Physics:Electrospinning

Electrospinning is a fiber production method that uses electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers.[1] The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product.

Process

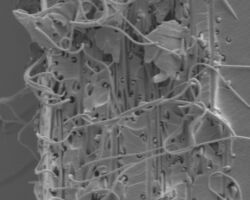

When a sufficiently high voltage is applied to a liquid droplet, the body of the liquid becomes charged, and electrostatic repulsion counteracts the surface tension and the droplet is stretched; at a critical point a stream of liquid erupts from the surface. This point of eruption is known as the Taylor cone. If the molecular cohesion of the liquid is sufficiently high, stream breakup does not occur (if it does, droplets are electrosprayed) and a charged liquid jet is formed.[2][3]

As the jet dries in flight, the mode of current flow changes from ohmic to convective as the charge migrates to the surface of the fiber. The jet is then elongated by a whipping process caused by electrostatic repulsion initiated at small bends in the fiber, until it is finally deposited on the grounded collector.[4] The elongation and thinning of the fiber resulting from this bending instability leads to the formation of uniform fibers with nanometer-scale diameters.[5]

|

|

Parameters

- Molecular weight, molecular-weight distribution and architecture (branched, linear etc.) of the polymer

- Solution properties (viscosity, conductivity and surface tension)

- Electric potential, flow rate and concentration

- Distance between the capillary and collection screen

- Ambient parameters (temperature, humidity and air velocity in the chamber)

- Motion and size of target screen (collector)

- Needle gauge

| Parameters | Effect on fibers | Linked to |

|---|---|---|

| Solution Parameters | ||

| Viscosity | If too low, no continuous fiber formation will occur; if too high, the ejection of the jet from the needle tip will be impeded. | Polymer concentration, Molecular Weight |

| Polymer Concentration | Increase in concentration results in increased diameter. A minimum concentration is required: if too low, there will not be enough entanglements to sustain the jet (beads). | Surface tension, Viscosity |

| Molecular weight | Reflects the number of entanglements of polymeric chains in solution, thus its viscosity. | Viscosity, Surface tension, Conductivity |

| Conductivity | Directly related to the accumulation of charges under the electric field. Higher conductivity results in stronger stretching of the jet producing smaller diameter fiber. | Voltage |

| Surface tension | With all other parameters fixed, it determines the upper and lower boundaries of the electrospinning window. | |

| Processing Parameters | ||

| Voltage | Fiber formation occurs only after a certain threshold voltage. Higher voltages cause greater stretching of the solution with reduction of fiber diameters; but if the voltage is too high, it may cause instability of the jet and increase the fiber diameter. | Tip to collector distance, Conductivity, Feed rate |

| Tip to collector distance | Affects the traveling time of the polymer jet; should be high enough to allow complete evaporation of the solvent. | Voltage, Feed rate |

| Feed rate | Determines the amount of solution available per unit of time. Influences the jet velocity and the material transfer rate. Increasing the rate causes more polymer to be processed at a given instant, thus increasing fiber diameter. | Tip to collector distance, Voltage, Viscosity |

| Ambient Parameters | ||

| Humidity | High humidity may result in pores on fiber surface | |

| Temperature | An increase in temperature results in a decrease in fiber diameter thanks to a decrease in viscosity. | Viscosity |

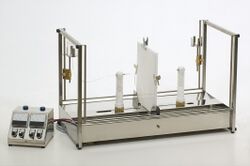

Apparatus and range

The standard laboratory setup for electrospinning consists of a spinneret (typically a hypodermic syringe needle) connected to a high-voltage (5 to 50 kV) direct current power supply, a syringe pump, and a grounded collector. A polymer solution, sol-gel, particulate suspension or melt is loaded into the syringe and this liquid is extruded from the needle tip at a constant rate by a syringe pump.[6] Alternatively, the droplet at the tip of the spinneret can be replenished by feeding from a header tank providing a constant feed pressure. This constant pressure type feed works better for lower viscosity feedstocks.

| File:Electrospinning Image for Wikipedia.tif |  |

Scaling-up possibilities

- Alternating current electrospinning[7][8][9][10][11][12]

- Needleless (also known as, nozzle-free) electrospinning [13][14]

- Multiplying the needles[15]

- High-throughput roller electrospinning[16]

- Wire electrospinning

- Bubble electrospinning[17]

- Ball electrospinning[18][19]

- High speed electrospinning[20]

- Plate edge electrospinning[21]

- Bowl electrospinning[22]

- Hollow tube electrospinning[23]

- Rotary cone electrospinning[24]

- Spiral coil electrospinning[25]

- Electroblowing[26]

