Earth:Ore

Ore is natural rock or sediment that contains one or more valuable minerals concentrated above background levels, typically containing metals, that can be mined, treated and sold at a profit.[1][2][3] The grade of ore refers to the concentration of the desired material it contains. The value of the metals or minerals a rock contains must be weighed against the cost of extraction to determine whether it is of sufficiently high grade to be worth mining and is therefore considered an ore.[4] A complex ore is one containing more than one valuable mineral.[5]

Minerals of interest are generally oxides, sulfides, silicates, or native metals such as copper or gold.[5] Ore bodies are formed by a variety of geological processes generally referred to as ore genesis and can be classified based on their deposit type. Ore is extracted from the earth through mining and treated or refined, often via smelting, to extract the valuable metals or minerals.[4] Some ores, depending on their composition, may pose threats to health or surrounding ecosystems.

The word ore is of Anglo-Saxon origin, meaning lump of metal.[6]

Gangue and tailings

In most cases, an ore does not consist entirely of a single ore mineral, but it is mixed with other valuable minerals and with unwanted or valueless rocks and minerals. The part of an ore that is not economically desirable and that cannot be avoided in mining is known as gangue.[2][3] The valuable ore minerals are separated from the gangue minerals by froth flotation, gravity concentration, electric or magnetic methods, and other operations known collectively as mineral processing[5][7] or ore dressing.[8]

Mineral processing consists of first liberation, to free the ore from the gangue, and concentration to separate the desired mineral(s) from it.[5] Once processed, the gangue is known as tailings, which are useless but potentially harmful materials produced in great quantity, especially from lower grade deposits.[5]

Ore deposits

An ore deposit is an economically significant accumulation of minerals within a host rock.[9] This is distinct from a mineral resource in that it is a mineral deposit occurring in high enough concentration to be economically viable.[4] An ore deposit is one occurrence of a particular ore type.[10] Most ore deposits are named according to their location, or after a discoverer (e.g. the Kambalda nickel shoots are named after drillers),[11] or after some whimsy, a historical figure, a prominent person, a city or town from which the owner came, something from mythology (such as the name of a god or goddess)[12] or the code name of the resource company which found it (e.g. MKD-5 was the in-house name for the Mount Keith nickel sulphide deposit).[13]

Classification

Ore deposits are classified according to various criteria developed via the study of economic geology, or ore genesis. The following is a general categorization of the main ore deposit types:

Magmatic deposits

Magmatic deposits are ones who originate directly from magma

- Pegmatites are very coarse grained, igneous rocks. They crystallize slowly at great depth beneath the surface, leading to their very large crystal sizes. Most are of granitic composition. They are a large source of industrial minerals such as quartz, feldspar, spodumene, petalite, and rare lithophile elements.[14]

- Carbonatites are an igneous rock whose volume is made up of over 50% carbonate minerals. They are produced from mantle derived magmas, typically at continental rift zones. They contain more rare earth elements than any other igneous rock, and as such are a major source of light rare earth elements.[15]

- Magmatic Sulfide Deposits form from mantle melts which rise upwards, and gain sulfur through interaction with the crust. This causes the sulfide minerals present to be immiscible, precipitating out when the melt crystallizes.[16][17] Magmatic sulfide deposits can be subdivided into two groups by their dominant ore element:

- Ni-Cu, found in komatiites, anorthosite complexes, and flood basalts.[16] This also includes the Sudbury Nickel Basin, the only known astrobleme source of such ore.[17]

- Platinum Group Elements (PGE) from large mafic intrusions and tholeiitic rock.[16]

- Stratiform Chromites are strongly linked to PGE magmatic sulfide deposits.[18] These highly mafic intrusions are a source of chromite, the only chromium ore.[19] They are so named due to their strata-like shape and formation via layered magmatic injection into the host rock. Chromium is usually located within the bottom of the intrusion. They are typically found within intrusions in continental cratons, the most famous example being the Bushveld Complex in South Africa.[18][20]

- Podiform Chromitites are found in ultramafic oceanic rocks resulting from complex magma mixing.[21] They are hosted in serpentine and dunite rich layers and are another source of chromite.[19]

- Kimberlites are a primary source for diamonds. They are originate from depths of 150 km in the mantle and are mostly composed of crustal xenocrysts, high amounts of magnesium, other trace elements, gases, and in some cases diamond.[22]

Metamorphic deposits

These are ore deposits which form as a direct result of metamorphism.

- Skarns occur in numerous geologic settings worldwide.[23] They are silicates derived from the recrystallization of carbonates like limestone through contact or regional metamorphism, or fluid related metasomatic events.[24] Not all are economic, but those that are, are classified depending on the dominant element such as Ca, Fe, Mg, or Mn among many others.[23][24] They are one of the most diverse and abundant mineral deposits.[24] As such they are classified solely by their common mineralogy, mainly garnets and pyroxenes.[23]

- Greisens, like skarns, are a metamorphosed silicate, quartz-mica mineral deposit. Formed from a granitic protolith due to alteration by intruding magmas, they are large ore sources of tin and tungsten in the form of wolframite, cassiterite, stannite and scheelite.[25][26]

Porphyry copper deposits

These are the leading source of copper ore.[27][28] Porphyry copper deposits form along convergent boundaries and are thought to originate from the partial melting of subducted oceanic plates and subsequent concentration of Cu, driven by oxidation.[28][29] These are large, round, disseminated deposits containing on average 0.8% copper by weight.[5]

Hydrothermal

Hydrothermal deposits are a large source of ore. They form as a result of the precipitation of dissolved ore constituents out of fluids.[1][30]

- Mississippi Valley-Type (MVT) deposits precipitate from relatively cool, basal brinal fluids within carbonate strata. These are sources of lead and zinc sulphide ore.[31]

- Sediment-Hosted Stratiform Copper Deposits (SSC) form when copper sulphides precipitate out of brinal fluids into sedimentary basins near the equator.[27][32] These are the second most common source of copper ore after porphyry copper deposits, supplying 20% of the worlds copper in addition to silver and cobalt.[27]

- Volcanogenic massive sulphide (VMS) deposits form on the seafloor from precipitation of metal rich solutions, typically associated with hydrothermal activity. They take the general form of a large sulphide rich mound above disseminated sulphides and viens. VMS deposits are a major source of zinc (Zn), copper (Cu), lead (Pb), silver (Ag), and gold (Au).[33]

