Chemistry:Tetrakis(acetonitrile)copper(I) hexafluorophosphate

| |

| |

| Names | |

|---|---|

| IUPAC name

Tetrakis(acetonitrile)copper(I) hexafluorophosphate

| |

| Identifiers | |

PubChem CID

|

|

| Properties | |

| [Cu(CH3CN)4]PF6 | |

| Molar mass | 372.7198 g/mol |

| Appearance | White powder |

| Melting point | 160 °C (320 °F; 433 K) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

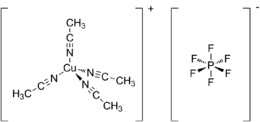

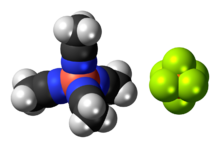

Tetrakis(acetonitrile)copper(I) hexafluorophosphate is a salt with the formula [Cu(CH3CN)4]PF6. It is a colourless solid that is used in the synthesis of other copper complexes. The cation [Cu(CH3CN)4]+ is a well-known example of a transition metal nitrile complex.[1]

Structure

As confirmed by X-ray crystallographic studies, the copper(I) ion is coordinated to four almost linear acetonitrile ligands in a nearly ideal tetrahedral geometry.[2][3] Similar complexes with other anions including the perchlorate, tetrafluoroborate, and nitrate are known.[1]

Synthesis

The cation was first reported in 1923 with a nitrate anion as a byproduct of the reduction of silver nitrate with a suspension of copper powder in acetonitrile.[4] [Cu(CH3CN)4]PF6 is generally produced by the addition of HPF6 to a suspension of copper(I) oxide in acetonitrile:[5]

- Cu2O + 2 HPF6 + 8 CH3CN → 2 [Cu(CH3CN)4]PF6 + H2O

The reaction is highly exothermic, and may bring the solution to a boil. Upon crystallization, the resulting microcrystals should be white, though a blue tinge is common, indicating the presence of Cu2+ impurities.[5]

Reactions and applications

The acetonitrile ligands protect the Cu+ ion from oxidation to Cu2+, but are rather poorly bound: with other counterions, the complex forms di-[1] and tri-acetonitrilo[6] complexes and is also a useful source of unbound Cu(I).[5]

Water-immiscible organic nitriles have been shown to selectively extract Cu(I) from aqueous chloride solutions.[7] Through this method, copper can be separated from a mixture of other metals. Dilution of acetonitrile solutions with water induces disproportionation:

- 2 [Cu(CH3CN)4]+ + 6 H2O → [Cu(H2O)6]2+ + Cu + 8 CH3CN

References

- ↑ 1.0 1.1 1.2 Silvana F. Rach, Fritz E. Kühn "Nitrile Ligated Transition Metal Complexes with Weakly Coordinating Counteranions and Their Catalytic Applications" Chem. Rev., 2009, volume 109, pp 2061–2080. doi:10.1021/cr800270h

- ↑ Kierkegaard C.P.; Norrestam R. (1975). "Copper(I) tetraacetonitrile perchlorate". Acta Crystallogr. B 31: 314–317. doi:10.1107/S0567740875002634.

- ↑ Black, J. R.; Levason, W.; Webster, M. (1995). "Tetrakis(acetonitrile-N)copper(I) Hexafluorophosphate(V) Acetonitrile Solvate". Acta Crystallographica Section C Crystal Structure Communications 51 (4): 623–625. doi:10.1107/S0108270194012527.

- ↑ Morgan, H.H.; Sand, Henry Julics Salomon (1923). "Preparation and Stability of Cuprous Nitrate and Other Cuprous Salts in the Presence of Nitriles". J. Chem. Soc. 19: 2901. doi:10.1039/CT9232302901.

- ↑ 5.0 5.1 5.2 Kubas, G.J. (1990). "Tetrakis(acetonitirile)copper(I) Hexaflurorophosphate". Inorganic Syntheses 28: 68–69. doi:10.1002/9780470132593.ch15.

- ↑ Elsayed Moussa, Mehdi; Piesch, Martin; Fleischmann, Martin; Schreiner, Andrea; Seidl, Michael; Scheer, Manfred (2018). "Highly soluble Cu(i)-acetonitrile salts as building blocks for novel phosphorus-rich organometallic-inorganic compounds". Dalton Transactions 47 (45): 16031–16035. doi:10.1039/C8DT03723J. PMID 30321246. https://epub.uni-regensburg.de/38440/1/Scheer%2C%20RSC%2C%20Dalton%20Transactions.pdf.

- ↑ Preston, J. S.; Muhr D. M; Parker A. J. (1980). "Cuprous hydrometallurgy: Part VIII. Solvent extraction and recovery of copper(I) chloride with organic nitriles from an iron(III), copper(II) chloride, two-step oxidative leach of chalcopyrite concentrate". Hydrometallurgy 5: 227. doi:10.1016/0304-386X(80)90041-9.

|