Other techniques

Modification of the spinneret and/or the type of solution can allow for the creation of fibers with unique structures and properties. Electrospun fibers can adopt a porous or core–shell morphology depending on the type of materials being spun as well as the evaporation rates and miscibility for the solvents involved. For techniques which involve multiple spinning fluids, the general criteria for the creation of fibers depends upon the spinnability of the outer solution.[27] This opens up the possibility of creating composite fibers which can function as drug delivery systems or possess the ability to self-heal upon failure.[28][29]

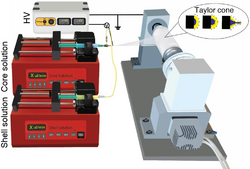

Co-axial electrospinning

A coaxial setup uses a dual-solution feed system which allows for the injection of one solution into another at the tip of the spinneret. The sheath fluid is believed to act as a carrier which draws in the inner fluid at the Taylor Cone of the electrospinning jet.[27] If the solutions are immiscible then a core shell structure is usually observed. Miscible solutions however can result in porosity or a fiber with distinct phases due to phase separation during solidification of the fiber. For more advanced setups, a triaxial or quadaxial (tetra-axial) spinneret can be used with multiple solutions.

Emulsion electrospinning

Emulsions can be used to create core shell or composite fibers without modification of the spinneret. However, these fibers are typically more difficult to produce compared to coaxial spinning due to the greater number of variables which must be accounted for in creating the emulsion. A water phase and an immiscible solvent phase are mixed in the presence of an emulsifying agent to form the emulsion. Any agent which stabilizes the interface between the immiscible phases can be used. Surfactants such as sodium dodecyl sulfate, Triton X-100 and nanoparticles have been used successfully. During the electrospinning process the emulsion droplets within the fluid are stretched and gradually confined leading to their coalescence. If the volume fraction of inner fluid is sufficiently high, a continuous inner core can be formed.[31]

Electrospinning of blends is a variation of this technique which uses the fact that polymers are generally immiscible with each and can phase segregate without the use of surfactants. This method can be simplified further if a solvent which dissolves both polymers is used.[32]

Melt electrospinning

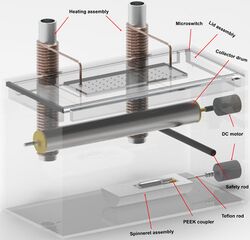

Electrospinning of polymer melts eliminates the need for volatile solvents in solution electrospinning.[33] Semi crystalline polymer fibers such as PE, PET and PP, which would otherwise be impossible or very difficult to create using solution spinning, can be created. The setup is very similar to that employed in conventional electrospinning and includes the use of a syringe or spinneret, a high voltage supply and the collector. The polymer melt is usually produced by heating from either resistance heating, circulating fluids, air heating or lasers.[34]

Due to the high viscosity of polymer melts, the fiber diameters are usually slightly larger than those obtained from solution electrospinning. The fiber uniformity upon achieving stable flow rates and thermal equilibrium, tends to be very good. The whipping instability which is the predominant stage in which the fiber is stretched for spinning from solutions can be absent from the process due to the low melt conductivity and high viscosity of the melt. The most significant factors which affect the fiber size tend to be the feed rate, the molecular weight of the polymer and the diameter of the spinneret. Fiber sizes ranging from ~250 nm to several hundreds of micrometers have been created thus far with the lower sizes being achieved using low molecular weight polymers.[35]

History

In the late 16th century William Gilbert[36] set out to describe the behavior of magnetic and electrostatic phenomena. He observed that when a suitably electrically charged piece of amber was brought near a droplet of water it would form a cone shape and small droplets would be ejected from the tip of the cone: this is the first recorded observation of electrospraying.

In 1887 C. V. Boys described “the old, but little known experiment of electrical spinning”. Boys’ apparatus consisted of “a small dish, insulated and connected with an electrical machine”.[37] He found that as his stock liquid reached the edge of the dish, that he could draw fibers from a number of materials including shellac, beeswax, sealing-wax, gutta-percha and collodion.

The process of electrospinning was patented by J.F. Cooley in May 1900[38] and February 1902[39] and by W.J. Morton in July 1902.[40]

In 1914 John Zeleny, published work on the behavior of fluid droplets at the end of metal capillaries.[41] His effort began the attempt to mathematically model the behavior of fluids under electrostatic forces.

Further developments toward commercialization were made by Anton Formhals, and described in a sequence of patents from 1934[42] to 1944[43] for the fabrication of textile yarns. Electrospinning from a melt rather than a solution was patented by C.L. Norton in 1936[44] using an air-blast to assist fiber formation.

