Chemistry:Green solvent

This article needs additional citations for verification. (January 2024) (Learn how and when to remove this template message) |

}}

Green solvents are environmentally friendly chemical solvents that are used as a part of green chemistry. They came to prominence in 2015, when the United Nations defined a new sustainability-focused development plan based on 17 sustainable development goals, recognizing the need for green chemistry and green solvents for a more sustainable future.[1] Green solvents are developed as more environmentally friendly solvents, derived from the processing of agricultural crops or otherwise sustainable methods as alternatives to petrochemical solvents.

Classification

The following are qualified as green solvents, based on their production methods or on the raw materials from which they are produced:

Water

Water is not an organic solvent, as it contains no carbon atoms. It is a polar protic solvent due to its chemical structure. It is non-toxic and renewable. In living matter, many ions and proteins are dissolved in water. It is the cheapest and most abundant solvent for a large range of reactions and processes in industrial chemistry. There are cases where traditional organic solvents can be replaced by aqueous preparations.[2] Water-based coatings have largely replaced standard petroleum-based paints for the construction industry; however, solvent-based anti-corrosion paints remain among the most used today.

Supercritical fluids

Some substances that occur in the gas phase at ambient temperature and pressure can act as solvents if elevated to temperatures and pressures above their critical point. At this point, gas and liquid states exist in a single phase with properties intermediate between liquid and gas, including the mobility of gas and the dissolving power of liquid: a supercritical fluid.

- Supercritical water (SCW) is obtained at a temperature of 374.2 °C and a pressure of 22.05 MPa.[3] It behaves as a dense gas with a dissolving power equivalent to that of organic solvents of low polarity. However, the solubility of inorganic salts in SCW is radically reduced. SCW is used as a reaction medium, especially in oxidation processes for the destruction of toxic substances such as those found in industrial aqueous effluents. The use of supercritical water has two main technical challenges, namely corrosion and salt deposition.

- Supercritical carbon dioxide (CO2) is the most commonly used supercritical fluid because of its relatively easy to reach conditions. Temperatures above 31 °C and pressures above 7.38 MPa are sufficient to obtain supercriticality,[4] at which point it behaves as a good nonpolar solvent.

Solvents derived from carbohydrates

- Ethanol is the second most used solvent after water. Thus, it is found used in toiletries, cosmetics, some cleaners and coatings. Studies show that simple alcohols such as methanol and ethanol are to be preferred environmentally, unlike formaldehyde or dioxane, indicating that methanol-water or ethanol-water mixtures are environmentally friendly compared to pure alcohol or propanol-water mixtures.

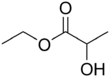

- Ethyl lactate, made from lactic acid obtained from corn starch, is notably used as a mixture with other solvents in some paint strippers and cleaners.[5] Ethyl lactate has replaced solvents such as toluene, acetone, and xylene in some applications.

- Bioethanol is made industrially by fermentation of sugars and starch, one of the oldest known chemical processes, and has been also produced from cellulose.

- Biobutanol (butyl alcohol, various isomers) is produced by fermentation of sugars. Isobutanol and tert-butanol, which are butanol isomers, can be used as solvents in paints.

- Tetrahydrofurfuryl alcohol (THFA) is a specialty solvent that may be obtained from hemicellulose.

Solvents derived from lipids

Lipids (triglycerides) themselves can be used as solvents, but are mostly hydrolyzed to fatty acids and glycerol (glycerin). Fatty acids can be esterified with an alcohol to give fatty acid esters, e.g., FAMEs (fatty acid methyl esters) if the esterification is performed with methanol. Usually derived from natural gas or petroleum, the methanol used to produce FAMEs can also be obtained by other routes, including gasification of biomass and household hazardous waste. Glycerol from lipid hydrolysis can be used as a solvent in synthetic chemistry, as can some of its derivatives.[7]

Deep eutectic solvents

A mixture whose melting point is lower than that of the constituents is called an eutectic mixture; many solid substances mixed in this way become liquids that can be used as solvents, especially when the melting-point depression is very large, hence the term deep eutectic solvent (DES). One of the most commonly used substances to obtain DES is the ammonium salt choline chloride. Smith, Abbott, and Ryder report that a mixture of urea (melting point: 133 °C) and choline chloride (melting point: 302 °C) in a 2:1 molar ratio has a melting point of 12 °C.[1]

Natural deep eutectic solvents (NADES) are also a research area relevant to green chemistry, being easy to produce from two low-cost and well-known ecotoxicity components, a hydrogen-bond acceptor, and a hydrogen-bond donor.[8]

Terpenes

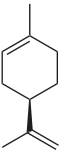

Solvents in a diverse class of natural substances called terpenes are obtained by extraction from certain parts of plants. All terpenes are structurally presented as multiples of isoprene with the gross formula (C5H8)n.

- D-limonene, a monoterpene, is one of the best known solvents in this class, as is turpentine.

