Physics:Spider silk

Spider silk is a protein fibre or silk spun by spiders. Spiders use silk to make webs or other structures that function as adhesive traps to catch prey, to entangle and restrain prey before biting, to transmit tactile information, or as nests or cocoons to protect their offspring. They can use the silk to suspend themselves from height, to float through the air, or to glide away from predators. Most spiders vary the thickness and adhesiveness of their silk according to its use.

In some cases, spiders may use silk as a food source.[1] While methods have been developed to collect silk from a spider by force,[2] gathering silk from many spiders is more difficult than from silk-spinning organisms such as silkworms.

All spiders produce silk, although some spiders do not make webs. Silk is tied to courtship and mating. Silk produced by females provides a transmission channel for male vibratory courtship signals, while webs and draglines provide a substrate for female sex pheromones. Observations of male spiders producing silk during sexual interactions are common across widespread taxa. The function of male-produced silk in mating has received little study.[3]

Properties

Structural

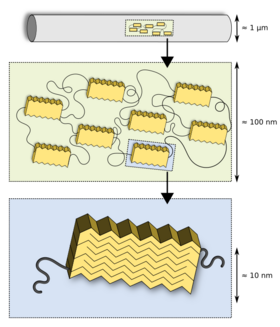

Silks, have a hierarchical structure. The primary structure is the amino acid sequence of its proteins (spidroin), mainly consisting of highly repetitive glycine and alanine blocks,[4][5] which is why silks are often referred to as a block co-polymer. On a secondary level, the short side-chained alanine is mainly found in the crystalline domains (beta sheets) of the nanofibril. Glycine is mostly found in the so-called amorphous matrix consisting of helical and beta turn structures.[5][6] The interplay between the hard crystalline segments and the strained elastic semi-amorphous regions gives spider silk its extraordinary properties.[7][8] Various compounds other than protein are used to enhance the fibre's properties. Pyrrolidine has hygroscopic properties that keep the silk moist while warding off ant invasion. It occurs in high concentration in glue threads. Potassium hydrogen phosphate releases hydrogen ions in aqueous solution, resulting in a pH of about 4, making the silk acidic and thus protecting it from fungi and bacteria that would otherwise digest the protein. Potassium nitrate is believed to prevent the protein from denaturing in the acidic milieu.[9]

Termonia introduced this first basic model of silk in 1994.[10] He suggested crystallites embedded in an amorphous matrix interlinked with hydrogen bonds. Refinements to this model include: semi-crystalline regions were found[5] as well as a fibrillar skin core model suggested for spider silk,[11] later visualised by AFM and TEM.[12] Sizes of the nanofibrillar structure and the crystalline and semi-crystalline regions were revealed by neutron scattering.[13]

The fibres' microstructural information and macroscopic mechanical properties are related.[14] Ordered regions (i) mainly reorient by deformation for low-stretched fibres and (ii) the fraction of ordered regions increases progressively for higher fibre stretching.

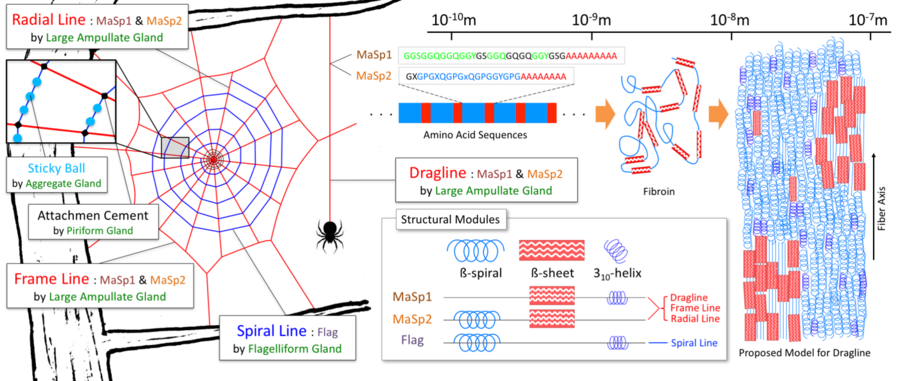

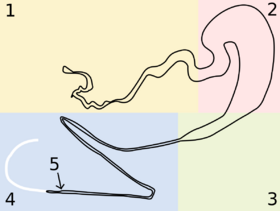

Schematic of the spider's orb web, structural modules, and spider silk structure.[15] On the left is shown a schematic drawing of an orb web. The red lines represent the dragline, radial line, and frame lines. The blue lines represent the spiral line, and the centre of the orb web is called the "hub". Sticky balls drawn in blue are made at equal intervals on the spiral line with viscous material secreted from the aggregate gland. Attachment cement secreted from the piriform gland is used to connect and fix different lines. Microscopically, the spider silk secondary structure is formed of spidroin with the structure shown on the right side. In the dragline and radial line, a crystalline β-sheet and an amorphous helical structure are interwoven. The large amount of β-spiral structure gives elastic properties to the capture part of the orb web. In the structural modules diagram, a microscopic structure of dragline and radial lines is shown, composed mainly of two proteins of MaSp1 and MaSp2, as shown in the upper central part. The spiral line has no crystalline β-sheet region.

Mechanical

Each spider and each type of silk has a set of mechanical properties optimised for their biological function.

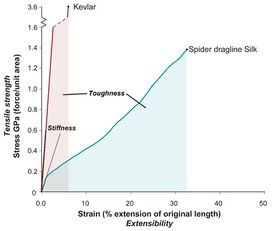

Most silks, in particular dragline silk, have exceptional mechanical properties. They exhibit a unique combination of high tensile strength and extensibility (ductility). This enables a silk fibre to absorb a large amount of energy before breaking (toughness, the area under a stress-strain curve).

Strength and toughness are distinct quantities. Weight for weight, silk is stronger than steel, but not as strong as Kevlar. Spider silk is, however, tougher than both.

The variability of spider silk fibre mechanical properties is related to their degree of molecular alignment.[16] Mechanical properties also depend on ambient conditions, i.e. humidity and temperature.[17]

Strength

A dragline silk's tensile strength is comparable to that of high-grade alloy steel (450−2000 MPa),[18][19] and about half as strong as aramid filaments, such as Twaron or Kevlar (3000 MPa).[20]

Density

Consisting of mainly protein, silks are about a sixth of the density of steel (1.3 g/cm3). As a result, a strand long enough to circle the Earth would weigh about 2 kilograms (4.4 lb). (Spider dragline silk has a tensile strength of roughly 1.3 GPa. The tensile strength listed for steel might be slightly higher – e.g. 1.65 GPa,[21][22] but spider silk is a much less dense material, so that a given weight of spider silk is five times as strong as the same weight of steel.)

Energy density

The energy density of dragline spider silk is roughly 1.2×108 J/m3.[23]

Ductility

Silks are ductile, with some able to stretch up to five times their relaxed length without breaking.

Toughness

The combination of strength and ductility gives dragline silks a high toughness (or work to fracture), which "equals that of commercial polyaramid (aromatic nylon) filaments, which themselves are benchmarks of modern polymer fibre technology".[24][25]

Temperature

While unlikely to be relevant in nature, dragline silks can hold their strength below -40 °C (-40 °F) and up to 220 °C (428 °F).[26] As occurs in many materials, spider silk fibres undergo a glass transition. The glass-transition temperature depends on humidity, as water is a plasticiser for spider silk.[17]

Supercontraction

When exposed to water, dragline silks undergo supercontraction, shrinking up to 50% in length and behaving like a weak rubber under tension.[17] Many hypotheses have attempted to explain its use in nature, most popularly to re-tension webs built in the night using the morning dew.[citation needed]

Highest-performance

The toughest known spider silk is produced by the species Darwin's bark spider (Caerostris darwini): "The toughness of forcibly silked fibers averages 350 MJ/m3, with some samples reaching 520 MJ/m3. Thus, C. darwini silk is more than twice as tough as any previously described silk and over 10 times tougher than Kevlar".[27]

Adhesive

Silk fibre is a two-compound pyriform secretion, spun into patterns (called "attachment discs") using a minimum of silk substrate.[28] The pyriform threads polymerise under ambient conditions, become functional immediately, and are usable indefinitely, remaining biodegradable, versatile and compatible with other materials in the environment.[28] The adhesive and durability properties of the attachment disc are controlled by functions within the spinnerets.[29] Some adhesive properties of the silk resemble glue, consisting of microfibrils and lipid enclosures.[28]