In 1938 Nathalie D. Rozenblum and Igor V. Petryanov-Sokolov,[45] working in Nikolai A. Fuchs' group at the Aerosol Laboratory of the L. Ya. Karpov Institute[46] in the USSR, generated electrospun fibers, which they developed into filter materials known as "Petryanov filters". By 1939, this work had led to the establishment of a factory in Tver' for the manufacture of electrospun smoke filter elements for gas masks. The material, dubbed BF (Battlefield Filter) was spun from cellulose acetate in a solvent mixture of dichloroethane and ethanol. By the 1960s output of spun filtration material was claimed as 20 million m2 per annum.[47]

Between 1964 and 1969 Sir Geoffrey Ingram Taylor produced the theoretical underpinning of electrospinning.[48][49][50] Taylor’s work contributed to electrospinning by mathematically modeling the shape of the cone formed by the fluid droplet under the effect of an electric field; this characteristic droplet shape is now known as the Taylor cone. He further worked with J. R. Melcher to develop the "leaky dielectric model" for conducting fluids.[51]

Simon, in a 1988 NIH SBIR grant report, showed that solution electrospinning could be used to produced nano- and submicron-scale polystyrene and polycarbonate fibrous mats specifically intended for use as in vitro cell substrates. This early application of electrospun fibrous lattices for cell culture and tissue engineering showed that various cell types would adhere to and proliferate upon the fibers in vitro. Small changes in the surface chemistry of the fibers were also observed depending upon the polarity of the electric field during spinning.[52]

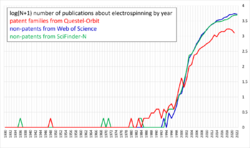

In the early 1990s several research groups (notably that of Reneker and Rutledge who popularised the name electrospinning for the process)[53] demonstrated that many organic polymers could be electrospun into nanofibers. Between 1996 and 2003 the interest in electrospinning underwent an explosive growth, with the number of publications and patent applications approximately doubling every year.[5]

Since 1995 there have been further theoretical developments of the driving mechanisms of the electrospinning process. Reznik et al. described the shape of the Taylor cone and the subsequent ejection of a fluid jet.[54] Hohman et al. investigated the relative growth rates of the numerous proposed instabilities in an electrically forced jet once in flight[55] and endeavors to describe the most important instability to the electrospinning process, the bending (whipping) instability.

Uses

The size of an electrospun fiber can be in the nano scale and the fibers may possess nano scale surface texture, leading to different modes of interaction with other materials compared with macroscale materials.[56] In addition to this, the ultra-fine fibers produced by electrospinning are expected to have two main properties, a very high surface to volume ratio, and a relatively defect free structure at the molecular level. This first property makes electrospun material suitable for activities requiring a high degree of physical contact, such as providing sites for chemical reactions, or the capture of small sized particulate material by physical entanglement – filtration. The second property should allow electrospun fibers to approach the theoretical maximum strength of the spun material, opening up the possibility of making high mechanical performance composite materials.

Filtration

The use of nanofiber webs as a filtering medium is well established. Due to the small size of the fibers London-Van Der Waals forces are an important method of adhesion between the fibers and the captured materials. Polymeric nanofibers have been used in air filtration applications for more than seven decades.[47][57] Because of poor bulk mechanical properties of thin nanowebs, they are laid over a filtration medium substrate. The small fiber diameters cause slip flows at fiber surfaces, causing an increase in the interception and inertial impaction efficiencies of these composite filter media. The enhanced filtration efficiency at the same pressure drop is possible with fibers having diameters less than 0.5 micrometer. Since the essential properties of protective clothing are high moisture vapor transport, increased fabric breath-ability, and enhanced toxic chemical resistance, electrospun nanofiber membranes are good candidates for these applications.[58]

Textile manufacturing

The majority of early patents for electrospinning were for textile applications, however little woven fabric was actually produced, perhaps due to difficulties in handling the barely visible fibers. However, electrospinning has the potential to produce seamless non-woven garments by integrating advanced manufacturing with fiber electrospinning. This would introduce multi-functionality (flame, chemical, environmental protection) by blending fibers into electrospinlaced (using electrospinning to combine different fibers and coatings to form three-dimensional shapes, such as clothing)[59] layers in combination with polymer coatings.[60]

Medical

Electrospinning can also be used for medical purposes.[61] The electrospun scaffolds made for tissue engineering applications can be penetrated with cells to treat or replace biological targets.[62] Nanofibrous wound dressings[63] have excellent capability to isolate the wound from microbial infections.[64][65] Other medical textile materials such as sutures are also attainable via electrospinning.[66] Through the addition of a drug substance into the electrospinning solution or melt[33] diverse fibrous drug delivery systems (e.g., implants,[67] transdermal patches,[68] oral forms[69]) can be prepared. Electropsun propolis nanofibrous membrane showed an antiviral effect against the SARS-CoV-2 virus, and an antibacterial effect against Staphylococcus aureus and Salmonella enterica bacteria.[70] Interestingly, electrospinning allows to fabricate nanofibers with advanced architecture [71] that can be used to promote the delivery of multiple drugs at the same time and with different kinetics.[72][73]

Cosmetic

Electrospun nanomaterials have been employed to control their delivery so they can work within skin to improve its appearance.[74] Electrospinning is an alternative to traditional nanoemulsions and nanoliposomes.