- D-limonene is extracted from citrus peels while turpentine is obtained from pine trees (sap, stump) and as a by-product of the Kraft paper-making process (Sell, 2006).[9]

- Turpentine is a mixture of terpenes whose composition varies according to its origin and production method. In Canada and the United States, a range of mass concentrations of 40 to 65% α-pinene, 20 to 35% β-pinene, and 2 to 20% d-limonene are found.[10]

- α-pinene can replace n-hexane for the extraction of vegetable oil, and as a substitute solvent for extracting molecules such as carotenoids used as food additives.[11]

Turpentine, formerly used as a solvent in organic coatings, is now largely replaced by petroleum hydrocarbons.[10] Nowadays, it is mainly used as a source of its constituents, including α-pinene and β-pinene.[12]

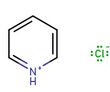

Ionic liquids

Ionic liquids are molten organic salts that are generally fluid at room temperature. Frequently used cationic liquids, include imidazolium, pyridinium, ammonium and phosphonium. Anionic liquids include halides, tetrafluoroborate, hexafluorophosphate, and nitrate. Bubalo et al. (2015) argue that ionic liquids are non-flammable, and chemically, electrochemically and thermally stable.[13] These properties allow for ionic liquids to be used as green solvents, as their low volatility limits VOC emissions compared to conventional solvents. The ecotoxicity and poor degradability of ionic liquids has been recognized in the past because the resources typically used for their production are non-renewable, as is the case for imidazole and halogenated alkanes (derived from petroleum). Ionic liquids produced from renewable and biodegradable materials have recently emerged, but their availability is low because of high production costs.[8]

Switchable solvents

Bubbling CO2 into water or an organic solvent results in changes to certain properties of the liquid such as its polarity, ionic strength, and hydrophilicity. This allows an organic solvent to form a homogeneous mixture with the otherwise immiscible water. This process is reversible, and was developed by Jessop et al. (2012) for potential uses in synthetic chemistry, extraction and separation of various substances. The degree of how green switchable solvents are is measured by the energy and material savings it provides; thus, one of the advantages of switchable solvents is the potential reuse of solvent and water in post-process applications.[14]

Solvents from waste materials

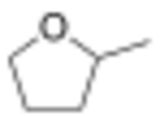

First-generation biorefineries exploit food-based substances such as starch and vegetable oils.[15] For example, corn grain is used to make ethanol. Second-generation biorefineries use residues or wastes generated by various industries as feedstock for the manufacture of their solvents. 2-Methyltetrahydrofuran, derived from lignocellulosic waste, would have the potential to replace tetrahydrofuran, toluene, DCM, and diethyl ether in some applications. Levulinic acid esters from the same source would have the potential to replace DCM in paint cleaners and strippers.

Used cooking oils can be used to produce FAMEs.[16] Glycerol, obtained as a byproduct of the synthesis of these, can in turn be used to produce various solvents such as 2,2-dimethyl-1,3-dioxolane-4-methanol, usable as a solvent in the formulation of inks and cleaners.[17]

Fusel oil, an isomeric mixture of amyl alcohol, is a byproduct of ethanol production from sugars. Green solvents derived from fusel oil such as isoamyl acetate or isoamyl methyl carbonate could be obtained. When these green solvents are used to manufacture nail polishes, VOC emissions report a minimum reduction of 68% compared to the emissions caused by using traditional solvents.

Petrochemical solvents with green characteristics

Due to the high price of new sustainable solvents, in 2017, Clark et al. listed twenty-five solvents that are currently considered acceptable to replace hazardous solvents, even if they are derived from petrochemicals.[18]

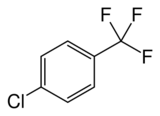

These include propylene carbonate and dibasic esters (DBEs). Propylene carbonate and DBEs have been the subject of monographs on solvent substitution.[19][20] Propylene carbonate and two DBEs are considered green in the manufacturer GlaxoSmithKline's (GSK) Solvent Sustainability Guide, which is used in the pharmaceutical industry.[21] Propylene carbonate can be produced from renewable resources, but DBEs that have appeared on the market in recent years are obtained as by-products of the synthesis of polyamides, derived from petroleum. Other petrochemical solvents are variously referred to as green solvents, such as halogenated hydrocarbons like parachlorobenzotrifluoride, which has been used since the early 1990s in paints to replace smog-forming solvents.

Siloxanes are compounds known in industry in the form of polymers (silicones, R-SiO-R'), for their thermal stability and elastic and non-stick properties. The early 1990s saw the emergence of low molecular weight siloxanes (methylsiloxanes), which can be used as solvents in precision cleaning, replacing stratospheric ozone-depleting solvents.

A final category of petrochemical solvents that qualify as green involves polymeric solvents. The International Union of Pure and Applied Chemistry defines the term "polymer solvent" as "a polymer that acts as a solvent for low-molecular weight compounds".[22] In industrial chemistry, polyethylene glycols (PEGs, H(OCH2CH2)nOH) are one of the most widely used polymeric solvent families.[23] PEGs, with molecular weights below 600 Da, are viscous liquids at room temperature, while heavier PEGs are waxy solids.

Soluble in water and readily biodegradable, liquid PEGs have the advantage of negligible volatility (< 0.01 mmHg or < 1.3 Pa at 20 °C).[24] PEGs are synthesized from ethylene glycol and ethylene oxide, both of which are petrochemical-derived molecules, though ethylene glycol from renewable sources (cellulose) is commercially available.[25]

Physical properties

The physical properties of solvents are important in identifying the solvent used according to the reaction conditions. In particular, their dissolution properties make it possible to assess the use of a particular solvent for a chemical reaction, such as an extraction or a washing. Evaporation is also important to consider, as it can be indicative of the potential volatile organic compound (VOC) emissions.

