Chemistry:Boron carbide

| |

| Names | |

|---|---|

| IUPAC name

Boron carbide

| |

| Other names

Tetrabor

| |

| Identifiers | |

3D model (JSmol)

|

|

| ChemSpider | |

PubChem CID

|

|

| UNII | |

| |

| |

| Properties | |

| B4C | |

| Molar mass | 55.255 g/mol |

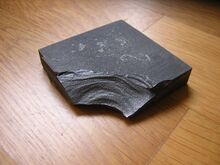

| Appearance | dark gray or black powder, odorless |

| Density | 2.50 g/cm3, solid.[1] |

| Melting point | 2,350 °C (4,260 °F; 2,620 K)[1] |

| Boiling point | >3500 °C [1] |

| insoluble | |

| Structure | |

| Rhombohedral | |

| Hazards | |

| Safety data sheet | External MSDS |

| Related compounds | |

Related compounds

|

Boron nitride |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

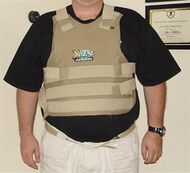

Boron carbide (chemical formula approximately B4C) is an extremely hard boron–carbon ceramic, a covalent material used in tank armor, bulletproof vests, engine sabotage powders,[2] as well as numerous industrial applications. With a Vickers hardness of >30 GPa, it is one of the hardest known materials, behind cubic boron nitride and diamond.[3]

History

Boron carbide was discovered in the 19th century as a by-product of reactions involving metal borides, but its chemical formula was unknown. It was not until the 1930s that the chemical composition was estimated as B4C.[4] Controversy remained as to whether or not the material had this exact 4:1 stoichiometry, as, in practice the material is always slightly carbon-deficient with regard to this formula, and X-ray crystallography shows that its structure is highly complex, with a mixture of C-B-C chains and B12 icosahedra.

These features argued against a very simple exact B4C empirical formula.[5] Because of the B12 structural unit, the chemical formula of "ideal" boron carbide is often written not as B4C, but as B12C3, and the carbon deficiency of boron carbide described in terms of a combination of the B12C3 and B12CBC units.

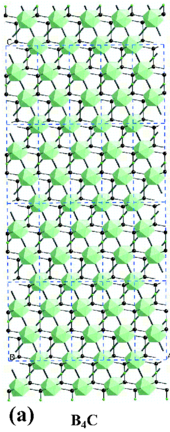

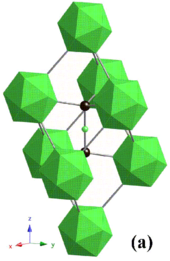

Crystal structure

Boron carbide has a complex crystal structure typical of icosahedron-based borides. There, B12 icosahedra form a rhombohedral lattice unit (space group: R3m (No. 166), lattice constants: a = 0.56 nm and c = 1.212 nm) surrounding a C-B-C chain that resides at the center of the unit cell, and both carbon atoms bridge the neighboring three icosahedra. This structure is layered: the B12 icosahedra and bridging carbons form a network plane that spreads parallel to the c-plane and stacks along the c-axis. The lattice has two basic structure units – the B12 icosahedron and the B6 octahedron. Because of the small size of the B6 octahedra, they cannot interconnect. Instead, they bond to the B12 icosahedra in the neighboring layer, and this decreases bonding strength in the c-plane.[6]

Because of the B12 structural unit, the chemical formula of "ideal" boron carbide is often written not as B4C, but as B12C3, and the carbon deficiency of boron carbide described in terms of a combination of the B12C3 and B12C2 units.[5][7] Some studies indicate the possibility of incorporation of one or more carbon atoms into the boron icosahedra, giving rise to formulas such as (B11C)CBC = B4C at the carbon-heavy end of the stoichiometry, but formulas such as B12(CBB) = B14C at the boron-rich end. "Boron carbide" is thus not a single compound, but a family of compounds of different compositions. A common intermediate, which approximates a commonly found ratio of elements, is B12(CBC) = B6.5C.[8] Quantum mechanical calculations have demonstrated that configurational disorder between boron and carbon atoms on the different positions in the crystal determines several of the materials properties – in particular, the crystal symmetry of the B4C composition[9] and the non-metallic electrical character of the B13C2 composition.[10]