Pharmaceutical manufacturing

The continuous manner and the effective drying effect enable the integration of electrospinning into continuous pharmaceutical manufacturing systems.[75] The synthesized liquid drug can be quickly turned into an electrospun solid product processable for tableting and other dosage forms.

Composites

Ultra-fine electrospun fibers show clear potential for the manufacture of long fiber composite materials.[76]

Application is limited by difficulties in making sufficient quantities of fiber to make substantial large scale articles in a reasonable time scale. For this reason medical applications requiring relatively small amounts of fiber are a popular area of application for electrospun fiber reinforced materials.

Electrospinning is being investigated as a source of cost-effective, easy to manufacture wound dressings, medical implants, and scaffolds for the production of artificial human tissues. These scaffolds fulfill a similar purpose as the extracellular matrix in natural tissue. Biodegradable polymers, such as polycaprolactone[77] and polysaccharides,[78] are typically used for this purpose. These fibers may then be coated with collagen to promote cell attachment, although collagen has successfully been spun directly into membranes.[79]

|

|

Catalysts

Electrospun fibers may have potential as a surface for enzymes to be immobilized on. These enzymes could be used to break down toxic chemicals in the environment, among other things.[5]

Mass production

Thus far, at least eight countries in the world have companies which provide industrial-level and laboratory-scale electrospinning machines: three companies each in Italy and Czech Republic, two each in Iran, Japan , and Spain , and one each in the Netherlands, New Zealand[80] and Turkey.[81]

References

- ↑ Ziabicki, A. (1976) Fundamentals of fiber formation, John Wiley and Sons, London, ISBN 0-471-98220-2.

- ↑ High speed video of the taylor cone formation and electrospinning. youtube.com

- ↑ Single nozzle electrospinning process nanofiber formation video. youtube.com

- ↑ High speed video of the whipping instability. youtube.com

- ↑ 5.0 5.1 5.2 "Electrospinning of Nanofibers: Reinventing the Wheel?". Advanced Materials 16 (14): 1151–1170. 2004. doi:10.1002/adma.200400719. Bibcode: 2004AdM....16.1151L.

- ↑ "Electrospinning and Imaging". Advanced Engineering Materials 14 (5): B266–B278. May 2012. doi:10.1002/adem.201180010.

- ↑ Sivan, Manikandan; Madheswaran, Divyabharathi; Valtera, Jan; Kostakova, Eva Kuzelova; Lukas, David (2022-01-01). "Alternating current electrospinning: The impacts of various high-voltage signal shapes and frequencies on the spinnability and productivity of polycaprolactone nanofibers" (in en). Materials & Design 213: 110308. doi:10.1016/j.matdes.2021.110308. ISSN 0264-1275.

- ↑ "Alternating current electrospinning for preparation of fibrous drug delivery systems". International Journal of Pharmaceutics 495 (1): 75–80. November 2015. doi:10.1016/j.ijpharm.2015.08.069. PMID 26320549.

- ↑ "Plasma treatment effects on bulk properties of polycaprolactone nanofibrous mats fabricated by uncommon AC electrospinning: A comparative study" (in en). Surface and Coatings Technology 399: 126203. 2020-10-15. doi:10.1016/j.surfcoat.2020.126203. ISSN 0257-8972.

- ↑ "Production of poly (ε-caprolactone) Antimicrobial Nanofibers by Needleless Alternating Current Electrospinning" (in en). Materials Today: Proceedings. 6th International Conference on Recent Advances in Materials, Minerals & Environment (RAMM) 2018, RAMM 2018, 27–29 November 2018, Penang, Malaysia 17: 1100–1104. 2019-01-01. doi:10.1016/j.matpr.2019.06.526. ISSN 2214-7853. http://www.sciencedirect.com/science/article/pii/S221478531931898X.

- ↑ "Rapid fabrication of poly(ε-caprolactone) nanofibers using needleless alternating current electrospinning" (in en). Journal of Applied Polymer Science 133 (13): n/a. 2016. doi:10.1002/app.43232. ISSN 1097-4628.

- ↑ Madheswaran, Divyabharathi; Sivan, Manikandan; Valtera, Jan; Kostakova, Eva Kuzelova; Egghe, Tim; Asadian, Mahtab; Novotny, Vit; Nguyen, Nhung H. A. et al. (2022). "Composite yarns with antibacterial nanofibrous sheaths produced by collectorless alternating-current electrospinning for suture applications" (in en). Journal of Applied Polymer Science 139 (13): 51851. doi:10.1002/app.51851. ISSN 1097-4628. https://onlinelibrary.wiley.com/doi/abs/10.1002/app.51851.

- ↑ Niu, Haitao; Lin, Tong (2012). "Fiber generators in needleless electrospinning". Journal of Nanomaterials 12. http://www.hindawi.com/journals/jnm/2012/725950.