The following table shows selected properties of green solvents in each category:

| Classification | Solvent | Molar mass

(g·mol−1) |

Solubility in water (at 25 °C) | Melting point (°C) | Boiling point (°C) | Density (g/mL) | Dielectric constant | Appearance | Vapor pressure | Viscosity |

|---|---|---|---|---|---|---|---|---|---|---|

| Water | Water[26][27][28] | 18 | 0 | 100 | 1.000 at 3.98 °C | 78.304 at 25 °C | colorless | 23.8 mmHg at 25 °C | 0.8949 cP·s at 25 °C | |

| Solvents derived from carbohydrates | Ethyl lactate[29][30][31] | 118.13 | Fully Miscible | –26 | 154 | 1.03 | 15.7 | colorless | 0.22 kPa

at 20 °C 17 kPa at 100 °C |

0.428 cP·s at 25 °C |

| Ethanol[32][33] | 46.07 | 106 mg/mL | –114.14 | 78.24 | 0.7893 at 20 °C | 24.5 | colorless | 10 kPa at 29.2 °C | 1.074 mPa·s at 25 °C | |

| Solvents from waste materials | 2-Methyltetrahydrofuran[34] | 86.13 | 150 g/L | –136 | 80 | 0.85 at 20 °C | colorless | 13.6 kPa at 20 °C

34,5kPa at 50 °C |

4 mPa·s at 25 °C | |

| Levulinic acid[35][36][37][38][39][40] | 116.11 | 6.746·105 mg/L | 33 | 245.5 | 1.134 at 25 °C | solid: large crystal

liquid: yellow to brown |

2.984 kPa at 156.85 °C | 14.26 mPa·s at 40 °C | ||

| Solvents obtained by extraction | Limonene[41][42][43][44] | 136.23 | 14 mg/L | −74.35 | 177~178 | 0.8402 at 20.85 °C | 2.3746 | colorless | 1.55 mmHg

at 25 °C |

0.897 mPa·s

at 25.15 °C |

| Petrochemical solvents | Propylene carbonate[45][46] | 102.09 | 1.75·105 mg/L | –48.8 | 241.6 | 1.204 at 25 °C | colorless | 0.13 mmHg at 20 °C |

Other categories of green solvent have additional properties that preclude their usage in various applications:

Deep eutectic solvents (DES)[47] have huge hydrogen bonds, leading them to have lower melting points. Some of them have lower melting points than 50 °C and they are investigated because they can be cheap, safe and useful in industries. Most of the DES have a higher density than water but its range is difficult to grasp as it depends on the components from which they are synthesized and their molecular arrangement and vacancies. For example, Octylammonium bromide/Decanoic acid (molar ratio of [1:2]) has a lower density compared to water of 0.8889 g.cm−3, up to 1.4851 g.cm−3 for Choline chloride/Trifluoroacetamine [1:2]. Their miscibility is also composition-dependent.

Fatty acid methyl esters[48][49][50] have been investigated and compared to fossil diesel. At 20 °C or 40 °C, those solvents have a lower density than water at 4 °C (temperature in which the water is the densest):

- : from 0.9079 (acetate) to 0.8488 (arachidate);

- : from 0.9338 (acetate) to 0.8663 (pentadecanoate).

Their kinematic viscosity depends if they are saturated or unsaturated or even the temperature. At 40 °C, for saturated FAMEs, it goes from 0.340 (acetate) to 6.39 (nonadecanoate), and for unsaturated FAMEs, it goes from 5.61 for the stearate to 7.21 for the erucate.

Their dielectric constant decreases as their alkyl chain gets longer. For example, acetate has a tiny alkyl chain and has a dielectric constant of ε40= 6.852 and ε40= 2.982 for the nonadecanoate.

The properties of switchable solvents[51][52] are caused by the strength of their conjugate acid's pKa and octanol-water partition coefficient ratio Kow. They must have a pKa above 9.5 to be protonated by carbonated water and also a log(Kow) between 1.2 and 2.5 to be switchable, otherwise they will be hydrophilic or hydrophobic. These properties depend on the volumetric ratio of the compound compared to water. For example, N,N,N′-Tributylpentanamidine is a switchable solvent, and for a volumetric ratio of compound to water of 2:1, it has a log(Kow)= 5.99, which is higher than 2.5.

Ionic liquids[53] with low melting points are associated with asymmetric cations, and liquids with high melting point are associated with symmetric cations. Additionally, if they have branched alkyl chains, they will have a higher melting point. They are more dense than water, ranging from 1.05 to 1.64 g·cm−3 at 20 °C and from 1.01 to 1.57 at 90 °C.

Applications

Some green solvents, in addition to being more sustainable, have been found to have more efficient physicochemical properties or reaction yields than when using traditional solvents. However, the results obtained are for the most part observations from experiments on particular green solvents and cannot be generalized. The effectiveness of a green solvent is quantified by calculating the "E factor", which is a ratio of waste materials to desired product produced through a process.