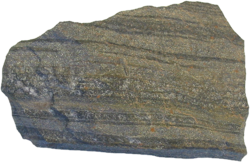

Gold ore (size: 7.5 × 6.1 × 4.1 cm)

Gold ore (size: 7.5 × 6.1 × 4.1 cm) - Sedimentary exhalative sulphide deposits (SEDEX) are a copper sulphide ore which form in the same manor as VMS from metal rich brine but are hosted within sedimentary rocks and are not directly related to volcanism.[25][34]

- Orogenic gold deposits are a bulk source for gold, with 75% of gold production originating from orogenic gold deposits. Formation occurs during late stage mountain building (see orogeny) where metamorphism forces gold containing fluids into joints and fractures where they precipitate. These tend to be strongly correlated with quartz veins.[1]

- Epithermal vein deposits form in the shallow crust from concentration of metal bearing fluids into veins and stockworks where conditions favour precipitation.[25][19] These volcanic related deposits are a source of gold and silver ore, the primary precipitants.[19]

Sedimentary deposits

Laterites form from the weathering of highly mafic rock near the equator. They can form in as little as one million years and are a source of iron (Fe), manganese (Mn), and aluminum (Al).[35] They may also be a source of nickel and cobalt when the parent rock is enriched in these elements.[36]

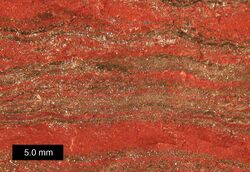

Banded iron formations (BIFs) are the highest concentration of any single metal available.[1] They are composed of chert beds alternating between high and low iron concentrations.[37] Their deposition occurred early in Earth's history when the atmospheric composition was significantly different from today. Iron rich water is thought to have upwelled where it oxidized to Fe (III) in the presence of early photosynthetic plankton producing oxygen. This iron then precipitated out and deposited on the ocean floor. The banding is thought to be a result of changing plankton population.[38][39]

Sediment Hosted Copper forms from the precipitation of a copper rich oxidized brine into sedimentary rocks. These are a source of copper primarily in the form of copper-sulfide minerals.[40][41]

Placer deposits are the result of weathering, transport, and subsequent concentration of a valuable mineral via water or wind. They are typically sources of gold (Au), platinum group elements (PGE), sulfide minerals, tin (Sn), tungsten (W), and rare-earth elements (REEs). A placer deposit is considered alluvial if formed via river, colluvial if by gravity, and eluvial when close to their parent rock.[42][43]

Manganese nodules

Polymetallic nodules, also called manganese nodules, are mineral concretions on the sea floor formed of concentric layers of iron and manganese hydroxides around a core.[44] They are formed by a combination of diagenetic and sedimentary precipitation at the estimated rate of about a centimeter over several million years.[45] The average diameter of a polymetallic nodule is between 3 and 10 cm (1 and 4 in) in diameter and are characterized by enrichment in iron, manganese, heavy metals, and rare earth element content when compared to the Earth's crust and surrounding sediment. The proposed mining of these nodules via remotely operated ocean floor trawling robots has raised a number of ecological concerns.[46]

Extraction

The extraction of ore deposits generally follows these steps.[4] Progression from stages 1–3 will see a continuous disqualification of potential ore bodies as more information is obtained on their viability:[47]

- Prospecting to find where an ore is located. The prospecting stage generally involves mapping, geophysical survey techniques (aerial and/or ground-based surveys), geochemical sampling, and preliminary drilling.[47][48]

- After a deposit is discovered, exploration is conducted to define its extent and value via further mapping and sampling techniques such as targeted diamond drilling to intersect the potential ore body. This exploration stage determines ore grade, tonnage, and if the deposit is a viable economic resource.[47][48]

- A feasibility study then considers the theoretical implications of the potential mining operation in order to determine if it should move ahead with development. This includes evaluating the economically recoverable portion of the deposit, marketability and payability of the ore concentrates, engineering, milling and infrastructure costs, finance and equity requirements, potential environmental impacts, political implications, and a cradle to grave analysis from the initial excavation all the way through to reclamation.[47] Multiple experts from differing fields must then approve the study before the project can move on to the next stage.[4] Depending on the size of the project, a pre-feasibility study is sometimes first performed to decide preliminary potential and if a much costlier full feasibility study is even warranted.[47]

- Development begins once an ore body has been confirmed economically viable and involves steps to prepare for its extraction such as building of a mine plant and equipment.[4]

- Production can then begin and is the operation of the mine in an active sense. The time a mine is active is dependent on its remaining reserves and profitability.[4][48] The extraction method used is entirely dependent on the deposit type, geometry, and surrounding geology.[49] Methods can be generally categorized into surface mining such as open pit or strip mining, and underground mining such as block caving, cut and fill, and stoping.[49][50]

- Reclamation, once the mine is no longer operational, makes the land where a mine had been suitable for future use.[48]

With rates of ore discovery in a steady decline since the mid 20th century, it is thought that most surface level, easily accessible sources have been exhausted. This means progressively lower grade deposits must be turned to, and new methods of extraction must be developed.[1]

Hazards

Some ores contain heavy metals, toxins, radioactive isotopes and other potentially negative compounds which may pose a risk to the environment or health. The exact effects an ore and its tailings have is dependent on the minerals present. Tailings of particular concern are those of older mines, as containment and remediation methods in the past were next to non-existent, leading to high levels of leaching into the surrounding environment.[5] Mercury and arsenic are two ore related elements of particular concern.[51] Additional elements found in ore which may have adverse health affects in organisms include iron, lead, uranium, zinc, silicon, titanium, sulfur, nitrogen, platinum, and chromium.[52] Exposure to these elements may result in respiratory and cardiovascular problems and neurological issues.[52] These are of particular danger to aquatic life if dissolved in water.[5] Ores such as those of sulphide minerals may severely increase the acidity of their immediate surroundings and of water, with numerous, long lasting impacts on ecosystems.[5][53] When water becomes contaminated it may transport these compounds far from the tailings site, greatly increasing the affected range.[52]

Uranium ores and those containing other radioactive elements may pose a significant threat if leaving occurs and isotope concentration increases above background levels. Radiation can have severe, long lasting environmental impacts and cause irreversible damage to living organisms.[54]

