Chemistry:Grubbs catalyst

Grubbs catalysts are a series of transition metal carbene complexes used as catalysts for olefin metathesis. They are named after Robert H. Grubbs, the chemist who supervised their synthesis. Several generations of the catalyst have also been developed.[1][2] Grubbs catalysts tolerate many functional groups in the alkene substrates, are air-tolerant, and are compatible with a wide range of solvents.[3][4] For these reasons, Grubbs catalysts have become popular in synthetic organic chemistry.[5] Grubbs, together with Richard R. Schrock and Yves Chauvin, won the Nobel Prize in Chemistry in recognition of their contributions to the development of olefin metathesis.

First-generation Grubbs catalyst

| |

| |

| Names | |

|---|---|

| IUPAC name

Benzylidene-bis(tricyclohexylphosphino)-dichlororuthenium

| |

| Identifiers | |

3D model (JSmol)

|

|

| ChemSpider | |

PubChem CID

|

|

| UNII | |

| |

| |

| Properties | |

| C43H72Cl2P2Ru | |

| Molar mass | 822.97 g·mol−1 |

| Appearance | Purple solid |

| Melting point | 153 °C (307 °F; 426 K) (decomposition) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

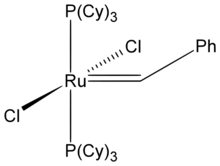

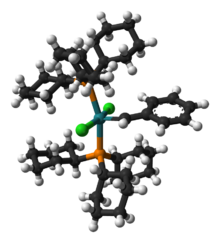

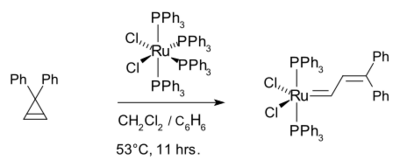

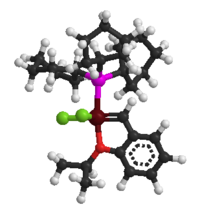

In the 1960s, ruthenium trichloride was found to catalyze olefin metathesis. Processes were commercialized based on these discoveries. These ill-defined but highly active homogeneous catalysts remain in industrial use.[6] The first well-defined ruthenium catalyst was reported in 1992.[7] It was prepared from RuCl2(PPh3)4 and diphenylcyclopropene.

This initial ruthenium catalyst was followed in 1995 by what is now known as the first-generation Grubbs catalyst. It is synthesized from RuCl2(PPh3)3, phenyldiazomethane, and tricyclohexylphosphine in a one-pot synthesis.[8][9]

The first-generation Grubbs catalyst was the first well-defined Ru-based catalyst. It is also important as a precursor to all other Grubbs-type catalysts.

Second-generation Grubbs catalyst

| |

| |

| Names | |

|---|---|

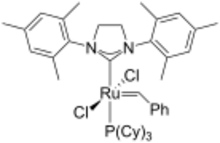

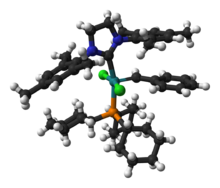

| IUPAC name

[1,3-bis-(2,4,6-trimethylphenyl)-2-imidazolidinylidene]dichloro(phenylmethylene)(tricyclohexylphosphino)ruthenium

| |

| Identifiers | |

3D model (JSmol)

|

|

| ChemSpider | |

PubChem CID

|

|

| |

| |

| Properties | |

| C46H65Cl2N2PRu | |

| Molar mass | 848.98 g·mol−1 |

| Appearance | Pinkish brown solid |

| Melting point | 143.5 to 148.5 °C (290.3 to 299.3 °F; 416.6 to 421.6 K) |

| Hazards | |

| GHS pictograms |

|

| GHS Signal word | Warning |

| H228 | |

| P210, P240, P241, P280, P378 | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

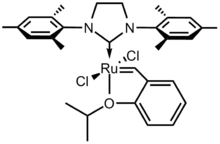

The second-generation catalyst has the same uses in organic synthesis as the first generation catalyst, but generally with higher activity. This catalyst is stable toward moisture and air, thus is easier to handle in laboratories.

Shortly before the discovery of the second-generation Grubbs catalyst, a very similar catalyst based on an unsaturated N-heterocyclic carbene (1,3-bis(2,4,6-trimethylphenyl)imidazole) was reported independently by Nolan[10] and Grubbs[11] in March 1999, and by Fürstner[12] in June of the same year. Shortly thereafter, in August 1999, Grubbs reported the second-generation catalyst, based on a saturated N-heterocyclic carbene (1,3-bis(2,4,6-trimethylphenyl)dihydroimidazole):[13]

In both the saturated and unsaturated cases a phosphine ligand is replaced with an N-heterocyclic carbene (NHC), which is characteristic of all second-generation-type catalysts.[3]

Both the first- and second-generation catalysts are commercially available, along with many derivatives of the second-generation catalyst.