Organic synthesis

Green solvent efficiency has mainly been proven in extractions and separations in comparison to traditional solvents.[54]

- Supercritical CO2 is largely used in the food industry as an extraction solvent. Among other processes like flavoring agents, fragrances, essential oils, or lipid extraction from plants, sc-CO2 is a green substitute to dichloromethane in coffee decaffeination, avoiding the use of a hazardous solvent and additional synthesis steps. Sc-CO2 can also apply to polymerization reactions, specifically in PTFE formation to manipulate monomers safely and avoid explosive reactions of peroxide with dioxygen. Although the original process involves water, a green solvent itself, sc-CO2 allows less waste materials.[55]

- In deep eutectic solvents, observations report that the higher the solvent's hydrophobicity, the higher the extraction efficiency of neonicotinoids from aqueous solutions, although the exact trend has not been established yet.[56] Additionally, the creation of a biphasic system is easier to achieve. In 2015, several hydrophobic DES composed of highly hydrophobic hydrogen bond donors were reported, one of them being decanoic acid with a quaternary ammonium salt, and a fatty acid as a hydrogen bond acceptor.[47]

- The pharmaceutical industry intends to substitute their solvents for greener options, emphasized as solvent use in active substance synthesis is important, which aggrandizes solvents with a high boiling point. Solvent must generally be evaporated at the end of a chemical reaction, hence the insistence on low-boiling solvents in order to minimize the energy required for its removal by distillation.[57]

Industrial chemistry

- Ethyl lactate has uses in cleaning metal surfaces, removing greases, oils, adhesives and solid fuels. They are included in aqueous preparations used for industrial degreasing, coatings, adhesives and inks.

- Fatty acid methyl esters (FAMEs) have been used as a reactive diluent in coatings for continuous metal strip coating (e.g., the interior coating of food cans),[58] reducing the amount of volatile solvent in this type of coating and lowering its overall toxicity.

- Tetrahydrofurfuryl alcohol (THFA) mixtures with other green solvents are studied for their cleaning properties. As an example, the mixture of THFA with FAME and ethyl lactate has been patented as a paint stripper.[59]

- Ionic liquids particularly have applications in electrodeposition.[60] Their relevance as green solvents is further enhanced by the emergence of production methods based on renewable and biodegradable resources.[61]

Solvent manufacturers also provide industrial companies with databases to propose green alternative solvent mixtures to those originally used in industrial processes with similar efficiency and reaction yield. However, environmental and safety requirements are not always considered in these suggestions.[62]

Safety

The use of green solvents is increasingly preferred because of their lower environmental impact. These solvents still present dangers for human health as well as for the environment. However, for a number of green solvents, their impact is still unclear, or at least, not categorized yet.

Listed here is selected information from the safety data sheets of common green solvents:[63][64]

| Solvents | Pictograms | Hazards |

|---|---|---|

| Ethyl lactate |  frameless|82x82px frameless|82x82px

|

Flammable liquid and vapors

Causes severe eye damage. May irritate the respiratory tract |

| Ethanol |  Error creating thumbnail: Unable to save thumbnail to destination Error creating thumbnail: Unable to save thumbnail to destination

|

Highly flammable liquid and vapors

Causes severe eye irritation |

| 2-Methyltetrahydrofuran |  frameless|81x81px frameless|81x81px

|

Highly flammable liquid and vapors

Harmful if swallowed. Causes skin irritation and severe eye damage |

| Levulinic acid |

|

Harmful if swallowed. Causes skin irritation

Causes severe eye irritation |

| Limonene |  frameless|81x81pxframeless|81x81px frameless|81x81pxframeless|81x81px

|

Flammable liquid and vapors

Causes skin irritation. May cause skin allergy Very toxic to aquatic organisms, causes long-term adverse effects |

| Propylene carbonate |

|

Solvents derived from carbohydrates

For ethanol, the American Conference of Governmental Industrial Hygienists, shortened ACGIH, advises a short-term exposure limit of 1000 ppm to avoid irritating the respiratory tract.[65]

The French National Agency for Food, Environmental, and Occupational Health Safety (ANSES) has recommended a short-term occupational exposure limit value of 100 mg/m3 for butan-1-ol, a solvent used in paints, cleaners, and degreasers, in order to prevent irritation of the mucous membranes of the eyes and upper airways. Since 1998, the ACGIH has suggested an 8 hour exposure limit value (ELV) of 20 ppm of butan-1-ol to prevent irritation of the upper respiratory tract and eyes.

Male rats exposed to THFA develop reproductive toxicity. Moreover, it has an impact on fetal and embryonic development in rats. The American Industrial Hygiene Association suggested an ELV of 2 ppm for THFA to prevent testicular degeneration in 1993 based on the No-observed-effect level of two subchronic investigations in rats and dogs

Deep eutectic solvents

DES components, according to Wazeer, Hayyan, and Hadj-Kali,[66] are typically non-toxic and biodegradable. According to Hayyan et al.,[67] the DES they investigated were more harmful to the small crustacean artemia than each of their individual components, which could be attributed to synergy. The abbreviation NADES refers to DES that contain only materials sourced from renewable resources. Compared to other DES, these would typically be less hazardous.

Legislation

Due to the recency of green solvent development, few laws related to their regulation have been developed beyond standard workplace safety precautions already in place, and laws that enforce the use of green solvents have not been widespread.

References

- ↑ 1.0 1.1 Denis Bégin; Caroline Couture; Michel Gérin; Maximilien Debia (2020) (in fr). Solvants verts: fondements, santé, sécurité, environnement et substitution. Montréal, QC, CA: Université de Montréal. Département de santé environnementale et santé au travail, IRSST, Bibliothèque numérique canadienne. ISBN 9782897971113. OCLC 1162187204.