Properties

Boron carbide is known as a robust material having extremely high hardness (about 9.5 up to 9.75 on Mohs hardness scale), high cross section for absorption of neutrons (i.e. good shielding properties against neutrons), stability to ionizing radiation and most chemicals.[11] Its Vickers hardness (38 GPa), elastic modulus (460 GPa)[12] and fracture toughness (3.5 MPa·m1/2) approach the corresponding values for diamond (1150 GPa and 5.3 MPa·m1/2).[13]

(As of 2015), boron carbide is the third hardest substance known, after diamond and cubic boron nitride, earning it the nickname "black diamond".[14][15]

Semiconductor properties

Boron carbide is a semiconductor, with electronic properties dominated by hopping-type transport.[8] The energy band gap depends on composition as well as the degree of order. The band gap is estimated at 2.09 eV, with multiple mid-bandgap states which complicate the photoluminescence spectrum.[8] The material is typically p-type.

Preparation

Boron carbide was first synthesized by Henri Moissan in 1899,[7] by reduction of boron trioxide either with carbon or magnesium in presence of carbon in an electric arc furnace. In the case of carbon, the reaction occurs at temperatures above the melting point of B4C and is accompanied by liberation of large amount of carbon monoxide:[16]

- 2 B2O3 + 7 C → B4C + 6 CO

If magnesium is used, the reaction can be carried out in a graphite crucible, and the magnesium byproducts are removed by treatment with acid.[17]

Applications

For its hardness :

- Padlocks

- Personal and vehicle anti-ballistic armor plating

- Grit blasting nozzles

- High-pressure water jet cutter nozzles

- Scratch and wear resistant coatings

- Cutting tools and dies

- Abrasives

- Metal matrix composites

- In brake linings of vehicles

For other properties :

- Neutron absorber in nuclear reactors (see below)

- High energy fuel for solid fuel ramjets

Nuclear applications

The ability of boron carbide to absorb neutrons without forming long-lived radionuclides makes it attractive as an absorbent for neutron radiation arising in nuclear power plants[18] and from anti-personnel neutron bombs. Nuclear applications of boron carbide include shielding.[11]

See also

- List of compounds with carbon number 1

References

- ↑ 1.0 1.1 1.2 Haynes, William M., ed (2016). CRC Handbook of Chemistry and Physics (97th ed.). CRC Press. p. 4.52. ISBN 9781498754293.

- ↑ Gray, Theodore (2012-04-03). The Elements: A Visual Exploration of Every Known Atom in the Universe. Black Dog & Leventhal Publishers. ISBN 9781579128951. https://books.google.com/books?id=IOY-8hxTJVAC&q=boron+carbide+sabotage+powder&pg=PT24. Retrieved 6 May 2014.

- ↑ "Rutgers working on body armor". Asbury Park Press (Asbury Park, N.J.). August 11, 2012. http://www.app.com/article/20120811/NJNEWS/308110051/Rutgers-working-on-body-armor. "... boron carbide is the third-hardest material on earth."

- ↑ Ridgway, Ramond R "Boron Carbide", European Patent CA339873 (A), publication date: 1934-03-06

- ↑ 5.0 5.1 Balakrishnarajan, Musiri M.; Pancharatna, Pattath D.; Hoffmann, Roald (2007). "Structure and bonding in boron carbide: The invincibility of imperfections". New J. Chem. 31 (4): 473. doi:10.1039/b618493f. http://www.rsc.org/Publishing/Journals/nj/Hotarticles/B618493F_Hoffmann.asp.