- ↑ "High-throughput production of silk fibroin-based electrospun fibers as biomaterial for skin tissue engineering applications". Materials Science & Engineering. C, Materials for Biological Applications 112: 110939. July 2020. doi:10.1016/j.msec.2020.110939. PMID 32409085. https://www.research.ed.ac.uk/en/publications/62973e7f-cb3d-4064-895b-d9e83458e062.

- ↑ Yan, Guilong; Niu, H.; Lin, T. (2019). "Chapter 7 - Needle-less Electrospinning". In Micro and Nano Technologies, Electrospinning: Nanofabrication and Applications. 219–247. doi:10.1016/B978-0-323-51270-1.00007-8. ISBN 9780323512701. https://www.sciencedirect.com/science/article/pii/B9780323512701000078.

- ↑ 16.0 16.1 Waqas, Muhammad; Keirouz, Antonios; Sanira Putri, Maria Kana; Fazal, Faraz; Diaz Sanchez, Francisco Javier; Ray, Dipa; Koutsos, Vasileios; Radacsi, Norbert (2021-06-01). "Design and development of a nozzle-free electrospinning device for the high-throughput production of biomaterial nanofibers" (in en). Medical Engineering & Physics 92: 80–87. doi:10.1016/j.medengphy.2021.04.007. ISSN 1350-4533. PMID 34167715. https://www.sciencedirect.com/science/article/pii/S1350453321000412.

- ↑ Liu, Y.; He, J.-H.; Yu, J.-Y. (2008). "Bubble-electrospinning: a novel method for making nanofibers". Journal of Physics: Conference Series 96 (1): 012001. doi:10.1088/1742-6596/96/1/012001. Bibcode: 2008JPhCS..96a2001L.

- ↑ Yan, Guilong; Niu, Haitao; Lin, Tong (2019), "Needle-less Electrospinning" (in en), Electrospinning: Nanofabrication and Applications (Elsevier): pp. 219–247, doi:10.1016/b978-0-323-51270-1.00007-8, ISBN 978-0-323-51270-1, https://linkinghub.elsevier.com/retrieve/pii/B9780323512701000078, retrieved 2024-01-31

- ↑ Smit, Eugene; Stegmann, H. (January 31, 2024). "Ball-Electrospinning Technology and It's Associated Advantages". https://www.sncfibers.com/snc-best.

- ↑ "High speed electrospinning for scaled-up production of amorphous solid dispersion of itraconazole". International Journal of Pharmaceutics 480 (1–2): 137–42. March 2015. doi:10.1016/j.ijpharm.2015.01.025. PMID 25596415.

- ↑ Thoppey, N.M.; Bochinski, J.R.; Clarke, L.I.; Gorga, R.E. (2010). "Unconfined fluid electrospun into high quality nanofibers from a plate edge". Polymer 51 (21): 4928–4936. doi:10.1016/j.polymer.2010.07.046. http://www.physics.ncsu.edu/clarke/papers/Polymer%2051,%204928%20%282010%29.pdf.

- ↑ "Edge electrospinning for high throughput production of quality nanofibers". Nanotechnology 22 (34): 345301. August 2011. doi:10.1088/0957-4484/22/34/345301. PMID 21799242. Bibcode: 2011Nanot..22H5301T.

- ↑ Varabhas, J.; Chase, G.; Reneker, D. (2008). "Electrospun nanofibers from a porous hollow tube". Polymer 49 (19): 4226–4229. doi:10.1016/j.polymer.2008.07.043.

- ↑ "Superhigh-throughput needleless electrospinning using a rotary cone as spinneret". Small 6 (15): 1612–6. August 2010. doi:10.1002/smll.201000454. PMID 20602427.

- ↑ "Continuous bundles of aligned electrospun PAN nano-fiber using electrostatic spiral collector and converging coil". Polymer 84 (10): 52–58. 2016. doi:10.1016/j.polymer.2015.11.046.

- ↑ "Electroblowing and electrospinning of fibrous diclofenac sodium-cyclodextrin complex-based reconstitution injection". Journal of Drug Delivery Science and Technology 26: 28–34. April 2015. doi:10.1016/j.jddst.2015.02.003.

- ↑ 27.0 27.1 "Co-electrospinning of core-shell fibers using a single-nozzle technique". Langmuir 23 (5): 2311–4. February 2007. doi:10.1021/la063194q. PMID 17266345.

- ↑ "Biodegradable electrospun fibers for drug delivery". Journal of Controlled Release 92 (3): 227–31. October 2003. doi:10.1016/S0168-3659(03)00372-9. PMID 14568403.

- ↑ "Encapsulation of self-healing materials by electrospinning, emulsion electrospinning, solution blowing and intercalation". Journal of Materials Chemistry 22 (18): 9138. 2012. doi:10.1039/C2JM15696B.