Uses

All spiders produce silks, and a single spider can produce up to seven different types of silk for different uses.[30] This is in contrast to insect silks, where an individual usually only produces a single type.[31] Spiders use silks in many ways, in accord with the silk's properties. As spiders have evolved, so has their silks' complexity and uses, for example from primitive tube webs 300–400 million years ago to complex orb webs 110 million years ago.[32]

| Use | Example | Reference |

|---|---|---|

| Prey capture | Orb webs produced by the Araneidae (typical orb-weavers); tube webs; tangle webs; sheet webs; lace webs, dome webs; single thread used by the Bolas spiders for "fishing". | [30][32] |

| Prey immobilisation | "Swathing bands" to envelop prey. Often combined with immobilising prey using a venom. In species of Scytodes the silk is combined with venom and squirted from the chelicerae. | [30] |

| Reproduction | Male spiders may produce sperm webs; spider eggs are covered in silk cocoons. | [30][33] |

| Dispersal | "Ballooning" or "kiting" used by smaller spiders to float through the air, for instance for dispersal. | [34] |

| Food | The kleptoparasitic Argyrodes eats the silk of host spider webs. Some daily weavers of temporary webs eat their own unused silk, thus mitigating an otherwise heavy metabolic expense. | [1][35] |

| Nest lining and nest construction | Tube webs used by "primitive" spiders such as the European tube web spider (Segestria florentina). Threads radiate out of the nest to provide a sensory link to the outside. Silk is a component of the lids of spiders that use "trapdoors", such as members of the family Ctenizidae, and the "water" or "diving bell" spider Argyroneta aquatica forms a silk diving bell. | [32] |

| Guide lines | Some spiders that venture from shelter leave a silk trail by which to find their way home again. | [35] |

| Drop lines and anchor lines | Spiders such as the Salticidae venture from shelter and leave a trail of silk, use that as an emergency line in case of falling from inverted or vertical surfaces. Others, even web dwellers, deliberately drop from a web when alarmed, using a silken thread as a drop line by which they can return in due course. Some, such as species of Paramystaria, hang from a drop line while feeding. | [35] |

| Alarm lines | Some spiders that do not spin actual trap build alarm webs that the feet of their prey (such as ants) can disturb, cueing the spider to pounce on prey or flee a formidable intruder. | [35] |

| Pheromonal trails | Some wandering spiders leave a largely continuous trail of silk impregnated with pheromones that the opposite sex can follow to find a mate. | [35] |

Silk types

right|thumb|A female Argiope picta immobilizing prey by wrapping a curtain of aciniform silk around the insect for later consumption Meeting the specification for all these ecological uses requires different types of silk presenting different properties, as either a fibre, a structure of fibres, or a globule. These types include glues and fibres. Some types of fibres are used for structural support, others for protective structures. Some can absorb energy effectively, whereas others transmit vibration efficiently. These silk types are produced in different glands; so the silk from a particular gland can be linked to its use.

| Gland | Silk Use |

|---|---|

| Ampullate (major) | Dragline silk – used for the web's outer rim and spokes, also for lifeline and for ballooning |

| Ampullate (minor) | Used for temporary scaffolding during web construction |

| Flagelliform | Capture-spiral silk – used for the capturing lines of the web |

| Tubuliform | Egg cocoon silk – used for egg sacs |

| Aciniform | Used to wrap and secure prey; used in male sperm webs; used in stabilimenta |

| Aggregate | Sticky globules |

| Piriform | Bonds between separate threads for attachment point. |

Many species have different glands to produce silk with different properties for different purposes, including housing, web construction, defence, capturing and detaining prey, egg protection, and mobility (fine "gossamer" thread for ballooning, or for a strand allowing the spider to drop down as silk is extruded).[36][37]

| Silk | Use |

|---|---|

| Major-ampullate (dragline) silk | The web's outer rim and spokes and the lifeline. Can be as strong per unit weight as steel, but much tougher. |

| Capture-spiral (flagelliform) silk | Capturing lines. Sticky, stretchy, and tough. The capture spiral is sticky due to droplets of aggregate (a spider glue) that are placed on the spiral. The elasticity of flagelliform allows enough time for the aggregate to adhere to the aerial prey flying into the web. |

| Tubiliform (a.k.a. cylindriform) silk | Protective egg sacs. Stiffest silk. |

| Aciniform silk | Wrap and secure prey. Two to three times as tough as the other silks, including dragline. |

| Minor-ampullate silk | Temporary scaffolding during web construction. |

Synthesis and fibre spinning

Silk production differs in an important aspect from that of most other fibrous biomaterials. It is pulled on demand from a precursor out of specialised glands,[38] rather than continuously grown like plant cell walls.[23]

The spinning process occurs when a fibre is pulled away from the body of a spider, whether by the spider's legs, by the spider's falling under its own weight, or by any other method. The term "spinning" is misleading because no rotation occurs. It comes from analogy to the textile spinning wheels. Silk production is a pultrusion,[39] similar to extrusion, with the subtlety that the force is induced by pulling at the finished fibre rather than squeezing it out of a reservoir. The fibre is pulled through (possibly multiple) silk glands of multiple types.[38]

Silk gland

The gland's visible, or external, part is termed the spinneret. Depending on the complexity of the species, spiders have two to eight spinnerets, usually in pairs. Species have varying specialised glands, ranging from a sac with an opening at one end, to the complex, multiple-section ampullate glands of the golden silk orb-weavers.[53]

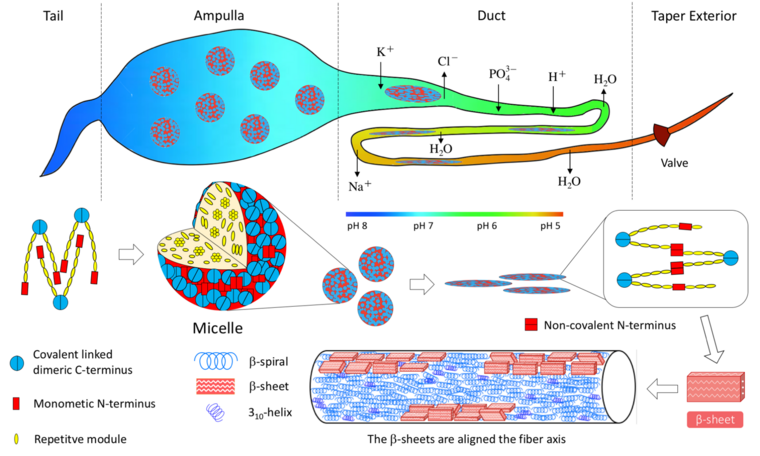

Behind each spinneret on the surface of the spider lies a gland, a generalised form of which is shown in the figure.

- Gland characteristics

- The leftmost section s the secretory or tail section. The walls of this section are lined with cells that secrete proteins Spidroin I and Spidroin II, the main components of this spider's dragline. These proteins are found in the form of droplets that gradually elongate to form long channels along the length of the final fibre, hypothesised to assist in preventing crack formation or self-healing.[56]

- The ampulla (storage sac) is next. This stores and maintains the gel-like unspun silk dope. In addition, it secretes proteins that coat the surface of the final fibre.[24]

- The funnel rapidly reduces the large diameter of the storage sac to the small diameter of the tapering duct.

- The final length is the tapering duct, the site of most of the fibre formation. This consists of a tapering tube with several tight sharp turns, a valve near the end includes a spigot from which the solid silk fibre emerges. The tube tapers hyperbolically, therefore the unspun silk is under constant elongational shear stress, an important factor in fibre formation. This section is lined with cells that exchange ions, reduce the dope pH from neutral to acidic, and remove water from the fibre.[57] Collectively, the shear stress and the ion and pH changes induce the liquid silk dope to undergo a phase transition and condense into a solid protein fibre with high molecular organisation. The spigot at the end has lips that clamp around the fibre, controlling fibre diameter and further retaining water.

- Almost at the end is a valve. Though discovered some time ago, its precise purpose is still under discussion. It is believed to assist in restarting and rejoining broken fibres,[58] acting much in the way of a helical pump, regulating the thickness of the fibre,[39] and/or clamping the fibre as a spider falls upon it.[58][59] The similarity of the silk worm's silk press and the roles each of these valves play in the silk production in these two organisms are under discussion.