- ↑ 6.0 6.1 "Crystal structure of new rare-earth boron-rich solids: REB28.5C4". J. Alloys Compd. 329 (1–2): 168–172. 2001. doi:10.1016/S0925-8388(01)01581-X.

- ↑ 7.0 7.1 Greenwood, Norman N.; Earnshaw, Alan (1997). Chemistry of the Elements (2nd ed.). Butterworth-Heinemann. p. 149. ISBN 978-0-08-037941-8.

- ↑ 8.0 8.1 8.2 Domnich, Vladislav; Reynaud, Sara; Haber, Richard A.; Chhowalla, Manish (2011). "Boron Carbide: Structure, Properties, and Stability under Stress". J. Am. Ceram. Soc. 94 (11): 3605–3628. doi:10.1111/j.1551-2916.2011.04865.x. http://nanotubes.rutgers.edu/PDFs/Domnich.2011.JACerS.pdf. Retrieved 23 July 2015.

- ↑ Ektarawong, A.; Simak, S. I.; Hultman, L.; Birch, J.; Alling, B. (2014). "First-principles study of configurational disorder in B4C using a superatom-special quasirandom structure method". Phys. Rev. B 90 (2): 024204. doi:10.1103/PhysRevB.90.024204. Bibcode: 2014PhRvB..90b4204E.

- ↑ Ektarawong, A.; Simak, S. I.; Hultman, L.; Birch, J.; Alling, B. (2015). "Configurational order-disorder induced metal-nonmetal transition in B13C2 studied with first-principles superatom-special quasirandom structure method". Phys. Rev. B 92 (1): 014202. doi:10.1103/PhysRevB.92.014202. Bibcode: 2015PhRvB..92a4202E.

- ↑ 11.0 11.1 Weimer, p. 330

- ↑ Sairam, K.; Sonber, J.K.; Murthy, T.S.R.Ch.; Subramanian, C.; Hubli, R.C.; Suri, A.K. (2012). "Development of B4C-HfB2 composites by reaction hot pressing". Int.J. Ref. Met. Hard Mater 35: 32–40. doi:10.1016/j.ijrmhm.2012.03.004.

- ↑ Solozhenko, V. L.; Kurakevych, Oleksandr O.; Le Godec, Yann; Mezouar, Mohamed; Mezouar, Mohamed (2009). "Ultimate Metastable Solubility of Boron in Diamond: Synthesis of Superhard Diamondlike BC5". Phys. Rev. Lett. 102 (1): 015506. doi:10.1103/PhysRevLett.102.015506. PMID 19257210. Bibcode: 2009PhRvL.102a5506S. http://bib-pubdb1.desy.de/record/87949/files/GetPDFServlet.pdf.

- ↑ "Boron Carbide". Precision Ceramics. http://www.precision-ceramics.co.uk/boron-carbide.htm.

- ↑ A. Sokhansanj; A.M. Hadian (2012). "Purification of Attrition Milled Nano-size Boron Carbide Powder". International Journal of Modern Physics: Conference Series 5: 94–101. doi:10.1142/S2010194512001894. Bibcode: 2012IJMPS...5...94S.

- ↑ Weimer, p. 131

- ↑ Patnaik, Pradyot (2002). Handbook of Inorganic Chemicals. McGraw-Hill. ISBN:0-07-049439-8

- ↑ Fabrication and Evaluation of Urania-Alumina Fuel Elements and Boron Carbide Burnable Poison Elements, Wisnyi, L. G. and Taylor, K.M., in "ASTM Special Technical Publication No. 276: Materials in Nuclear Applications", Committee E-10 Staff, American Society for Testing Materials, 1959

Bibliography

- Weimer, Alan W. (1997). Carbide, Nitride and Boride Materials Synthesis and Processing. Chapman & Hall (London, New York). ISBN 0-412-54060-6. https://books.google.com/books?id=PC4f40ETjeUC&pg=PA330.

External links

|