History

Metallurgy began with the direct working of native metals such as gold, lead and copper.[55] Placer deposits, for example, would have been the first source of native gold.[6] The first exploited ores were copper oxides such as malachite and azurite, over 7000 years ago at Çatalhöyük .[56][57][58] These were the easiest to work, with relatively limited mining and basic requirements for smelting.[55][58] It is believed they were once much more abundant on the surface than today.[58] After this, copper sulphides would have been turned to as oxide resources depleted and the Bronze Age progressed.[55][59] Lead production from galena smelting may have been occurring at this time as well.[6]

The smelting of arsenic-copper sulphides would have produced the first bronze alloys.[56] The majority of bronze creation however required tin, and thus the exploitation of cassiterite, the main tin source, began.[56] Some 3000 years ago, the smelting of iron ores began in Mesopotamia. Iron oxide is quite abundant on the surface and forms from a variety of processes.[6]

Until the 18th century gold, copper, lead, iron, silver, tin, arsenic and mercury were the only metals mined and used.[6] In recent decades, Rare Earth Elements have been increasingly exploited for various high-tech applications.[60] This has led to an ever-growing search for REE ore and novel ways of extracting said elements.[60][61]

Trade

Ores (metals) are traded internationally and comprise a sizeable portion of international trade in raw materials both in value and volume. This is because the worldwide distribution of ores is unequal and dislocated from locations of peak demand and from smelting infrastructure.

Most base metals (copper, lead, zinc, nickel) are traded internationally on the London Metal Exchange, with smaller stockpiles and metals exchanges monitored by the COMEX and NYMEX exchanges in the United States and the Shanghai Futures Exchange in China. The global Chromium market is currently dominated by the United States and China.[62]

Iron ore is traded between customer and producer, though various benchmark prices are set quarterly between the major mining conglomerates and the major consumers, and this sets the stage for smaller participants.

Other, lesser, commodities do not have international clearing houses and benchmark prices, with most prices negotiated between suppliers and customers one-on-one. This generally makes determining the price of ores of this nature opaque and difficult. Such metals include lithium, niobium-tantalum, bismuth, antimony and rare earths. Most of these commodities are also dominated by one or two major suppliers with >60% of the world's reserves. China is currently leading in world production of Rare Earth Elements.[63]

The World Bank reports that China was the top importer of ores and metals in 2005 followed by the US and Japan.[64]

Important ore minerals

For detailed petrographic descriptions of ore minerals see Tables for the Determination of Common Opaque Minerals by Spry and Gedlinske (1987).[65] Below are the major economic ore minerals and their deposits, grouped by primary elements.

| Type | Mineral | Symbol/formula | Uses | Source(s) | Ref |

|---|---|---|---|---|---|

| Metal ore minerals | Aluminum | Al | Alloys, conductive materials, lightweight applications | Gibbsite (Al(OH)3) and aluminium hydroxide oxide, which are found in laterites. Also Bauxite and Barite | [5] ' |

| Antimony | Sb | Alloys, flame retardation | Stibnite (Sb2S3) | [5] | |

| Beryllium | Be | Metal alloys, in the nuclear industry, in electronics | Beryl (Be3Al2Si6O18), found in granitic pegmatites | [5] | |

| Bismuth | Bi | Alloys, pharmeceuticals | Native bismuth and bismuthinite (Bi2S3) with sulphide ores | [5] | |

| Cesium | Cs | Photoelectrics, pharmaceuticals | Lepidolite (K(Li, Al)3 (Si, Al)4O10 (OH,F)2) from pegmatites | [5] | |

| Chromium | Cr | Alloys, electroplating, colouring agents | Chromite (FeCr2O4) from stratiform and podiform chromitites | [5][19][21] | |

| Cobalt | Co | Alloys, chemical catalysts, cemented carbide | Smaltite (CoAs2) in veins with cobaltite; silver, nickel and calcite; cobaltite (CoAsS) in veins with smaltite, silver, nickel and calcite; carrollite (CuCo2S4) and linnaeite (Co3S4) as constituents of copper ore; and linnaeite | ||

| Copper | Cu | Alloys, high conductivity, corrosion resistance | Sulphide minerals, including chalcopyrite (CuFeS2; primary ore mineral) in sulphide deposits, or porphyry copper deposits; covellite (CuS); chalcocite (Cu2S; secondary with other sulphide minerals) with native copper and cuprite deposits and bornite (Cu5FeS4; secondary with other sulphide minerals) Oxidized minerals, including malachite (Cu2CO3(OH)2) in the oxidized zone of copper deposits; cuprite (Cu2O; secondary mineral ); and azurite (Cu3(CO3)2(OH)2; secondary) |

[5][6][28][55] | |

| Iron | Fe | Industry use, construction, steel | Hematite (Fe2O3; primary source) in banded iron formations, veins, and igneous rock; magnetite (Fe3O4) in igneous and metamorphic rocks; goethite (FeO(OH); secondary to hematite); limonite (FeO(OH)nH2O; secondary to hematite) | [5][1][66] | |

| Lead | Pb | Alloys, pigmentation, batteries, corrosion resistance, radiation shielding | Galena (PbS) in veins with other sulphide materials and in pegmatites; cerussite (PbCO3) in oxidized lead zones along with galena | [5][6][31] | |

| Lithium | Li | Metal production, batteries, ceramics | Spodumene (LiAlSi2O6) in pegmatites | [5] | |

| Manganese | Mn | Steel alloys, chemical manufacturing | Pyrolusite (MnO2) in oxidized manganese zones like laterites and skarns; manganite (MnO(OH)) and braunite (3Mn2O3 MnSiO3) with pyrolusite | [5][23][35] | |

| Mercury | Hg | Scientific instruments, electrical applications, paint, solvent, pharmeceuticals | Cinnabar (HgS) in sedimentary fractures with other sulphide minerals | [5][6] | |

| Molybdenum | Mo | Alloys, electronics, industry | Molybdenite (MoS2) in porphyry deposits, powellite (CaMoO4) in hydrothermal deposits | [5] | |

| Nickel | Ni | Alloys, food and pharmaceutical applications, corrosion resistance | Pentlandite (Fe,Ni)9S8 with other sulphide minerals; garnierite (NiMg) with chromite and in laterites; niccolite (NiAs) in magmatic sulphide deposits | [5][16] | |

| Niobium | Nb | Alloys, corrosion resistance | Pyrochlore (Na,Ca) 2Nb 2O 6(OH,F) and columbite ((FeII ,MnII )Nb 2O 6) in granitic pegmatites |