Throughout the process the silk appears to have a nematic texture,[60] in a manner similar to a liquid crystal, arising in part due to the high protein concentration of silk dope (around 30% in terms of weight per volume).[61] This allows the silk to flow through the duct as a liquid while maintaining molecular order.

As an example of a complex spinning field, the spinneret apparatus of an adult Araneus diadematus (garden cross spider) consists of many glands shown below.[9] A similar gland architecture appears in the black widow spider.[62]

- 500 pyriform glands for attachment points

- 4 ampullate glands for the web frame

- 300 aciniform glands for the outer lining of egg sacs, and for ensnaring prey

- 4 tubuliform glands for egg sac silk

- 4 aggregate glands for adhesive functions

- 2 coronate glands for the thread of adhesion lines

Artificial synthesis

To artificially synthesise spider silk into fibres, two broad tasks are required. These are synthesis of the feedstock (the unspun silk dope in spiders), and synthesis of the production conditions (the funnel, valve, tapering duct, and spigot). Few strategies have produced silk that can efficiently be synthesised into fibres.

Feedstock

The molecular structure of unspun silk is both complex and long. Though this endows the fibres with desirable properties, it also complicates replication. Various organisms have been used as a basis for attempts to replicate necessary protein components. These proteins must then be extracted, purified, and then spun before their properties can be tested.

| Organism | Details | Average Maximum breaking stress (MPa) | Average Strain (%) | Reference |

|---|---|---|---|---|

| Darwin's bark spider (Caerostris darwini) | Malagasy spider famed for making 25 m long strands. "C. darwini silk is more than twice as tough as any previously described silk"[citation needed] | 1850 ±350 | 33 ±0.08 | [27] |

| Nephila clavipes | Typical golden orb weaving spider | 710–1200 | 18–27 | [63][64] |

| Bombyx mori Silkworms | Silkworms genetically altered to express spider proteins and fibres.[65] | 660 | 18.5 | [66] |

| Escherichia coli | Synthesising a large and repetitive molecule (~300 kDa) is complex, but required for the strongest silk. Here E. coli was engineered to produce a 556 kDa protein. Fibers spun from these synthetic spidroins are the first to fully replicate the mechanical performance of natural spider silk by all common metrics. | 1030 ±110 | 18 ±6 | [67] |

| Goats | Genetically modified to secrete silk proteins in their milk. | 285–250 | 30–40 | [68] |

| Tobacco & potato plants | Genetically modified to produce silk proteins. Patents were granted in 2010,[69] but no fibres have yet been described. | n/a | n/a | [70] |

Geometry

Spider silks with comparatively simple molecular structure need complex ducts to be able to form an effective fibre. Approaches:

Syringe and needle

Feedstock is forced through a hollow needle using a syringe.[71][72]

Although cheap and easy to produce, gland shape and conditions are loosely approximated. Fibres created using this method may need encouragement to solidify by removing water from the fibre with chemicals such as (environmentally undesirable) methanol[73] or acetone,[72] and also may require later stretching of the fibre to achieve desirable properties.[74][71]

Superhydrophobic surfaces

Placing a solution of spider silk on a superhydrophobic surface can generate sheets, particles, and nanowires of spider silk.[75][76]

Sheets

Self-assembly of silk at standing liquid-gas interphases of a solution tough and strong sheets. These sheets are now explored for mimicking the basal membrane in tissue modeling.[77][78]

Microfluidics

Microfluidics have the advantage of being controllable and able to test spin small volumes of unspun fibre,[79][80] but setup and development costs are high. A patent has been granted and continuously spun fibres have achieved commercial use.[81]

Electrospinning

Electrospinning is an old technique whereby a fluid is held in a container such that it flows out through capillary action. A conducting substrate is positioned below, and a difference in electrical potential is applied between the fluid and the substrate. The fluid is attracted to the substrate, and tiny fibres jump from their point of emission, the Taylor cone, to the substrate, drying as they travel. This method creates nano-scale fibres from silk dissected from organisms and regenerated silk fibroin.[citation needed]

Other shapes

Silk can be formed into other shapes and sizes such as spherical capsules for drug delivery, cell scaffolds and wound healing, textiles, cosmetics, coatings, and many others.[82][83] Spider silk proteins can self-assemble on superhydrophobic surfaces into nanowires, as well as micron-sized circular sheets.[83] Recombinant spider silk proteins can self-assemble at the liquid-air interface of a standing solution to form protein-permeable, strong and flexible nanomembranes that support cell proliferation. Potential applications include skin transplants, and supportive membranes in organ-on-a-chip.[84] These nanomembranes have been used to create a static in-vitro model of a blood vessel.[85]

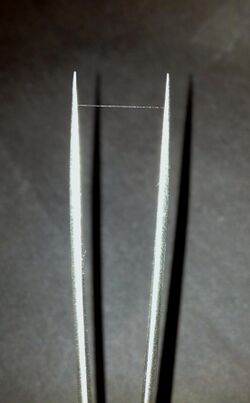

Synthetic spider silk

Replicating the complex conditions required to produce comparable fibres has challenged research and early-stage manufacturing. Through genetic engineering, E. coli bacteria, yeasts, plants, silkworms, and animals other than silkworms have been used to produce spider silk-like proteins, which have different characteristics than those from a spider.[86] Extrusion of protein fibres in an aqueous environment is known as "wet-spinning". This process has produced silk fibres of diameters ranging from 10 to 60 μm, compared to diameters of 2.5–4 μm for natural spider silk. Artificial spider silks have fewer and simpler proteins than natural dragline silk, and consequently offer half the diameter, strength, and flexibility of natural dragline silk.[86]

Research

- In March 2010, researchers from the Korea Advanced Institute of Science & Technology succeeded in making spider silk directly using E. coli modified with certain genes of the spider Nephila clavipes. This approach eliminates the need to "milk" spiders.[87]

- A 556 kDa spider silk protein was manufactured from 192 repeat motifs of the N. clavipes dragline spidroin, having similar mechanical characteristics as their natural counterparts, i.e., tensile strength (1.03 ± 0.11 GPa), modulus (13.7 ± 3.0 GPa), extensibility (18 ± 6%), and toughness (114 ± 51 MJ/m3).[67]

- AMSilk developed spidroin using bacteria.[86][88]

- Bolt Threads produced a recombinant spidroin using yeast, for use in apparel fibers and personal care. They produced the first commercial apparel products made of recombinant spider silk, trademarked Microsilk, demonstrated in ties and beanies.[89][90]

- Kraig Biocraft Laboratories used research from the Universities of Wyoming and Notre Dame to create silkworms genetically altered to produce spider silk.[91][92]

- Defunct Canadian biotechnology company Nexia produced spider silk protein in transgenic goats; the milk produced by the goats contained significant quantities of the protein, 1–2 grams of silk proteins per litre of milk. Attempts to spin the protein into a fibre similar to natural spider silk resulted in fibres with tenacities of 2–3 grams per denier.[93] Nexia used wet spinning and squeezed the silk protein solution through small extrusion holes to simulate the spinneret, but this was not sufficient to replicate native spider silk properties.[94]

- Spiber produced a synthetic spider silk (Q/QMONOS). In partnership with Goldwin, a ski parka made from this was in testing in 2016.[95][96]

Research

| Area of contribution | Year | Main researchers | Title | Contribution to the field |

|---|---|---|---|---|

| Chemical Basis | 1960 | Fischer, F. & Brander, J.[97] | "Eine Analyse der Gespinste der Kreuzspinne" (Amino acid composition analysis of spider silk) | |

| 1960 | Lucas, F. et al.[98][99] | "The Composition of Arthropod Silk Fibroins; Comparative studies of fibroins" | ||

| Gene Sequence | 1990 | Xu, M. & Lewis, R. V.[100] | "Structure of a Protein Superfiber − Spider Dragline Silk" | |

| Mechanical Properties | 1964 | Lucas, F.[101] | "Spiders and their silks" | First time mechanical properties of spider silk compared with other materials in a scientific paper. |

| 1989 | Vollrath, F. & Edmonds, D. T.[102] | "Modulation of the Mechanical Properties of Spider Silk by Coating with Water" | First important paper suggesting the water interplay with spider silk fibroin modulating silk properties. | |

| 2001 | Vollrath, F. & Shao, Z.Z.[103] | "The effect of spinning conditions on the mechanics of a spider's dragline silk" | ||