- ↑ "Nylon-6/chitosan core/shell antimicrobial nanofibers for the prevention of mesh-associated surgical site infection". Journal of Nanobiotechnology 18 (1): 51. March 2020. doi:10.1186/s12951-020-00602-9. PMID 32188479.

- ↑ "Preparation of Core-Sheath Composite Nanofibers by Emulsion Electrospinning". Macromolecular Rapid Communications 27 (19): 1637–1642. 2006. doi:10.1002/marc.200600384.

- ↑ "Electrospun nanofiber reinforced and toughened composites through in situ nano-interface formation". Composites Science and Technology 68 (15–16): 3322–3329. 2008. doi:10.1016/j.compscitech.2008.08.033. http://ss.bjmu.edu.cn/departments/tsg/Search/sci/sci-paper/2008sci/2008-dengxuliang-Electrospun%20nanofiber%20reinforced%20and%20toughened%20composites%20through%20in%20situ%20nano-interface%20formation.pdf. Retrieved 2013-05-16.

- ↑ 33.0 33.1 "Solvent-free melt electrospinning for preparation of fast dissolving drug delivery system and comparison with solvent-based electrospun and melt extruded systems". Journal of Pharmaceutical Sciences 102 (2): 508–17. February 2013. doi:10.1002/jps.23374. PMID 23161110.

- ↑ "Melt electrospinning". Chemistry: An Asian Journal 6 (1): 44–56. January 2011. doi:10.1002/asia.201000436. PMID 21080400.

- ↑ "Electrospinning of polymer melts: Phenomenological observations". Polymer 48 (23): 6823–6833. 2007. doi:10.1016/j.polymer.2007.09.037. http://med-x.sjtu.edu.cn/daltonlab/Literature/Dalton%20et%20al%20%28melt%20espinning%29.pdf.

- ↑ Gilbert, W. (1628) De Magnete, Magneticisque Corporibus, et de Magno Magnete Tellure (On the Magnet and Magnetic Bodies, and on That Great Magnet the Earth), London, Peter Short.

- ↑ Boys, C. V. (1887). "On the Production, Properties, and some suggested Uses of the Finest Threads". Proceedings of the Physical Society 9 (1): 8–19. doi:10.1088/1478-7814/9/1/303. Bibcode: 1887PPSL....9....8B. https://zenodo.org/record/1431517.

- ↑ Cooley, J.F. Patent GB 06385 "Improved methods of and apparatus for electrically separating the relatively volatile liquid component from the component of relatively fixed substances of composite fluids" 19 May 1900

- ↑ Cooley, J. F. et al. "Apparatus for electrically dispersing fluids" U.S. Patent 692,631 Issue date: February 4, 1902

- ↑ Morton, W.J. et al. "Method of dispersing fluids" U.S. Patent 0,705,691 Issue date: July 29, 1902

- ↑ Zeleny, J. (1914). "The Electrical Discharge from Liquid Points, and a Hydrostatic Method of Measuring the Electric Intensity at Their Surfaces". Physical Review 3 (2): 69–91. doi:10.1103/PhysRev.3.69. Bibcode: 1914PhRv....3...69Z. https://zenodo.org/record/1517382.

- ↑ Formhals, Anton et al. "Process and apparatus for preparing artificial threads" U.S. Patent 1,975,504 Issue date: October 2, 1934

- ↑ Formhals, Anton et al. "Method and apparatus for spinning" U.S. Patent 2,349,950 Issue date: May 30, 1944

- ↑ Norton, C.L. "Method and apparatus for producing fibrous or filamentary material" U.S. Patent 2,048,651 Issue date: July 21, 1936

- ↑ Colleagues; Students (2007). "On the 100th anniversary of the birth of I.V. Petryanov-Sokolov". Izvestiya, Atmospheric and Oceanic Physics 43 (3): 395. doi:10.1134/S0001433807030164. Bibcode: 2007IzAOP..43..395..

- ↑ Fiber Materials Electrospinning Laboratory (FMEL) . electrospinning.ru

- ↑ 47.0 47.1 Electrospinning of micro-and nanofibers : fundamentals and applications in separation and filtration processes. New York: Begell House. 2007. ISBN 978-1-56700-241-6.

- ↑ Taylor, G. (1964). "Disintegration of Water Drops in an Electric Field". Proceedings of the Royal Society A 280 (1382): 383–397. doi:10.1098/rspa.1964.0151. Bibcode: 1964RSPSA.280..383T.

- ↑ Taylor, G. (1966). "The Force Exerted by an Electric Field on a Long Cylindrical Conductor". Proceedings of the Royal Society A 291 (1425): 145–158. doi:10.1098/rspa.1966.0085. Bibcode: 1966RSPSA.291..145T.