- ↑ Lavoué, J.; Bégin, D.; Géerin, M. (2003). "Technical, Occupational Health and Environmental Aspects of Metal Degreasing with Aqueous Cleaners". The Annals of Occupational Hygiene 47 (6): 441–459. doi:10.1093/annhyg/meg057. ISSN 1475-3162. PMID 12890654.

- ↑ Martín, Ángel; José Cocero, María (2016). "Supercritical Fluids". Kirk-Othmer Encyclopedia of Chemical Technology. Hoboken, NJ, USA: John Wiley & Sons. pp. 1–28. doi:10.1002/0471238961.1921160504092415.a01.pub3. ISBN 9780471238966.

- ↑ Lumia, Guy (2002). "Utilisation du CO2 supercritique comme solvant de substitution". Environnement. doi:10.51257/a-v1-in5.

- ↑ "Institut de Recherche Robert-Sauvé en Santé et en Sécurité du Travail (IRSST)", The Grants Register 2021 (London: Palgrave Macmillan UK): pp. 452–453, 2020, doi:10.1057/978-1-349-95988-4_465, ISBN 978-1-349-95987-7

- ↑ Saxena, Neha; Pal, Nilanjan; Ojha, Keka; Dey, Swapan; Mandal, Ajay (2018-07-02). "Synthesis, characterization, physical and thermodynamic properties of a novel anionic surfactant derived from Sapindus laurifolius" (in en). RSC Advances 8 (43): 24485–24499. doi:10.1039/C8RA03888K. ISSN 2046-2069. PMID 35539155. Bibcode: 2018RSCAd...824485S.

- ↑ Gu, Yanlong; Jérôme, François (2013). "Bio-based solvents: an emerging generation of fluids for the design of eco-efficient processes in catalysis and organic chemistry". Chemical Society Reviews 42 (24): 9550–9570. doi:10.1039/c3cs60241a. ISSN 0306-0012. PMID 24056753.

- ↑ 8.0 8.1 Winterton, Neil (2021). "The green solvent: a critical perspective" (in en). Clean Technologies and Environmental Policy 23 (9): 2499–2522. doi:10.1007/s10098-021-02188-8. ISSN 1618-9558. PMID 34608382.

- ↑ Sell, Charles S. (2006). "Terpenoids". Kirk-Othmer Encyclopedia of Chemical Technology. Hoboken, NJ, USA: John Wiley & Sons. doi:10.1002/0471238961.2005181602120504.a01.pub2. ISBN 0471238961.

- ↑ 10.0 10.1 Gscheidmeier, Manfred; Fleig, Helmut (2000). "Turpentines". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA. doi:10.1002/14356007.a27_267. ISBN 978-3-527-30673-2.

- ↑ Boutekedjiret, Chahrazed; Vian, Maryline Abert; Chemat, Farid (2014), "Terpenes as Green Solvents for Natural Products Extraction", Alternative Solvents for Natural Products Extraction, Green Chemistry and Sustainable Technology (Berlin, Heidelberg: Springer Berlin Heidelberg): pp. 205–219, doi:10.1007/978-3-662-43628-8_9, ISBN 978-3-662-43627-1

- ↑ "Turpentine (8006-64-2)", Chemical Effects in Biological Systems (CEBS) (Research Triangle Park, NC (USA): National Toxicology Program (NTP)), 2017, doi:10.22427/NTP-DATA-DTXSID6027717

- ↑ Cvjetko Bubalo, Marina; Vidović, Senka; Radojčić Redovniković, Ivana; Jokić, Stela (2015). "Green solvents for green technologies". Journal of Chemical Technology & Biotechnology 90 (9): 1631–1639. doi:10.1002/jctb.4668. ISSN 0268-2575.

- ↑ Jessop, Philip G.; Mercer, Sean M.; Heldebrant, David J. (2012). "CO2-triggered switchable solvents, surfactants, and other materials" (in en). Energy & Environmental Science 5 (6): 7240–7253. doi:10.1039/C2EE02912J. ISSN 1754-5706.

- ↑ Bayart, Marie; Foruzanmehr, M. Reza; Vuillaume, Pascal Y.; Ovlaque, Pierre; Robert, Mathieu; Elkoun, Saïd (2021). "Poly(lactic acid)/flax composites: effect of surface modification and thermal treatment on interfacial adhesion, crystallization, microstructure, and mechanical properties". Composite Interfaces 29 (1): 17–36. doi:10.1080/09276440.2021.1884470. ISSN 0927-6440.

- ↑ Jin, Saimeng; Byrne, Fergal; McElroy, Con Robert; Sherwood, James; Clark, James H.; Hunt, Andrew J. (2017). "Challenges in the development of bio-based solvents: a case study on methyl(2,2-dimethyl-1,3-dioxolan-4-yl)methyl carbonate as an alternative aprotic solvent". Faraday Discussions 202: 157–173. doi:10.1039/c7fd00049a. ISSN 1359-6640. PMID 28661518. Bibcode: 2017FaDi..202..157J. https://eprints.whiterose.ac.uk/113512/1/MMC_paper_submitted_16_2_17.pdf.

- ↑ Byrne, Fergal P.; Jin, Saimeng; Paggiola, Giulia; Petchey, Tabitha H. M.; Clark, James H.; Farmer, Thomas J.; Hunt, Andrew J.; Robert McElroy, C. et al. (2016). "Tools and techniques for solvent selection: green solvent selection guides". Sustainable Chemical Processes 4 (1). doi:10.1186/s40508-016-0051-z. ISSN 2043-7129.