| 2006 | Plaza, G.R., Guinea, G.V., Pérez-Rigueiro, J. & Elices, M.[17] | "Thermo-hygro-mechanical behavior of spider dragline silk: Glassy and rubbery states" | Combined effect of humidity and temperature on mechanical properties. Glass-transition temperature dependence on humidity. | |

| Structural Characterisation | 1992 | Hinman, M.B. & Lewis, R. V[4] | "Isolation of a clone encoding a second dragline silk fibroin. Nephila clavipes dragline silk is a two-protein fiber" | |

| 1994 | Simmons, A. et al.[104] | "Solid-State C-13 Nmr of Nephila-Clavipes Dragline Silk Establishes Structure and Identity of Crystalline Regions" | First NMR study of spider silk. | |

| 1999 | Shao, Z., Vollrath, F. et al.[105] | "Analysis of spider silk in native and supercontracted states using Raman spectroscopy" | First Raman study of spider silk. | |

| 1999 | Riekel, C., Muller, M.et al.[106] | "Aspects of X-ray diffraction on single spider fibers" | First X-ray on single spider silk fibres. | |

| 2000 | Knight, D.P., Vollrath, F. et al.[107] | "Beta transition and stress-induced phase separation in the spinning of spider dragline silk" | Secondary structural transition confirmation during spinning. | |

| 2001 | Riekel, C. & Vollrath, F.[108] | "Spider silk fibre extrusion: combined wide- and small-angle X- ray microdiffraction experiments" | First X-ray on spider silk dope. | |

| 2002 | Van Beek, J. D. et al.[6] | "The molecular structure of spider dragline silk: Folding and orientation of the protein backbone" | ||

| Structure-Property Relationship | ||||

| 1994 | Termonia, Y[10] | "Molecular Modeling of Spider Silk Elasticity" | X-ray evidence presented in this paper; simple model of crystallites embedded in amorphous regions. | |

| 1996 | Simmons, A. et al.[5] | "Molecular orientation and two-component nature of the crystalline fraction of spider dragline silk" | Two types of alanine-rich crystalline regions were defined. | |

| 2006 | Vollrath, F. & Porter, D.[109] | "Spider silk as an archetypal protein elastomer" | New insight and model to spider silk based on Group Interaction Modelling. | |

| Native Spinning | 1991 | Kerkam, K., Kaplan, D. et al.[110] | "Liquid Crystallinity of Natural Silk Secretions" | |

| 1999 | Knight, D.P. & Vollrath, F.[111] | "Liquid crystals and flow elongation in a spider's silk production line" | ||

| 2001 | Vollrath, F. & Knight, D.P.[23] | "Liquid crystalline spinning of spider silk" | Most cited spider silk paper | |

| 2005 | Guinea, G.V., Elices, M., Pérez-Rigueiro, J. & Plaza, G.R.[16] | "Stretching of supercontracted fibers: a link between spinning and the variability of spider silk" | Explanation of the variability of mechanical properties. | |

| Reconstituted /Synthetic Spider Silk and Artificial Spinning | ||||

| 1998 | Arcidiacono, S., Kaplan, D.L. et al.[112] | "Purification and characterization of recombinant spider silk expressed in Escherichia coli" | ||

| 1998 | Seidel, A., Jelinski, L.W. et al.[113] | "Artificial Spinning of Spider Silk" | First controlled wet-spinning of reconstituted spider silk. |

Human uses

The earliest recorded attempt to weave fabric from spider silk was in 1709 by François Xavier Bon who, using a process similar to creating silkworm silk, wove silk derived spider's egg cocoons into stockings and gloves. Fifty years later Jesuit missionary Ramón M. Termeyer (pl), invented a reeling device for harvesting spider silk directly from spiders, allowing it to be spun into threads. Neither Bon nor Termeyer were successful in producing commercially viable quantities.[115]

The development of methods to mass-produce spider silk led to the manufacturing of military, medical, and consumer goods, such as ballistic armour, athletic footwear, personal care products, breast implant and catheter coatings, mechanical insulin pumps, fashion clothing, and outerwear.[86] However, due to the difficulties in extracting and processing, the largest known piece of cloth made of spider silk is an 11-by-4-foot (3.4 by 1.2 m) textile with a golden tint made in Madagascar in 2009.[116] Eighty-two people worked for four years to collect over one million golden orb spiders and extract silk from them.[117] In 2012, spider silk fibres were used to create a set of violin strings.[118]

Medicine

Peasants in the southern Carpathian Mountains used to cut up tubes built by Atypus and cover wounds with the inner lining. It reportedly facilitated healing, and connected with the skin. This is believed to be due to the silk's antiseptic properties,[119] and because silk is rich in vitamin K, which can aid in clotting blood.[120][verify] N. clavipes silk was used in research concerning mammalian neuronal regeneration.[121]

Scientific instruments

Spider silk has been used as a thread for crosshairs in optical instruments such as telescopes, microscopes,[122] and telescopic rifle sights.[123] In 2011, silk fibres were used to generate fine diffraction patterns over N-slit interferometric signals used in optical communications.[124] Silk has been used to create biolenses that could be used in conjunction with lasers to create high-resolution images of the inside of the human body.[125]

Silk has been used to suspend inertial confinement fusion targets during laser ignition, as it remains considerably elastic and has a high energy to break at temperatures as low as 10–20 K. In addition, it is made from "light" atomic number elements that emit no x-rays during irradiation that could preheat the target, limiting the pressure differential required for fusion.[126]

References

- ↑ 1.0 1.1 Miyashita, Tadashi; Maezono, Yasunori; Shimazaki, Aya (2004). "Silk feeding as an alternative foraging tactic in a kleptoparasitic spider under seasonally changing environments". Journal of Zoology 262 (3): 225–29. doi:10.1017/S0952836903004540. http://frank.itlab.us/photo_essays/papers/Argyrodes_kleptoparasite_spider.pdf.

- ↑ Work, Robert W.; Emerson, Paul D. (1982). "An Apparatus and Technique for the Forcible Silking of Spiders". Journal of Arachnology 10 (1): 1–10.

- ↑ Scott, Catherine E.; Anderson, Alissa G.; Andrade, Maydianne C. B. (August 2018). "A review of the mechanisms and functional roles of male silk use in spider courtship and mating". The Journal of Arachnology 46 (2): 173–206. doi:10.1636/JoA-S-17-093.1. ISSN 0161-8202. https://bioone.org/journals/the-journal-of-arachnology/volume-46/issue-2/JoA-S-17-093.1/A-review-of-the-mechanisms-and-functional-roles-of-male/10.1636/JoA-S-17-093.1.full.

- ↑ 4.0 4.1 Hinman, M. B.; Lewis, R. V. (1992). "Isolation of a clone encoding a second dragline silk fibroin. Nephila clavipes dragline silk is a two-protein fiber". J. Biol. Chem. 267 (27): 19320–24. doi:10.1016/S0021-9258(18)41777-2. PMID 1527052.

- ↑ 5.0 5.1 5.2 5.3 Simmons, A. H.; Michal, C. A.; Jelinski, L. W. (1996). "Molecular orientation and two-component nature of the crystalline fraction of spider dragline silk". Science 271 (5245): 84–87. doi:10.1126/science.271.5245.84. PMID 8539605. Bibcode: 1996Sci...271...84S.

- ↑ 6.0 6.1 van Beek, J. D.; Hess, S.; Vollrath, F.; Meier, B. H. (2002). "The molecular structure of spider dragline silk: Folding and orientation of the protein backbone". Proc. Natl. Acad. Sci. U.S.A. 99 (16): 10266–71. doi:10.1073/pnas.152162299. PMID 12149440. Bibcode: 2002PNAS...9910266V.

- ↑ Liu, Y.; Sponner, A.; Porter, D.; Vollrath, F. (2008). "Proline and Processing of Spider Silks". Biomacromolecules 9 (1): 116–21. doi:10.1021/bm700877g. PMID 18052126.

- ↑ Papadopoulos, P.; Ene, R.; Weidner, I.; Kremer, F. (2009). "Similarities in the Structural Organization of Major and Minor Ampullate Spider Silk". Macromol. Rapid Commun. 30 (9–10): 851–57. doi:10.1002/marc.200900018. PMID 21706668.

- ↑ 9.0 9.1 Heimer, S. (1988). Wunderbare Welt der Spinnen. Urania. p. 12

- ↑ 10.0 10.1 Termonia, Y. (1994). "Molecular Modeling of Spider Silk Elasticity". Macromolecules 27 (25): 7378–81. doi:10.1021/ma00103a018. Bibcode: 1994MaMol..27.7378T.