Hoveyda–Grubbs catalysts

| |

| |

| Names | |

|---|---|

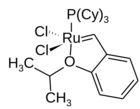

| IUPAC name

Dichloro(o-isopropoxyphenylmethylene)(tricyclohexylphosphine)ruthenium(II)

| |

| Identifiers | |

3D model (JSmol)

|

|

| ChemSpider | |

PubChem CID

|

|

| |

| |

| Properties | |

| C28H45Cl2OPRu | |

| Molar mass | 600.61 g·mol−1 |

| Appearance | Brown solid |

| Melting point | 195 to 197 °C (383 to 387 °F; 468 to 470 K) |

| Hazards | |

| GHS pictograms |

|

| GHS Signal word | Warning |

| H228 | |

| P210, P240, P241, P280, P378 | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

| |

| |

| Names | |

|---|---|

| IUPAC name

[1,3-Bis-(2,4,6-trimethylphenyl)-2-imidazolidinylidene]dichloro(o-isopropoxyphenylmethylene)ruthenium

| |

| Identifiers | |

3D model (JSmol)

|

|

| ChemSpider | |

| EC Number |

|

PubChem CID

|

|

| |

| |

| Properties | |

| C31H38Cl2N2ORu | |

| Molar mass | 626.63 g·mol−1 |

| Appearance | Green solid |

| Melting point | 216 to 220 °C (421 to 428 °F; 489 to 493 K) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

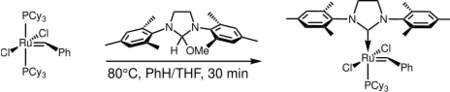

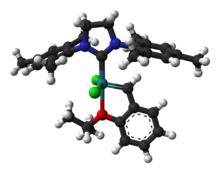

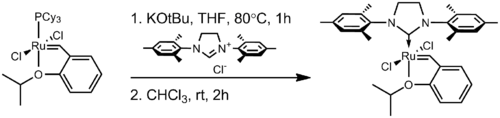

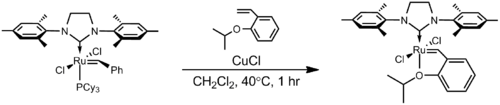

In the Hoveyda–Grubbs catalysts, the benzylidene ligands have a chelating ortho-isopropoxy group attached to the benzene rings. The ortho-isopropoxybenzylidene moiety is sometimes referred to as a Hoveyda chelate. The chelating oxygen atom replaces a phosphine ligand, which in the case of the 2nd generation catalyst, gives a completely phosphine-free structure. The 1st generation Hoveyda–Grubbs catalyst was reported in 1999 by Amir H. Hoveyda's group,[14] and in the following year, the second-generation Hoveyda–Grubbs catalyst was described in nearly simultaneous publications by the Blechert[15] and Hoveyda[16] laboratories. Siegfried Blechert's name is not commonly included in the eponymous catalyst name. The Hoveyda–Grubbs catalysts, while more expensive and slower to initiate than the Grubbs catalyst from which they are derived, are popular because of their improved stability.[3] By changing the steric and electronic properties of the chelate, the initiation rate of the catalyst can be modulated,[17][18] such as in the Zhan catalysts. Hoveyda–Grubbs catalysts are easily formed from the corresponding Grubbs catalyst by the addition of the chelating ligand and the use of a phosphine scavenger like copper(I) chloride:[16]

The second-generation Hoveyda–Grubbs catalysts can also be prepared from the 1st generation Hoveyda–Grubbs catalyst by the addition of the NHC:[15]

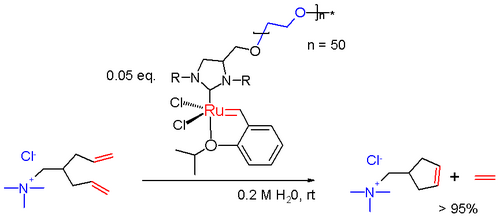

In one study published by Grubbs and Hong in 2006, a water-soluble Grubbs catalyst was prepared by attaching a polyethylene glycol chain to the imidazolidine group.[19] This catalyst is used in the ring-closing metathesis reaction in water of a diene carrying an ammonium salt group making it water-soluble as well.

