Biology:Clostridium acetobutylicum

| Clostridium acetobutylicum | |

|---|---|

| |

| Scientific classification | |

| Domain: | Bacteria |

| Phylum: | Bacillota |

| Class: | Clostridia |

| Order: | Eubacteriales |

| Family: | Lachnospiraceae |

| Genus: | Clostridium |

| Species: | C. acetobutylicum

|

| Binomial name | |

| Clostridium acetobutylicum McCoy et al. 1926 (Approved Lists 1980)

| |

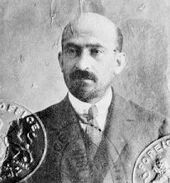

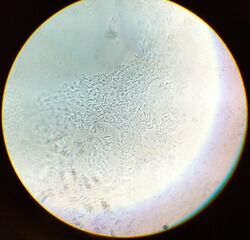

Clostridium acetobutylicum, ATCC 824, is a commercially valuable bacterium sometimes called the "Weizmann Organism", after Jewish Russian-born biochemist Chaim Weizmann. A senior lecturer at the University of Manchester, England , he used them in 1916 as a bio-chemical tool to produce at the same time, jointly, acetone, ethanol, and n-butanol from starch. The method has been described since as the ABE process, (Acetone Butanol Ethanol fermentation process), yielding 3 parts of acetone, 6 of n-butanol, and 1 of ethanol. Acetone was used in the important wartime task of casting cordite. The alcohols were used to produce vehicle fuels and synthetic rubber.

Unlike yeast, which can digest only some sugars into alcohol and carbon dioxide, C. acetobutylicum and other Clostridia can digest whey, sugar, starch, cellulose and perhaps certain types of lignin, yielding n-butanol, propionic acid, ether, and glycerin.

In genetic engineering

In 2008, a strain of Escherichia coli was genetically engineered to synthesize butanol; the genes were derived from Clostridium acetobutylicum.[1][2] In 2013, the first microbial production of short-chain alkanes was reported[3] - which is a considerable step toward the production of gasoline. One of the crucial enzymes - a fatty acyl-CoA reductase - came from Clostridium acetobutylicum.

See also

References

- ↑ M. Goho, Alexandra (2008-01-16). "Better Bugs for Making Butanol". http://www.technologyreview.com/news/409400/better-bugs-for-making-butanol/.

- ↑ Atsumi, S.; Hanai, T.; Liao, JC. (Jan 2008). "Non-fermentative pathways for synthesis of branched-chain higher alcohols as biofuels.". Nature 451 (7174): 86–9. doi:10.1038/nature06450. PMID 18172501. Bibcode: 2008Natur.451...86A.

- ↑ Choi, YJ.; Lee, SY. (Oct 2013). "Microbial production of short-chain alkanes.". Nature 502 (7472): 571–4. doi:10.1038/nature12536. PMID 24077097. Bibcode: 2013Natur.502..571C.

Further reading

- Nölling J; Breton G; Omelchenko MV et al. (August 2001). "Genome sequence and comparative analysis of the solvent-producing bacterium Clostridium acetobutylicum". J. Bacteriol. 183 (16): 4823–38. doi:10.1128/JB.183.16.4823-4838.2001. PMID 11466286.

- "Amino acid transport by membrane vesicles of an obligate anaerobic bacterium, Clostridium acetobutylicum". J. Bacteriol. 170 (2): 817–20. February 1988. doi:10.1128/jb.170.2.817-820.1988. PMID 2828326.

- "Structure of an endo-beta-1,4-glucanase gene from Clostridium acetobutylicum P262 showing homology with endoglucanase genes from Bacillus spp". Appl. Environ. Microbiol. 54 (5): 1289–92. May 1988. doi:10.1128/AEM.54.5.1289-1292.1988. PMID 3389820. Bibcode: 1988ApEnM..54.1289Z.

- "Effects of butanol on Clostridium acetobutylicum". Appl. Environ. Microbiol. 50 (5): 1165–70. November 1985. doi:10.1128/AEM.50.5.1165-1170.1985. PMID 2868690. Bibcode: 1985ApEnM..50.1165B.

- US patent 1875536

- US patent 1315585

- Weber, Christian; Farwick, Alexander; Benisch, Feline; Brat, Dawid; Dietz, Heiko; Subtil, Thorsten; Boles, Eckhard (10 June 2010). "Trends and challenges in the microbial production of lignocellulosic bioalcohol fuels". Applied Microbiology and Biotechnology 87 (4): 1303–1315. doi:10.1007/s00253-010-2707-z. ISSN 0175-7598. PMID 20535464.

- Jones, DT; Woods, DR (1986). "Acetone-butanol fermentation revisited". Microbiological Reviews 50 (4): 484–524. doi:10.1128/MMBR.50.4.484-524.1986. PMID 3540574.

- Bartha, Ronald M. Atlas & Richard (1993). Microbial ecology : fundamentals and applications (3rd ed.). Redwood City, Calif.: Benjamin/Cummings Pub. Co.. p. 563. ISBN 978-0-8053-0653-8. https://archive.org/details/microbialecology00atla/page/563.

- Microbial Processes: Promising Technologies for Developing Countries. Washington: National Academy of Sciences. 1979. doi:10.17226/9544. ISBN 978-0-309-57050-3. http://www.nap.edu/openbook.php?record_id=9544&page=R1. Retrieved 10 May 2011.

- Wong Kromhout, Wileen (2011-03-16). "UCLA researchers engineer E. coli to produce record-setting amounts of alternative fuel". http://newsroom.ucla.edu/releases/ucla-engineers-drive-e-coli-to-197675.

External links

- ATCC reference organism 824 C.Acetobutylicum.

- findarticles.com: Bacteria speeds drug to tumors - use of Clostridium acetobutylicum enzyme to activate cancer drug CB 1954.

- EPA Clostridium acetobutylicum Final Risk Assessment

- Genetic Engineering of Clostridium acetobutylicum for Enhanced Production of Hydrogen Gas: Penn State University.

- Pathema-Clostridium Resource

- Chaim Weizmann

- Type strain of Clostridium acetobutylicum at BacDive - the Bacterial Diversity Metadatabase

Wikidata ☰ Q148692 entry

|