- ↑ Vollrath, F.; Holtet, T.; Thogersen, H. C.; Frische, S. (1996). "Structural organization of spider silk". Proceedings of the Royal Society B 263 (1367): 147–51. doi:10.1098/rspb.1996.0023. Bibcode: 1996RSPSB.263..147V.

- ↑ Sponner, A.; Vater, Wolfram, Wolfram; Monajembashi, Shamci, Shamci; Unger, Eberhard, Eberhard; Grosse, Frank, Frank; Weisshart, Klaus, Klaus (2007). Scheibel, Thomas. ed. "Composition and hierarchical organization of a spider silk". PLOS ONE 2 (10): e998. doi:10.1371/journal.pone.0000998. PMID 17912375. Bibcode: 2007PLoSO...2..998S.

- ↑ Sapede, D.; Seydel, T.; Forsyth, V. T.; Koza, M. M.; Schweins, R.; Vollrath, F.; Riekel, C. (2005). "Nanofibrillar structure and molecular mobility in spider dragline silk". Macromolecules 34 (20): 623. doi:10.1021/ma0507995. Bibcode: 2005MaMol..38.8447S.

- ↑ Plaza, G.R.; Pérez-Rigueiro, J.; Riekel, C.; Perea, G.B.; Agulló-Rueda, F.; Burghammer, M.; Guinea, G.V.; Elices, M. (2012). "Relationship between microstructure and mechanical properties in spider silk fibers: identification of two regimes in the microstructural changes". Soft Matter 8 (22): 6015–26. doi:10.1039/C2SM25446H. Bibcode: 2012SMat....8.6015P. https://zenodo.org/record/897750.

- ↑ Zhao, Yue; Hien, Khuat Thi Thu; Mizutani, Goro; Rutt, Harvey N. (June 2017). "Second-order nonlinear optical microscopy of spider silk". Applied Physics B 123 (6): 188. doi:10.1007/s00340-017-6766-z. Bibcode: 2017ApPhB.123..188Z.

- ↑ 16.0 16.1 Guinea, G.V.; Elices, M.; Pérez-Rigueiro, J.; Plaza, G.R. (2005). "Stretching of supercontracted fibers: a link between spinning and the variability of spider silk". Journal of Experimental Biology 208 (1): 25–30. doi:10.1242/jeb.01344. PMID 15601874.

- ↑ 17.0 17.1 17.2 17.3 Plaza, Gustavo R.; Guinea, Gustavo V.; Pérez-Rigueiro, José; Elices, Manuel (2006). "Thermo-hygro-mechanical behavior of spider dragline silk: Glassy and rubbery states". Journal of Polymer Science Part B: Polymer Physics 44 (6): 994–99. doi:10.1002/polb.20751. Bibcode: 2006JPoSB..44..994P.

- ↑ Griffiths, J. R.; Salanitri, V. R. (1980). "The strength of spider silk". Journal of Materials Science 15 (2): 491–96. doi:10.1007/BF00551703. Bibcode: 1980JMatS..15..491G.

- ↑ "Overview of materials for AISI 4000 Series Steel". matweb.com. http://www.matweb.com/search/datasheettext.aspx?matguid=210fcd12132049d0a3e0cabe7d091eef.

- ↑ "DuPont Kevlar 49 Aramid Fiber". matweb.com. http://www.matweb.com/search/datasheettext.aspx?matguid=77b5205f0dcc43bb8cbe6fee7d36cbb5.

- ↑ Ganio Mego, Paolo (c. 2002). "Material Tensile Strength Comparison". http://www.geocities.com/pganio/materials.html.

- ↑ Shao, Zhengzhong; Vollrath, F (2002). "Materials: Surprising strength of silkworm silk". Nature 418 (6899): 741. doi:10.1038/418741a. PMID 12181556. Bibcode: 2002Natur.418..741S.

- ↑ 23.0 23.1 23.2 Porter, D.; Vollrath, F.; Shao, Z. (2005). "Predicting the mechanical properties of spider silk as a model nanostructured polymer". European Physical Journal E 16 (2): 199–206. doi:10.1140/epje/e2005-00021-2. PMID 15729511. Bibcode: 2005EPJE...16..199P.

- ↑ 24.0 24.1 Vollrath, F.; Knight, D. P. (2001). "Liquid crystalline spinning of spider silk". Nature 410 (6828): 541–48. doi:10.1038/35069000. PMID 11279484. Bibcode: 2001Natur.410..541V.

- ↑ "Spider Silk". chm.bris.ac.uk. http://www.chm.bris.ac.uk/motm/spider/page2.htm.

- ↑ Yang, Y.; Chen, X.; Shao, Z.; Zhou, P.; Porter, D.; Knight, D. P.; Vollrath, F. (2005). "Toughness of Spider Silk at High and Low Temperatures". Advanced Materials 17 (1): 84–88. doi:10.1002/adma.200400344. Bibcode: 2005AdM....17...84Y.

- ↑ 27.0 27.1 Agnarsson, Ingi; Kuntner, Matjaž; Blackledge, Todd A. (2010). Lalueza-Fox, Carles. ed. "Bioprospecting Finds the Toughest Biological Material: Extraordinary Silk from a Giant Riverine Orb Spider". PLOS ONE 5 (9): 11234. doi:10.1371/journal.pone.0011234. PMID 20856804. Bibcode: 2010PLoSO...511234A.

- ↑ 28.0 28.1 28.2 Wolff, J. O.; Grawe, I; Wirth, M; Karstedt, A; Gorb, S. N. (2015). "Spider's super-glue: Thread anchors are composite adhesives with synergistic hierarchical organization". Soft Matter 11 (12): 2394–403. doi:10.1039/c4sm02130d. PMID 25672841. Bibcode: 2015SMat...11.2394W.

- ↑ Sahni, V; Harris, J; Blackledge, T. A.; Dhinojwala, A (2012). "Cobweb-weaving spiders produce different attachment discs for locomotion and prey capture". Nature Communications 3: 1106. doi:10.1038/ncomms2099. PMID 23033082. Bibcode: 2012NatCo...3.1106S.

- ↑ 30.0 30.1 30.2 30.3 Foelix, R. F. (1996). Biology of Spiders. Oxford; New York: Oxford University Press. p. 330. ISBN 978-0-19-509594-4. https://archive.org/details/biologyofspiders00foel_0.

- ↑ Sutherland, TD; Young, JH; Weisman, S; Hayashi, CY; Merritt, DJ (2010). "Insect silk: One name, many materials". Annual Review of Entomology 55: 171–88. doi:10.1146/annurev-ento-112408-085401. PMID 19728833.

- ↑ 32.0 32.1 32.2 Hillyard, P. (2007). The Private Life of Spiders. London: New Holland. p. 160. ISBN 978-1-84537-690-1.

- ↑ Nentwig, Wolfgang; Heimer, Stefan (1987). "Ecological Aspects of Spider Webs". Ecophysiology of Spiders. pp. 211–225. doi:10.1007/978-3-642-71552-5_15. ISBN 978-3-642-71554-9.

- ↑ Flying spiders over Texas! Coast to Coast. Chad B., Texas State University Undergrad Describes the mechanical kiting of Spider "ballooning".

- ↑ 35.0 35.1 35.2 35.3 35.4 Holm, Erik, Dippenaar-Schoeman, Ansie; Goggo Guide; LAPA publishers (URL: WWW.LAPA.co.za). 2010[page needed]

- ↑ Cunningham, Aimee (2009). "Taken for a spin: Scientists look to spiders for the goods on silk". Science News 171 (15): 231–34. doi:10.1002/scin.2007.5591711509.

- ↑ Blackledge, TA; Hayashi, CY (2006). "Silken toolkits: Biomechanics of silk fibers spun by the orb web spider Argiope argentata (Fabricius 1775)". The Journal of Experimental Biology 209 (Pt 13): 2452–61. doi:10.1242/jeb.02275. PMID 16788028.

- ↑ 38.0 38.1 Andersson, M; Johansson, J; Rising, A (2016). "Silk Spinning in Silkworms and Spiders". International Journal of Molecular Sciences 17 (8): 1290. doi:10.3390/ijms17081290. PMID 27517908.

- ↑ 39.0 39.1 Wilson, R. S. (1969). "control of drag-line spinning in certain spiders". Am. Zool. 9: 103–. doi:10.1093/icb/9.1.103.