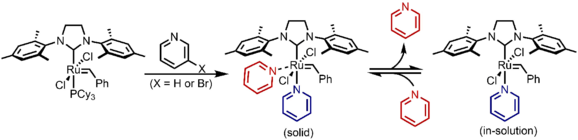

Third-generation Grubbs catalyst (fast-initiating catalysts)

The rate of the Grubbs catalyst can be altered by replacing the phosphine ligand with more labile pyridine ligands. By using 3-bromopyridine the initiation rate is increased more than a millionfold.[20] Both pyridine and 3-bromopyridine are commonly used, with the bromo- version 4.8 times more labile resulting in even faster rates.[21] The catalyst is traditionally isolated as a two pyridine complex, however one pyridine is lost upon dissolving and reversibly inhibits the ruthenium center throughout any chemical reaction.

The principal application of the fast-initiating catalysts is as initiators for ring opening metathesis polymerisation (ROMP). Because of their usefulness in ROMP these catalysts are sometimes referred to as the 3rd generation Grubbs catalysts.[22] The high ratio of the rate of initiation to the rate of propagation makes these catalysts useful in living polymerization, yielding polymers with low polydispersity.[23]

Applications

Grubbs catalysts are of interest for olefin metathesis. It is mainly applied to fine chemical synthesis. Large-scale commercial applications of olefin metathesis almost always employ heterogeneous catalysts or ill-defined systems based on ruthenium trichloride.[6]

References

- ↑ Grubbs, Robert H. (2003). Handbook of Metathesis (1st ed.). Weinheim: Wiley-VCH. ISBN 978-3-527-30616-9.

- ↑ Grubbs, R. H.; Trnka, T. M. (2004). "Ruthenium‐Catalyzed Olefin Metathesis". in Murahashi, S.. Ruthenium in Organic Synthesis. Weinheim: Wiley-VCH. pp. 153–177. doi:10.1002/3527603832.ch6. ISBN 978-3-527-60383-1.

- ↑ 3.0 3.1 3.2 Vougioukalakis, G. C.; Grubbs, R. H. (2010). "Ruthenium-Based Heterocyclic Carbene-Coordinated Olefin Metathesis Catalysts". Chemical Reviews 110 (3): 1746–1787. doi:10.1021/cr9002424. PMID 20000700.

- ↑ Trnka, T. M.; Grubbs, R. H. (2001). "The Development of L2X2Ru=CHR Olefin Metathesis Catalysts: An Organometallic Success Story". Accounts of Chemical Research 34 (1): 18–29. doi:10.1021/ar000114f. PMID 11170353.

- ↑ Cossy, Janine; Arseniyadis, Stellios; Meyer, Christophe (2010). Metathesis in Natural Product Synthesis: Strategies, Substrates and Catalysts (1st ed.). Weinheim: Wiley-VCH. ISBN 978-3-527-32440-8.

- ↑ 6.0 6.1 Lionel Delaude; Alfred F. Noels (2005). Kirk-Othmer Encyclopedia of Chemical Technology. Weinheim: Wiley-VCH. doi:10.1002/0471238961.metanoel.a01. ISBN 978-0-471-23896-6.

- ↑ Nguyen, S. T.; Johnson, L. K.; Grubbs, R. H.; Ziller, J. W. (1992). "Ring-opening metathesis polymerization (ROMP) of norbornene by a Group VIII carbene complex in protic media". Journal of the American Chemical Society 114 (10): 3974–3975. doi:10.1021/ja00036a053. https://authors.library.caltech.edu/88217/2/ja00036a053_si_001.pdf.

- ↑ Schwab, P.; France, M. B.; Ziller, J. W.; Grubbs, R. H. (1995). "A Series of Well-Defined Metathesis Catalysts – Synthesis of [RuCl2(=CHR′)(PR3)2] and Its Reactions". Angew. Chem. Int. Ed. 34 (18): 2039–2041. doi:10.1002/anie.199520391.

- ↑ Schwab, P.; Grubbs, R. H.; Ziller, J. W. (1996). "Synthesis and Applications of RuCl2(=CHR′)(PR3)2: The Influence of the Alkylidene Moiety on Metathesis Activity". J. Am. Chem. Soc. 118 (1): 100–110. doi:10.1021/ja952676d.

- ↑ Huang, J.-K.; Stevens, E. D.; Nolan, S. P.; Petersen, J. L. (1999). "Olefin Metathesis-Active Ruthenium Complexes Bearing a Nucleophilic Carbene Ligand". J. Am. Chem. Soc. 121 (12): 2674–2678. doi:10.1021/ja9831352.

- ↑ Scholl, M.; Trnka, T. M.; Morgan, J. P.; Grubbs, R. H. (1999). "Increased Ring Closing Metathesis Activity of Ruthenium-Based Olefin Metathesis Catalysts Coordinated with Imidazolin-2-ylidene Ligands". Tetrahedron Letters 40 (12): 2247–2250. doi:10.1016/S0040-4039(99)00217-8.

