Chemistry:Cerium(III) oxide

| |

| Names | |

|---|---|

| IUPAC name

Cerium(III) oxide

| |

| Other names

Cerium sesquioxide

| |

| Identifiers | |

3D model (JSmol)

|

|

| ChemSpider | |

| EC Number |

|

PubChem CID

|

|

| UNII | |

| |

| |

| Properties | |

| Ce2O3 | |

| Molar mass | 328.229 g·mol−1 |

| Appearance | yellow-green dust[citation needed] |

| Density | 6.2 g/cm3 |

| Melting point | 2,177 °C (3,951 °F; 2,450 K) |

| Boiling point | 3,730 °C (6,750 °F; 4,000 K) |

| insoluble | |

| Solubility in sulfuric acid | soluble |

| Solubility in hydrochloric acid | insoluble |

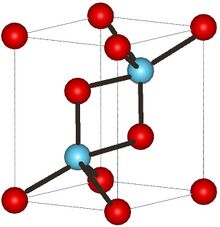

| Structure | |

| Hexagonal, hP5 | |

| P3m1, No. 164 | |

| Hazards | |

| GHS pictograms |

|

| Related compounds | |

Other anions

|

Cerium(III) chloride |

Other cations

|

Lanthanum(III) oxide, Praseodymium(III) oxide |

Related compounds

|

Cerium(IV) oxide |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

Cerium(III) oxide, also known as cerium oxide, cerium trioxide, cerium sesquioxide, cerous oxide or dicerium trioxide, is an oxide of the rare-earth metal cerium. It has chemical formula Ce

2O

3 and is gold-yellow in color.

Applications

Engine and exhaust catalysts

Cerium oxide is used as a catalytic converter for the minimisation of CO emissions in the exhaust gases from motor vehicles.

When there is a shortage of oxygen, cerium(IV) oxide is reduced by carbon monoxide to cerium(III) oxide:

- 2 CeO

2 + CO → Ce

2O

3 + CO

2

When there is an oxygen surplus, the process is reversed and cerium(III) oxide is oxidized to cerium(IV) oxide:

- 2 Ce

2O

3 + O

2 → 4 CeO

2

Major automotive applications for cerium(III) oxide are as a catalytic converter for the oxidation of CO and NO {x} emissions in the exhaust gases from motor vehicles,[1][2] and secondly, cerium oxide finds use as a fuel additive to diesel fuels, which results in increased fuel efficiency and decreased hydrocarbon derived particulate matter emissions,[3] however the health effects of the cerium oxide bearing engine exhaust is a point of study and dispute.[4][5][6]

Water splitting

The cerium(IV) oxide–cerium(III) oxide cycle or CeO

2/Ce

2O

3 cycle is a two step thermochemical water splitting process based on cerium(IV) oxide and cerium(III) oxide for hydrogen production.[7]

Photoluminescence

Cerium(III) oxide combined with tin(II) oxide (SnO) in ceramic form is used for illumination with UV light. It absorbs light with a wavelength of 320 nm and emits light with a wavelength of 412 nm.[8] This combination of cerium(III) oxide and tin(II) oxide is rare, and obtained only with difficulty on a laboratory scale.[citation needed]

Production

Cerium(III) oxide is produced by the reduction of cerium(IV) oxide with hydrogen at approximately 1,400 °C (2,550 °F). Samples produced in this way are only slowly air-oxidized back to the dioxide at room temperature.[9]

References

- ↑ Bleiwas, D.I. (2013). Potential for Recovery of Cerium Contained in Automotive Catalytic Converters. Reston, Va.: U.S. Department of the Interior, U.S. Geological Survey.

- ↑ "Argonne's deNOx Catalyst Begins Extensive Diesel Engine Exhaust Testing". http://www.transportation.anl.gov/engines/cerium-oxide_catalyst.html.

- ↑ "Exploring Nano-sized Fuel Additives EPA scientists examine nanoparticle impacts on vehicle emissions and air pollution.". http://www.epa.gov/sciencematters/april2011/nano.htm.

- ↑ "Nanoparticles used as additives in diesel fuels can travel from lungs to liver, November 18, 2011. Marshall University Research Corporation". https://www.sciencedaily.com/releases/2011/11/111117141157.htm.

- ↑ Park, B.; Donaldson, K.; Duffin, R.; Tran, L.; Kelly, F.; Mudway, I.; Morin, J. P.; Guest, R. et al. (Apr 2008). "Hazard and risk assessment of a nanoparticulate cerium oxide-based diesel fuel additive - a case study.". Inhal Toxicol 20 (6): 547–66. doi:10.1080/08958370801915309. PMID 18444008.

- ↑ "Exploring Nano-sized Fuel Additives EPA scientists examine nanoparticle impacts on vehicle emissions and air pollution.". http://www.epa.gov/sciencematters/april2011/nano.htm.

- ↑ Hydrogen production from solar thermochemical water splitting cycles

- ↑ Peplinski, D.R.; Wozniak, W. T.; Moser, J. B. (1980). "Spectral Studies of New Luminophors for Dental Porcelain". Journal of Dental Research 59 (9): 1501–1509. doi:10.1177/00220345800590090801. PMID 6931128.

- ↑ Y. Wetzel (1963). "Scandium, Yttrium, Rare Earths". in G. Brauer. Handbook of Preparative Inorganic Chemistry, 2nd Ed.. 1. NY, NY: Academic Press. pp. 1151.

External links

|