- ↑ Taylor, G. (1969). "Electrically Driven Jets". Proceedings of the Royal Society A 313 (1515): 453–475. doi:10.1098/rspa.1969.0205. Bibcode: 1969RSPSA.313..453T.

- ↑ "Electrohydrodynamics: A Review of the Role of Interfacial Shear Stresses". Annual Review of Fluid Mechanics 1 (1): 111–146. 1969. doi:10.1146/annurev.fl.01.010169.000551. Bibcode: 1969AnRFM...1..111M.

- ↑ "NIH Phase I Final Report: Fibrous Substrates for Cell Culture (R3RR03544A)" (in en). 1988. https://www.researchgate.net/publication/317053872.

- ↑ "Electrospinning process and applications of electrospun fibers". Journal of Electrostatics 35 (2–3): 151–160. 1995. doi:10.1016/0304-3886(95)00041-8.

- ↑ Reznik, S. N.; Yarin, A. L.; Theron, A.; Zussman, E. (2004). "Transient and steady shapes of droplets attached to a surface in a strong electric field". Journal of Fluid Mechanics 516: 349–377. doi:10.1017/S0022112004000679. Bibcode: 2004JFM...516..349R. http://www.hitech.technion.ac.il/~eyal/publications/JFM1.pdf. Retrieved 2013-05-16.

- ↑ Hohman, M. M.; Shin, M.; Rutledge, G.; Brenner, M. P. (2001). "Electrospinning and electrically forced jets. I. Stability theory". Physics of Fluids 13 (8): 2201. doi:10.1063/1.1383791. Bibcode: 2001PhFl...13.2201H. http://www.deas.harvard.edu/brenner/physfluid1.pdf.

- ↑ Ajayan P. M., Schadler, L. S. and Braun, P. V. (2003) Nanocomposite Science and Technology, Weinheim, Wiley-VCH, ISBN 9783527602124, doi:10.1002/3527602127.

- ↑ Donaldson Nanofiber Products

- ↑ "Electrospinning of nanofibers". Journal of Applied Polymer Science 96 (2): 557–569. 2005. doi:10.1002/app.21481.

- ↑ "Use of Electrospun Nanofiber Web for Protective Textile Materials as Barriers to Liquid Penetration". Textile Research Journal 77 (9): 696–702. 2007. doi:10.1177/0040517507080284.

- ↑ Yu-Jun Zhang; Yu-Dong Huang (2004). "Electrospun non-woven mats of EVOH". 1. p. 106. doi:10.1109/DEIV.2004.1418615. ISBN 0-7803-8461-X.

- ↑ "Electrospinning: applications in drug delivery and tissue engineering". Biomaterials 29 (13): 1989–2006. May 2008. doi:10.1016/j.biomaterials.2008.01.011. PMID 18281090.

- ↑ "Electrospun nanofibrous structure: a novel scaffold for tissue engineering". Journal of Biomedical Materials Research 60 (4): 613–21. June 2002. doi:10.1002/jbm.10167. PMID 11948520.

- ↑ Jaberifard, Farnaz; Ramezani, Soghra; Ghorbani, Marjan; Arsalani, Nasser; Mortazavi Moghadam, Fatemeh (January 2023). "Investigation of wound healing efficiency of multifunctional eudragit/soy protein isolate electrospun nanofiber incorporated with ZnO loaded halloysite nanotubes and allantoin" (in en). International Journal of Pharmaceutics 630: 122434. doi:10.1016/j.ijpharm.2022.122434. PMID 36435502. https://linkinghub.elsevier.com/retrieve/pii/S0378517322009899.

- ↑ Doustdar, Fatemeh; Ramezani, Soghra; Ghorbani, Marjan; Mortazavi Moghadam, Fatemeh (November 2022). "Optimization and characterization of a novel tea tree oil-integrated poly (ε-caprolactone)/soy protein isolate electrospun mat as a wound care system" (in en). International Journal of Pharmaceutics 627: 122218. doi:10.1016/j.ijpharm.2022.122218. PMID 36155796. https://linkinghub.elsevier.com/retrieve/pii/S0378517322007724.

- ↑ "Electrospun nanofibrous polyurethane membrane as wound dressing". Journal of Biomedical Materials Research Part B: Applied Biomaterials 67 (2): 675–9. November 2003. doi:10.1002/jbm.b.10058. PMID 14598393.

- ↑ "Electrospun drug-eluting sutures for local anesthesia". Journal of Controlled Release 161 (3): 903–9. August 2012. doi:10.1016/j.jconrel.2012.05.021. PMID 22609349.

- ↑ "A hybrid biomimetic nanomatrix composed of electrospun polycaprolactone and bioactive peptide amphiphiles for cardiovascular implants". Acta Biomaterialia 7 (1): 225–33. January 2011. doi:10.1016/j.actbio.2010.08.013. PMID 20728588.