[5] | |

| Platinum Group | Pt | Dentistry, jewelry, chemical applications, corrosion resistance, electronics | With chromite and copper ore, in placer deposits; sperrylite (PtAs2) in sulphide deposits and gold veins | [5][67] | |

| Rare-earth elements | La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Sc, Y | Permanent magnets, batteries, glass treatment, petroleum industry, micro-electronics, alloys, nuclear applications, corrosion protection (La and Ce are the most widely applicable) | Bastnäsite (REECO3F; for Ce, La, Pr, Nd) in carbonatites; monazite (REEPO4; for La, Ce, Pr, Nd) in placer deposits; xenotime (YPO4; for Y) in pegmatites; eudialyte (Na15Ca6(Fe,Mn)3Zr3SiO(O,OH,H2O)3 (Si3O9)2(Si9O27)2(OH,Cl)2) in igneous rocks; allanite ((REE,Ca,Y)2(Al,Fe2+,Fe3+)3(SiO4)3(OH)) in pegmatites and carbonatites |

[5][15][60][68][63] | |

| Rhenium | Re | Catalyst, temperature applications | Molybdenite (MoS2) in porphyry deposits | [5][69] | |

| Silver | Ag | Jewellery, glass, photo-electric applications, batteries | Sulfide deposits; Argentite (Ag2S; secondary to copper, lead and zinc ores) | [5][70] | |

| Tin | Sn | Solder, bronze, cans, pewter | Cassiterite (SnO2) in placer and magmatic deposits | [5][56] | |

| Titanium | Ti | Aerospace, industrial tubing | Ilmenite (FeTiO3) and rutile (TiO2) economically sourced from placer deposits with REEs | [5][71] | |

| Tungsten | W | Filaments, electronics, lighting | Wolframite ((Fe,Mn)WO4) and scheelite (CaWO4) in skarns and in porphyry along with sulphide minerals | [5][72] | |

| Uranium | U | Nuclear fuel, ammunition, radiation shielding | Pitchblende (UO2) in uraninite placer deposits; carnotite (K2(UO2)2(VO4)2 3H2O) in placer deposits | [5][73] | |

| Vanadium | V | Alloys, catalysts, glass colouring, batteries | Patronite (VS4) with sulphide minerals; roscoelite (K(V,Al,Mg)2 AlSi3O10(OH)2) in epithermal gold deposits | [5][74] | |

| Zinc | Zn | Corrosion protection, alloys, various industrial compounds | Sphalerite ((Zn,Fe)S) with other sulphide minerals in vein deposits; smithsonite (ZnCO3) in oxidized zone of zinc bearing sulphide deposits | [5][6][31] | |

| Zirconium | Zr | Alloys, nuclear reactors, corrosion resistance | Zircon (ZrSiO4) in igneous rocks and in placers | [5][75] | |

| Non-metal ore minerals | Fluorospar | CaF2 | Steelmaking, optical equipment | Hydrothermal veins and pegmatites | [5][76] |

| Graphite | C | Lubricant, industrial molds, paint | Pegmatites and metamorphic rocks | [5] | |

| Gypsum | CaSO42H2O | Fertilizer, filler, cement, pharmaceuticals, textiles | Evaporites; VMS | [5][77] | |

| Diamond | C | Cutting, jewelry | Kimberlites | [5][22] | |

| Feldspar | Fsp | Ceramics, glassmaking, glazes | Orthoclase (KAlSi3O8) and albite (NaAlSi3O8) are ubiquitous throughout Earth's crust | [5] |

See also

- Economic geology

- Extractive metallurgy (ore processing)

- Froth Flotation

- Mineral resource classification

- Ore genesis

- Petrology

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 Jenkin, Gawen R. T.; Lusty, Paul A. J.; McDonald, Iain; Smith, Martin P.; Boyce, Adrian J.; Wilkinson, Jamie J. (2014). "Ore deposits in an evolving Earth: an introduction". Geological Society 393 (1): 1–8. doi:10.1144/sp393.14. ISSN 0305-8719. https://doi.org/10.1144/SP393.14.

- ↑ 2.0 2.1 "Ore". Encyclopædia Britannica. https://www.britannica.com/science/ore-mining. Retrieved 2021-04-07.

- ↑ 3.0 3.1 Glossary of Geology. American Geological Institute. 2011. p. 799.

- ↑ 4.0 4.1 4.2 4.3 4.4 4.5 4.6 Hustrulid, William A.; Kuchta, Mark; Martin, Randall K. (2013). Open Pit Mine Planning and Design. Boca Raton, Florida: CRC Press. p. 1. ISBN 978-1-4822-2117-6. https://books.google.com/books?id=3XTOBQAAQBAJ&pg=PA1. Retrieved 5 May 2020.

- ↑ 5.00 5.01 5.02 5.03 5.04 5.05 5.06 5.07 5.08 5.09 5.10 5.11 5.12 5.13 5.14 5.15 5.16 5.17 5.18 5.19 5.20 5.21 5.22 5.23 5.24 5.25 5.26 5.27 5.28 5.29 5.30 5.31 5.32 5.33 5.34 5.35 5.36 5.37 5.38 5.39 Wills, B. A. (2015). Wills' mineral processing technology : an introduction to the practical aspects of ore treatment and mineral recovery (8th ed.). Oxford: Elsevier Science & Technology. ISBN 978-0-08-097054-7. OCLC 920545608. https://www.worldcat.org/oclc/920545608.

- ↑ 6.0 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 Rapp, George (2009), "Metals and Related Minerals and Ores", Archaeomineralogy, Natural Science in Archaeology (Berlin, Heidelberg: Springer Berlin Heidelberg): pp. 143–182, doi:10.1007/978-3-540-78594-1_7, ISBN 978-3-540-78593-4, http://link.springer.com/10.1007/978-3-540-78594-1_7, retrieved 2023-03-06

- ↑ Drzymała, Jan (2007). Mineral processing : foundations of theory and practice of minerallurgy (1st eng. ed.). Wroclaw: University of Technology. ISBN 978-83-7493-362-9. https://www.dbc.wroc.pl/Content/2070/Drzymala_mineral.pdf. Retrieved 24 September 2021.