- ↑ Sustainable Solvents. Green Chemistry Series. 2017. doi:10.1039/9781782624035. ISBN 978-1-78262-335-9.

- ↑ "Institut de Recherche Robert-Sauvé en Santé et en Sécurité du Travail (IRSST)", The Grants Register 2022 (London: Palgrave Macmillan UK): pp. 494–495, 2021, doi:10.1057/978-1-349-96042-2_6517, ISBN 978-1-349-96041-5

- ↑ Bisson Desrochers, Alexandra; Rouleau, Isabelle; Angehrn, Andréanne; Vasiliadis, Helen-Maria; Saumier, Daniel; Brunet, Alain (2021). "Trauma on duty: cognitive functioning in police officers with and without posttraumatic stress disorder (PTSD)". European Journal of Psychotraumatology 12 (1). doi:10.1080/20008198.2021.1959117. ISSN 2000-8066. PMID 34721819.

- ↑ Alder, Catherine M.; Hayler, John D.; Henderson, Richard K.; Redman, Anikó M.; Shukla, Lena; Shuster, Leanna E.; Sneddon, Helen F. (2016). "Updating and further expanding GSK's solvent sustainability guide". Green Chemistry 18 (13): 3879–3890. doi:10.1039/c6gc00611f. ISSN 1463-9262.

- ↑ Horie, K.; Barón, Máximo; Fox, R. B.; He, J.; Hess, M.; Kahovec, J.; Kitayama, T.; Kubisa, P. et al. (2004). "Definitions of terms relating to reactions of polymers and to functional polymeric materials (IUPAC Recommendations 2003)" (in en). Pure and Applied Chemistry 76 (4): 889–906. doi:10.1351/pac200476040889. ISSN 1365-3075.

- ↑ Clarke, Coby J.; Tu, Wei-Chien; Levers, Oliver; Bröhl, Andreas; Hallett, Jason P. (2018). "Green and Sustainable Solvents in Chemical Processes". Chemical Reviews 118 (2): 747–800. doi:10.1021/acs.chemrev.7b00571. ISSN 0009-2665. PMID 29300087.

- ↑ (in en) Technical study for the chemical cleaning of Dresden-1. Volume I, Section 1 and 2 (Report). 1977. doi:10.2172/5335747.

- ↑ Zhu, Yunqing; Romain, Charles; Williams, Charlotte K. (2016). "Sustainable polymers from renewable resources". Nature 540 (7633): 354–362. doi:10.1038/nature21001. ISSN 0028-0836. PMID 27974763. Bibcode: 2016Natur.540..354Z. https://ora.ox.ac.uk/objects/uuid:402c9282-f107-4e2a-9edf-b883ffc081fa.

- ↑ "Water" (in en). National Center for Biotechnology Information. https://pubchem.ncbi.nlm.nih.gov/compound/962.

- ↑ Malmberg, C.G.; Maryott, A.A. (1956). "Dielectric constant of water from 0° to 100 °C" (in en). Journal of Research of the National Bureau of Standards 56 (1): 1. doi:10.6028/jres.056.001. ISSN 0091-0635.

- ↑ "The Drive to Make Things Happen". 2005. https://vrchemistry.chem.ox.ac.uk/potential/text/solutions3.htm.

- ↑ Kua, Yin Leng; Gan, Suyin; Morris, Andrew; Ng, Hoon Kiat (2016). "Ethyl lactate as a potential green solvent to extract hydrophilic (polar) and lipophilic (non-polar) phytonutrients simultaneously from fruit and vegetable by-products" (in en). Sustainable Chemistry and Pharmacy 4: 21–31. doi:10.1016/j.scp.2016.07.003. ISSN 2352-5541.

- ↑ "Lactate d'éthyle - Fiche toxicologique n° 240" (in fr). 2001. https://www.inrs.fr/publications/bdd/fichetox/fiche.html?refINRS=FICHETOX_240.

- ↑ Chen, Jui-Tang; Chu, Hsiao-Pei (2007). "Densities and Viscosities for Binary Mixtures of Ethyl Lactate with Methacrylic Acid, Benzyl Methacrylate, and 2-Hydroxyethyl Methacrylate at (298.15, 308.15, and 318.15) K" (in en). Journal of Chemical & Engineering Data 52 (2): 650–654. doi:10.1021/je600568w. ISSN 0021-9568.

- ↑ "Annotation Record for Ethanol" (in en). National Center for Biotechnology Information. https://pubchem.ncbi.nlm.nih.gov/source/hsdb/82#section=FDA-Requirements-(Complete).

- ↑ Sierra-Amor, Rosa (2001). "CRC Handbook of Laboratory Safety, 5th ed. A. Keith Furr, ed. Boca Raton, FL: CRC Press LCC, 2000, 774 pp., $149.99" (in en). Clinical Chemistry 47 (11): 2075. doi:10.1093/clinchem/47.11.2075a. ISBN 0-8493-2523-4. ISSN 0009-9147.

- ↑ Institut für Arbeitsschutz der Deutschen Gesetzlichen Unfallversicherung (IFA) (2016). "2-Methyltetrahydrofuran anhydrous". https://gestis.dguv.de/data?name=510639&lang=en.