- ↑ "Vitamin-loaded electrospun cellulose acetate nanofiber mats as transdermal and dermal therapeutic agents of vitamin A acid and vitamin E". European Journal of Pharmaceutics and Biopharmaceutics 67 (2): 387–97. September 2007. doi:10.1016/j.ejpb.2007.03.018. PMID 17498935.

- ↑ "Electrospun water soluble polymer mat for ultrafast release of Donepezil HCl". Express Polymer Letters 4 (12): 763–772. 2010. doi:10.3144/expresspolymlett.2010.92. http://real.mtak.hu/28278/1/EPL_0001669_article_2_u.pdf.

- ↑ "Propolis nanofibers: Development and effect against SARS-CoV-2 virus and S. aureus, S. enterica bacteria". Materials Today Chemistry 33: 1–8. September 2023. doi:10.1016/j.mtchem.2023.101749.

- ↑ "Electrospun Scaffolds in Tendons Regeneration: a review". Muscles, Ligaments and Tendons Journal 9 (4): 478–493. October 2019. doi:10.32098/mltj.04.2019.02.

- ↑ "Advances in multidrug delivery from electrospun nanomaterials". InCore-Shell Nanostructures for Drug Delivery and Theranostics. Woodhead Publishing. January 2018. pp. 405–430. doi:10.1016/B978-0-08-102198-9.00014-4. ISBN 978-0-08-102198-9.

- ↑ "Design and In Vitro Study of a Dual Drug-Loaded Delivery System Produced by Electrospinning for the Treatment of Acute Injuries of the Central Nervous System". Pharmaceutics 13 (6): 848. June 2021. doi:10.3390/pharmaceutics13060848. PMID 34201089.

- ↑ "A New Spin on Delivery: Electrospun Collagen Drives Actives to New Depths". Cosmetics & Toiletries. New Revolution Fibres Ltd. 28 June 2018. https://www.cosmeticsandtoiletries.com/research/chemistry/A-New-Spin-on-Delivery-Electrospun-Collagen-Drives-Actives-to-New-Depths-486865351.html.

- ↑ "Continuous end-to-end production of solid drug dosage forms: Coupling flow synthesis and formulation by electrospinning". Chemical Engineering Journal 350: 290–299. October 2018. doi:10.1016/j.cej.2018.05.188. http://www.fiberpharma.co.nf/Continuous_electrospinning_2018.pdf.

- ↑ "Determination of tensile strength of electrospun single nanofibers through modeling tensile behavior of the nanofibrous mat". Composites Part B: Engineering 43: 15–21. 2011. doi:10.1016/j.compositesb.2011.04.024.

- ↑ "Electropsun Polycaprolactone Fibres in Bone Tissue Engineering: A Review". Molecular Biotechnology 63 (5): 363–388. 2021. doi:10.1007/s12033-021-00311-0. PMID 33689142.

- ↑ "Electrospinning of Polysaccharides for Tissue Engineering Applications". Reviews and Advances in Chemistry 11 (1–2): 112–133. 2021. doi:10.1134/S2079978021010052.

- ↑ "Electrospinning of collagen nanofibers". Biomacromolecules 3 (2): 232–8. 2002. doi:10.1021/bm015533u. PMID 11888306.

- ↑ "Revolution Fibres is manufacturing to the sun and back" (in en-NZ). https://techweek.co.nz/news/manufacturing-from-here-to-the-sun-and-back/.

- ↑ "Electrospinning Mass Production Machine Providers". http://electrospintech.com/massproductionmachine.html#.VpjsjlR9603.

Further reading

- "The history of the science and technology of electrospinning from 1600 to 1995". Journal of Engineered Fibers and Fabrics 7 (2): 63–73. June 2012. doi:10.1177/155892501200702S10. http://www.jeffjournal.org/papers/Volume7/7.2b.10N.Tucker.pdf.

- Electrospinning : Materials, Processing, and Applications. Hoboken: John Wiley & Sons. 2012. ISBN 978-3-527-32080-6.

- Science and technology of polymer nanofibers. Hoboken, N.J.: John Wiley & Sons. 2008. ISBN 978-0-471-79059-4.

- Electrospinning. Shawbury, Shrewsbury, Shropshire: I-Smithers Rapra publishing. 2008. ISBN 978-1-84735-091-6.

- An introduction to electrospinning and nanofibers. Singapore: World Scientific. 2005. ISBN 981-256-415-2.

- "Revealing novel power laws and quantization in electrospinning considering jet splitting—toward predicting fiber diameter and its distribution". Macromolecular Theory and Simulations 28 (4): 1900006. July 2019. doi:10.1002/mats.201900006.

External links

- Polish Academy of Science's page on electrospinning

- How to describe the electrospinning process

- Hackaday, "OpenESpin Building an Electrospinning machine for everyone."

- Nanofiberlabs,"Electrospinning of Nanofibers and Nanofiber Morphology"

- Electrospinning

|