- ↑ Petruk, William (1987). "Applied Mineralogy in Ore Dressing". Mineral Processing Design. pp. 2–36. doi:10.1007/978-94-009-3549-5_2. ISBN 978-94-010-8087-3.

- ↑ Heinrich, C. A.; Candela, P. A. (2014-01-01), Holland, Heinrich D.; Turekian, Karl K., eds., "13.1 – Fluids and Ore Formation in the Earth's Crust" (in en), Treatise on Geochemistry (Second Edition) (Oxford: Elsevier): pp. 1–28, ISBN 978-0-08-098300-4, https://www.sciencedirect.com/science/article/pii/B9780080959757011013, retrieved 2023-02-10

- ↑ Joint Ore Reserves Committee (2012). The JORC Code 2012 (2012 ed.). pp. 44. http://www.jorc.org/docs/jorc_code2012.pdf. Retrieved 10 June 2020.

- ↑ Chiat, Josh (10 June 2021). "These secret Kambalda mines missed the 2000s nickel boom – meet the company bringing them back to life". Stockhead. https://stockhead.com.au/resources/kambalda-nickel-boom-lunnon/.

- ↑ Thornton, Tracy (19 July 2020). "Mines of the past had some odd names". Montana Standard. https://mtstandard.com/lifestyles/mines-of-the-past-had-some-odd-names/article_efce26cc-a021-5493-b4ed-834aa6fe0dfe.html.

- ↑ Dowling, S. E.; Hill, R. E. T. (July 1992). "The distribution of PGE in fractionated Archaean komatiites, Western and Central Ultramafic Units, Mt Keith region, Western Australia". Australian Journal of Earth Sciences 39 (3): 349–363. doi:10.1080/08120099208728029. Bibcode: 1992AuJES..39..349D.

- ↑ London, David (2018). "Ore-forming processes within granitic pegmatites". Ore Geology Reviews 101: 349–383. doi:10.1016/j.oregeorev.2018.04.020. ISSN 0169-1368. Bibcode: 2018OGRv..101..349L. https://www.sciencedirect.com/science/article/pii/S0169136818300283.

- ↑ 15.0 15.1 Verplanck, Philip L.; Mariano, Anthony N.; Mariano Jr, Anthony (2016). "Rare earth element ore geology of carbonatites". Rare earth and critical elements in ore deposits. Littleton, CO: Society of Economic Geologists, Inc.. pp. 5–32. ISBN 978-1-62949-218-6. OCLC 946549103. https://pubs.er.usgs.gov/publication/70138176.

- ↑ 16.0 16.1 16.2 16.3 Naldrett, A. J. (2011). "Fundamentals of Magmatic Sulfide Deposits". Magmatic Ni-Cu and PGE Deposits: Geology, Geochemistry, and Genesis. Society of Economic Geologists. ISBN 9781934969359.

- ↑ 17.0 17.1 Song, Xieyan; Wang, Yushan; Chen, Liemeng (2011). "Magmatic Ni-Cu-(PGE) deposits in magma plumbing systems: Features, formation and exploration". Geoscience Frontiers 2 (3): 375–384. doi:10.1016/j.gsf.2011.05.005. Bibcode: 2011GeoFr...2..375S.

- ↑ 18.0 18.1 Schulte, Ruth F.; Taylor, Ryan D.; Piatak, Nadine M.; Seal, Robert R. (2010). "Stratiform chromite deposit model". Open-File Report. doi:10.3133/ofr20101232. ISSN 2331-1258. http://dx.doi.org/10.3133/ofr20101232.

- ↑ 19.0 19.1 19.2 19.3 19.4 Mosier, Dan L.; Singer, Donald A.; Moring, Barry C.; Galloway, John P. (2012). "Podiform chromite deposits—database and grade and tonnage models". Scientific Investigations Report (USGS): i–45. doi:10.3133/sir20125157. ISSN 2328-0328.

- ↑ Condie, Kent C. (2022), "Tectonic settings" (in en), Earth as an Evolving Planetary System (Elsevier): pp. 39–79, doi:10.1016/b978-0-12-819914-5.00002-0, ISBN 978-0-12-819914-5, https://linkinghub.elsevier.com/retrieve/pii/B9780128199145000020, retrieved 2023-03-03

- ↑ 21.0 21.1 Arai, Shoji (1997). "Origin of podiform chromitites". Journal of Asian Earth Sciences 15 (2–3): 303–310. doi:10.1016/S0743-9547(97)00015-9. Bibcode: 1997JAESc..15..303A. https://linkinghub.elsevier.com/retrieve/pii/S0743954797000159.

- ↑ 22.0 22.1 Giuliani, Andrea; Pearson, D. Graham (2019-12-01). "Kimberlites: From Deep Earth to Diamond Mines" (in en). Elements 15 (6): 377–380. doi:10.2138/gselements.15.6.377. ISSN 1811-5217. Bibcode: 2019Eleme..15..377G. https://pubs.geoscienceworld.org/msa/elements/article/15/6/377/579743/Kimberlites-From-Deep-Earth-to-Diamond-Mines.

- ↑ 23.0 23.1 23.2 23.3 Meinert, Lawrence D. (1992). "Skarns and Skarn Deposits". Geoscience Canada 19 (4). ISSN 1911-4850. https://journals.lib.unb.ca/index.php/GC/article/view/3773.

- ↑ 24.0 24.1 24.2 Einaudi, M. T.; Meinert, L. D.; Newberry, R. J. (1981). "Skarn Deposits". Economic Geology Seventy-fifth anniversary volume. Brian J. Skinner, Society of Economic Geologists (75th ed.). Littleton, Colorado: Society of Economic Geologists. ISBN 978-1-934969-53-3. OCLC 989865633. https://www.worldcat.org/oclc/989865633.

- ↑ 25.0 25.1 25.2 Pirajno, Franco (1992). Hydrothermal Mineral Deposits : Principles and Fundamental Concepts for the Exploration Geologist. Berlin, Heidelberg: Springer Berlin Heidelberg. ISBN 978-3-642-75671-9. OCLC 851777050. https://www.worldcat.org/oclc/851777050.