- ↑ Kumar, Anuj; Shende, Diwakar Z.; Wasewar, Kailas L. (2020). "Extractive separation of levulinic acid using natural and chemical solvents" (in en). Chemical Data Collections 28: 100417. doi:10.1016/j.cdc.2020.100417.

- ↑ "Levulinic acid" (in en). National Center for Biotechnology Information. https://pubchem.ncbi.nlm.nih.gov/compound/11579.

- ↑ Ariba, Houda; Wang, Yanjun; Devouge-Boyer, Christine; Stateva, Roumiana P.; Leveneur, Sébastien (2020). "Physicochemical Properties for the Reaction Systems: Levulinic Acid, Its Esters, and γ-Valerolactone" (in en). Journal of Chemical & Engineering Data 65 (6): 3008–3020. doi:10.1021/acs.jced.9b00965. ISSN 0021-9568. https://hal.archives-ouvertes.fr/hal-02904648/file/Ariba%20et%20al.%20-%202020%20-%20Physicochemical%20Properties%20for%20the%20Reaction%20System.pdf.

- ↑ Wohlfarth, Christian (2016), Lechner, M. D., ed., "Surface tension of levulinic acid" (in en), Surface Tension of Pure Liquids and Binary Liquid Mixtures (Berlin, Heidelberg: Springer Berlin Heidelberg): pp. 86, doi:10.1007/978-3-662-48336-7_83, ISBN 978-3-662-48335-0, https://materials.springer.com/lb/docs/sm_lbs_978-3-662-48336-7_83

- ↑ Agrawal, Kushagra; Chakraborty, Pritam; Kishore, Nanda (2020). "Thermochemical Mapping of Levulinic Acid Conversion to Pentane in Supercritical Water within the Framework of Density Functional Theory" (in en). Energy & Fuels 34 (9): 11061–11072. doi:10.1021/acs.energyfuels.0c01906. ISSN 0887-0624.

- ↑ Stull, Daniel R. (1947). "Vapor Pressure of Pure Substances. Organic and Inorganic Compounds" (in en). Industrial & Engineering Chemistry 39 (4): 517–540. doi:10.1021/ie50448a022. ISSN 0019-7866.

- ↑ Clará, René A.; Marigliano, Ana C. Gómez; Sólimo, Horacio N. (2009). "Density, Viscosity, and Refractive Index in the Range (283.15 to 353.15) K and Vapor Pressure of α-Pinene, d -Limonene, (±)-Linalool, and Citral Over the Pressure Range 1.0 kPa Atmospheric Pressure" (in en). Journal of Chemical & Engineering Data 54 (3): 1087–1090. doi:10.1021/je8007414. ISSN 0021-9568.

- ↑ "Limonene" (in en). National Center for Biotechnology Information. https://pubchem.ncbi.nlm.nih.gov/compound/22311.

- ↑ "Limonene" (in en). 2021. https://www.acs.org/molecule-of-the-week/archive/l/limonene.html.

- ↑ Thomas, Gerald A.; Hawkins, J. Erskine (1954). "Physical and Thermodynamic Properties of Terpenes. IV. The Dielectric Constant, Refractive Index and Density of Some Terpenes 1" (in en). Journal of the American Chemical Society 76 (19): 4856–4858. doi:10.1021/ja01648a026. ISSN 0002-7863.

- ↑ Wang, Xiangyu; Pan, Hongwei; Jia, Shiling; Lu, Zifeng; Han, Lijing; Zhang, Huiliang (2023). "Mechanical properties, thermal behavior, miscibility and light stability of the poly(butylene adipate-co-terephthalate)/poly(propylene carbonate)/polylactide mulch films" (in en). Polymer Bulletin 80 (3): 2485–2501. doi:10.1007/s00289-022-04173-7. ISSN 0170-0839.

- ↑ "Propylene Carbonate" (in en). National Center for Biotechnology Information. https://pubchem.ncbi.nlm.nih.gov/compound/7924.

- ↑ 47.0 47.1 Omar, Karzan A.; Sadeghi, Rahmat (2022). "Physicochemical properties of deep eutectic solvents: A review" (in en). Journal of Molecular Liquids 360: 119524. doi:10.1016/j.molliq.2022.119524.

- ↑ Gouw, T. H.; Vlugter, J. C. (1964). "Physical properties of fatty acid methyl esters. I. density and molar volume" (in en). Journal of the American Oil Chemists' Society 41 (2): 142–145. doi:10.1007/BF02673494.

- ↑ Gouw, T. H.; Vlugter, J. C. (1964). "Physical properties of fatty acid methyl esters. V. Dielectric constant" (in en). Journal of the American Oil Chemists' Society 41 (10): 675–678. doi:10.1007/BF02661406.

- ↑ Gouw, T. H.; Vlugter, J. C.; Roelands, C. J. A. (1966). "Physical properties of fatty acid methyl esters. VI. Viscosity" (in en). Journal of the American Oil Chemists' Society 43 (7): 433–434. doi:10.1007/BF02682408.

- ↑ Jessop, Philip G.; Phan, Lam; Carrier, Andrew; Robinson, Shona; Dürr, Christoph J.; Harjani, Jitendra R. (2010). "A solvent having switchable hydrophilicity" (in en). Green Chemistry 12 (5): 809. doi:10.1039/b926885e. ISSN 1463-9262. http://xlink.rsc.org/?DOI=b926885e.