- ↑ Zhao, Yue; Li, Yanrong; Hien, K. T. T.; Mizutani, Goro; Rutt, Harvey N. (2019). "Observation of Spider Silk by Femtosecond Pulse Laser Second Harmonic Generation Microscopy". Surf. Interface Anal. 51 (1): 50–56. doi:10.1002/sia.6545.

- ↑ 41.0 41.1 Rising, A.; Johansson, J. (2015). "Toward spinning artificial spider silk". Nat. Chem. Biol. 11 (5): 309–15. doi:10.1038/nchembio.1789. PMID 25885958.

- ↑ 42.0 42.1 42.2 Eisoldt, L.; Thamm, C.; Scheibel, T. (2012). "The role of terminal domains during storage and assembly of spider silk proteins". Biopolymers 97 (6): 355–61. doi:10.1002/bip.22006. PMID 22057429.

- ↑ Eisoldt, L.; Smith, A.; Scheibel, T. (2011). "Decoding the secrets of spider silk". Mater. Today 14 (3): 80–86. doi:10.1016/S1369-7021(11)70057-8.

- ↑ Tokareva, O.; Jacobsen, M.; Buehler, M.; Wong, J.; Kaplan, D. L. (2014). "Structure–function–property–design interplay in biopolymers: Spider silk". Acta Biomater. 10 (4): 1612–26. doi:10.1016/j.actbio.2013.08.020. PMID 23962644.

- ↑ 45.0 45.1 Vollrath, F.; Knight, D. P. (2001). "Liquid crystalline spinning of spider silk". Nature 410 (6828): 541–48. doi:10.1038/35069000. PMID 11279484. Bibcode: 2001Natur.410..541V.

- ↑ 46.0 46.1 Kluge, J. A.; Rabotyagova, O.; Leisk, G. G.; Kaplan, D. L. (2008). "Spider silks and their applications". Trends Biotechnol. 26 (5): 244–51. doi:10.1016/j.tibtech.2008.02.006. PMID 18367277.

- ↑ Hijirida, D. H.; Do, K. G.; Michal, C.; Wong, S.; Zax, D.; Jelinski, L. W. (1996). "13C NMR of Nephila clavipes major ampullate silk gland". Biophys. J. 71 (6): 3442–47. doi:10.1016/S0006-3495(96)79539-5. PMID 8968613. Bibcode: 1996BpJ....71.3442H.

- ↑ Lefvre, T.; Boudreault, S.; Cloutier, C.; Pezolet, M. (2008). "Conformational and orientational transformation of silk proteins in the major ampullate gland of Nephila clavipes spiders". Biomacromolecules 9 (9): 2399–407. doi:10.1021/bm800390j. PMID 18702545.

- ↑ Lewis, R. V. (2006). "Spider silk: Ancient ideas for new biomaterials". Chem. Rev. 106 (9): 3762–74. doi:10.1021/cr010194g. PMID 16967919.

- ↑ Andersson, M. (2014). "Carbonic anhydrase generates CO2 and H+ that drive spider silk formation via opposite effects on the terminal domains". PLOS Biol. 12 (8): e1001921. doi:10.1371/journal.pbio.1001921. PMID 25093327.

- ↑ Kronqvist, N. (2014). "Sequential pH-driven dimerization and stabilization of the N-terminal domain enables rapid spider silk formation". Nat. Commun. 5: 3254. doi:10.1038/ncomms4254. PMID 24510122. Bibcode: 2014NatCo...5.3254K.

- ↑ Knight, D. P.; Vollrath, F. (1999). "Liquid crystals and flow elongation in a spider's silk production line". Proc. R. Soc. B 266 (1418): 519–23. doi:10.1098/rspb.1999.0667.

- ↑ Dicko, C.; Porter, D.; Bond, J.; Kenney, J. M.; Vollratht, F. (2008). "Structural disorder in silk proteins reveals the emergence of elastomericity". Biomacromolecules 9 (1): 216–21. doi:10.1021/bm701069y. PMID 18078324.

- ↑ Lefèvre, T.; Boudreault, S.; Cloutier, C.; Pézolet, M. (2008). "Conformational and orientational transformation of silk proteins in the major ampullate gland of Nephila clavipes spiders". Biomacromolecules 9 (9): 2399–407. doi:10.1021/bm800390j. PMID 18702545.

- ↑ Heim, M.; Keerl, D.; Scheibel, T. (2009). "Spider Silk: From Soluble Protein to Extraordinary Fiber". Angewandte Chemie International Edition 48 (20): 3584–96. doi:10.1002/anie.200803341. PMID 19212993.

- ↑ Heinhorst, S.; Cannon, G. (2002). "Nature: Self-Healing Polymers and Other Improved Materials". J. Chem. Educ. 79 (1): 10. doi:10.1021/ed079p10. Bibcode: 2002JChEd..79...10H.

- ↑ Knight, D. P.; Vollrath, F. (2001-04-01). "Changes in element composition along the spinning duct in a Nephila spider". Die Naturwissenschaften 88 (4): 179–82. doi:10.1007/s001140100220. ISSN 0028-1042. PMID 11480706. Bibcode: 2001NW.....88..179K.

- ↑ 58.0 58.1 Vollrath, F.; Knight, D. P. (1998). "Structure and function of the silk production pathway in spider Nephila edulis". Int J Biol Macromol 24 (2–3): 243–49. doi:10.1016/S0141-8130(98)00095-6. PMID 10342771.

- ↑ Wilson, R. S. (1962). "The Control of Dragline Spinning in the Garden Spider". Quarterly Journal of Microscopical Science 103: 557–71.

- ↑ Magoshi, J.; Magoshi, Y.; Nakamura, S. (1985). "Physical properties and structure of silk: 9. Liquid crystal formation of silk fibroin". Polym. Commun. 26: 60–61.

- ↑ Chen, Xin; Knight, David P.; Vollrath, Fritz (2002-07-01). "Rheological characterization of nephila spidroin solution". Biomacromolecules 3 (4): 644–48. doi:10.1021/bm0156126. ISSN 1525-7797. PMID 12099805.

- ↑ Jeffery, F; La Mattina, C; Tuton-Blasingame, T; Hsia, Y; Gnesa, E; Zhao, L; Franz, A; Vierra, C (2011). "Microdissection of Black Widow Spider Silk-producing Glands". Journal of Visualized Experiments (47): 2382. doi:10.3791/2382. PMID 21248709.

- ↑ Elices, M.; Plaza, G.R.; Arnedo, M.A.; Perez-Rigueiro, J.; Torres, F.G.; Guinea, G. (2009). "Mechanical Behavior of Silk During the Evolution of Orb-Web Spinning Spiders". Biomacromolecules 10 (7): 1904–10. doi:10.1021/bm900312c. PMID 19505138.

- ↑ Swanson, B. O.; Blackledge, T. A.; Summers, A. P.; Hayashi, C. Y. (2006). "Spider dragline silk: Correlated and mosaic evolution in high-performance biological materials". Evolution 60 (12): 2539–51. doi:10.1554/06-267.1. PMID 17263115. https://faculty.washington.edu/fishguy/Resources/Research_PDFs/2006-evolution-spider-silk-material-properties.pdf.

- ↑ Shao, Z. Z.; Vollrath, F. (2002). "Materials: Surprising strength of silkworm silk". Nature 418 (6899): 741. doi:10.1038/418741a. PMID 12181556. Bibcode: 2002Natur.418..741S.

- ↑ Wen, H. X. (2010). "Transgenic silkworms (Bombyx mori) produce recombinant spider dragline silk in cocoons". Molecular Biology Reports 37 (4): 1815–21. doi:10.1007/s11033-009-9615-2. PMID 19633923.

- ↑ 67.0 67.1 Bowen, C.H. (2018). "Recombinant Spidroins Fully Replicate Primary Mechanical Properties of Natural Spider Silk". Biomacromolecules 19 (9): 3853–60. doi:10.1021/acs.biomac.8b00980. PMID 30080972.

- ↑ Elices, M.; Guinea, G. V.; Plaza, G. R.; Karatzas, C.; Riekel, C.; Agulló-Rueda, F.; Daza, R.; Pérez-Rigueiro, J. (2011). "Bioinspired Fibers Follow the Track of Natural Spider Silk". Macromolecules 44 (5): 1166–76. doi:10.1021/ma102291m. Bibcode: 2011MaMol..44.1166E.