- ↑ Manutchehr-Danai, Mohsen (2009). Dictionary of gems and gemology. Christian Witschel, Kerstin Kindler (3rd ed.). Berlin: Springer. ISBN 9783540727958. OCLC 646793373. https://www.worldcat.org/oclc/646793373.

- ↑ 27.0 27.1 27.2 Hayes, Timothy S.; Cox, Dennis P.; Bliss, James D.; Piatak, Nadine M.; Seal, Robert R. (2015). "Sediment-hosted stratabound copper deposit model". Scientific Investigations Report. doi:10.3133/sir20105070m. ISSN 2328-0328.

- ↑ 28.0 28.1 28.2 Lee, Cin-Ty A; Tang, Ming (2020). "How to make porphyry copper deposits". Earth and Planetary Science Letters 529: 115868. doi:10.1016/j.epsl.2019.115868. Bibcode: 2020E&PSL.52915868L.

- ↑ Sun, Weidong; Wang, Jin-tuan; Zhang, Li-peng; Zhang, Chan-chan; Li, He; Ling, Ming-xing; Ding, Xing; Li, Cong-ying et al. (2016). "The formation of porphyry copper deposits". Acta Geochimica 36 (1): 9–15. doi:10.1007/s11631-016-0132-4. ISSN 2096-0956. http://link.springer.com/10.1007/s11631-016-0132-4.

- ↑ Arndt, N. and others (2017) Future mineral resources, Chap. 2, Formation of mineral resources, Geochemical Perspectives, v6-1, p. 18-51.

- ↑ 31.0 31.1 31.2 Leach, David L.; Bradley, Dwight; Lewchuk, Michael T.; Symons, David T.; de Marsily, Ghislain; Brannon, Joyce (2001). "Mississippi Valley-type lead–zinc deposits through geological time: implications from recent age-dating research". Mineralium Deposita 36 (8): 711–740. doi:10.1007/s001260100208. ISSN 0026-4598. Bibcode: 2001MinDe..36..711L. http://link.springer.com/10.1007/s001260100208.

- ↑ Hitzman, M. W.; Selley, D.; Bull, S. (2010). "Formation of Sedimentary Rock-Hosted Stratiform Copper Deposits through Earth History". Economic Geology 105 (3): 627–639. doi:10.2113/gsecongeo.105.3.627. ISSN 0361-0128. Bibcode: 2010EcGeo.105..627H. http://dx.doi.org/10.2113/gsecongeo.105.3.627.

- ↑ Cite error: Invalid

<ref>tag; no text was provided for refs namedGalley-2007 - ↑ Hannington, Mark (2021) (in en), VMS and SEDEX Deposits, Elsevier, pp. 867–876, doi:10.1016/b978-0-08-102908-4.00075-8, ISBN 978-0-08-102909-1, https://linkinghub.elsevier.com/retrieve/pii/B9780081029084000758, retrieved 2023-03-03

- ↑ 35.0 35.1 Persons, Benjamin S. (1970). Laterite : Genesis, Location, Use. Boston, MA: Springer US. ISBN 978-1-4684-7215-8. OCLC 840289476. https://www.worldcat.org/oclc/840289476.

- ↑ Marsh, Erin E.; Anderson, Eric D.; Gray, Floyd (2013). "Nickel-cobalt laterites: a deposit model". Scientific Investigations Report. doi:10.3133/sir20105070h. ISSN 2328-0328.

- ↑ Cloud, Preston (1973). "Paleoecological Significance of the Banded Iron-Formation" (in en). Economic Geology 68 (7): 1135–1143. doi:10.2113/gsecongeo.68.7.1135. ISSN 1554-0774. Bibcode: 1973EcGeo..68.1135C. http://pubs.geoscienceworld.org/economicgeology/article/68/7/1135/18462/Paleoecological-Significance-of-the-Banded.

- ↑ Cloud, Preston E. (1968). "Atmospheric and Hydrospheric Evolution on the Primitive Earth.". Science 160 (3829): 729–736. doi:10.1126/science.160.3829.729. PMID 5646415. Bibcode: 1968Sci...160..729C.

- ↑ Schad, Manuel; Byrne, James M.; ThomasArrigo, Laurel K.; Kretzschmar, Ruben; Konhauser, Kurt O.; Kappler, Andreas (2022). "Microbial Fe cycling in a simulated Precambrian ocean environment: Implications for secondary mineral (trans)formation and deposition during BIF genesis" (in en). Geochimica et Cosmochimica Acta 331: 165–191. doi:10.1016/j.gca.2022.05.016. Bibcode: 2022GeCoA.331..165S. https://linkinghub.elsevier.com/retrieve/pii/S0016703722002514.

- ↑ Sillitoe, Richard H.; Perelló, José; Creaser, Robert A.; Wilton, John; Wilson, Alan J.; Dawborn, Toby (2017). "Reply to discussions of "Age of the Zambian Copperbelt" by Hitzman and Broughton and Muchez et al". Mineralium Deposita 52 (8): 1277–1281. doi:10.1007/s00126-017-0769-x. Bibcode: 2017MinDe..52.1277S.

- ↑ Hitzman, Murray; Kirkham, Rodney; Broughton, David; Thorson, Jon; Selley, David (2005), "The Sediment-Hosted Stratiform Copper Ore System" (in en), One Hundredth Anniversary Volume (Society of Economic Geologists), doi:10.5382/av100.19, ISBN 978-1-887483-01-8, https://pubs.geoscienceworld.org/books/book/1940/chapter/107716228, retrieved 2023-03-05

- ↑ Cite error: Invalid

<ref>tag; no text was provided for refs namedBest-2015 - ↑ Cite error: Invalid

<ref>tag; no text was provided for refs namedHaldar-2013 - ↑ Huang, Laiming (2022-09-01). "Pedogenic ferromanganese nodules and their impacts on nutrient cycles and heavy metal sequestration". Earth-Science Reviews 232: 104147. doi:10.1016/j.earscirev.2022.104147. ISSN 0012-8252. https://www.sciencedirect.com/science/article/pii/S0012825222002318.