- ↑ Vanderveen, Jesse R.; Durelle, Jeremy; Jessop, Philip G. (2014). "Design and evaluation of switchable-hydrophilicity solvents" (in en). Green Chem. 16 (3): 1187–1197. doi:10.1039/C3GC42164C. ISSN 1463-9262. http://xlink.rsc.org/?DOI=C3GC42164C.

- ↑ Braunstein, J.; Mamantov, Gleb; Smith, G. P. (1973). Advances in Molten Salt Chemistry : Volume 2. Boston, MA: Springer US. ISBN 978-1-4757-0662-8. OCLC 853263478.

- ↑ Clarke, Coby J.; Tu, Wei-Chien; Levers, Oliver; Bröhl, Andreas; Hallett, Jason P. (2018). "Green and Sustainable Solvents in Chemical Processes" (in en). Chemical Reviews 118 (2): 747–800. doi:10.1021/acs.chemrev.7b00571. ISSN 0009-2665. PMID 29300087.

- ↑ Sheldon, Roger A. (2000). "Atom utilisation, E factors and the catalytic solution" (in en). Comptes Rendus de l'Académie des Sciences - Series IIC - Chemistry 3 (7): 541–551. doi:10.1016/S1387-1609(00)01174-9. ISSN 1387-1609.

- ↑ Osch, Dannie J. G. P. van; Zubeir, Lawien F.; Bruinhorst, Adriaan van den; Rocha, Marisa A. A.; Kroon, Maaike C. (2015). "Hydrophobic deep eutectic solvents as water-immiscible extractants" (in en). Green Chemistry 17 (9): 4518–4521. doi:10.1039/C5GC01451D. ISSN 1463-9270. https://pubs.rsc.org/en/content/articlelanding/2015/gc/c5gc01451d.

- ↑ Byrne, Fergal P.; Jin, Saimeng; Paggiola, Giulia; Petchey, Tabitha H. M.; Clark, James H.; Farmer, Thomas J.; Hunt, Andrew J.; Robert McElroy, C. et al. (2016). "Tools and techniques for solvent selection: green solvent selection guides" (in en). Sustainable Chemical Processes 4 (1): 7. doi:10.1186/s40508-016-0051-z. ISSN 2043-7129.

- ↑ Johansson, Katarina; Johansson, Mats K. G. (2007). "Fatty Acid Methyl Esters as Reactive Diluents in Coil-Coatings". Polymer Preprints 48 (2): 857–858. http://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-24127.

- ↑ Bergemann, E. P., Opre, J. E. et Henneberry, M. (2000). "Environmentally friendly solvent". Patent n°6,096,699. Washington, DC: United States Patent and Trademark Office

- ↑ Electrodeposition from ionic liquids (2nd ed.). Weinheim, Germany. 2017. ISBN 978-3-527-68270-6. OCLC 973412068.

- ↑ Hulsbosch, Joris; De Vos, Dirk E.; Binnemans, Koen; Ameloot, Rob (2016). "Biobased Ionic Liquids: Solvents for a Green Processing Industry?" (in en). ACS Sustainable Chemistry & Engineering 4 (6): 2917–2931. doi:10.1021/acssuschemeng.6b00553. ISSN 2168-0485.

- ↑ Wiersma, R. (2014). "Formula for success in developing advanced solvent blends". Polymer Paint Colour Journal - PPCJ, 204 (4592), 54-55.

- ↑ "Information en matière de sécurité donnée (CE) N°1907, 2006 (REACH)". 2021. https://www.carlroth.com/medias/SDB-5876-BE-FR.pdf?context=bWFzdGVyfHNlY3VyaXR5RGF0YXNoZWV0c3wyMjgzNzF8YXBwbGljYXRpb24vcGRmfHNlY3VyaXR5RGF0YXNoZWV0cy9oY2QvaDY3LzkwMjM3MjE5MzA3ODIucGRmfGE1MTYzZGNjZWNiYTZiNzczMDViNjM5OTVlOTVmYTc1YWFjYmEyNzZlYWRhM2YzNTNlNTEzZDNhNWMyZjJkZDg.

- ↑ "Fiches toxicologiques" (in fr). Institut National de Recherche et de Sécurité (INRS). https://www.inrs.fr/publications/bdd/fichetox.html.

- ↑ 2018 TLVs and BEIs: based on the documentation of the threshold limit values for chemical substances and physical agents & biological exposure indices. Cincinnati, OH: American Conference of Governmental Industrial Hygienists. 2018. ISBN 978-1-60726-097-4. OCLC 1029463040.

- ↑ Wazeer, Irfan; Hayyan, Maan; Hadj-Kali, Mohamed K (2017). "Deep eutectic solvents: designer fluids for chemical processes". Journal of Chemical Technology & Biotechnology 93 (4): 945–958. doi:10.1002/jctb.5491. ISSN 0268-2575.

- ↑ Hayyan, Maan; Hashim, Mohd Ali; Hayyan, Adeeb; Al-Saadi, Mohammed A.; AlNashef, Inas M.; Mirghani, Mohamed E.S.; Saheed, Olorunnisola Kola (2013). "Are deep eutectic solvents benign or toxic?". Chemosphere 90 (7): 2193–2195. doi:10.1016/j.chemosphere.2012.11.004. ISSN 0045-6535. PMID 23200570. Bibcode: 2013Chmsp..90.2193H.

|