- ↑ "Expression of spider silk proteins" US patent 2008109923, published 2010-05-25, assigned to University of Wyoming

- ↑ Scheller, J.; Conrad, U. (2005). "Plant-based material, protein and biodegradable plastic". Current Opinion in Plant Biology 8 (2): 188–96. doi:10.1016/j.pbi.2005.01.010. PMID 15753000.

- ↑ 71.0 71.1 Lazaris, A.; Arcidiacono, S, S; Huang, Y, Y; Zhou, J. F., JF; Duguay, F, F; Chretien, N, N; Welsh, E. A., EA; Soares, J. W., JW et al. (2002). "Spider silk fibers spun from soluble recombinant silk produced in mammalian cells". Science 295 (5554): 472–76. doi:10.1126/science.1065780. PMID 11799236. Bibcode: 2002Sci...295..472L.

- ↑ 72.0 72.1 Seidel, A.; Liivak, Oskar; Calve, Sarah; Adaska, Jason; Ji, Gending; Yang, Zhitong; Grubb, David; Zax, David B. et al. (2000). "Regenerated spider silk: Processing, properties, and structure". Macromolecules 33 (3): 775–80. doi:10.1021/ma990893j. Bibcode: 2000MaMol..33..775S.

- ↑ Arcidiacono, S.; Mello, Charlene M.; Butler, Michelle; Welsh, Elizabeth; Soares, Jason W.; Allen, Alfred; Ziegler, David; Laue, Thomas et al. (2002). "Aqueous processing and fiber spinning of recombinant spider silks". Macromolecules 35 (4): 1262–66. doi:10.1021/ma011471o. Bibcode: 2002MaMol..35.1262A.

- ↑ Xia, X. X. (2010). "Native-sized recombinant spider silk protein produced in metabolically engineered Escherichia coli results in a strong fiber". Proceedings of the National Academy of Sciences of the United States of America 107 (32): 14,059–63. doi:10.1073/pnas.1003366107. PMID 20660779. Bibcode: 2010PNAS..10714059X.

- ↑ Gustafsson, L.; Jansson, R.; Hedhammar, M.; van der Wijngaart, W. (2018). "Structuring of Functional Spider Silk Wires, Coatings, and Sheets by Self-Assembly on Superhydrophobic Pillar Surfaces". Advanced Materials 30 (3). doi:10.1002/adma.201704325. PMID 29205540. Bibcode: 2018AdM....3004325G.

- ↑ Gustafsson, L.; Kvick, M.; Åstrand, C.; Ponsteen, N.; Dorka, N.; Hegrová, V.; Svanberg, S.; Horák, J. et al. (2023). "Scalable Production of Monodisperse Bioactive Spider Silk Nanowires". Macromolecular Bioscience 23 (4): e2200450. doi:10.1002/mabi.202200450. PMID 36662774.

- ↑ "Recombinant Spider Silk Forms Tough and Elastic Nanomembranes that are Protein-Permeable and Support Cell Attachment and Growth", Advanced Functional Materials 30 (40), 2020, doi:10.1002/adfm.202002982

- ↑ "Fibrillar Nanomembranes of Recombinant Spider Silk Protein Support Cell Co-culture in an In Vitro Blood Vessel Wall Model", ACS Biomaterials Science & Engineering 7 (7): 3332–3339, 2021, doi:10.1021/acsbiomaterials.1c00612, PMID 34169711, PMC 8290846, http://dx.doi.org/10.1021/acsbiomaterials.1c00612

- ↑ Kinahan, M. E. (2011). "Tunable Silk: Using Microfluidics to Fabricate Silk Fibers with Controllable Properties". Biomacromolecules 12 (5): 1504–11. doi:10.1021/bm1014624. PMID 21438624.

- ↑ Rammensee, S.; Slotta, U.; Scheibel, T.; Bausch, A. R. (2008). "Assembly mechanism of recombinant spider silk proteins (microfluidic)". Proceedings of the National Academy of Sciences of the United States of America 105 (18): 6590–95. doi:10.1073/pnas.0709246105. PMID 18445655. Bibcode: 2008PNAS..105.6590R.

- ↑ Spintec Engineering GmbH (in German)

- ↑ Eisoldt, L.; Smith, A.; Scheibel, T. (2011). "Decoding the secrets of spider silk". Mater. Today 14 (3): 80–86. doi:10.1016/s1369-7021(11)70057-8.

- ↑ 83.0 83.1 Gustafsson, L.; Jansson, R.; Hedhammar, M.; van der Wijngaart, W. (2018). "Structuring of Functional Spider Silk Wires, Coatings, and Sheets by Self-Assembly on Superhydrophobic Pillar Surfaces". Adv. Mater. 30 (3): 1704325. doi:10.1002/adma.201704325. PMID 29205540. Bibcode: 2018AdM....3004325G.

- ↑ Gustafsson, Linnea; Panagiotis Tasiopoulos, Christos; Jansson, Ronnie; Kvick, Mathias; Duursma, Thijs; Gasser, Thomas Christian; van der Wijngaart, Wouter; Hedhammar, My (16 August 2020). "Recombinant Spider Silk Forms Tough and Elastic Nanomembranes that are Protein-Permeable and Support Cell Attachment and Growth". Advanced Functional Materials 30 (40): 2002982. doi:10.1002/adfm.202002982.

- ↑ Tasiopoulos, Christos Panagiotis; Gustafsson, Linnea; van der Wijngaart, Wouter; Hedhammar, My (2021-06-25). "Fibrillar Nanomembranes of Recombinant Spider Silk Protein Support Cell Co-culture in an in Vitro Blood Vessel Wall Model". ACS Biomaterials Science & Engineering 7 (7): 3332–3339. doi:10.1021/acsbiomaterials.1c00612. PMID 34169711.

- ↑ 86.0 86.1 86.2 86.3 Service, Robert F. (18 October 2017). "Spinning spider silk into startup gold". Science Magazine, American Association for the Advancement of Science. https://www.science.org/content/article/spinning-spider-silk-startup-gold.

- ↑ Xia, Xiao-Xia; Qian, Zhi-Gang; Ki, Chang Seok; Park, Young Hwan; Kaplan, David L.; Lee, Sang Yup (2010). "Native-sized recombinant spider silk protein produced in metabolically engineered Escherichia coli results in a strong fiber". Proceedings of the National Academy of Sciences 107 (32): 14059–63. doi:10.1073/pnas.1003366107. PMID 20660779. Bibcode: 2010PNAS..10714059X.

- ↑ "Draadkracht: spindoctors maken supersterk nepweb" (in nl). KIJK. 21 April 2012. http://www.kijkmagazine.nl/artikel/spinnendraad/.

- ↑ "Bolt Threads – Microsilk". https://boltthreads.com/technology/microsilk.

- ↑ "Bolt Threads – B-silk protein". https://boltthreads.com/technology/silk-protein.

- ↑ "University of Notre Dame and Kraig Biocraft Laboratories Create Artificial Spider Silk Breakthrough" (Press release). Kraig Biocraft Laboratories. 29 September 2010. Archived from the original on 25 May 2011. Retrieved 3 January 2012.

- ↑ "Fraser Research Publicly Announced at Press Conference" (Press release). University of Notre Dame. 1 October 2010. Archived from the original on 10 October 2010. Retrieved 3 January 2012.

- ↑ Kluge, Jonathan A.; Rabotyagova, Olena; Leisk, Gary G.; Kaplan, David L. (May 2008). "Spider silks and their applications". Trends in Biotechnology 26 (5): 244–51. doi:10.1016/j.tibtech.2008.02.006. PMID 18367277.

- ↑ Scheibel, Thomas (November 2004). "Spider silks: recombinant synthesis, assembly, spinning, and engineering of synthetic proteins". Microbial Cell Factories 3 (1): 14. doi:10.1186/1475-2859-3-14. PMID 15546497.

- ↑ "Goldwin x Spiber Ski Jacket". https://www.goldwin-sports.com/us/feature/goldwinskijacket/.

- ↑ Bain, Marc (July 3, 2016). "Synthetic spider silk could be the biggest technological advance in clothing since nylon". https://qz.com/708298/synthetic-spider-silk-could-be-the-biggest-technological-advance-in-clothing-since-nylon/.

- ↑ Fischer, F.; Brander, J. (1960). "Eine Analyse der Gespinste der Kreuzspinne". Hoppe-Seyler's Zeitschrift für Physiologische Chemie 320: 92–102. doi:10.1515/bchm2.1960.320.1.92. PMID 13699837.