- ↑ Ackermann, L.; Fürstner, A.; Weskamp, T.; Kohl, F. J.; Herrmann, W. A. (1999). "Ruthenium Carbene Complexes with Imidazolin-2-ylidene Ligands Allow the Formation of Tetrasubstituted Cycloalkenes by RCM". Tetrahedron Lett. 40 (26): 4787–4790. doi:10.1016/S0040-4039(99)00919-3.

- ↑ Scholl, M.; Ding, S.; Lee, C. W.; Grubbs, R. H. (1999). "Synthesis and Activity of a New Generation of Ruthenium-Based Olefin Metathesis Catalysts Coordinated with 1,3-Dimesityl-4,5-dihydroimidazol-2-ylidene Ligands". Org. Lett. 1 (6): 953–956. doi:10.1021/ol990909q. PMID 10823227.

- ↑ Kingsbury, Jason S.; Harrity, Joseph P. A.; Bonitatebus, Peter J.; Hoveyda, Amir H. (1999). "A Recyclable Ru-Based Metathesis Catalyst". Journal of the American Chemical Society 121 (4): 791–799. doi:10.1021/ja983222u.

- ↑ 15.0 15.1 Gessler, S.; Randl, S.; Blechert, S. (2000). "Synthesis and metathesis reactions of phosphine-free dihydroimidazole carbene ruthenium complex". Tetrahedron Letters 41 (51): 9973–9976. doi:10.1016/S0040-4039(00)01808-6.

- ↑ 16.0 16.1 Garber, S. B.; Kingsbury, J. S.; Gray, B. L.; Hoveyda, A. H. (2000). "Efficient and Recyclable Monomeric and Dendritic Ru-Based Metathesis Catalysts". Journal of the American Chemical Society 122 (34): 8168–8179. doi:10.1021/ja001179g.

- ↑ Engle, Keary M.; Lu, Gang; Luo, Shao-Xiong; Henling, Lawrence M.; Takase, Michael K.; Liu, Peng; Houk, K. N.; Grubbs, Robert H. (2015). "Origins of Initiation Rate Differences in Ruthenium Olefin Metathesis Catalysts Containing Chelating Benzylidenes". Journal of the American Chemical Society 137 (17): 5782–5792. doi:10.1021/jacs.5b01144. PMID 25897653.

- ↑ Luo, Shao-Xiong; Engle, Keary M.; Deng, Xiaofei; Hejl, Andrew; Takase, Michael K.; Henling, Lawrence M.; Liu, Peng; Houk, K. N. et al. (2018). "An Initiation Kinetics Prediction Model Enables Rational Design of Ruthenium Olefin Metathesis Catalysts Bearing Modified Chelating Benzylidenes". ACS Catalysis 8 (5): 4600–4611. doi:10.1021/acscatal.8b00843. PMID 32528741.

- ↑ Grubbs, Robert H.; Hong, Soon Hyeok (2006). "Highly Active Water-Soluble Olefin Metathesis Catalyst". Journal of the American Chemical Society 128 (11): 3508–3509. doi:10.1021/ja058451c. PMID 16536510. https://authors.library.caltech.edu/76728/2/ja058451csi20051213_124352.pdf.

- ↑ Love, J. A.; Morgan, J. P.; Trnka, T. M.; Grubbs, R. H. (2002). "A Practical and Highly Active Ruthenium-Based Catalyst that Effects the Cross Metathesis of Acrylonitrile". Angew. Chem. Int. Ed. Engl. 41 (21): 4035–4037. doi:10.1002/1521-3773(20021104)41:21<4035::AID-ANIE4035>3.0.CO;2-I. PMID 12412073.

- ↑ Walsh, Dylan J.; Lau, Sii Hong; Hyatt, Michael G.; Guironnet, Damien (2017-09-25). "Kinetic Study of Living Ring-Opening Metathesis Polymerization with Third-Generation Grubbs Catalysts" (in EN). Journal of the American Chemical Society 139 (39): 13644–13647. doi:10.1021/jacs.7b08010. ISSN 0002-7863. PMID 28944665.

- ↑ Leitgeb, Anita; Wappel, Julia; Slugovc, Christian (2010). "The ROMP toolbox upgraded". Polymer 51 (14): 2927–2946. doi:10.1016/j.polymer.2010.05.002.

- ↑ Choi, T.-L.; Grubbs, R. H. (2003). "Controlled Living Ring-Opening-Metathesis Polymerization by a Fast-Initiating Ruthenium Catalyst". Angewandte Chemie International Edition 42 (15): 1743–1746. doi:10.1002/anie.200250632. PMID 12707895.

|