for deep foundation application. They can be easily cut off or joined by welding or mechanical drive-fit splicers. If the pile is driven into a soil with low pH value, then there is a risk of corrosion, coal-tar epoxy or cathodic protection can be applied to slow or eliminate the corrosion process. It is common to allow for an amount of corrosion in design by simply over dimensioning the cross-sectional area of the steel pile. In this way, the corrosion process can be prolonged up to 50 years.

Prestressed concrete piles

Concrete piles are typically made with steel reinforcing and prestressing tendons to obtain the tensile strength required, to survive handling and driving, and to provide sufficient bending resistance.

Long piles can be difficult to handle and transport. Pile joints can be used to join two or more short piles to form one long pile. Pile joints can be used with both precast and prestressed concrete piles.

Composite piles

A "composite pile" is a pile made of steel and concrete members that are fastened together, end to end, to form a single pile. It is a combination of different materials or different shaped materials such as pipe and H-beams or steel and concrete.

Aquatic pilings/Marine pilings

Wood (and other) pilings are used for supports in structures raised above water, for docks, piers, jettys, bridges, oil platforms, and lighthouses. These must be treated specially to avoid corrosion.[16]

See also

- Eurocode EN 1997

- International Society for Micropiles

- Post in ground construction also called earthfast or posthole construction; a historic method of building wooden structures.

- Stilt house, also known as a lake house; an ancient, historic house type built on pilings.

- Shallow foundations

- Pile bridge

Notes

- ↑ PDCA

- ↑ "Reinforced Pier Systems - Pile Foundation Systems". http://www.houstonfoundationpros.com/reinforced-pier-systems/. Retrieved 26 Jul 2013.

- ↑ Offshore Wind Turbine Foundations, 2009-09-09, accessed 2010-04-12.

- ↑ 4.0 4.1 Constructing a turbine foundation Horns Rev project, Elsam monopile foundation construction process, accessed 2010-04-12]

- ↑ Horns Revolution , Modern Power Systems, 2002-10-05, accessed 2010-04-14.

- ↑ Lynn and Inner Dowsing description

- ↑ Handbook on Under-reamed and bored compaction pile foundation, Central building research institute Roorkee, Prepared by Devendra Sharma, M. P. Jain, Chandra Prakash

- ↑ Marshall, Brain. "How House Construction Works". How Stuff Works. HowStuffWorks, Inc. http://home.howstuffworks.com/home-improvement/repair/house6.htm. Retrieved 4 April 2013.

- ↑ pwri.go.jp

- ↑ dfi.org

- ↑ "International Society for Micropiles". http://www.ismicropiles.org. Retrieved 2007-02-02.

- ↑ "CHANCE® Helical Pulldown® Micropiles". Foundation Technologies, Inc.. http://www.foundationtechnologies.com/products/chance-helical-pulldown-micropiles/.

- ↑ "Helical Piers FAQ". https://www.piertech.com/products/helical-piers.html.

- ↑ terrasystemsonline.com

- ↑ "ductile iron piles". https://helicaldrilling.com/company-news/ductile-iron-piles/.

- ↑ "Fuzzy Dock Posts". http://stjohns.ifas.ufl.edu/Sea/documents/Docks3-10.pdf.

References

- Italiantrivelle Foundation Industry The Deep Foundation web portal Italiantrivelle is the number one source of information regarding the Foundation Industry.

- Fleming, W. G. K. et al., 1985, Piling Engineering, Surrey University Press; Hunt, R. E., Geotechnical Engineering Analysis and Evaluation, 1986, McGraw-Hill.

- Coduto, Donald P. Foundation Design: Principles and Practices 2nd ed., Prentice-Hall Inc., 2001.

- NAVFAC DM 7.02 Foundations and Earth Structures U.S. Naval Facilities Engineering Command, 1986.

- Rajapakse, Ruwan., Pile Design and Construction Guide, 2003

- Tomlinson, P.J., Pile Design and Construction Practice, 1984

- Stabilization of Organic Soils

- Sheet piling handbook, 2010

External links

- Deep Foundations Institute

- International Construction Equipment

- PDCA: Pile Driving Contractors' Association

- ADSC: The International Association of Foundation Drilling

- International Society for Micropiles

- Federation of Piling Specialists (UK)

- Procedure of Installing Drilled Shaft (Bored Pile)