- ↑ Lucas, F.; Shaw, J. T. B.; Smith, S. G. (1960). "The Composition of Arthropod Silk Fibrons". Insect Chemistry Symp. 3: 208–14.

- ↑ Lucas, F.; Shaw, J. T. B.; Smith, S. G. (1960). "Comparative studies of fibroins.I. The amino acid composition of various fibroins and its significance in relation to their crystal structure and taxonomy". Journal of Molecular Biology 2 (6): 339–49. doi:10.1016/S0022-2836(60)80045-9. PMID 13763962.

- ↑ Xu, M.; Lewis, R. V. (1990). "Structure of a Protein Superfiber – Spider Dragline Silk". Proceedings of the National Academy of Sciences of the United States of America 87 (18): 7120–24. doi:10.1073/pnas.87.18.7120. PMID 2402494. Bibcode: 1990PNAS...87.7120X.

- ↑ Lucas, F. (1964). "Spiders and their silks". Discovery 25: 20–26.

- ↑ Vollrath, F.; Edmonds, D. T. (1989). "Modulation of the Mechanical-Properties of Spider Silk By Coating With Water". Nature 340 (6231): 305–07. doi:10.1038/340305a0. Bibcode: 1989Natur.340..305V.

- ↑ Vollrath, F.; Madsen, B.; Shao, Z. Z. (2001). "The effect of spinning conditions on the mechanics of a spider's dragline silk". Proceedings of the Royal Society B 268 (1483): 2339–46. doi:10.1098/rspb.2001.1590. PMID 11703874.

- ↑ Simmons, A.; Ray, E.; Jelinski, L. W. (1994). "Solid-State C-13 NMR of Nephila-Clavipes Dragline Silk Establishes Structure and Identity of Crystalline Regions". Macromolecules 27 (18): 5235–37. doi:10.1021/ma00096a060. Bibcode: 1994MaMol..27.5235S.

- ↑ Shao, Z.; Vollrath, F.; Sirichaisit, J.; Young, R. J. (1999). "Analysis of spider silk in native and supercontracted states using Raman spectroscopy". Polymer 40 (10): 2493–500. doi:10.1016/S0032-3861(98)00475-3.

- ↑ Riekel, C.; Bränden, C; Craig, C; Ferrero, C; Heidelbach, F; Müller, M (1999). "Aspects of X-ray diffraction on single spider fibers". Int. J. Biol. Macromol. 24 (2–3): 179–86. doi:10.1016/S0141-8130(98)00084-1. PMID 10342763.

- ↑ Knight, D. P.; Knight, M. M.; Vollrath, F. (2000). "Beta transition and stress-induced phase separation in the spinning of spider dragline silk". Int. J. Biol. Macromol. 27 (3): 205–10. doi:10.1016/S0141-8130(00)00124-0. PMID 10828366.

- ↑ Riekel, C.; Vollrath, F. (2001). "Spider silk fibre extrusion: combined wide- and small-angle X- ray microdiffraction experiments". Int. J. Biol. Macromol. 29 (3): 203–10. doi:10.1016/S0141-8130(01)00166-0. PMID 11589973.

- ↑ Vollrath, F.; Porter, D. (2006). "Spider silk as an archetypal protein elastomer". Soft Matter 2 (5): 377–85. doi:10.1039/b600098n. PMID 32680251. Bibcode: 2006SMat....2..377V.

- ↑ Kerkam, K.; Viney, C.; Kaplan, D.; Lombardi, S. (1991). "Liquid Crystallinity of Natural Silk Secretions". Nature 349 (6310): 596–98. doi:10.1038/349596a0. Bibcode: 1991Natur.349..596K.

- ↑ Knight, D. P.; Vollrath, F. (1999). "Liquid crystals and flow elongation in a spider's silk production line". Proceedings of the Royal Society B 266 (1418): 519–23. doi:10.1098/rspb.1999.0667.

- ↑ Arcidiacono, S.; Mello, C.; Kaplan, D.; Cheley, S.; Bayley, H. (1998). "Purification and characterization of recombinant spider silk expressed in Escherichia coli". Applied Microbiology and Biotechnology 49 (1): 31–38. doi:10.1007/s002530051133. PMID 9487707.

- ↑ Seidel, A.; Liivak, O.; Jelinski, L. W. (1998). "Artificial Spinning of Spider Silk". Macromolecules 31 (19): 6733–36. doi:10.1021/ma9808880. Bibcode: 1998MaMol..31.6733S.

- ↑ Maev Kennedy (2012-01-24). "Spider silk cape goes on show at V&A". the Guardian. https://www.theguardian.com/artanddesign/2012/jan/24/spider-silk-cape-show.

- ↑ Morgan, Eleanor (2016). "Sticky Layers and Shimmering Weaves: A Study of Two Human Uses of Spider Silk" (in en). Journal of Design History 29 (1): 8–23. doi:10.1093/jdh/epv019. ISSN 0952-4649.

- ↑ "V&A · Golden spider silk" (in en). https://www.vam.ac.uk/articles/golden-spider-silk.

- ↑ Leggett, Hadley (23 September 2009). "1 Million Spiders Make Golden Silk for Rare Cloth". Wired. https://www.wired.com/wiredscience/2009/09/spider-silk/.

- ↑ Osaki, Shigeyoshi (2012). "Spider Silk Violin Strings with a Unique Packing Structure Generate a Soft and Profound Timbre". Physical Review Letters 108 (15): 154301. doi:10.1103/PhysRevLett.108.154301. PMID 22587257. Bibcode: 2012PhRvL.108o4301O.

- ↑ Heimer, S. (1988). Wunderbare Welt der Spinnen. Urania. p. 14

- ↑ Jackson, Robert R. (1974). "Effects of D-Amphetamine Sulfate and Diazepam on Thread Connection Fine Structure in a Spider's Web". Journal of Arachnology 2 (1): 37–41.

- ↑ Allmeling, Christina; Jokuszies, Andreas; Reimers, Kerstin; Kall, Susanne; Vogt, Peter M. (2006). "Use of spider silk fibres as an innovative material in a biocompatible artificial nerve conduit". Journal of Cellular and Molecular Medicine 10 (3): 770–77. doi:10.1111/j.1582-4934.2006.tb00436.x. PMID 16989736.

- ↑ Berenbaum, May R., Field Notes – Spin Control, The Sciences, The New York Academy of Sciences, September/October 1995

- ↑ Example of use of spider silk for telescopic rifle sights. Bonnier Corporation. 1955. https://books.google.com/books?id=WyYDAAAAMBAJ&q=%22telescopic+sight%22+spider+silk&pg=RA1-PA216. Retrieved 24 August 2011.

- ↑ Duarte F. J.; Taylor, T S; Black, A M; Davenport, W E; Varmette, P G (2011). "N-slit interferometer for secure free-space optical communications: 527 m intra interferometric path length". Journal of Optics 13 (3): 5710. doi:10.1088/2040-8978/13/3/035710. Bibcode: 2011JOpt...13c5710D.

- ↑ Goodyer, Jason (July 5, 2020). "Spider silk used to create lenses for imaging human tissue". BBC Science Focus. https://www.sciencefocus.com/news/spider-silk-used-to-create-lenses-for-imaging-human-tissue/.

- ↑ Bonino, Mark J.. "Material Properties of Spider Silk". http://www.lle.rochester.edu/media/publications/documents/theses/Bonino.pdf.

External links

- "The Silk Spinners", a BBC program about silk-producing animals

- Meadows, Robin (5 August 2014). "How Spiders Spin Silk". PLOS Biology 12 (8): e1001922. doi:10.1371/journal.pbio.1001922. PMID 25093404.

- Rejcek, Peter (2019-04-11). "The Tangled Web of Turning Spider Silk into a Super Material" (in en-US). https://singularityhub.com/2019/04/11/the-tangled-web-of-turning-spider-silk-into-a-super-material/.

- Archived at Ghostarchive and the Wayback Machine: Victoria and Albert Museum (2019-07-29). "How was it made? Golden spider silk" (in en-US). https://www.youtube.com/watch?v=Fv1qq6ypiTk.

- "Synthetic spider silk stronger and tougher than the real thing" (in en-US). 2021-07-21. https://newatlas.com/materials/synthetic-spider-silk-stronger-tougher/.

|