- ↑ Kobayashi, Takayuki; Nagai, Hisao; Kobayashi, Koichi (October 2000). "Concentration profiles of 10Be in large manganese crusts" (in en). Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms 172 (1–4): 579–582. doi:10.1016/S0168-583X(00)00206-8. https://linkinghub.elsevier.com/retrieve/pii/S0168583X00002068.

- ↑ Neate, Rupert (2022-04-29). "‘Deep-sea gold rush’ for rare metals could cause irreversible harm" (in en-GB). The Guardian. ISSN 0261-3077. https://www.theguardian.com/environment/2022/apr/29/deep-sea-gold-rush-rare-metals-environmental-harm.

- ↑ 47.0 47.1 47.2 47.3 47.4 Marjoribanks, Roger W. (1997). Geological methods in mineral exploration and mining (1st ed.). London: Chapman & Hall. ISBN 0-412-80010-1. OCLC 37694569. https://www.worldcat.org/oclc/37694569.

- ↑ 48.0 48.1 48.2 48.3 "The Mining Cycle | novascotia.ca". https://novascotia.ca/natr/meb/education/mining-cycle.asp.

- ↑ 49.0 49.1 Onargan, Turgay (2012). Mining Methods. IntechOpen. ISBN 978-953-51-0289-2.

- ↑ Brady, B. H. G. (2006). Rock mechanics : for underground mining. E. T. Brown (3rd ed.). Dordrecht: Kluwer Academic Publishers. ISBN 978-1-4020-2116-9. OCLC 262680067. https://www.worldcat.org/oclc/262680067.

- ↑ Franks, DM; Boger, DV; Côte, CM; Mulligan, DR (2011). "Sustainable Development Principles for the Disposal of Mining and Mineral Processing Wastes". Resources Policy 36 (2): 114–122. doi:10.1016/j.resourpol.2010.12.001. Bibcode: 2011RePol..36..114F.

- ↑ 52.0 52.1 52.2 da Silva-Rêgo, Leonardo Lucas; de Almeida, Leonardo Augusto; Gasparotto, Juciano (2022). "Toxicological effects of mining hazard elements" (in en). Energy Geoscience 3 (3): 255–262. doi:10.1016/j.engeos.2022.03.003. Bibcode: 2022EneG....3..255D.

- ↑ Mestre, Nélia C.; Rocha, Thiago L.; Canals, Miquel; Cardoso, Cátia; Danovaro, Roberto; Dell’Anno, Antonio; Gambi, Cristina; Regoli, Francesco et al. (September 2017). "Environmental hazard assessment of a marine mine tailings deposit site and potential implications for deep-sea mining" (in en). Environmental Pollution 228: 169–178. doi:10.1016/j.envpol.2017.05.027. PMID 28531798. https://linkinghub.elsevier.com/retrieve/pii/S026974911632574X.

- ↑ Kamunda, Caspah; Mathuthu, Manny; Madhuku, Morgan (2016-01-18). "An Assessment of Radiological Hazards from Gold Mine Tailings in the Province of Gauteng in South Africa" (in en). International Journal of Environmental Research and Public Health 13 (1): 138. doi:10.3390/ijerph13010138. ISSN 1660-4601. PMID 26797624.

- ↑ 55.0 55.1 55.2 55.3 Rostoker, William (1975). "Some Experiments in Prehistoric Copper Smelting". Paléorient 3 (1): 311–315. doi:10.3406/paleo.1975.4209. ISSN 0153-9345. http://dx.doi.org/10.3406/paleo.1975.4209.

- ↑ 56.0 56.1 56.2 56.3 Penhallurick, R. D. (2008). Tin in antiquity : its mining and trade throughout the ancient world with particular reference to Cornwall. Minerals, and Mining Institute of Materials (Pbk. ed.). Hanover Walk, Leeds: Maney for the Institute of Materials, Minerals and Mining. ISBN 978-1-907747-78-6. OCLC 705331805. https://www.worldcat.org/oclc/705331805.

- ↑ Radivojević, Miljana; Rehren, Thilo; Pernicka, Ernst; Šljivar, Dušan; Brauns, Michael; Borić, Dušan (2010). "On the origins of extractive metallurgy: new evidence from Europe" (in en). Journal of Archaeological Science 37 (11): 2775–2787. doi:10.1016/j.jas.2010.06.012. Bibcode: 2010JArSc..37.2775R. https://linkinghub.elsevier.com/retrieve/pii/S0305440310001986.

- ↑ 58.0 58.1 58.2 H., Coghlan, H. (1975). Notes on the prehistoric metallurgy of copper and bronze in the Old World : examination of specimens from the Pitt rivers Museum and Bronze castings in ancient moulds, by E. voce.. University Press. OCLC 610533025. http://worldcat.org/oclc/610533025.

- ↑ Amzallag, Nissim (2009). "From Metallurgy to Bronze Age Civilizations: The Synthetic Theory". American Journal of Archaeology 113 (4): 497–519. doi:10.3764/aja.113.4.497. ISSN 0002-9114. https://www.jstor.org/stable/20627616.

- ↑ 60.0 60.1 60.2 Mariano, A. N.; Mariano, A. (2012-10-01). "Rare Earth Mining and Exploration in North America" (in en). Elements 8 (5): 369–376. doi:10.2113/gselements.8.5.369. ISSN 1811-5209. Bibcode: 2012Eleme...8..369M. https://pubs.geoscienceworld.org/elements/article/8/5/369-376/137950.

- ↑ Chakhmouradian, A. R.; Wall, F. (2012-10-01). "Rare Earth Elements: Minerals, Mines, Magnets (and More)" (in en). Elements 8 (5): 333–340. doi:10.2113/gselements.8.5.333. ISSN 1811-5209. Bibcode: 2012Eleme...8..333C. https://pubs.geoscienceworld.org/elements/article/8/5/333-340/137928.

- ↑ Ren, Shuai; Li, Huajiao; Wang, Yanli; Guo, Chen; Feng, Sida; Wang, Xingxing (2021-10-01). "Comparative study of the China and U.S. import trade structure based on the global chromium ore trade network" (in en). Resources Policy 73: 102198. doi:10.1016/j.resourpol.2021.102198. ISSN 0301-4207. Bibcode: 2021RePol..7302198R. https://www.sciencedirect.com/science/article/pii/S0301420721002129.

- ↑ 63.0 63.1 Haque, Nawshad; Hughes, Anthony; Lim, Seng; Vernon, Chris (2014-10-29). "Rare Earth Elements: Overview of Mining, Mineralogy, Uses, Sustainability and Environmental Impact" (in en). Resources 3 (4): 614–635. doi:10.3390/resources3040614. ISSN 2079-9276.

- ↑ "Background Paper – The Outlook for Metals Markets Prepared for G20 Deputies Meeting Sydney 2006". September 2006. p. 4. http://siteresources.worldbank.org/INTOGMC/Resources/outlook_for_metals_market.pdf.

- ↑ "Tables For The Determination of Common Opaque Minerals | PDF" (in en). https://www.scribd.com/doc/281657856/Tables-for-the-Determination-of-Common-Opaque-Minerals.

- ↑ James, Harold Lloyd (1954-05-01). "Sedimentary facies of iron-formation" (in en). Economic Geology 49 (3): 235–293. doi:10.2113/gsecongeo.49.3.235. ISSN 1554-0774. Bibcode: 1954EcGeo..49..235J. http://pubs.geoscienceworld.org/economicgeology/article/49/3/235/16333/Sedimentary-facies-of-ironformation.

- ↑ Barkov, Andrei Y.; Zaccarini, Federica (2019) (in en). New Results and Advances in PGE Mineralogy in Ni-Cu-Cr-PGE Ore Systems. MDPI, Basel. doi:10.3390/books978-3-03921-717-5. ISBN 978-3-03921-717-5.

- ↑ Chakhmouradian, A. R.; Zaitsev, A. N. (2012-10-01). "Rare Earth Mineralization in Igneous Rocks: Sources and Processes" (in en). Elements 8 (5): 347–353. doi:10.2113/gselements.8.5.347. ISSN 1811-5209. Bibcode: 2012Eleme...8..347C. https://pubs.geoscienceworld.org/elements/article/8/5/347-353/137935.

- ↑ Engalychev, S. Yu. (2019-04-01). "New Data on the Mineral Composition of Unique Rhenium (U–Mo–Re) Ores of the Briketno-Zheltukhinskoe Deposit in the Moscow Basin" (in en). Doklady Earth Sciences 485 (2): 355–357. doi:10.1134/S1028334X19040019. ISSN 1531-8354. Bibcode: 2019DokES.485..355E. https://doi.org/10.1134/S1028334X19040019.

- ↑ Volkov, A. V.; Kolova, E. E.; Savva, N. E.; Sidorov, A. A.; Prokof’ev, V. Yu.; Ali, A. A. (2016-09-01). "Formation conditions of high-grade gold–silver ore of epithermal Tikhoe deposit, Russian Northeast" (in en). Geology of Ore Deposits 58 (5): 427–441. doi:10.1134/S107570151605007X. ISSN 1555-6476. Bibcode: 2016GeoOD..58..427V. https://doi.org/10.1134/S107570151605007X.

- ↑ Charlier, Bernard; Namur, Olivier; Bolle, Olivier; Latypov, Rais; Duchesne, Jean-Clair (2015-02-01). "Fe–Ti–V–P ore deposits associated with Proterozoic massif-type anorthosites and related rocks" (in en). Earth-Science Reviews 141: 56–81. doi:10.1016/j.earscirev.2014.11.005. ISSN 0012-8252. Bibcode: 2015ESRv..141...56C. https://www.sciencedirect.com/science/article/pii/S0012825214002037.

- ↑ Yang, Xiaosheng (2018-08-15). "Beneficiation studies of tungsten ores – A review" (in en). Minerals Engineering 125: 111–119. doi:10.1016/j.mineng.2018.06.001. ISSN 0892-6875. Bibcode: 2018MiEng.125..111Y. https://www.sciencedirect.com/science/article/pii/S0892687518302607.

- ↑ Dahlkamp, Franz J. (1993) (in en). Uranium Ore Deposits. Berlin. doi:10.1007/978-3-662-02892-6. ISBN 978-3-642-08095-1. https://link.springer.com/book/10.1007/978-3-662-02892-6.

- ↑ Nejad, Davood Ghoddocy; Khanchi, Ali Reza; Taghizadeh, Majid (2018-06-01). "Recovery of Vanadium from Magnetite Ore Using Direct Acid Leaching: Optimization of Parameters by Plackett–Burman and Response Surface Methodologies" (in en). JOM 70 (6): 1024–1030. doi:10.1007/s11837-018-2821-4. ISSN 1543-1851. Bibcode: 2018JOM....70f1024N. https://doi.org/10.1007/s11837-018-2821-4.

- ↑ Perks, Cameron; Mudd, Gavin (2019-04-01). "Titanium, zirconium resources and production: A state of the art literature review" (in en). Ore Geology Reviews 107: 629–646. doi:10.1016/j.oregeorev.2019.02.025. ISSN 0169-1368. Bibcode: 2019OGRv..107..629P. https://www.sciencedirect.com/science/article/pii/S0169136818306073.

- ↑ Hagni, Richard D.; Shivdasan, Purnima A. (2000-04-01). "Characterizing megascopic textures in fluorospar ores at Okorusu mine" (in en). JOM 52 (4): 17–19. doi:10.1007/s11837-000-0124-y. ISSN 1543-1851. Bibcode: 2000JOM....52d..17H. https://doi.org/10.1007/s11837-000-0124-y.

- ↑ Öksüzoğlu, Bilge; Uçurum, Metin (2016-04-01). "An experimental study on the ultra-fine grinding of gypsum ore in a dry ball mill" (in en). Powder Technology 291: 186–192. doi:10.1016/j.powtec.2015.12.027. ISSN 0032-5910. https://www.sciencedirect.com/science/article/pii/S0032591015302394.

Further reading

External links

{{Navbox |name = Ores |title = Ore minerals, mineral mixtures and ore deposits |listclass = hlist

|group1 = Ores |list1 =

{{Navbox|subgroup

|groupwidth = 7.0em

|group1 = Oxides |list1 =

- Cassiterite (tin)

- Chromite (chromium)

- Coltan (niobium and tantalum)

- Columbite (niobium)

- Hematite (iron)

- Ilmenite (titanium)

- Magnetite (iron)}}

- Pyrolusite (manganese)

- Tantalite (tantalum)

- Uraninite (uranium)

|